The repairing of the Caravelle's right wingtipMaanantai 21.11.2022 - Tuesday Club member The right wingtip of the Caravelle III (SE-DAF), which was acquired from Sweden by Aviation Museum Society Finland and is now in a hall in the Pansio port area in Turku, has been badly damaged at its leading edge. The damage has been caused by some airport vehicle which has hit the Caravelle’s wingtip during the decades when the aircraft stood on the side of the airfield. There is a dent also in the middle of the tip of the left wing. Furthermore, the trailing edge of the horizontal stabilizer tip and the radome at the nose of the aircraft have been damaged in collisions. The wings, the horizontal stabilizer and the radome will be repaired at the Tuesday Club.

Fortunately, the tips of the Caravelle’s wings and the horizontal stabilizer can be detached. The Aviation Museum Society’s volunteer team in Turku detached the wing tips, the damaged tip of the horizontal stabilizer and the radome to be taken to Vantaa. These parts were brought from Pansio in the boot of a car and on a trailer to Vantaa, to be repaired at the Tuesday Club.

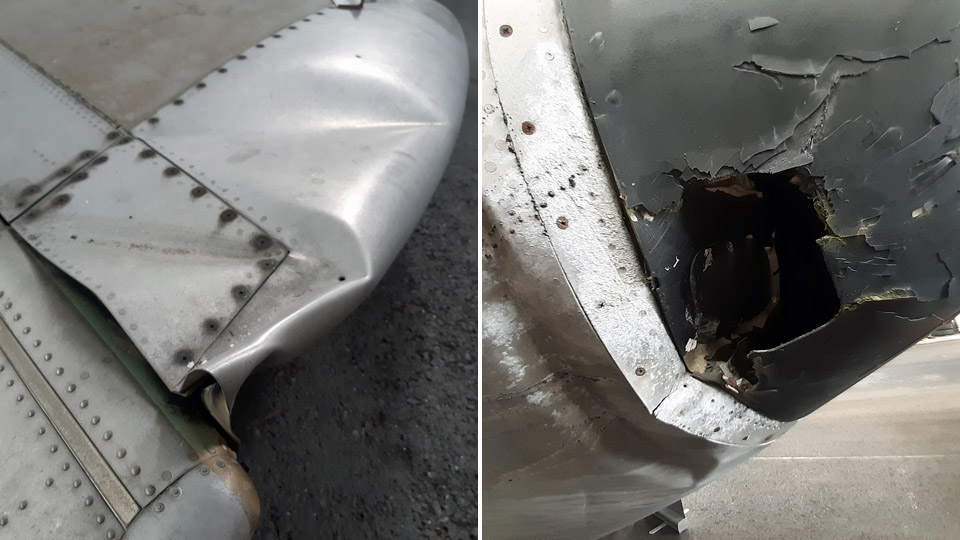

The leading edge of the right wingtip is broken along a distance of 40 cm. The navigation light and its uniquely shaped lamp shade are broken too. The navigation light shade on the left wing is unbroken. When repairing the right wingtip, the left wing will be used as a model.

The navigation light is badly broken. It may be possible to make a new lamp socket for the light bulb, but it will probably be impossible to make the navigation light shade which has a complicated shape. It can hardly be found as a spare part, either. Well, we can surely ask Le Caravelle Club in Sweden, they have restored a former SAS Caravelle.

The repair of the right wingtip was started by drilling out the rivets which fastened the crumpled aluminium sheets on the wingtip. After this the sheets could be bent open, and we could get a better view of the damaged tip’s structure.

We tried to mould the damaged aluminium sheets and see if they could be bent into their original shape. However, the duralumin sheets on the wingtip are made of such hard aluminium that they broke when they were bent back into their original shape. We had to admit that the damaged wingtip can’t be repaired by using the original sheets. The wingtip and its supporting structures will have to be rebuilt from new aluminium sheets. Fortunately, we have the unbroken tip of the left wing to use as a model. We dismantled the whole damaged area of the right wingtip.

We analysed different alternatives for building the right wingtip and concluded that the broken part will be rebuilt from several sheets of aluminium, which are moulded into the shape of the wingtip and riveted together. For this purpose, a wooden last will be made, shaped as the unbroken left wingtip, but its mirror image. Each sheet of aluminium will be bent into shape against this last and then riveted to each other to form the new wingtip. Before riveting, a new supporting structure for the wingtip will have to be built.

We started to build the wooden last by gluing together some pieces of plank to make a piece of wood, larger than the wingtip. This piece of wood will be gradually shaped by sawing, carving, planing, and grinding to match the shape of the wingtip’s leading edge. To make the piece of wood exactly match the shape of the wingtip, profile jigs, made of plywood and shaped as the unbroken wingtip, will be used. When the shaping progresses, the profile jigs will be used for testing where the wooden last still needs to be shaped.

When the glue had dried, we could start shaping the chunk of wood into the wooden last. First the curved side profile of the wingtip was drawn on the piece of wood. A band saw was used for sawing along the drawn line and almost one half of the piece of wood was cut off. Then the shaping continued with a hand milling machine and a plane. When the shaping work is continued, the shape of the last will be checked with the profile jigs. There is still a lot of work ahead before the wooden blank matches the shape of the wingtip’s leading edge and can be used as a last for moulding the aluminium sheets for the broken wing. Photos by Lassi Karivalo Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, Tuesday Club, SE-DAF |