The Kurki windshields got their aluminium framesSunnuntai 14.5.2017 - Member of Tuesday Club During the autumn of 2016 the Tuesday Club fit new polycarbonate windshields to the I.V.L.K. 1 Kurki as the original celluloid ones had met their end during the long storage. In addition to this the three missing side-supports were made and installed. These were already covered in the December 2016 blog. However the making of the aluminium wind-screen edge-stiffeners was due this year. The original windscreens had been strengthened using a grooved aluminium edge-stiffeners. A few small pieces of the original ones had survived, and with these as a model we could make new ones. From the surviving pieces we could also establish that the edge stiffener of the cockpit windscreen was a bit wider than that of the windscreen of the passenger compartment. The reason for this remains unclear.

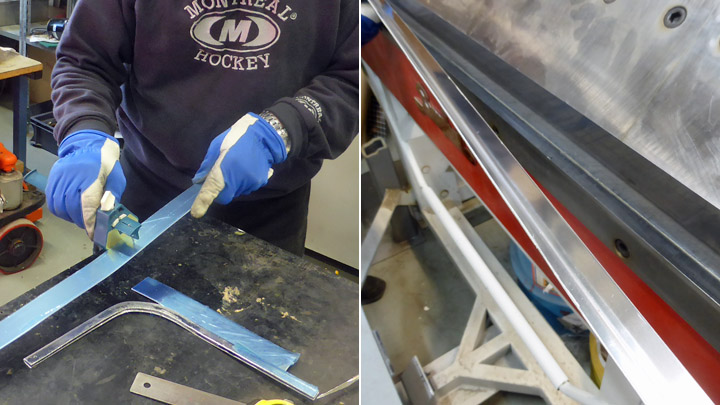

We started with the edge-stiffener for the cockpit windscreen. From a 1mm thick aluminium sheet we cut a piece with appropriate length and width. Then we made a 90 degree longitudinal bend to it using a sheet-bender. After this it was forced in a vice to make a groove. Now we faced the trickiest part of the job – shaping the groove-shaped piece to the shape of the windscreen edge with its rounded corners.

The edge-stiffener was hammered into shape against an inserted steel plate whilst simultaneously bending it to give it the proper curvature. Step by step we moved towards the final shape.

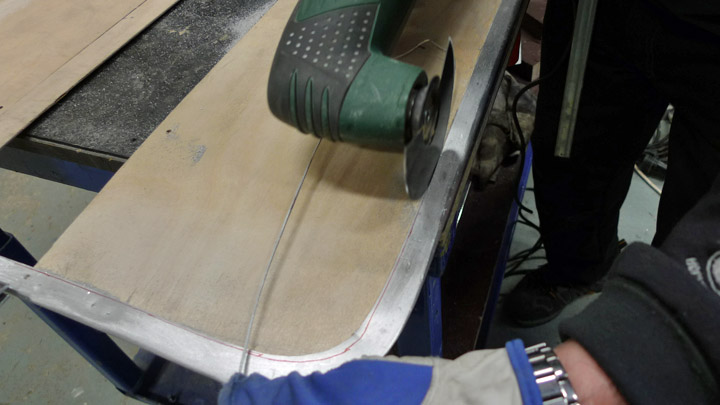

When the preliminary shaping of the cockpit windscreens edge-stiffener had been done we proceeded to make the passenger-compartment windscreen edge-stiffener. First we made it with the same width as that of the cockpit edge-stiffener. When both edge-stiffeners had been given their rough form their forming was tuned using plywood models of the actual windscreens, to which they were fitted and their fit stepwise refined until it was fine. Their tightness was ensured by squeezing to proper fit. When we were satisfied that they were OK, they were test-fitted to the actual windscreens. They fit nicely, and now the passenger-compartment windscreen edge-stiffener was cut to its final width.

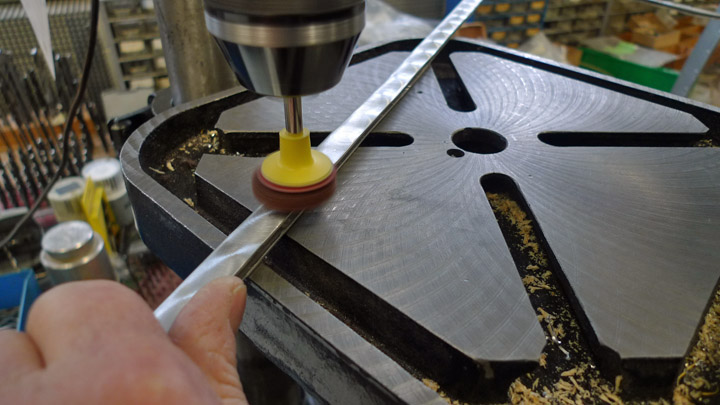

Now the edge-stiffeners were ready for finishing. First their surface was ground smooth and then polished. Then they were given the typical 1920ies perlée finish, as we were able to see traces of such a finish on the surviving original pieces.

The perlée finish was applied using a grinding-pad of 30 mm diameter in a drill-press. The pattern was such that it covered all of the surface. When the surface finishing was done, the edge-stiffeners were put in place on the windscreens and secured using small bolts.

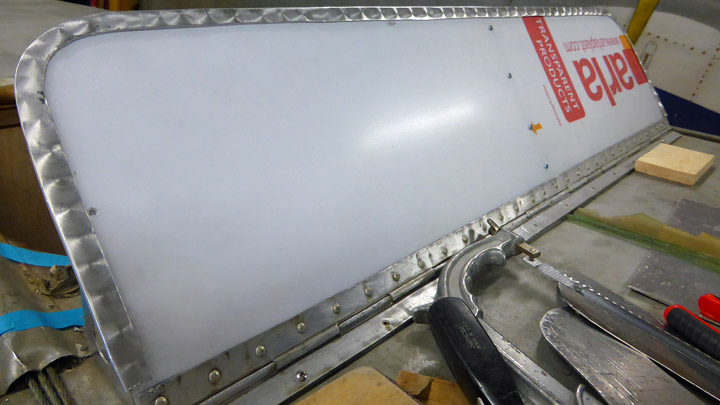

We still had to add the aluminium laths at the outside of the windscreens at the point of the triangular support brackets. Before securing the lathes in place using small bolts going through the windscreens we gave the laths the same perlée finish we had given the windscreen edge-stiffeners.

Now we could finally fasten the windscreens to the fuselage of the Kurki. The base-lathe of the foldable cockpit windscreen was secured to the fuselage using brass-screws (as it would not be proper to use modern torx or other modern types of screws when working on a 1920ies plane). The passenger compartment windscreen base-plate was secured to the plywood fuselage surface using 3x10 mm bolts as originally in 1927.

The windscreens of the cockpit and the passenger-compartment had now been finished – well not completely. The plexi-glass screens still had their plastic-film protective cover in place. They will be removed only when the work on the Kurki-fuselage has been completed and the I.V.L. K.1 Kurki returned to the Päijänne-Tavastia Aviation Museum in Vesivehmaa next autumn. In this way we can avoid damaging the windscreens during our continuing work on the Kurki fuselage. |

|

Avainsanat: aviation history, restoring, old aircraft, I.V.L. K.1 Kurki |