Stiffeners are fastened on Myrsky?s wheel and oleo compartment doorsTiistai 14.4.2020 - Member of Tuesday Club The VL Myrsky (MY-14) is being restored and its parts around the wheel well, including the outer door of the wheel well, the door of the oleo compartment and the door stiffeners were sent to be chromated. When they came back from the chromating process, it was time to fasten the stiffeners on the doors. Chromate bathing means that the aluminum plate is treated with acid solutions containing chromates and a thin inorganic film is formed on the surface of the aluminum with the components of the surfacing bath liquid. This surfacing protects the aluminum plate from oxidization. In the chromate process the Myrsky’s landing gear doors and their parts got a beautiful golden hue on the surface.

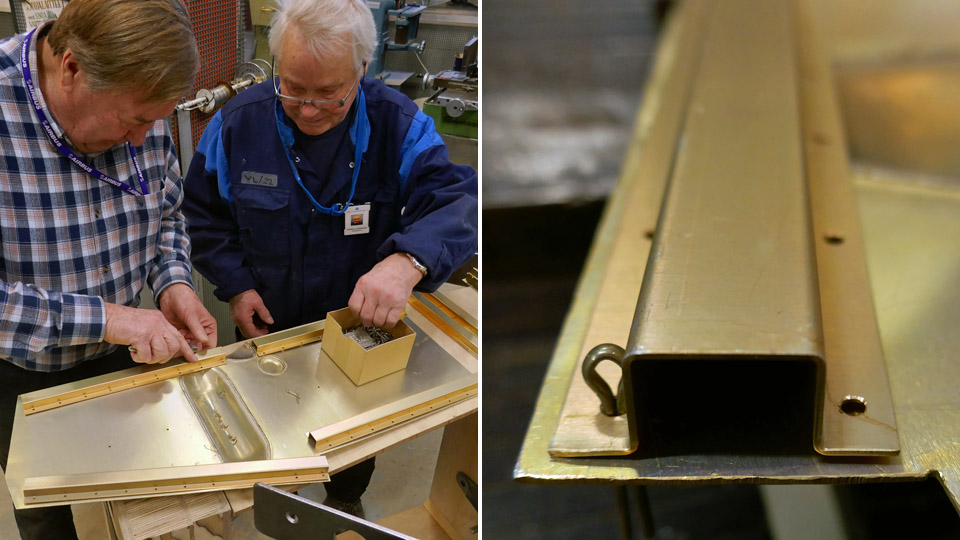

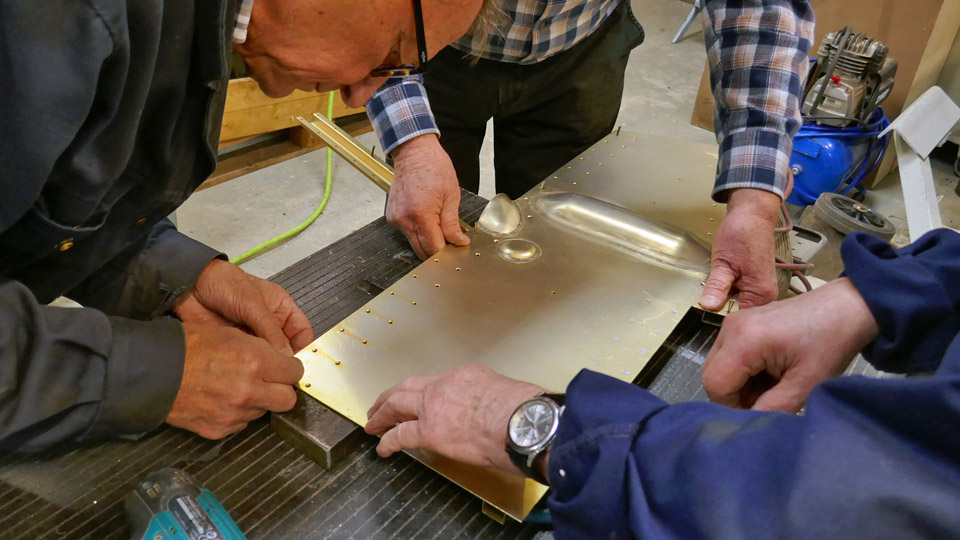

First the stiffening battens were fastened on the landing gear oleo compartment door. The battens have top hat profile. This means that the square batten is open at the bottom and it has sleeves bent to the sides. The sleeves have holes for riveting the stiffening batten on the edges of the door.

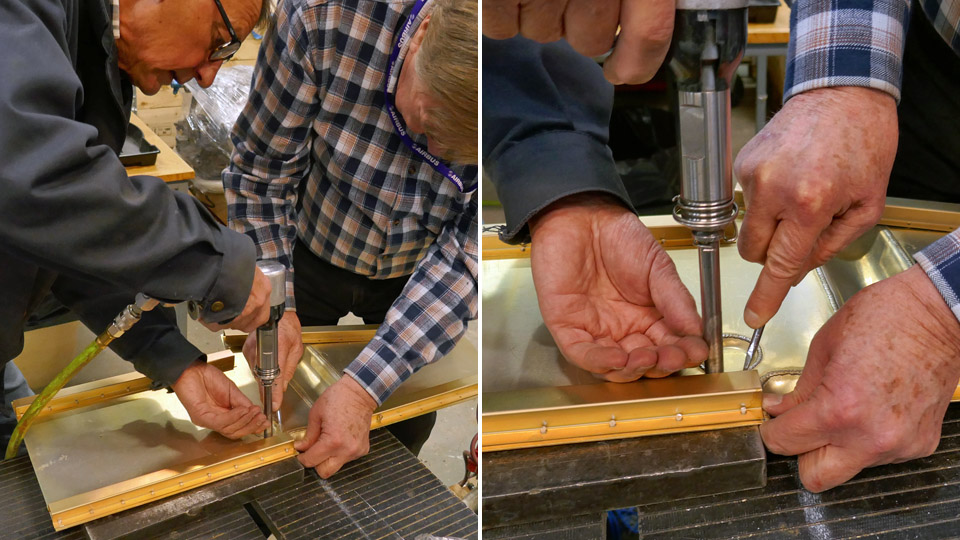

The holes for the rivets had already been drilled earlier on the oleo compartment door and on the stiffening battens. The rivet holes on the edges of the door had also been beveled for flat head rivets. The stiffening battens were riveted on the lower side of the door. The work was started by fastening the battens into place with a couple of pins which were pushed through the rivet holes. Before riveting the battens the oleo compartment door was assembled into place and the team made sure that it fitted properly in its place also with the stiffening battens.

Then the battens were riveted on to the inner side of the door, rivet by rivet, using the riveting gun. The riveting gun is faster and more practical than using a hammer for the riveting work. When all the stiffening battens had been fastened on the oleo compartment door, the work on the stiffeners for the door on the wheel hub was started.

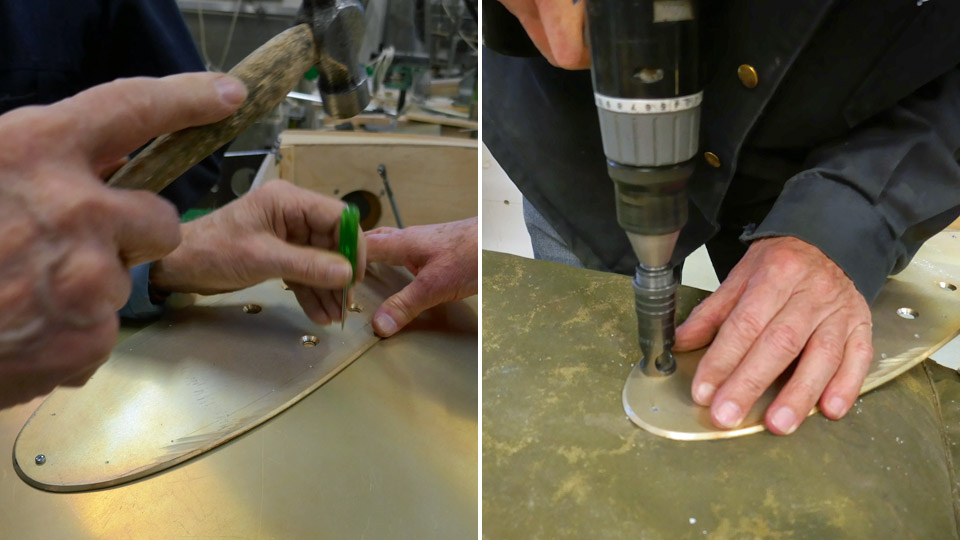

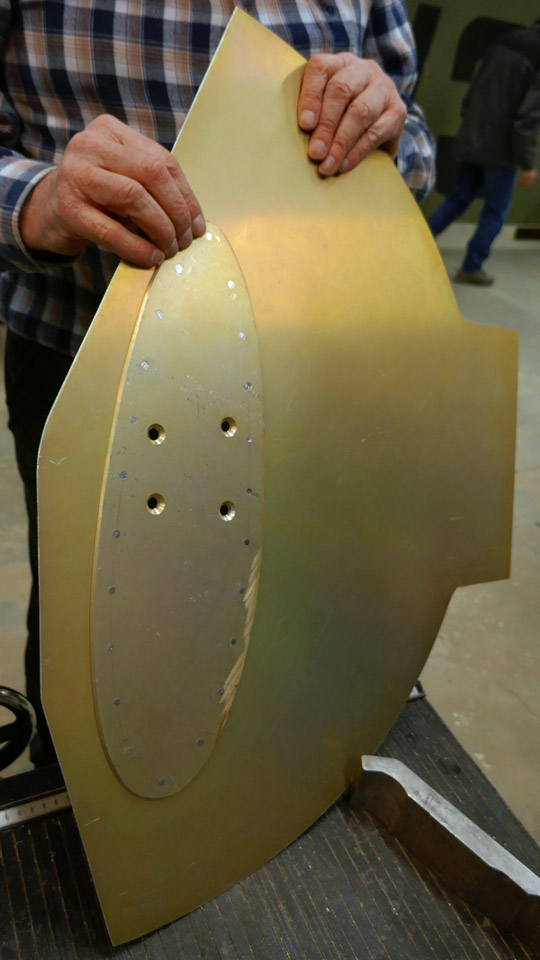

The oval stiffening plate on the outside of the outer door of the wheel well was fastened on the wheel hub with four machine screws. Then the places for the rivet holes were marked on the edges of the stiffening plate. The oval plate is fastened on the door with rivets. A prick was used for marking the location of the holes. A temporary screw was fastened to both ends of the oval plate so that the stiffening plate could be pressed tightly on the slightly convex door. The screws keep the stiffening plate in its place on the door while the rivet holes are being drilled.

The holes were drilled using a vertical drill and beveled with a beveling drill bit. Then the stiffening plate was riveted on the door, from the inside of the door, using a riveting gun.

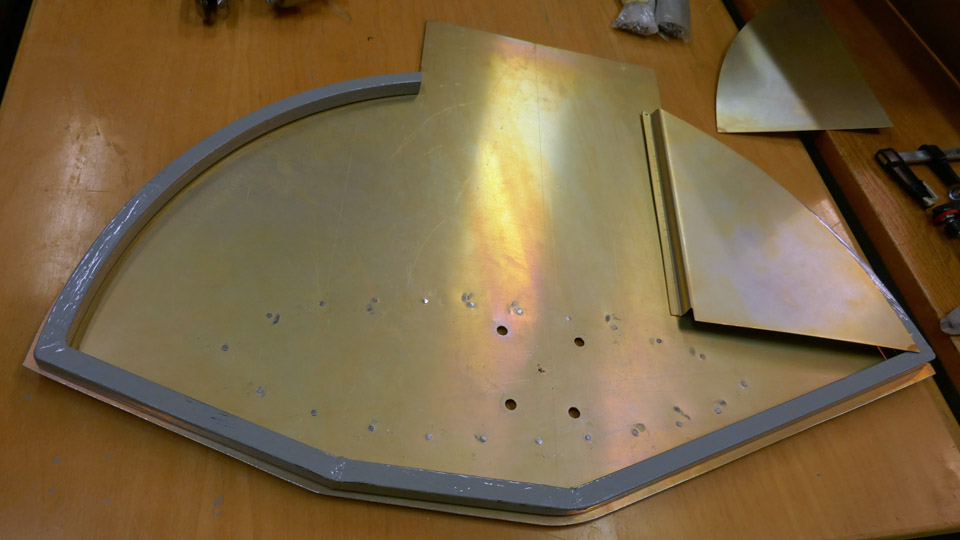

Then the box shaped stiffeners were preliminarily placed on the inner side of the outer wheel well door. There are stiffeners on both sides of the door and one at the bottom edge. The stiffeners are riveted by their outer edge on the supporting frame around the inner edge of the door, made of square steel tube, and by their hems on the door. The supporting frame of steel tube was not chromated but painted with grey Isotrol paint to prevent it from rust.

The riveting of the box-shaped stiffeners was not started before the Tuesday Club activities were terminated due to the Corona virus pandemic. The stiffeners were riveted on the oleo door but the stiffeners on the outer door of the wheel well are still under work. The landing gear of the test wing will have to wait until the work continues after the virus epidemic is over. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |