Hatch for Myrsky auxiliary fuel tank rack is being madeLauantai 8.12.2018 - Member of Tuesday Club There are several different inspection, maintenance and operation hatches on the wing of VL Myrsky II. There are four hatches for the auxiliary fuel tank racks which also served as bomb racks, two on either side. The hatches are made of 1 mm aluminium sheet. They are round and 17,5 cm in diameter. In the middle of each hatch there is an elongated lock disk, which has a spring and can be pushed open and closed using a finger.

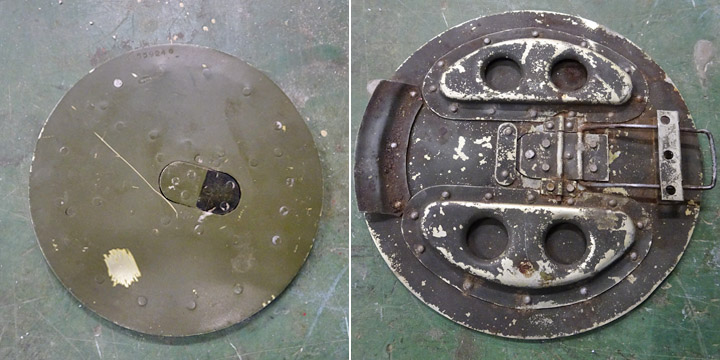

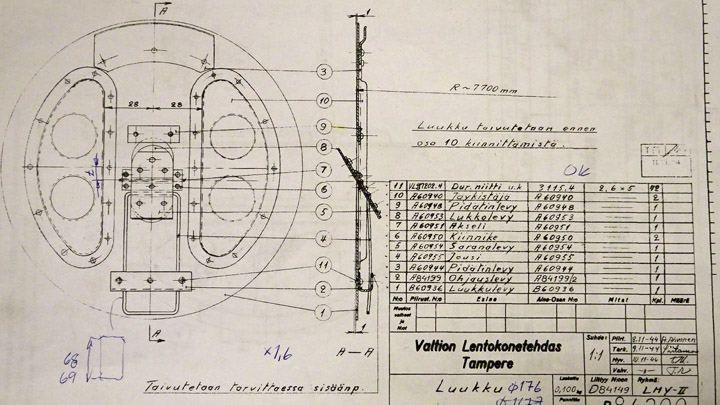

The operation hatches of the auxiliary fuel tank rack have a complicated structure. Fortunately, the Tuesday Club team had a detailed original construction drawing for making the hatches. The drawing has been dated in November 1944, so it is from the time when the Myrsky planes were in production. Also one original auxiliary fuel tank rack hatch had been found. Other original hatches are not available.

The drawing on the auxiliary fuel tank rack hatch illustrates well how detailed drawings have been made even of the smallest parts when the Myrsky was designed. The drawing describes in detail the construction of the hatch and its parts, 12 of them in total. 42 rivets are needed when the parts are assembled together.

When the team started making the hatches for the Myrsky wings, billets for all the different hatches were cut from 1 mm aluminium sheet. Some of the hatches are round, some rectangular. A laser cutter was used for cutting the hatches. The exact shape and size of each hatch was programmed for the laser cutter and the data was fed into the cutter using a memory stick. The holes for the rivets were also cut using the laser, several rivets are needed to fasten the parts together. The advantage of the laser cutter is that the outcome is exactly according to the original drawing.

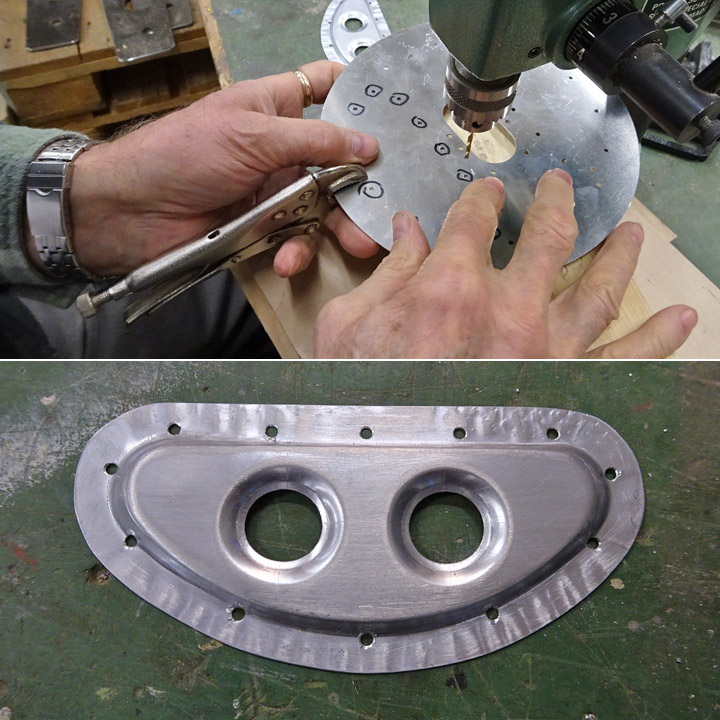

The first task of the team was to make the hatches for the auxiliary fuel tank and bomb racks. Six hatches are needed, two for each side and two for the Myrsky test wing. The first item to be made were the crescent-shaped stiffeners on the inside of the hatch. Twelve billets, slightly larger than the final stiffeners, were cut from 1 mm aluminium sheet. Two holes were cut according to the original drawing for making the stiffener lighter. For pressing the billets into shape, female and male pressing moulds were made. The billets were pressed into shape between the moulds.

The extra “skirt” was cut off.

The following task was to drill rivet holes on the edges of the crescent-shaped plates, so that they could be riveted on the inside of the hatch. The stiffener was clamped tightly on the inside of the hatch plate, exactly on the right place. Then the hatch plate was turned around and the rivet holes for fastening the stiffener, already laser cut on the hatch, were marked using a marker pen.

The holes were drilled along the edge of the stiffener. Soon all 12 stiffeners were ready to be fastened on the hatch plates.

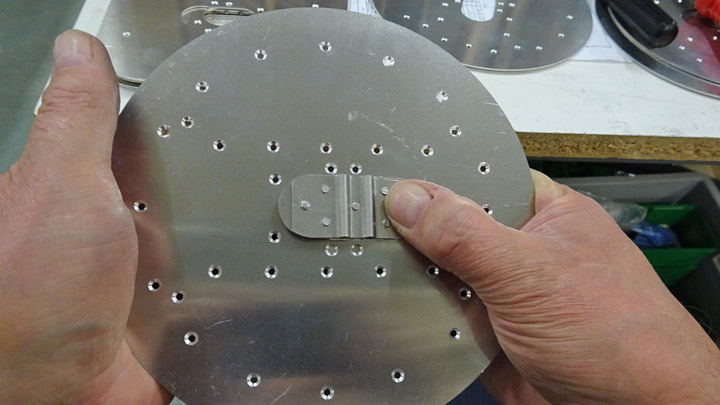

Another Tuesday Club team was working on the lock disks which will be placed in the middle of the auxiliary fuel tank hatch. The parts of the lock disk were riveted together and the lock disk was preliminarily placed into the opening in the middle of the hatch. A lot of work will be needed before the six auxiliary fuel tank hatches are ready, not to mention all the other hatches, which are at the billet stage. |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |