Assembly of Myrsky's wing ribs on trailing edgeTorstai 11.4.2019 - Member of Tuesday Club The preparation of ribs for Myrsky’s wings was started in the very beginning of the Myrsky restoration project in 2016. At the time ribs were made for the mid-wing section (between the wing spars) and for the leading and trailing edges.

Now the Myrsky wing restoration and assembly has reached the point where only the ribs on the wings’ trailing edge are missing.

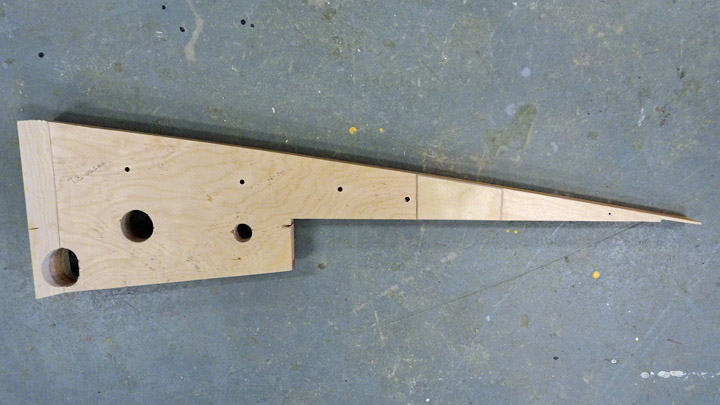

Both wings have 12 ribs on the trailing edge between the root of the wing and the aileron gap. Each rib has a notch for the flap on the lower side of the trailing edge. There are also holes in the ribs for the operating mechanisms of the ailerons and landing gear. For the installation of the trailing edge ribs the wing was placed upside down. This way it is easier to install the operation mechanisms for the ailerons and landing gear through the holes in the ribs. Furthermore, it is easier to make sure that the flap fits into the notch in the ribs.

As preliminary work the bearing block, operation bars and angle gear box for the flaps and ailerons have been installed. Also the operation mechanism for the landing gear, which penetrates the ribs, had been tested in its place.

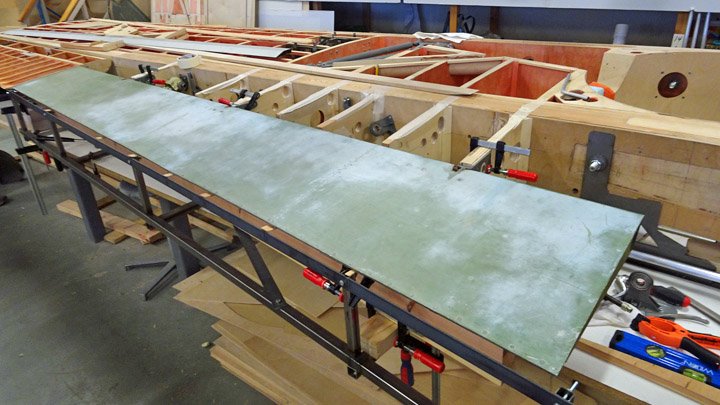

The most important preparatory work item was to build the assembly jig from steel tubes. It is necessary to use the jig to be able to place the ribs on the trailing edge in the right position. They must be exactly on the same level with each other and with the rear spar and the batten on the trailing edge.

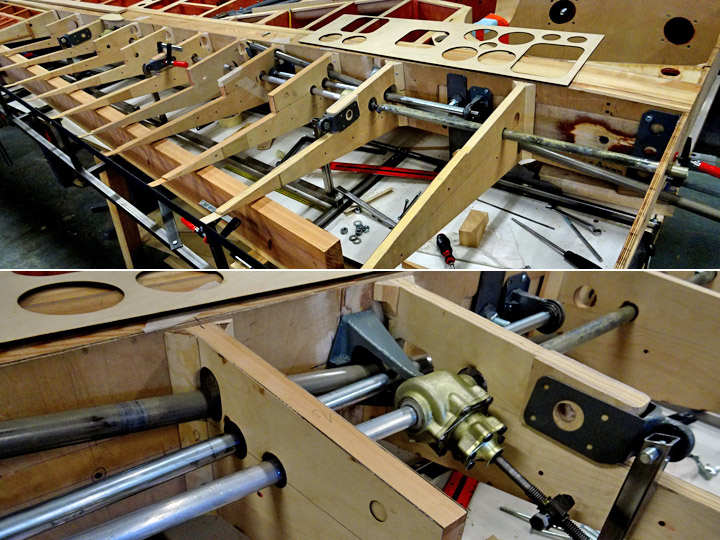

The assembly work was started on the right / starboard wing. When the assembly jig was in place, the ribs could be placed one by one between the rear spar and the rear tube of the jig. At this phase the ribs were only preliminarily fastened.

When all the ribs on the trailing edge had been placed in a neat row between the rear spar and the rear tube of the jig, the operation mechanisms of the flap, aileron and landing gear were pushed through the holes in the ribs. At first glimpse the several operation bars and mechanisms are a jumble, but each bar and tube has a purpose and has its own route through the ribs.

It was also tested how the flap settles into the notch in the ribs. The original aluminum flap pressed nicely into the notch and it also opened as expected.

The ribs will be glued onto the rear spar when the trailing edge batten which joins the tips of the ribs is ready and has been assembled into the jig. Translated from Finnish to English by Erja Reinikainen. |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |