About Myrsky MY-14 oil cooler, wing root fairings, landing gear doors and MY-5 fuselage frameMaanantai 24.8.2020 - Tuesday Club member When the VL Myrsky II (MY-14) port wing half covering was being finished in the restoration space of the Finnish Aviation Museum, also other Myrsky-project items were under work.

Before the Corona virus pandemic interrupted the work, the Tuesday Club team had completed most of the engine’s oil cooler supply and exhaust air duct parts. They have been made from 1 mm thick aluminium plate. Now it was time to start building, according to the original drawing, the airflow control device into the supply air duct. The control device consists of a circular frame, inside which there are three flaps, which move on their axles. The air flow into the oil cooler can be controlled continuously with these flaps. The air flow control is done from the cockpit.

The parts needed for the air flow control device were cut from 1 mm thick aluminium plate, using a laser cutter, at ProLaser Oy. Holes for the rivets, which are needed in the assembly work, were drilled on the semi-finished control flaps. The parts of the air flow control device were also chromated to prevent corrosion.

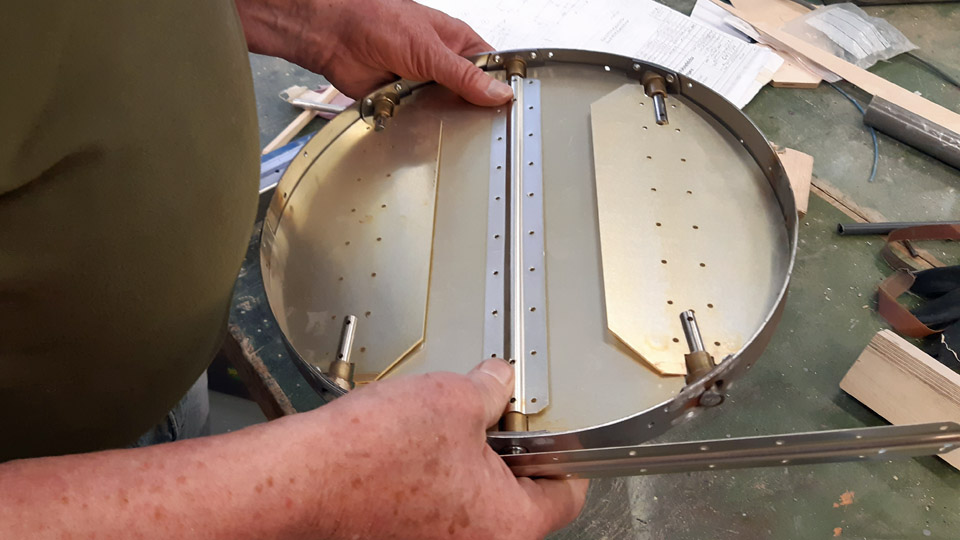

The assembly work of the oil cooler control device was started at the circular frame. When the round frame had reached its final shape, the ends of the axles of the three control flaps were riveted on the frame. There is a slot on the end of the axle, into which the edge of the aluminium flap fits. The three flap plates fitted perfectly on the axle slots. The following phase will be to rivet an aluminium profile on the flaps, which locks the flaps on the axles.

Some metal work has been needed when making the aluminium fairings, which cover the connecting point of the Myrsky’s fuselage and wing. The work was started on the fairing which covers the wing’s leading edge and the fuselage. The complicated fairing shape consists of three pieces of aluminium plate, which are welded together. The preliminary fairing parts were cut from 1 mm thick aluminium plate. A wooden last was made for shaping the aluminium sheets into the desired shape. Two lasts are needed, one for the starboard wing and the other for the port wing. The preliminary fairing parts were shaped into their final shape at Flanco Oy, using the last. The shaped fairing parts were welded together at GA Telesis Engine Services Oy.

The work on the landing gear enclosure doors of the test wing has also continued, including the door fastened on the wheel hub and the oleo strut door. The doors had been nearly finished already in March. The remaining aluminium profile stiffeners were riveted on the inner surface of the doors. The doors were now ready to be installed. The bulging parts or the “bumps” on the outside of the oleo strut door have also been welded into place. These bumps are needed for the landing gear retraction fork which is fastened on the oleo. These bumps have also been welded on the preliminary oleo door plates of the actual Myrsky wing’s landing gear. However, the actual wing doors have not been chromated yet and their stiffeners have not been fastened.

The Myrsky MY-5 fuselage frame, which was brought from Tikkakoski, has also been under work. The parts, which were still fastened to the frame, have been unfastened and now the frame is “clean” for sandblasting. The fuselage frame will be sandblasted at Auto- ja Teollisuusmaalaamo Oy, where it will also be painted grey.

A pile of different kinds of brackets and parts was dismantled from the MY-5 fuselage frame. Some of the parts had to be unfastened with some violence, using an angle grinder for the work, because the badly rusted fastening bolts couldn’t be opened. The rust will be removed, and the parts will be painted. All the parts will be needed when the MY-5 fuselage frame is restored to be the exhibition fuselage, which illustrates the structure of the Myrsky fighter. The 2,5-meter test wing, built during the Myrsky project for testing the wing construction procedure, will eventually be fastened to the MY-5 fuselage. Before that, the MY-5 fuselage frame will be used for test assembling and fitting the Myrsky MY-14 wings. In the fitting phase the MY-5 fuselage frame will be lowered on the MY-14 wing, built by the Tuesday Club team. The wing will be locked onto the fuselage with the four wing attachment brackets or bolsters. The wing parts will be fastened with steel plates and the whole wing can be test fitted in about a month’s time. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |