Horizontal stabilizer's frame of Caudron is repairedKeskiviikko 4.3.2020 - Member of Tuesday Club The restoration work on Caudron C.59 advanced trainer’s wooden horizontal stabilizer frame has involved a lot of work and after about six months it is finally ready. The starting point in the restoration work was that the stabilizer’s covering was rotten and broken and had to be replaced. It turned out that the whole frame of the stabilizer was bent and its ribs were rotten. The Tuesday Club team decided to dismantle the whole structure and rebuild most of the ribs, and straighten the bent battens on the leading and trailing edge.

The restoration work on the various parts of the horizontal stabilizer was completed in the beginning of this year. The ribs have been repaired, the bracing wires have been cleaned and painted and the battens on the leading and trailing edge have been straightened. On one rib the half-rotten plywood waist could be fixed with glue, but on the rest of the ribs the plywood waist had to be replaced. Before assembling the horizontal stabilizer the holes, which make the rib lighter, were made even larger to match the size on the original rib holes. This work was done using a vertical rotary tiller.

The assembly work was started by fitting the repaired plywood ribs preliminarily into their places between the leading and trailing edge battens. Some adjustment was needed on the ends of the upper and lower battens on the ribs before they fitted tightly into their places. After the fitting, the fastening of the ribs was started, beginning on the leading edge.

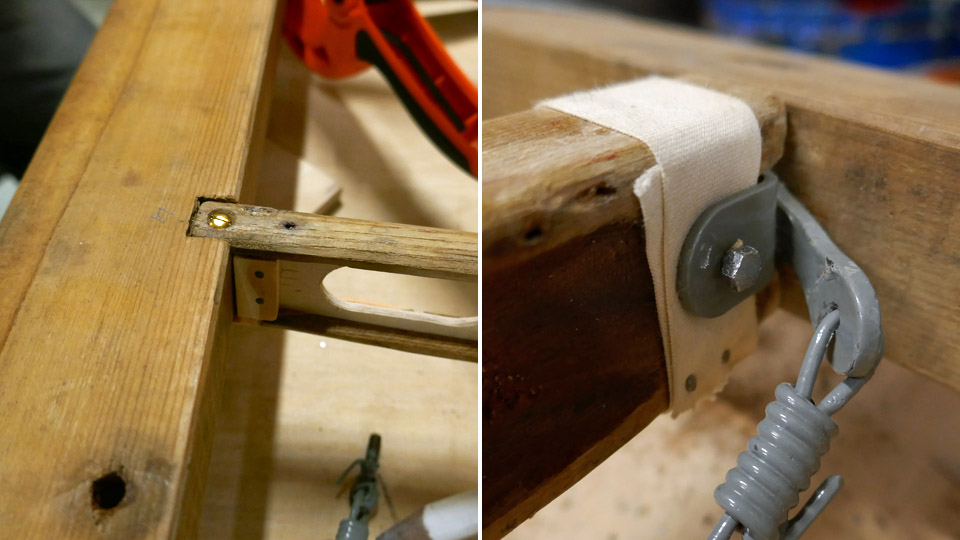

The ends of the upper and lower battens on each rib were pushed into the fishtail joint notches on the leading edge. Then the rib batten ends were fastened on the leading edge batten, using 3x16 mm countersunk brass screws. First a preliminary hole was made, using a thin drill piece, to prevent the batten ends from splitting. In addition to the plywood ribs, also three solid wood ribs were fastened on the leading edge batten. The fasteners for the bracing wires were fastened between the wooden ribs and the leading edge batten. The bracing wires, still attached on the fasteners, were left loose.

The Tuesday Club team didn’t use any glue when fastening the ribs and assembling the horizontal stabilizer. When dismantling the Caudron’s horizontal stabilizer, the team found out that the stabilizer has been originally built in France at the Caudron factory without any glue.

When all the ribs had been fastened on the leading edge batten at one end, the work on the trailing edge could be started. The first step was to fasten the end of each rib into its notch in the trailing edge batten. Three cargo straps were tightened around the horizontal stabilizer to keep it in shape when fastening all nine plywood ribs and three wooden ribs into place.

When all ends of the upper and lower rib battens had been fastened on the trailing edge with fishtail joints, the battens were secured using brass screws. The solid wood ribs with the bracing wires were also fastened on the trailing edge. Now the crossing bracing wires could be slipped through the lightening holes on the plywood ribs. The last step in the assembly work was to fasten the end strips of the port and starboard end of the horizontal stabilizer onto the joints at the ends of the leading edge and trailing edge battens. Now the assembly work had been completed.

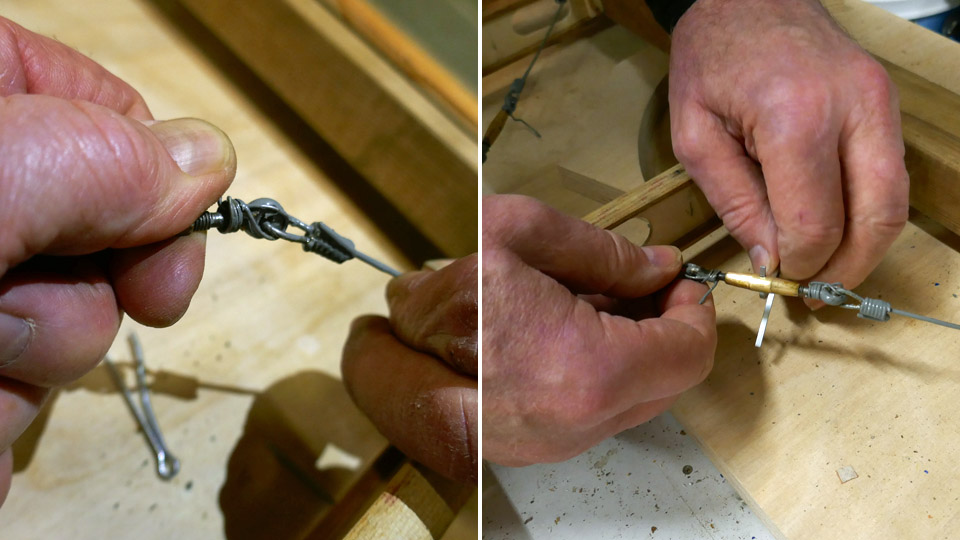

At this point the bracing wires of the horizontal stabilizer could be preliminarily tightened. The work was started by removing remaining old wire strips from the turnbuckles and cleaning the threads on the turnbuckles. Then the crossing wires were tightened using the turnbuckle. The final tightening of the bracing wires will be done before the stabilizer covering work is started.

The horizontal stabilizer had been assembled and the bracing wires preliminarily tightened, so the supporting cargo straps could be removed. When this had been done, the team noticed that the port rear corner of the stabilizer was a couple of millimetres above the table surface. When assembling the stabilizer frame, the team didn’t use any glue, so it was natural that the uncovered stabilizer will bend a little. The team managed to straighten the frame manually so that it rested evenly on the table surface.

After the assembly, the horizontal stabilizer frame was varnished using protective clear Le Tonkinois varnish. The varnish is a mixture of linseed oil varnish and China wood oil. The Tuesday Club team didn’t use varnish tinted red, as it would normally have done when varnishing a new wooden frame. Clear varnish was chosen because the team wanted to preserve some of the still remaining original red protecting varnish which had been applied on the horizontal stabilizer frame at the Caudron factory in the 1920s. Now the horizontal stabilizer is ready to be covered. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoring, old aircraft, Caudron C.59, CA-50 |