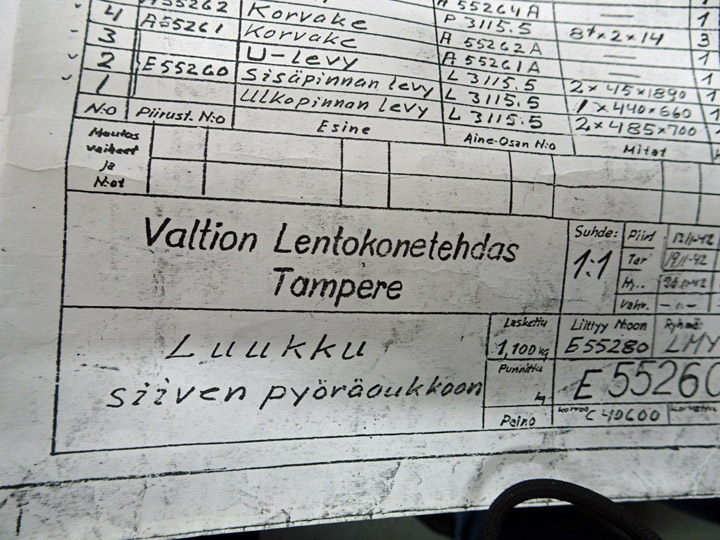

Myrsky's daisy cutters under constructionSunnuntai 25.3.2018 - Member of Tuesday Club The test wing in the VL Myrsky II restoration project has progressed to the phase where the construction of the mainwheel inner door (“the angel wing”) has been started. In the original VL Myrsky drawings this part has been named “hatch” but the word “door” has been used in this translation. The inner door covers about half of the wheel well. The other half is covered by the mainwheel door, which is attached to the landing gear leg and covers half of the wheel.

The opening and closing mechanism of the mainwheel door operates like this: when the landing gear is pulled into the mainwheel well inside the wing, on its way in the wheel pushes a lever on the mainwheel door which closes the door. The outer edge of the mainwheel door fairing presses against the inner door fairing, shutting it firmly. When the landing gear is taken out, the inner door linkage mechanism pushes the door automatically open using spring load.

The mainwheel inner door in Myrsky has box construction. It consists of two aluminium fairings with a supporting metal frame in between. The inner door fairing is 2 mm thick aluminium plate on the outside and 1mm thick aluminium plate on the inside. The outer measurements of the inner fairing are 440x660 mm and those of the outer fairing 485x700 mm, so the inner fairing is smaller than the outer. This means that the outer fairing forms a flange at the edge of the fairing.

Some hinge mechanisms of daisy cutters have been survived but the doors not. Therefore the doors have to be manufactures as new production. There is metal frame between the inner and outer fairing of the mainwheel inner door. It runs along the edge of the inner fairing. The aluminium fairings are attached to the frame by riveting. Originally the Myrsky mainwheel inner door had an open U-shaped aluminium frame structure, on which the fairings were separately riveted. A different structure was chosen in the Myrsky restoration project. The supporting frame between the fairings is made of 15x15mm rectangular steel tube. The outer and inner fairing are attached to the frame with rows of rivets penetrating the frame. Rows of holes are drilled into the supporting frame for the rivets. The test wing in the Myrsky project is a wing half, couple of meters long, and it has only one mainwheel well. Therefore only one mainwheel inner door is needed for the test wing. The Tuesday Club team decided, however, to build three doors: one for the test wing and two for the actual Myrsky (which naturally has two mainwheel wells).

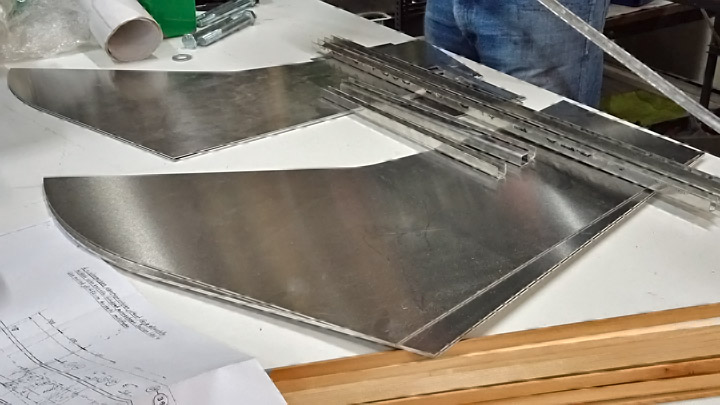

The work was started by laser-cutting the fairings according to their accurate measurements: the three outer fairings from 2 mm plate and the three inner fairings from 1 mm plate.

Then the supporting frame structures were made. Pieces matching the inner fairing measurements were cut from 15x15 mm rectangular steel tube. Three sets of pieces were cut, one set of pieces for each “daisy cutter”. Some of the tubes had to be bent to match the curving edges of the inner fairing.

The frame pieces were placed along the edge of the inner fairing of the mainwheel inner door and attached to it using small clamps. Then the work continued in the “welding space”, i.e. a sea container outside the Finnish Aviation Museum where the pieces were welded together to form the frame along the edge of the inner fairing. A similar procedure was used to weld the two other frames.

Now the mainwheel inner door supporting frames and inner and outer fairings were ready. The next phase will be to rivet the fairings onto the frame. |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |