Kurki got its venturi tubeMaanantai 26.11.2018 - Member of Tuesday Club The I.V.L. K.1 Kurki was built in 1927 in the Air Force airplane factory at the Viapori sea fortress. The restoration of the Kurki prototype has reached its final phases in the Tuesday Club. One of the last, but not least tasks was to find and install the lost venturi tube on Kurki’s wing strut. The venturi tube is used for indicating the plane’s speed and it is based on the changes in air flow velocity.

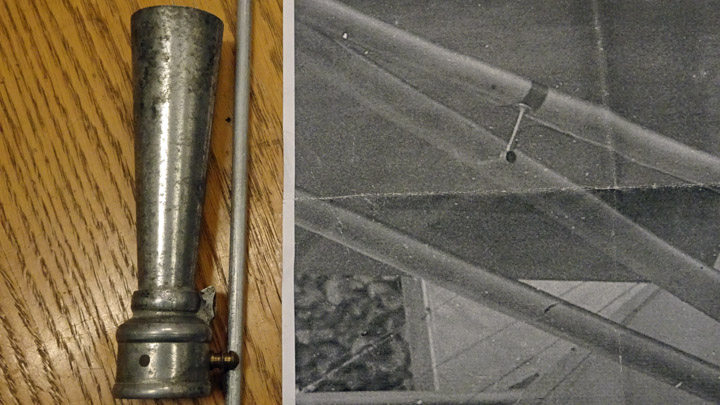

The venturi tube has been fastened on the forward wing strut on the right / starboard wing – this can be seen on old photographs of Kurki. On the original wing strut the fastening point of the venturi tube can be seen and also some fastener clips for the air tube leading from the venturi tube to the cockpit.

An old but damaged venturi tube was found at the Finnish Air Force Museum, resembling the old one on the Kurki photograph. The Tuesday Club was pleased of the find, although the stem of the venturi tube had disappeared. Also the round plate at the end of the stem had disappeared, the plate is necessary for fastening the venturi tube on the wing strut. The old venturi tube from the 1920’s is made of cast siluminium, an alloy of zink and aluminium.

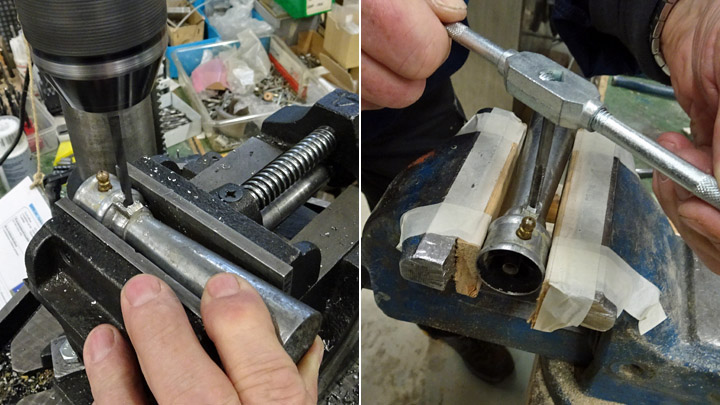

The motto of the Tuesday Club says: what is missing, we will make. So without further discussion the club members started making the missing venturi tube stem and fastening plate. The first task was to drill a hole on the venturi tube at the point where the original stem had broken. New nut thread was made for fastening the new stem. The new 15 cm long stem was cut from round aluminium pole, 5,5 mm in diameter. Screw thread was made on both ends of the stem so that it can be fastened on the venturi tube and on the fastening plate.

The fastening plate was made by cutting a piece from 4 mm thick aluminium plate and grinding it round. Holes for fastening screws were made and a hole was drilled in the middle, with nut thread for fastening the venturi tube stem. The sides of the wing strut are slightly curved, the fastening plate of the venturi tube has to be similarly curved. A model of the wing strut was made from stiff steel plate and this was used when hammering the fastening plate into the right curved shape.

Finally the parts of the venturi tube were ready to be fastened to one another. First the stem was screwed into the hole in the venturi tube. Then the fastening plate was screwed onto the other end of the stem so that the end of the stem penetrated the plate and was about 2mm out on the other side. The venturi tube was firmly fastened on a vise by its stem and the end of the stem was hammered flat on the underside of the fastening plate. Now the stem was tightly fastened and locked onto the fastening plate. The final phase was to stamp the year 2018 on the underside of the fastening plate so that the new plate and tube stem can be seen to be different from the original parts of the venturi tube. The venturi tube had now been repaired and was ready to be fastened.

The venturi tube was preliminarily attached on the front wing strut of Kurki’s starboard wing. The tube won’t be fastened before the collar-shaped support made of aluminium plate has been installed around the wing strut. This supporting collar under the venturi tube can be seen on old photographs of Kurki. The covering plywood on the wing strut is only 1,2mm thick so the venturi tube fastening plate and its screws need the additional support of the collar. Photos: Lassi Karivalo. |

|

Avainsanat: aviation history, restoring, old aircraft, I.V.L. K.1 Kurki |