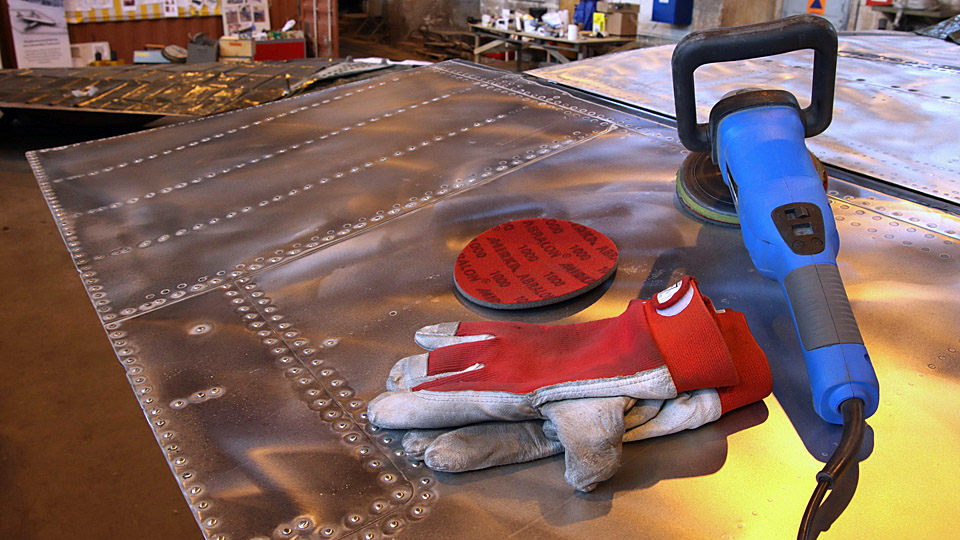

About Caravelle's sandingMaanantai 6.3.2023 - Erja Reinikainen Caravelle’s sanding work is progressing well in the port hall in Pansio. During the autumn season work methods were developed and now the best practices are producing results. The first phase in cleaning the Caravelle’s surfaces was to remove the black tar streaks and blotches left by rainwater and air pollutants during the decades when the aircraft stood outside at Arlanda airport. After some experimenting it was noticed that persistent scratching was the best work method. Different chemicals for removing graffiti and even oven cleaner foam were tested, but the results were not mentionable. Angle grinders have been used in the sanding work, starting with coarse sanding discs, and progressing to finer ones. Sanding discs P240 grit have been used for removing old paint. The surfaces which will be painted are left to this sanded coarseness, which is sufficient for the new paint to cover the surface well. The surfaces which will be polished have been sanded first using discs with P500 grit and then with P1000 grit.

The most burdensome areas for sanding have been the round head riveted painted areas on the rear fuselage and flaps. There the first grinding phase has been to use a steel-wire brush before moving to sanding discs.

The sanding work was started on the left side of the fuselage and on the lower side of the right side. After the transportation from Sweden, for some time the fuselage was resting tilted 45 degrees to the left, and this made it possible to restore the bottom on the right side and sand the left side at the top of the fuselage. The fuselage was lifted upright in the beginning of November. Before the Christmas break the 18 cm wide white strip of SAS-paint scheme white paint under the windows was sanded away on the left side, below the window line. It has been agreed that the aircraft will be painted to the 1960s Finnair paint scheme used on the Caravelle OH-LEA. There the lower side of the fuselage is polished up to the window level and the top part of the fuselage and the vertical stabilizer are painted white. The window area is painted blue with a narrow white line below. On the other side of the fuselage the paint-removing work was finished in the beginning of February. Also the sanding of the horizontal stabilizer, vertical stabilizer and engine nacelles was finished in early February.

Now also on the upper sides of the wings the middle sections have been sanded. The wings’ middle sections will be painted, and the leading edges and flaps will be polished. There the sanding work is under way. The lower sides of the wings were cleaned with dry-ice blasting, and they are ready for painting.

Before polishing, the finer grit discs (P3000 or P4000) are used at the final phases of sanding, when necessary, to remove the scratches caused by sanding. On a surface which is in poor condition, or which hasn’t been polished before, there are microscopic “hills” and “valleys” and these differences on the surface are smoothed out by moving material from the high points to the low ones (this is called compounding). This surface processing requires a lot of polishing power and therefore a rotary polisher and a wool disc are used. After using a rotary polisher the surface has a bright finish, but the wool disc has left thin spiralling scratches on it. To remove these the final polishing must be done using a double-disc random orbital polisher, “cyclo”. As you can see, there is a lot of polishing ahead before all Caravelle’s surfaces are shining bright. The use of polishing abrasives requires a temperature of +5…+10°C, so polishing work in Pansio will have to wait for spring weather. Translation with help of Martti Saarinen. Photos by Jouko Tarponen |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |