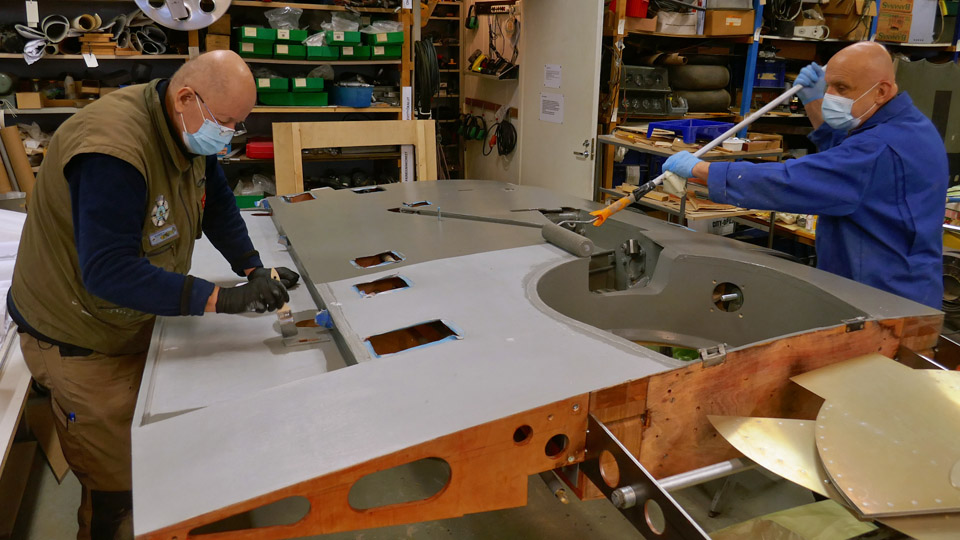

Myrsky's demo wing was moved to mid hall of Finnish Aviation MuseumTiistai 22.2.2022 - Tuesday Club member When the underside of the demo-wing, built in the VL Myrsky II (MY-14) restoration project, had been painted with Futura 3 adhesive primer, it was ready to be moved from the restoration workshop of the Finnish Aviation Museum into the museum’s mid hall. An exhibition about the VL Myrsky II restoration project will be built in the mid hall. The demo wing will be used in the exhibition to show the museum visitors what the wood-structured wing and the equipment were like in the Finnish WWII VL Myrsky fighter. All the equipment of the Myrsky’s wing have been assembled into the demo wing, including landing gear, operating mechanisms of the ailerons and the hanger for the auxiliary fuel tank / bomb. To allow a better view of the wing structure, the upper side of the wing has not been covered with plywood.

The demo wing includes a 2,5-metre section of the starboard wing and a one-metre root part of the port wing. The demo wing was used for testing how to build the Myrsky wing’s root part before starting to build the actual wings for the Myrsky MY-14. Now the demo wing will be used as a showpiece.

For moving the demo wing into the exhibition, pallets with wheels were fastened at both ends of the wing, which weighs nearly two hundred kilos. The demo wing was supported on racks made of steel and plywood, fastened on the pallets. The wing was locked into a vertical position with the leading edge downwards.

Having the wing in this position was the only way to manoeuvre the wing through the flight simulator room in the Aviation Museum’s mid hall and into the space reserved for the exhibition in the mid hall. Even this way the wing had to be wriggled through the hall inch by inch.

The wing was moved from the museum’s restoration workshop to the mid hall’s outer door on a lorry with a hoist. The transfer took place on a very rainy day, so the wing was protected from the rain by wrapping it in plastic.

The wing package was pushed out of the restoration workshop on the pallets with wheels, then the hoist straps were fastened. The wing was lifted, using the hoist, and moved onto the bed of the lorry. The lorry transported the demo wing to the mid hall’s outer door. There the wing was lowered in front of the door with the hoist, then it was pushed on the pallets through the door and into the simulator room in the mid hall. The one-metre section of the port wing was also brought to the mid hall on the same lorry.

In the simulator room the four-metre demo wing on its pallets was manoeuvred between the simulators until it was at a right angle facing the doorway to the mid hall exhibition area. The demo wing was gently pushed into the space which is reserved for the Myrsky exhibition. It was a close call, because there was only an inch between the pallets and the door frame. When the demo wing had reached its destination, the rain protecting plastic could be removed.

Now the demo wing will be prepared for exhibition. First the pallets will be removed, then the starboard and port side wing halves will be joined, and the landing gear will be assembled into the starboard wing. There will be also a Myrsky’s rear fuselage in the exhibition, with the wooden vertical and horizontal stabilizers, which were built in the Myrsky MY-14 restoration project, and the original metal elevators will be assembled, too. In the Myrsky restoration project the Aviation Museum Society’s Tuesday Club has concentrated, among other things, on the wings, tail, landing gear, oil cooler and engine cowlings. The Finnish Air Force Museum has been working on the fuselage restoration. Hopefully the MY-14 restoration will be completed next year. Then the genuine Finnish WWII Myrsky fighter would be on display for the public.

The VL Myrsky II restoration project exhibition is open between 5.3. – 31.5.2022 at the Finnish Aviation Museum during its normal opening hours. The exhibition is in the mid hall, used for changing exhibitions, and a museum ticket is needed. The ticket prices are: adults 12 €, reduced groups 6 €, children below 7 years € eur and Museum Card 0 €.

I warmly recommend a visit at the Myrsky exhibition which will open in March. There you will learn about the restoration work of Myrsky MY-14 and about the history of the Myrsky fighter, which was the only WWII fighter of the State Aircraft Factory to reach series production phase. Photos: Lassi Karivalo. Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

Myrsky project goes on Christmas breakKeskiviikko 23.12.2020 - Tuesday Club member

Merry Christmas 2020 and New Year 2021! The Tuesday Club Member. The hammering and tinkling of the Myrsky project have stopped in the restoration space of the Finnish Aviation Museum. It is time to have a break and rest over Christmas. We will be back at work on January 5th. Because of the coronavirus pandemic this year has been very exceptional for the Tuesday Club. Naturally it has also been exceptional for Finland and for the whole world. In March we had to terminate all our activities. Since June it has been possible to continue the restoration of VL Myrsky II (MY-14), but with only a handful of club members working at a time. The restoration of the Caudron C.50 aircraft and the reparation of the PZL SM-1SZ helicopter blades have been on a break all the time. In spite of the small task force, a lot has been accomplished in the Myrsky restoration work. The Myrsky’s wing structures have been completed and now the lower sides of the wings have been painted with undercoat paint. After the Christmas break the undercoat painting will continue on the upper sides of the wings. The Tuesday Club team has worked in close co-operation with the Finnish Aviation Museum and the Finnish Air Force Museum. I hope sincerely that the coronavirus pandemic will be blocked next year and the whole Tuesday Club team can return to work at the Finnish Aviation Museum. Hopefully in the autumn 2021, at the latest, it will be possible to continue the restoration work on the historically valuable aircraft with the full task force. We wish you a peaceful Christmas time and a better New Year 2021! Photo: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

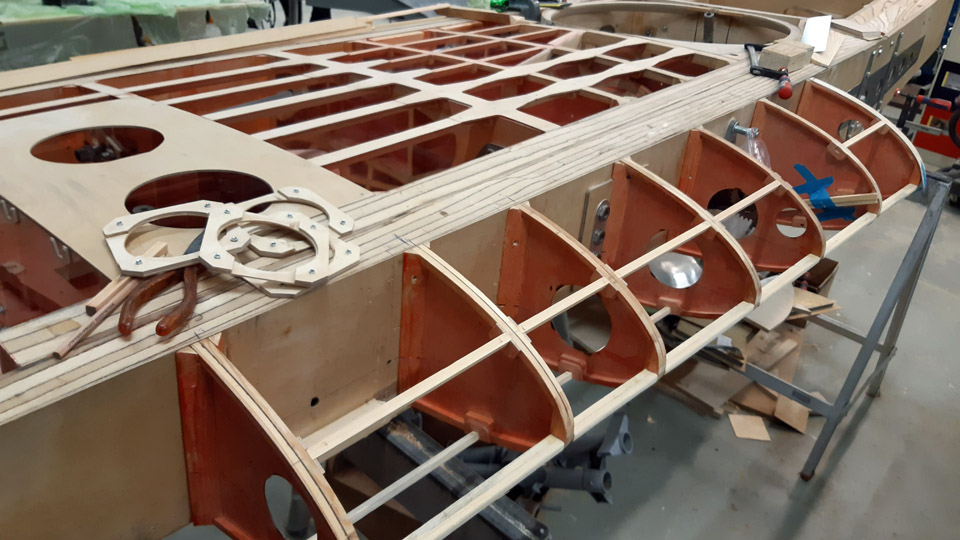

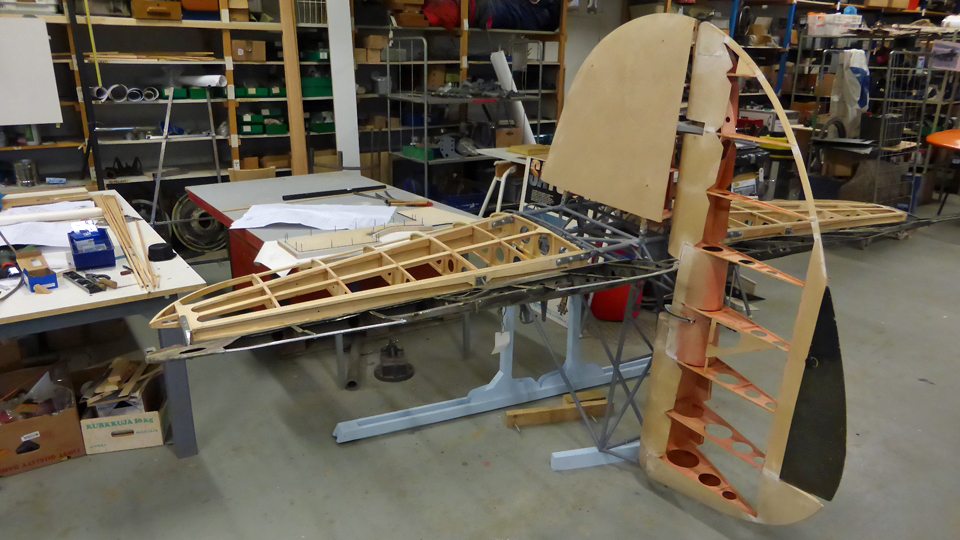

Myrsky?s test wing is built to be wing for MY-5Tiistai 22.12.2020 - Tuesday Club member During the corona virus pandemic, the work in the Tuesday Club has concentrated on the restoration of VL Myrsky II (MY-14) and the number of workers has been limited to only a few at a time. The finalisation of the Myrsky-project’s test wing has been on a break. Now both wing halves of the MY-14 are in the undercoat painting phase and carpenters are available for other work. The team decided to continue building the test wing and to get it ready.

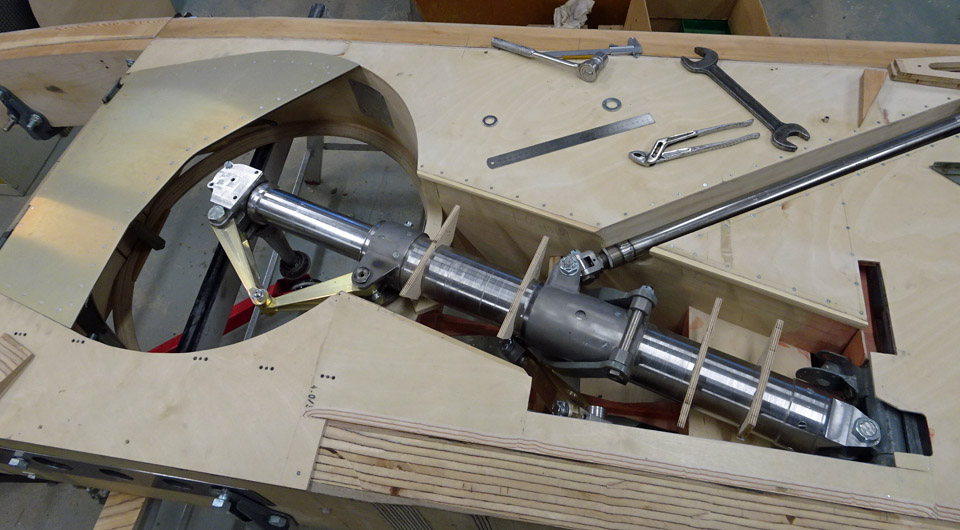

The test wing is the root section, 2.5 meters long, of the Myrsky’s starboard wing, which was built to test and model the construction of the actual wing for the Myrsky. The main emphasis was on testing how the landing gear area is built, and the landing gear installed. Testing was useful because the original drawings were inadequate and inconsistent and several times it was necessary to discuss how to proceed. Sometimes the built section had to be dismantled. Due to the test wing the mistakes were not repeated when the actual Myrsky wing was built.

The test wing will be useful also in the future. Originally the aim was to place the test wing on display at the museum as an example of a wooden wing structure in a WWII fighter, designed by the State Aircraft Factory. This is why the upper surface of the wing will be partly covered with transparent plexiglass so that the interesting inner structures and equipment can be seen.

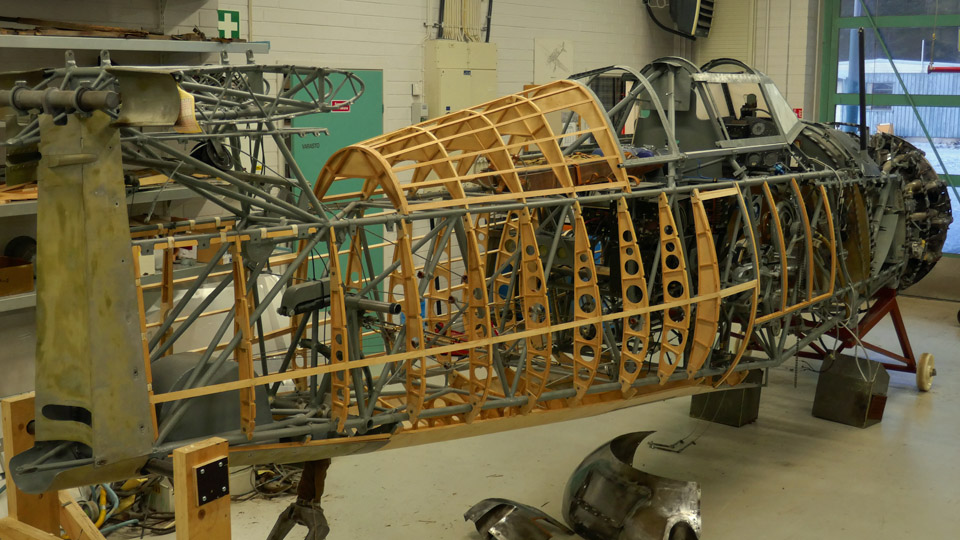

The saying goes that the appetite grows while you are eating, and this is what happened with the test wing. A fuselage frame of Myrsky MY-5, in poor condition, is available for the test assembly of the MY-14 wing. The Tuesday Club team decided to restore this fuselage frame so that it could be placed on display with the test wing assembled on it. Then the museum visitors could see the mixed-structure Myrsky, having a fuselage frame made of steel tube and the wooden root part of the starboard wing. The MY-5 fuselage frame has already been restored, but it has been cut behind the cockpit and is now waiting for the test assembly of the MY-14 wing

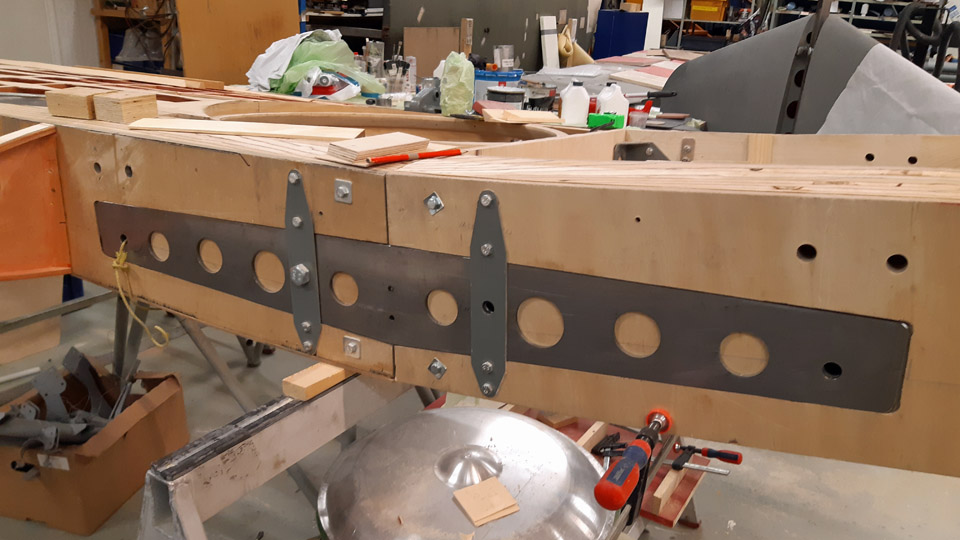

But the appetite kept on growing. The team decided to build a 1.0-meter section of the Myrsky’s port wing to go with the 2.5-meter section of the starboard wing. The port wing section includes the wheel well of the landing gear. Neither of the wing sections is ready but they have been joined with a steel plate and the preliminary wing assembly for the MY-5 can already be seen. We can start talking about the Myrsky MY-5 wing instead of the test wing, because it has already done its task as the test item in the MY-14 restoration.

And this is not all yet! The Tuesday Club team is dreaming – when the Myrsky MY-14 restoration has been completed – of continuing with the MY-5 fuselage frame and assembling original parts and equipment, which are available, and building the missing vertical and horizontal stabilizers and elevators. The MY-5 would be a great example for the museum visitor of how the mixed-structure Myrsky has been built. How far the MY-5 fighter will eventually be built and assembled remains to be seen in the future.

The Tuesday Club team will continue with the construction of the Myrsky’s wing sections, 2.5 m on the starboard side and 1.0 m on the port side. The starboard side section structures are almost ready, and the landing gear has once already been assembled on it. Work continues with the leading edge. The leading edge ribs have now been glued on the front spar. The edge strip connecting the ribs to each other has been glued on the tips of the ribs as well as the battens between the ribs.

The construction of the wheel well on the port wing section is ongoing. The plywood ring on the upper edge of the wheel well was built from narrow plywood strips which were glued into a pack on a mould. The wheel well cover is fastened on this ring. The wheel well cover will be made from aluminium sheet by metal spinning. For the 2,5 m starboard wing the cover has already been made.

The wheel well walls are also being covered with plywood. The billets for the walls were cut from 1,2 mm plywood sheet. The billets will be fitted into place and finalised. The short wing section on the port side will not have the landing gear as the longer starboard wing section does, the wheel well will remain empty. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

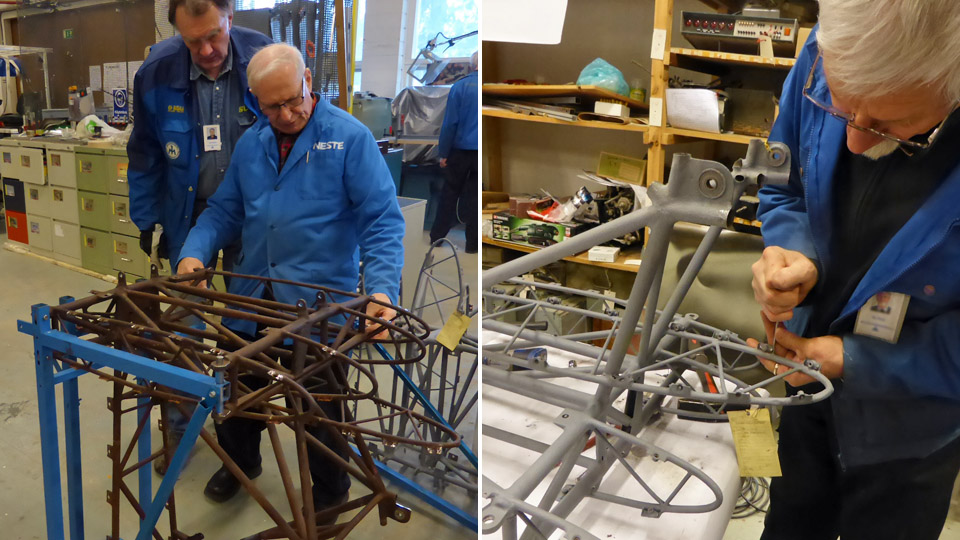

Myrsky MY-5's fuselage frame was taken to sandblasting and paintingKeskiviikko 16.9.2020 - Tuesday Club member The earlier blogs describe how the Myrsky MY-5’s rusted fuselage frame will be straightened, sandblasted and painted before it can be used for the wing test assembly of Myrsky MY-14.

The text in the box: Original paint under the bracket. The MY-5 fuselage frame has been fastened on a sturdy metal frame, the assembly jig, outside the restoration space at the Finnish Aviation Museum. It has been straightened on the jig and the remaining parts and equipment have been dismantled. Most of these are different band-shaped fastening brackets. The fuselage frame was cut behind the cockpit, so that it became easier to handle and it can be brought into the museum’s restoration space for the test assembly of the MY-14 wing. Later the fuselage frame parts will be welded together so that it will be the whole Myrsky MY-5 fuselage frame.

The fastening brackets, which were still attached on the MY-5 fuselage frame, are important when the original paint and its tint are being investigated. When the brackets were unfastened, some well-preserved original paint of the fuselage frame was revealed. The painted surface has been protected from rusting, hidden under the brackets.

The original paint surface was cleaned by grinding it lightly, so that the tint of the paint became even more intensified. On both sides of the cleaned painted area a paint test was made, using two different shades of grey Isotrol paint (linseed oil alkyd paint). This was necessary so that the team could choose the appropriate tint of the undercoat paint for the fuselage frame. The tints of the tested grey paint were RAL 7005 ja RAL 7042.

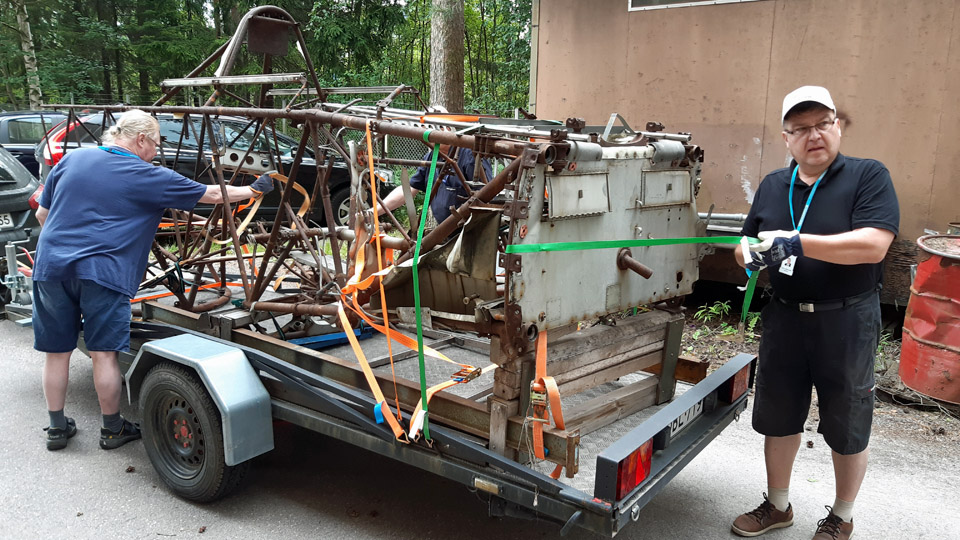

On Tuesday, September 15th, the shortened MY-5 fuselage frame was loaded on a trailer, using a stacker. The frame will be taken to Auto- ja Teollisuusmaalaamo Oy, a paint workshop in Vantaa. The Tuesday Club team tried also to fit the rusted engine frame on the trailer, but it wasn’t possible. The engine frame will be transported to the paint workshop later.

At Auto- ja Teollisuusmaalaamo Oy the fuselage frame will be sandblasted and painted with undercoat paint. When the sandblasting has been done, the clean metal surfaces will be covered with clear varnish, which protects the frame from rusting. The grey Isotrol undercoat paint will be applied on top of the varnish. The MY-5 fuselage frame, with its undercoat paint, will return to the Finnish Aviation Museum in a couple of weeks. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

About Myrsky MY-14 oil cooler, wing root fairings, landing gear doors and MY-5 fuselage frameMaanantai 24.8.2020 - Tuesday Club member When the VL Myrsky II (MY-14) port wing half covering was being finished in the restoration space of the Finnish Aviation Museum, also other Myrsky-project items were under work.

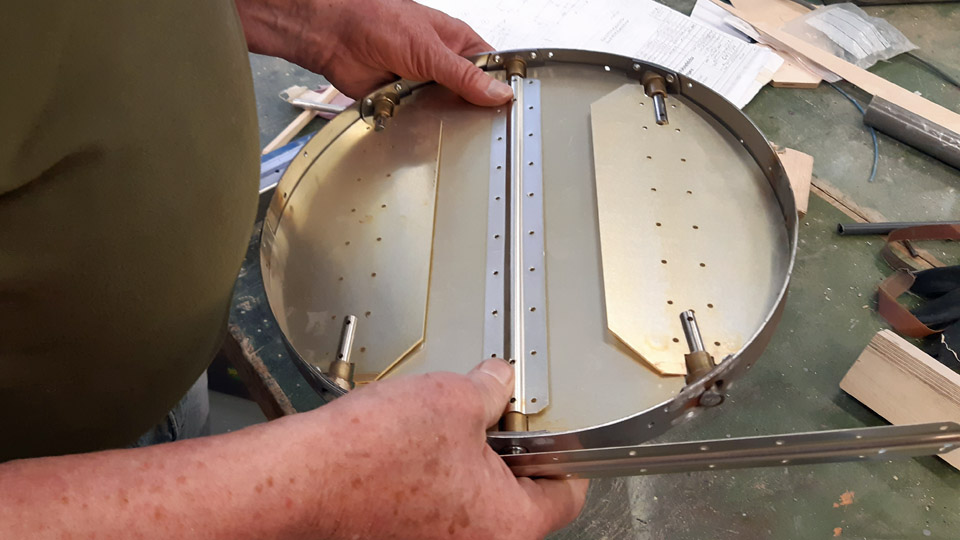

Before the Corona virus pandemic interrupted the work, the Tuesday Club team had completed most of the engine’s oil cooler supply and exhaust air duct parts. They have been made from 1 mm thick aluminium plate. Now it was time to start building, according to the original drawing, the airflow control device into the supply air duct. The control device consists of a circular frame, inside which there are three flaps, which move on their axles. The air flow into the oil cooler can be controlled continuously with these flaps. The air flow control is done from the cockpit.

The parts needed for the air flow control device were cut from 1 mm thick aluminium plate, using a laser cutter, at ProLaser Oy. Holes for the rivets, which are needed in the assembly work, were drilled on the semi-finished control flaps. The parts of the air flow control device were also chromated to prevent corrosion.

The assembly work of the oil cooler control device was started at the circular frame. When the round frame had reached its final shape, the ends of the axles of the three control flaps were riveted on the frame. There is a slot on the end of the axle, into which the edge of the aluminium flap fits. The three flap plates fitted perfectly on the axle slots. The following phase will be to rivet an aluminium profile on the flaps, which locks the flaps on the axles.

