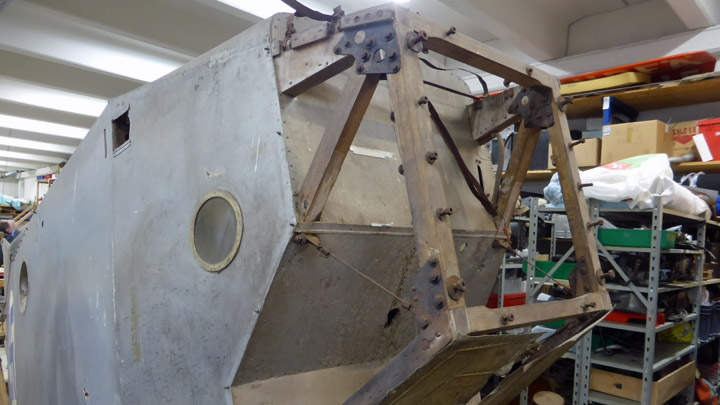

The engine-mounting cover-plate for the Kurki in placeMaanantai 22.5.2017 - Member of Tuesday Club When the fuselage of the I.V.L. K.1 Kurki was brought from the Päijät-Tavastia Avaition Museum to the Aviation Museum Society (Finland) Tuesday-Club for renovation it was a rather sorry sight. The tail was broken, the covering of the fuselage had holes and other damage, only bits and pieces of the windscreens remained, the metal parts were badly corroded and the engine mounting lacked both cover- and endplates.

During the year this fuselage has been worked on in the restauration workshop at the Finnish Aviation Museum and this work will soon be finished. In the Tuesday-Club the last months have been spent making the missing parts of the engine-mounting. The first part to be finished was the engine mounting plate, the work on which has already bene covered in an earlier blog-entry. Now we have finished the upper cover-plate and work on the side-plates is ongoing.

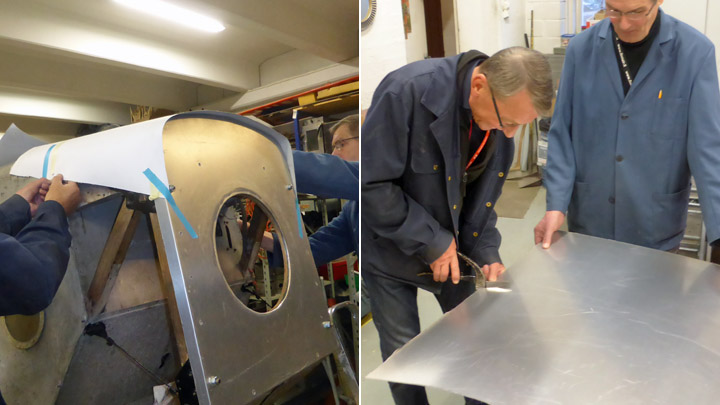

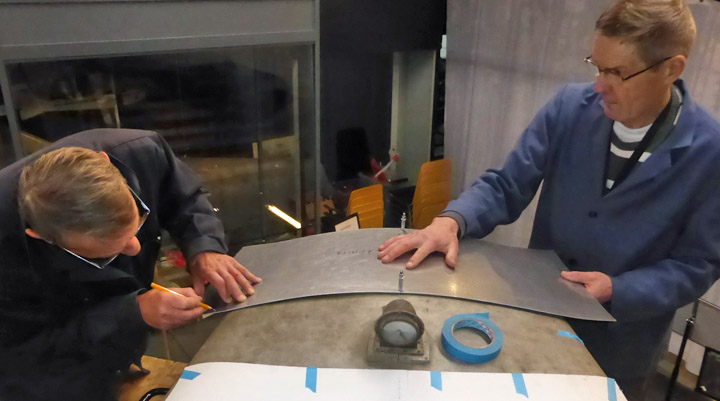

The work on making the top cover-plate started with making a cardboard model of it. Then a piece of 1.4 mm aluminium plate was cut to measure according to the cardboard model, after which the fitting of the aluminium plate to the engine-mountings top framework was begun. Working the aluminium plate proved to be a bit of a challenge as it was rather stiff and bending it into the required form took some doing. But we did it anyway, and did not try to do the work using a thinner plate.

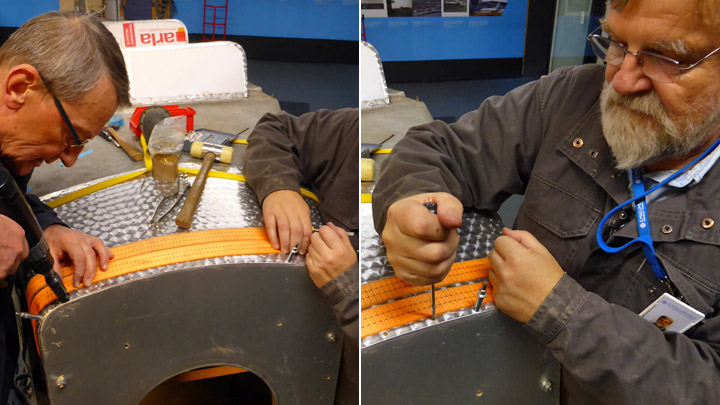

When the plate had been formed into its nearly finished shape work was continued by fastening the front- and rear parts of the plate to the cover framework using Cleco-pins.

Thus the plate was held in place so that we could determine where and to what extent the plate still needed bending. It took a number of fastenings, removals and bending of the plate before it had been given its final shape.

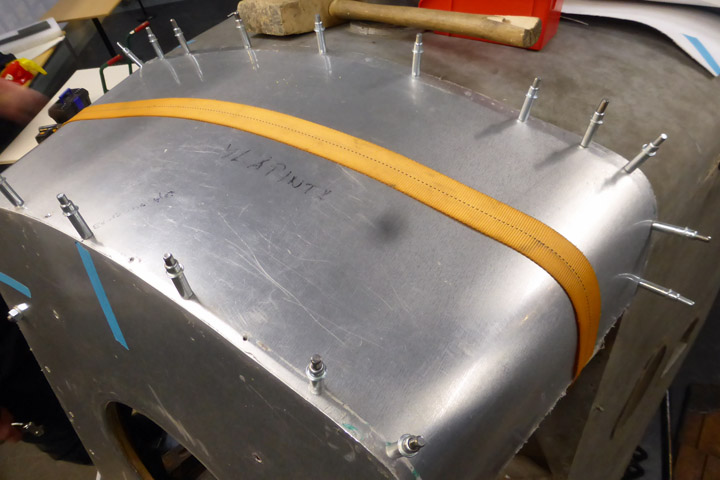

This done, the cover-plate was fastened to the engine-mounting framework using Cleco-pins. The forward edge was fastened to the top of the engine-mounting front-plate and the rear edge to the plywood cover at the joint of the engine-mounting and fuselage. Ca. 15 mm of the edge of the cover-plate was bent downwards/inwards to fit tightly to the plywood.

Before installing the top cover-plate, its surface was given a perlée finish using about 50% overlap.

The final fastening of the finished cover-plate was done using slot-drive brass screws in the holes drilled for the Cleco-pins. As such screws were not readily available at the hardware stores, but such screws were obtained by special order from a specialist screw supplier and thus the top cover-plate could be secured in place in a proper manner. Using modern cross-drive or torx screws is not an option in a 1920ies aeroplane.

Beneath the top cover-plate there is space for the oil-tank of the Kurki´s Siemens-Halske Sh 10 engine. This means that there has been a hole in the top cover-plate for the oil filler-tube and cap. As the original oil-tank has disappeared and we have no drawings for it we were not able to determine the original location of the filler-tube. Thus we did not make any hole for the oil filler-tube. If we could find the original oil-tank, then we would fit it and make the needed hole in the top cover-plate. |

|

Avainsanat: aviation history, restoring, old aircraft, I.V.L. K.1 Kurki |