Some metal work has been needed when making the aluminium fairings, which cover the connecting point of the Myrsky’s fuselage and wing. The work was started on the fairing which covers the wing’s leading edge and the fuselage. The complicated fairing shape consists of three pieces of aluminium plate, which are welded together. The preliminary fairing parts were cut from 1 mm thick aluminium plate. A wooden last was made for shaping the aluminium sheets into the desired shape. Two lasts are needed, one for the starboard wing and the other for the port wing. The preliminary fairing parts were shaped into their final shape at Flanco Oy, using the last. The shaped fairing parts were welded together at GA Telesis Engine Services Oy.

The work on the landing gear enclosure doors of the test wing has also continued, including the door fastened on the wheel hub and the oleo strut door. The doors had been nearly finished already in March. The remaining aluminium profile stiffeners were riveted on the inner surface of the doors. The doors were now ready to be installed. The bulging parts or the “bumps” on the outside of the oleo strut door have also been welded into place. These bumps are needed for the landing gear retraction fork which is fastened on the oleo. These bumps have also been welded on the preliminary oleo door plates of the actual Myrsky wing’s landing gear. However, the actual wing doors have not been chromated yet and their stiffeners have not been fastened.

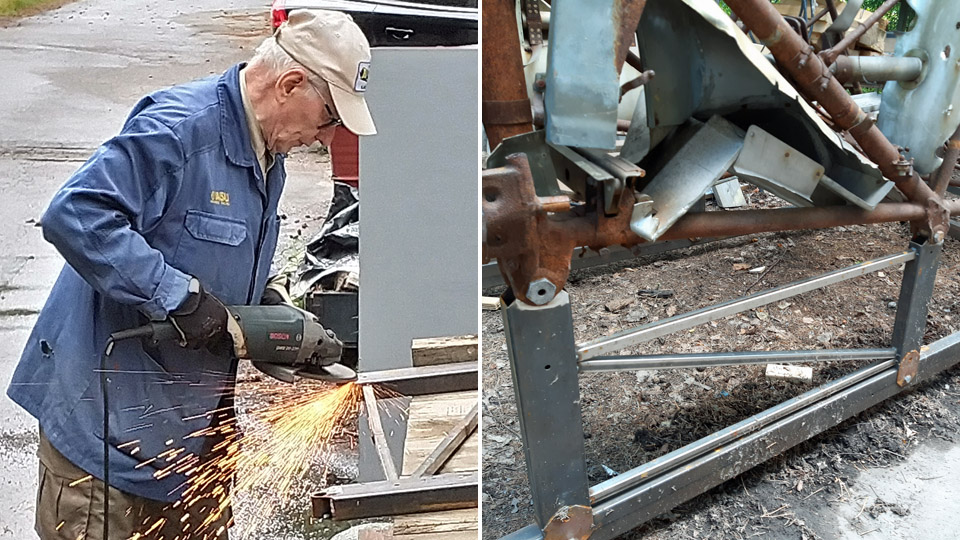

The Myrsky MY-5 fuselage frame, which was brought from Tikkakoski, has also been under work. The parts, which were still fastened to the frame, have been unfastened and now the frame is “clean” for sandblasting. The fuselage frame will be sandblasted at Auto- ja Teollisuusmaalaamo Oy, where it will also be painted grey.

A pile of different kinds of brackets and parts was dismantled from the MY-5 fuselage frame. Some of the parts had to be unfastened with some violence, using an angle grinder for the work, because the badly rusted fastening bolts couldn’t be opened. The rust will be removed, and the parts will be painted. All the parts will be needed when the MY-5 fuselage frame is restored to be the exhibition fuselage, which illustrates the structure of the Myrsky fighter. The 2,5-meter test wing, built during the Myrsky project for testing the wing construction procedure, will eventually be fastened to the MY-5 fuselage. Before that, the MY-5 fuselage frame will be used for test assembling and fitting the Myrsky MY-14 wings. In the fitting phase the MY-5 fuselage frame will be lowered on the MY-14 wing, built by the Tuesday Club team. The wing will be locked onto the fuselage with the four wing attachment brackets or bolsters. The wing parts will be fastened with steel plates and the whole wing can be test fitted in about a month’s time. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

About the fuselage frame of VL Myrsky MY-5Tiistai 4.8.2020 - Tuesday Club member When the restoration project of VL Myrsky was launched, three damaged Myrsky fuselage frames were available at the Finnish Air Force Museum in Tikkakoski. The rear section has been violently cut away from all three fuselage frames. The least damaged fuselage frame of MY-14 was chosen for the restoration project. This is how the project became the restoration project of the VL Myrsky MY-14 fighter. The MY-14 fuselage rear section, which has been cut off, has disappeared and therefore the rear section of MY-9 was chosen to be connected to the MY-14 fuselage frame. Also a fourth Myrsky fuselage frame (MY-10) exists, in a private collection, and there have been negotiations about purchasing it for the Myrsky project.

The MY-14 fuselage with its engine and control equipment is mainly restored at the Finnish Air Force Museum in Tikkakoski. The main task of the Aviation Museum Society’s Tuesday Club is to build in Vantaa in co-operation with the Finnish Aviation Museum the other parts of the fighter, such as the wings with all their equipment, the parts of the tail and to build the parts for the nose, e.g. the front engine cowling, NACA-ring and the engine cowlings on the sides.

Photo: Jorma Laakkonen. The restoration project started in 2013 and the development of the project has been followed all the time on homepages of the Aviation Museum Society and Myrsky Project, and also in yearly journals. In Tikkakoski the restoration of MY-14 fuselage is already quite far. In Vantaa the Tuesday Club has prepared the tail parts and the wings to the point where their surfaces can be honed smooth and painted. The aim is that the restored – but static – MY-14 can be placed on display during the year 2021.

The second best Myrsky fuselage from Tikkakoski, i.e. MY-5, was also taken into the restoration project with its separate rear fuselage and engine mounting. The MY-5 fuselage frame has its own important role in the Myrsky restoration project. Some useful parts have been dismantled from the fuselage frame and repaired in Tikkakoski for the needs of the MY-14 fuselage frame restoration. On the other hand, the fuselage frame of the MY-5 will be used by the Tuesday Club for the fitting of Myrsky’s wings. The wing positioning and fastening will be tested on the fuselage frame by the Tuesday Club before the wings are sent to Tikkakoski to be installed on the fuselage of MY-14.

Additionally, an even bigger role has been planned for the MY-5 fuselage frame. It will be used to build a demo-fuselage of the Myrsky-fighter to illustrate the metal and wood structure of the aircraft. The 2.5-meter piece of the starboard test wing and the 1-meter piece of the port test wing will be fastened on the fuselage frame. Before building the actual wings, the test wings have been built to test the methods how to build the complicated root of the wing with the landing gear and how to lock the wing halves to each other with steel plates.

The rear fuselage of MY-5, brought from Tikkakoski to Vantaa to the Finnish Aviation Museum, has already been used in the Myrsky-project. The badly rusted rear fuselage frame was straightened in a jig, specially made for the purpose, and sandblasted and painted, using grey alkyd paint. After this the rear fuselage has been used by the Tuesday Club to fit and support the horizontal and vertical stabilizers when they are being built.

The fuselage frame and engine mounting of MY-5 were brought from Tikkakoski to the Finnish Aviation Museum in Vantaa on July 21st, 2020. The MY-5 fuselage was transported by the Myrsky-project’s PR-man, on his holiday trip to Ostrobothnia. On Friday 10.7 on his way there he took the trailer and “some Myrsky items” to Tikkakoski. On Tuesday 14.7 a group of Tuesday Club members travelled to Tikkakoski and moved, with some assistance from the Air Force Museum, the MY-5 fuselage frame and engine mounting on the trailer to wait for the transportation. The unusual load travelled successfully to the Finnish Aviation Museum on 21.7. Fortunately, the traffic was rather quiet and it wasn’t raining.

When the fuselage frame was outside the museum, the cargo straps were unfastened. Then the MY-5 fuselage was lifted from the trailer with a forklift and placed on the ground to wait for cleaning and repair. The badly rusted and partly bent and damaged fuselage frame will be straightened and cleaned by sandblasting, straightened and repaired, and then painted grey. Behind the cockpit some frame pipes have been bent and some are even missing.

Left photo: Heikki Kaakinen. The assembly jig, which was made from square steel pipe for the straightening of MY-14’s fuselage frame, was re-assembled and modified for the MY-5 work. The jig was fastened on the four brackets by the cockpit on the MY-5 fuselage. These brackets are used for fastening the wings with four fastening bolsters on the wings.

Photo: Heikki Kaakinen.

The MY-5 fuselage frame, now fastened on the assembly jig, will be measured carefully and straightened. The places of some parts or their fastening brackets will be defined and photographed before they are dismantled for cleaning. Also the rusty engine mounting, brought from Tikkakoski, will be cleaned by sandblasting and painted.

When the fuselage frame has been cleaned and painted, the rear fuselage frame (which has already been restored earlier) will be welded to it. Then the MY-5 fuselage frame will be ready to serve as the fitting frame or assembly jig for the MY-14 wings, and later as the basis of the Myrsky demo fuselage. The MY-5 demo fuselage will be restored so that the structures remain visible in the way they were left visible when building the short test wings. The restoration of this demo fuselage is not the main priority at the moment, the work will be started when the restoration of the MY-14 has been completed. Photos (except if separately otherwise mentioned): Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |