Work on the nosewheel and wing filletsKeskiviikko 31.5.2023 - Erja Reinikainen On Wednesday, May 31st, the Caravelle assembly team worked at Turku airport in windy weather, concentrating on smaller and less impressive, but nevertheless important details.

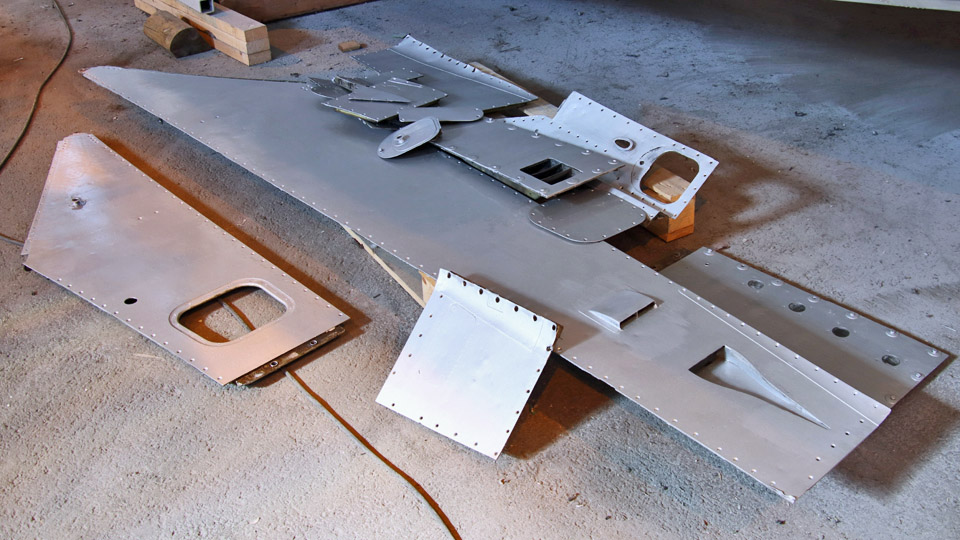

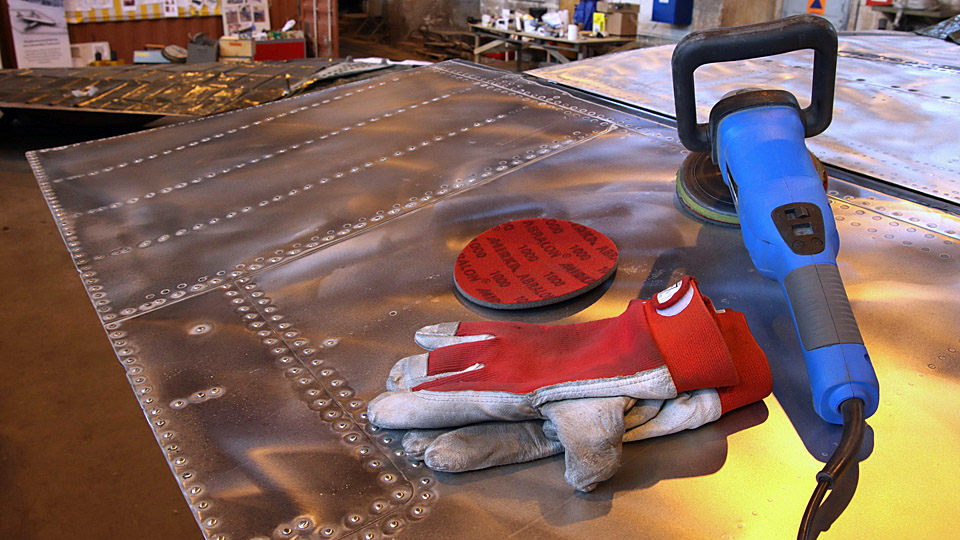

Photos by Erja Reinikainen The assembly of the wing to fuselage fillets was continued. In the wing root there are several fillets, of different shapes and sizes, fastened with rivets and screws. The assembly team spent all day fitting these fillets into place, on top of the wing and below it. Fasteners, which had been drilled out in Arlanda had to be removed, holes were opened, and countersunk edges drilled. New fasteners were installed, screws with cup washers and pop rivets. Probably hundreds of pop rivets were used during the day. Unfortunately the bottleneck in the assembly work was that there was only one battery-driven pop rivet gun in use.

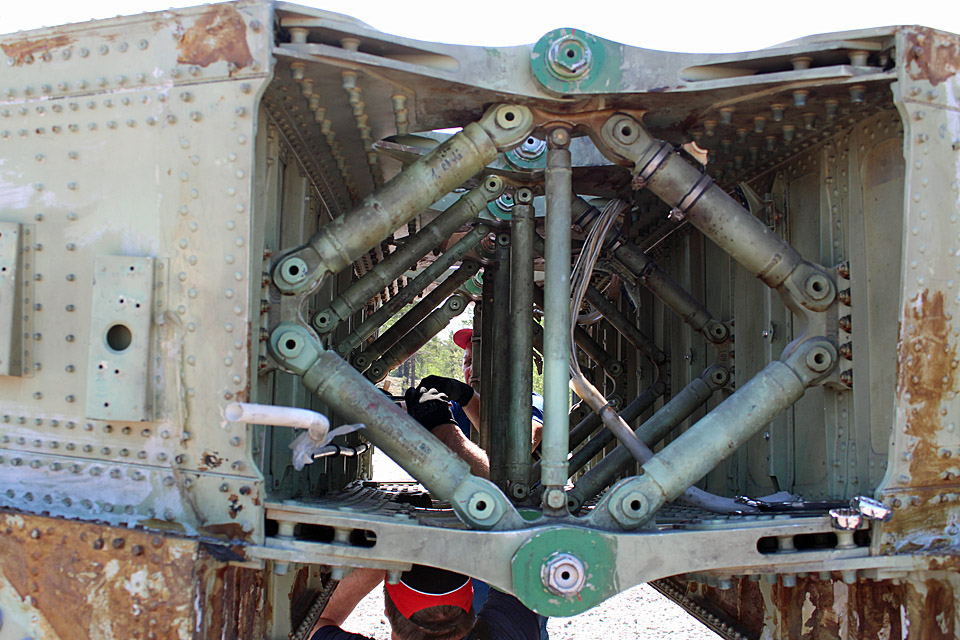

Photo by Erja Reinikainen The nose landing gear has been retracted since Arlanda as the fuselage has been on supporters on the floor. Now an external hydraulic pump was connected to the actuating cylinder of the nose landing gear and using the emergency manual unlock mechanism the landing gear was extended. The nose was lifted a little with the jacks under the front fuselage and now the aircraft looks as if it is positioned on the nose wheels, although its weight is still on the jacks. In the future a support will be made for the nose landing gear to take the weight off the wheels.

Photo by Erja Reinikainen During the day scaffolding was built around the tail for the assembly of the stabilizers. On Thursday, June 1st, the horizontal and vertical stabilizers will be transported from Pansio to the airport. The aim is to lift the horizontal stabilizer from the trailer on the Caravelle’s tail. It remains to be seen whether this is possible or not if the wind is as strong as it was today.

Photos by Jouko Tarponen While the riveting of the wing fillets was going on at the airport, the Pansio hall was cleared. The hall contract ends on June 1st and all the parts, tools and accessories which are still there will be brought to the airport in a sea container. In the coming weeks the Pansio team will go on with the remaining painting and polishing work at the airport. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird |

The fuselage is installed on the wingTiistai 30.5.2023 - Erja Reinikainen The Caravelle’s fuselage was transported from Pansio to Turku airport during the night, May 29th-30th. The load on the trailer was so tall that the Ahola truck had to do quite a detour to get to the airport. On Tuesday morning the Caravelle trailer was waiting for the assembly team to arrive.

Photos by Jouko Tarponen

Photo by Janne Salonen In the morning there was a mobile crane with two hooks and a “hiab” loader crane, on which the free-turning cable pulley system was fastened. This made it possible to lift the fuselage and to turn it around all its axes. First the fuselage was lifted from the trailer and supported by the cranes. The assembly team placed groups of three jacks on plywood boards under the fuselage, one group in front and another in the rear. Then the fuselage was lowered slowly into its position on the wing.

Photos by Erja Reinikainen The fuselage was carefully manoeuvred downwards, inch by inch, guiding it to meet the assembly points on the wing and the front and rear edges of the wing joint. The final inches required accuracy from the crane operators when the fuselage had to be turned towards the road or towards the forest, the nose or the tail had to be lowered or the whole fuselage rolled slightly. Fortunately there were calm professionals on the crane controls as well as in the assembly team and eventually the fuselage settled into place. This phase took about one hour.

Photos by Erja Reinikainen Getting the bolts connecting the wing and the fuselage into place took more time. The fuselage was still supported by the crane slings when the position of the fuselage was manoeuvred so that the bolts could be fastened. The first fasteners were easy to get into place but the attachment bolts in the fuselage keel tunnel area and especially the front lower fittings were the most difficult to install. To get the bolts into place the position of the aircraft was inched by using the tripod jacks, changing the position of the wings, and trying to get weight into the tail. A couple of times all members of the assembly team climbed into the tail section as weight load. By lunchtime all bolts had been installed.

Photos by Erja Reinikainen In the afternoon a large tripod jack was brought under the tail to support it, assembly work in the keel tunnel was continued, and the assembly of the wing leading edges and the wing to fuselage fillets was started. During the disassembly in Arlanda the leading edge, flaps and wing root fillets of the left-hand wing had been removed – and now they will be installed back into place. A lot of fasteners will be needed, and there will be demand for the fasteners which were cleaned in the ultrasonic washer in Pansio. A leak was observed in the hydraulic system of the integral stairway, now it was repaired, and the stairway is operating again.

Photo by Erja Reinikainen Members of the Pansio team and of the airport staff came to see the Caravelle and to take pictures. There were also curious visitors who had read about the aircraft in the local paper, Turun Sanomat. There will be more to see on Thursday when the vertical stabilizer is lifted into place. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird |

The Caravelle left PansioMaanantai 29.5.2023 klo 22.20 - Erja Reinikainen On Monday, May 29th, the Pansio team was finishing the last tasks on the Caravelle’s fuselage as the loading on the Ahola Special Transport trailer had been scheduled for the afternoon. And naturally there was the final rush: the last layer of lacquer was spread on the blue strip on the window line around noon. A padlock was installed on the service door. The stencil sticker for painting OH-LEA registration on the right-hand side of the fuselage was fitted into place.

Photo by Jouko Tarponen

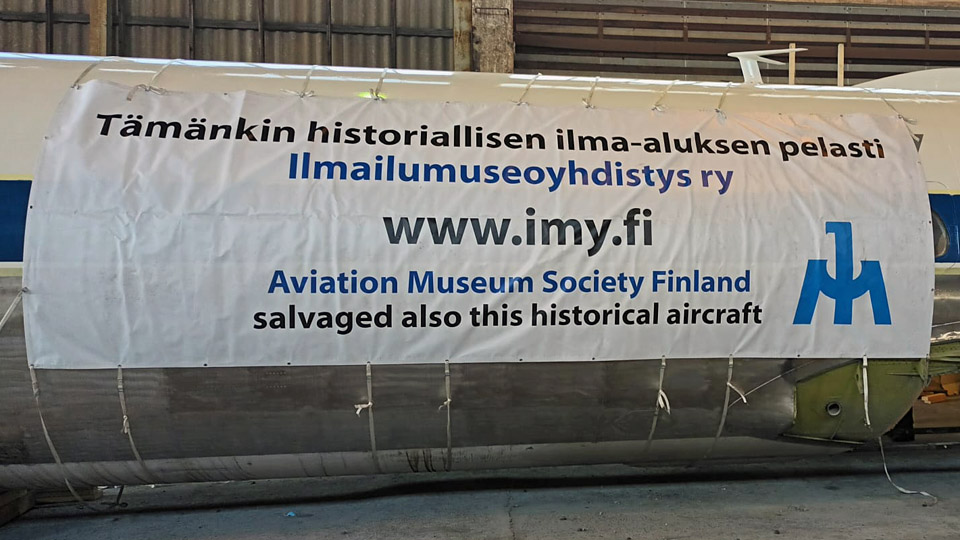

Photos by Janne Salonen The assembly team had arrived, and they were helping to install nets into the openings in the rear fuselage and vertical stabilizer so that birds wouldn’t nest inside the aircraft’s structures. In Arlanda there had been a whole colony of bird’s nests in the openings. Two large Aviation Museum Society Finland banners were fastened on the fuselage for the duration of the transport. This was a task easier said than done!

Photos by Jouko Tarponen The fuselage was lifted from its supports using the bridge cranes in the hall. Then the Ahola trailer was reversed under the fuselage and the fuselage was lowered on its supports. Everything went well – and no wonder, this had already been done in Arlanda in August last year. Many thanks to the Ahola professionals for good work and co-operation!

Photos by Jouko Tarponen An unpredictable setback occurred when the pallet with the free-turning cable pulley system was loaded on the trailer. The cable pulley system is needed when the fuselage is lifted from the trailer and on the wing at the airport and it will be necessary to turn the fuselage around its longitudinal axis. The pallet had already been lifted from the floor, using the bridge crane, when the crane suddenly stopped and wouldn’t move. Fortunately a fork-lift from the shipyard happened to drive by at that moment and the driver kindly helped in lifting the pallet with the pulley system on the Ahola trailer. The Caravelle was ready to be pulled out from the hall.

Photos by Jouko Tarponen

Photo by Janne Salonen Now the Pansio port hall is almost empty. Only the stabilizers, two passenger stairs and the storage container remained there. The fuselage will be transported to the Turku airport during the night and on Tuesday morning, May 30th, it will be lifted on the wing. The remaining parts and the sea container will be transported to the airport on June 1st. |

|

Avainsanat: ilmailuhistoria, entisöinti, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Last-minute rush in PansioMaanantai 29.5.2023 klo 22.00 - Erja Reinikainen The transportation of the Caravelle’s fuselage is approaching and the Pansio team members have been busy all weekend, completing the last tasks on the fuselage. The fuselage will be lifted on a trailer on Monday evening, May 29th, and transported to the airport during the night.

Photo by Erja Reinikainen The last tasks included the stencil stickers, which were fastened on the fuselage for painting the texts and logos according to the Finnair paint scheme. The stencils came from the print cut into individual text sheets and the largest Finnair texts divided into several parts. The letters and logos which will be painted were picked away from the sheets – i.e. there are holes in the areas which are painted. When this had been done, an adhesive foil was placed on the stickers to hold the letters in shape when the stickers are fastened on the aircraft. The stickers used as stencils are placed carefully on the fuselage and the texts, logos and registration are painted with a roller, following the holes in the stencils. When the paint has dried, the stencils are removed.

Photos by Ismo Matinlauri The stencil stickers for painting Finnair and OH-LEA, which are the largest and most difficult stickers to handle, were fastened on both sides of the fuselage on Friday, May 26th. The stencils stayed well in place when the adhesive foil was removed, and the texts have been painted. Some of the stencils have already been removed, some of the texts are still drying.

Photo by Jouko Tarponen During the weekend the blue stripe on the window line was painted once more. The blue paint is drying and the preparations for transporting the fuselage are on the way. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu, Bluebird |

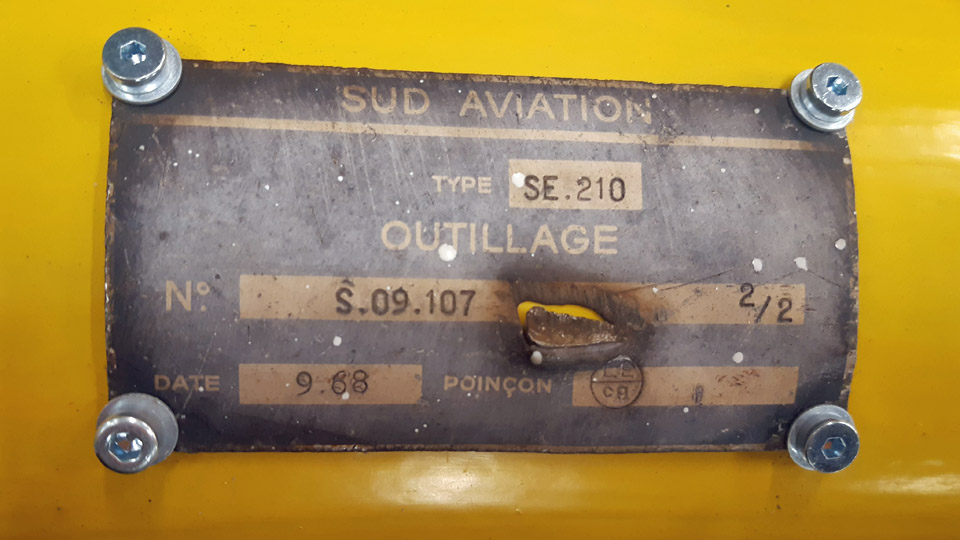

Caravelle towbar restoredLauantai 27.5.2023 - Tuesday Club member The original towbar for Caravelle III (SE-DAF), acquired from Sweden by Aviation Museum Society, was brought along. It was used by SAS. The towbar was abandoned by SAS along with the termination of the Caravelle fleet’s career. The towbar had lain decades at Arlanda Airport along SE-DAF.

The towbar was taken under restoration at the Tuesday Club in the autumn of 2022, in a similar fashion as the derelict Super Caravelle towbar was restored, used by Finnair. The SAS towbar is of the first version made by the Sud Aviation industries. For its part the Super Caravelle towbar used by Finnair is of the third and last version. The differences between these towbars are minimal and concern mainly the wheel rack of the towbar.

Along with the spring all the parts of the towbar were refurbished and painted. The last job before assembling the towbar was to repair the wheel rack to working order. When the towbar wheel rack was dismantled in the autumn season, it was noticed that the rim of the other wheel was so far gone that it was unusable. The other wheel’s rim was sound enough to be usable with a bit of welding. A new tyre and inner tube were bought for it and one of the bearings, which had broken when the wheel was dislocated from the axle of the wheel rack. When the rim had received its blue colour, the inner tube and the tyre were fitted in place.

To replace the unusable wheel, we managed, after a spot of searching, to find a wheel with an inner tube looking like the original wheel, and fitting the towbar’s 25 mm axle. A majority of the “wheelbarrow” wheels on sale were made for a 20 mm axle. When the rim of the new wheel had also been painted blue you could hardly tell them apart. The wheels were attached on to the wheel rack’s axles, after which the test assembling of the towbar could be commenced.

The test assembling will be necessary, because the towbar will be transported in parts to the Turku Airport area, where it will be assembled on show next to the ex SAS Caravelle SE-DAF, now being restored as the Finnair “Bluebird”. By test assembling it will be ensured that the assembling in Turku will take place without surprises.

The towbar test assembly was started by setting against each other the flanges of the halves of the towbar. We had to do some thinking, because the guiding pins for the flanges of the towbar halves didn’t line up with their holes so that the lifting handles are in the same line. We established that the towbar halves must have been 180 degrees out of line of each other already when they came to Finland.

This we hadn’t noticed when dismantling the towbar, because the towbar lacked the lifting handles, which would have indicated the position. If they had been there, we would have noticed that one handle was beneath the towbar, the other one above. So our conclusion is that the towbar was wrongly assembled at Arlanda. An indication of this is that in the photos we took before the dismantling of the towbar, the metal support of the towbar which should touch the ground is sticking to the skies.

To solve the problem of test assembling we sawed off the guiding pins and pressed the flanges of both the bar halves against each other so that the lifting handles were above the towbar and lined up properly with each other. After this the flanges were locked to each other with two locking collars around them. The collars were tightened fast by their brackets with bolts. This way the towbar halves had been connected.

Now it was time to attach the wheel rack to the towbar. The wheel rack was attached to the towbar by its attachment collars. The rack wasn’t attached in the middle of the towbar, but some way on the pull loop end side of the centre of gravity. Thus the aircraft towhead end, which connects with the nose gear, weighs down and leans on the ground by its support. Finally we attached the manufacturer’s plaque on the side of the towbar. The towbar is still lacking the Caravelle logo, which will be painted on its side before it will be ready to be delivered to Turku.

The derelict towbar underwent a complete transformation at the hands of the Tuesday Club. It changed from the rusty and partly damaged towbar into a renewed one, resembling the towbars used by the Finnair Caravelle fleet. It received the same appearance as the Finnair Super Caravelle towbar we restored a year ago. Photos by Lassi Karivalo Translation by Matti Liuskallio |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird;Tuesday Club |

Caravelle's fuselage is paintedTorstai 25.5.2023 - Erja Reinikainen While the assembly team was working at the airport with the wing junction, the upper part of the Caravelle’s fuselage was being painted white in the port hall in Pansio. The spray-painting was done by a contractor (Maalausliike T. Nikander). A layer of white paint was sprayed on the fuselage surface on two consecutive days, so two layers. Finally a protective layer of lacquer was sprayed on the painted surface.

The Pansio team found spray-painting to be a challenging task for amateurs and decided to hire a professional to do the work. The project schedule doesn’t allow any practise rounds at this point. The spray-painted area looks good, thanks to the professional.

Photo by Ismo Matinlauri. Actually we ran short of time with the painting work because the spring was very cold, the temperature in the unheated hall remained low for so long that the painting couldn’t be started in the planned schedule.

Photo by Ismo Matinlauri

When the paint and lacquer on the fuselage have dried, the protecting plastic can be removed from the window line and the stencil stickers can be fastened on the fuselage for painting the airline and aircraft type texts. Photos by Jouko Tarponen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu, Bluebird |

Caravelle's wings are transported and assembledTiistai 23.5.2023 - Erja Reinikainen At the end of May the lease of the port hall in Pansio will terminate, and during the winter all Caravelle’s restoration, painting and assembly work has been scheduled to keep this deadline. The assembly phase started on Monday, May 22nd, when the assembly team (6 people) and an experienced aircraft polisher came to help the hard-working painters and polishers in Pansio.

Photos by Erja Reinikainen A lot happened in the hall in just half a day, when preparations were made for the transportation, painting, and assembly, which were at hand. The list of completed work is long: The lower part of the aircraft’s fuselage on the left side was polished, mainly below the wing area. A large area of shiny polished surface was completed. The ready painted and polished surfaces of the fuselage were covered with thin plastic to protect them from the spray painting of the upper fuselage, which will begin on the following day. The remaining fasteners of the wing junction were cleaned. The stabilizers, which have been painted and polished, were covered with tarpaulins. Aviation Museum Society Finland banner was fastened on one wing for the transportation as a commercial. The sea container, which has been used as a storage in the hall, was emptied. All essential aircraft parts, tools, fasteners, assembly accessories, etc. which are needed in the assembly work, were loaded into another sea container, parked outside the hall. Only the tools, paint, and stencil stickers, which are needed in the painting and polishing work during the next ten days were left in Pansio.

Photo by Erja Reinikainen The assembly team spent part of the afternoon on the aircraft’s future location at Turku airport, measuring and planning how to make sure the wings are in the correct position and can be joined.

Photo by Janne Salonen In the afternoon the sea container was packed and ready to be taken to the Caravelle’s future location at the airport. Moving the container on the trailer was not an easy task, but eventually the chains were in the correct position and the container was on the trailer. The truck carried also a couple of passenger stairs and two large jacks.

Photos by Jouko Tarponen

Photo by Juha Paju

Photo by Jouko Tarponen Loading the wings on the Ahola Special Transport trailers went well, the same procedure had been done in August 2022 when the aircraft was brought from Arlanda. The bridge cranes in the hall were used to lift up the wings, one at a time, then the trailer was reversed under the wing. When the position of the wing had been checked the wing was lowered on its supports on the trailer. The two trailers were taken to Turku airport before midnight.

In Pansio the hall was almost empty now and it is really strange that the hectic final push is almost over. The top part of the fuselage will be painted during this week and the stabilizers are waiting to be transported at the end of May.

Photos by Erja Reinikainen. On Tuesday, May 23rd, the wing assembly work began at Turku airport. In the morning two mobile cranes were on site bright and early. Before the wings were moved, the aircraft’s future position was measured carefully and marked on the concrete slabs, which had been dug into the ground. The left wing was lifted from the trailer. Finding the correct position required some work and patience from the crane crew and the assembly team members who were measuring and operating the jack. Finally the wing was lowered on the ground, its weight resting on the support under the landing gear, on a wing jack and on two wing supports. The right wing was aligned into place, inch by inch, using the two cranes. The wing junction brackets met each other, and they were secured using the assembly pins which had been made to assist in the aligning. When some final adjustments had been made on the wing position, the wing junction expansion pins could be installed, and the wing lowered on its supports. By mid-day all expansion pins were in place and the assembly team could sigh with relief: everything had gone far better than expected.

Photo by Erja Reinikainen The wing junction’s canted brace struts were installed into place, then all tools and assembly accessories were collected into the sea container and the aircraft was surrounded with warning tape. The assembly will be continued next week when the fuselage has been painted and it will be transported from Pansio and lifted on the wing. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu, Bluebird |

The work in Pansio is taking the final sprintTorstai 18.5.2023 - Erja Reinikainen During the last weeks of May the Caravelle team in Pansio is facing the final push when the finishing touch is put on the restored parts of the aircraft before they are transported to Turku airport. The transportation of the wings is planned to take place on May 22nd, the fuselage is transported during the night on May 29th-30th, and the stabilizers at the end of that week.

The painting of the wings has been completed and the surfaces have been covered with a layer of lacquer which increases the lifetime of the painted surface and makes its maintenance easier. The registration markings (OH-LEA) will hopefully be painted on the upper surface of the wing before the wings leave the Pansio hall. The polishing work on one wing is lagging behind and only its flaps have been polished. This means that some polishing remains to be done at the airport. The wing junction expansion pins were cleaned this week and the work will be continued. The wing junction’s canted brace struts and their bolts are still waiting to be cleaned.

When the wings are taken to the airport, they will have to be placed in the correct position, so that it will be possible to lower the fuselage on the wing. This manoeuvre was planned this week when the fuselage was lifted from its trestles and into a horizontal position, using a levelling instrument. Then the position of the wing-to-fuselage fittings were measured.

The lower side of the fuselage has been sanded, excluding the lowest area. We aim to polish the tail section and the wing junction area before the fuselage is moved from the hall. Then about half of the fuselage polishing would be ready and the rest will be done at the airport.

The painting of the Finnair blue stripe on the window line has been started in the tail section. The painting line has been marked all the way along the side of the aircraft. This was easier said than done in the nose section, where the surface curves in two directions. The blue stripe and the narrow white line below will be completed this week. Then the only remaining painting task is to paint the upper fuselage white. When the wings have left the hall, a company specialized in spray painting will apply the two layers of white and the finishing lacquer.

The engine nacelles were painted and covering plates were installed in the air intake and exhaust nozzle. The plate in the air intake looks very much like a real Avon engine with its spinner. The covering plate in the exhaust nozzle is grey with the logo of Aviation Museum Society Finland.

Photo by Ismo Matinlauri. Work has been started also at the future Caravelle site at Turku airport. The three hollow-core slabs, donated to the project, have been dug into the ground under the landing gear positions. The second driveway has been built and the sheathing for the power cable has been installed into its trench. However, the power supply won’t be available when the assembly work will be started on the site.

Photos by Ossi Harjula Next week the Caravelle work is picking up speed when the Pansio team is busy with the final painting work and the Vantaa team begins the assembly work at the airport. The work can be followed in these blogs, there will be several updates in the coming weeks. Photos by Jouko Tarponen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Caravelle is getting its appearanceTiistai 9.5.2023 - Erja Reinikainen Today the teams in Pansio and in Vantaa were working on the most significant elements of Caravelle’s outward appearance, which define its identity and its Finnish look.

In Pansio Caravelle’s former registration SE-DAF was covered when the lower side of the wing was painted with primer. It will be replaced with the Bluebird’s registration OH-LEA. Furthermore, the blue cross of the Finnish flag was painted on the horizontal stabilizer and rudder. The painting team was worrying about how to get the cross level and straight as there is a gap between the stabilizer and the rudder. It looks great! It was almost like a topping-out ceremony, although the stabilizer is still on the floor and “the flag was not hoisted”.

In Vantaa a team of volunteers worked on the stencil stickers which will be used when painting the registration, airline name and logos on the aircraft’s fuselage. The stencils came from the print pre-cut but intact, and the volunteers picked out the letters and logos which will be painted – that is to say: made holes to the areas which will be painted. When this had been done, an adhesive foil was placed on the stickers to hold the letters in shape when the stickers are fastened on the aircraft. The stickers used as stencils will be placed carefully on the fuselage according to the paint-scheme. The texts, logos and registration will be painted with a roller, following the holes in the stencils. When the paint has dried, the stencils will be removed.

Photo by Erja Reinikainen. Working on the decals proved to require good eyesight and a surgeon’s scalpel. The large Finnair and OH-LEA texts were easy enough to pick out from the sticker, but the more complicated Caravelle and Bluebird texts required more work. Placing the adhesive foil on the sticker sheets was also rather challenging, but a best practice was soon learned, and major wrinkles were avoided. Another work session is needed for picking the dozens of “No step” stencils. Photos by Jouko Tarponen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Hollow-core slabs for Caravelle's display siteTorstai 4.5.2023 - Reino Myllymäki The Caravelle III, which is owned by Aviation Museum Society Finland, will be placed on display at Turku airport. The display site is a fenced area, which now has gravel surface. The aircraft will be displayed with its landing gear down, but a trestle will be placed between its tyres and the ground. The ground plate of the trestle is 300 x 300 mm. An aircraft made of duraluminium is light but with the snow, wind and visitor loads considered, the Caravelle weighs so much that the surface pressure which is created under the ground plate will require some sort of concrete slab under it. After some calculations it was decided that three 1 x 2 m concrete slabs are sufficient. Consolis Parma hollow-core slab factory in Tuusula checked their surplus storage and found three hollow-core slabs, three metres long, and donated them to the Caravelle-project. We appreciate this kind of recycling!

Photo by Jussi Mäkelä. You may wonder whether hollow core slabs could not have been found closer to Turku, where the aircraft is. Yes, they probably would have, but this solution has an extra twist: during the winter Aviation Museum Society acquired a 40-foot sea container from an auction and it has been waiting on the transporting company R. Stenvall’s yard in Tuusula to be moved to Turku. To kill the famous two flies with one blow, Jussi Mäkelä from R. Stenvall fetched the hollow-core slabs and loaded them into the sea container, and the journey to Turku could begin. The cherry on the cake was that Mäkelä borrowed a 1968 Vanaja truck from Raimo Stenvall’s private car museum to fetch the slabs!

The hollow-core slabs were delivered to Turku airport and the sea container was taken to the hall in Pansio, where the Caravelle restoration work is going on. At the end of May the aircraft will be assembled on the three slabs at the airport.

Finavia (the airport operator in Finland) lent a helping hand and unloaded the three hollow-core slabs, each weighing about 1,5 tons, from the sea container with a wheel loader fitted with forks. The slabs were placed on the ground to wait for assembly. The aim is to dig the slabs into the ground so that only the top part is visible. The slabs will be placed under the main landing gear and the nose wheel so that the area can later be surfaced with asphalt. This, however, has proved to be so expensive that a sponsor will be needed. Take part in the Caravelle’s fund-raising campaign! Photos by Janne Salonen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |

Caravelle team on a picnicKeskiviikko 26.4.2023 - Erja Reinikainen In the past weeks the volunteer team in Pansio has been working so efficiently sanding, painting and polishing the Caravelle that it was time to take a breath and spend some free time together. On Tuesday April 25th a group of Pansio volunteers and members from the Caravelle technical team went on a Picnic cruise on Viking Line ferry from Turku to Maarianhamina (on Åland islands) and back. There were 11 participants on the cruise: Elias, Hannu, Ismo, Jari, Kari, Markku, Mikko, Risto H, Risto P, Ykä and Erja.

M/S Viking Glory left Turku in the morning (heading to Stockholm) and in Maarianhamina we changed to M/S Viking Grace (coming from Stockholm) which arrived in Turku in the evening. Unfortunately, the weather was very foggy and there was not much to see of the beautiful archipelago between the mainland and Åland islands, just a glimpse of the Ruissalo area outside Turku in the morning.

On the way to Maarianhamina we had a conference room reserved for us and we spent the morning talking about the Caravelle restoration and assembly work which is ahead. The weeks between the First of May (a spring carnival in Finland) and the Turku Airshow (on June 17th and 18th) will be very busy when the aircraft is being painted, polished, and assembled. Ismo Matinlauri and Markku Ahokoski had made a daily schedule of what is happening in Pansio and at the airport after the first parts of the aircraft are transported there on May 23rd and this was discussed thoroughly with the group. We also looked at the photos which were taken in Arlanda when the aircraft was dismantled for transport. This was very useful when discussing the details of the assembly work.

On the way back to Turku we enjoyed a lunch from the ferry buffet and concentrated on informal conversation. This group will not easily run out of aviation stories! Or fishing, car, travel, and other stories either… Photos via Ismo Matinlauri. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Caravelle polishing work partyMaanantai 24.4.2023 - Reino Myllymäki It was necessary to arrange a work party to get the Caravelle polishing work under way. The work party took place on the weekend April 22nd – 23rd, 2023.

On Saturday the work was started on the leading edge of the horizontal stabilizer and elevators. All the surfaces don’t need polishing because some of them will be painted. The first round of polishing was done using Nushine 9 polishing agent and the second round with Nushine 7.

In some areas on the aluminium surfaces there was still some black dirt left after two rounds of polishing. First we tried to remove it using paint thinner – without results. Finally the solution was the cleaning spray for brakes, with which the black dirt could be removed. After this the surface was polished once more, using Nushine 2 and working with a cloth. The polishing agent contains wax which protects the aluminium surface.

Photo by Reino Myllymäki. On Saturday morning we had a positive problem: there were more volunteers than we had polishing machines. A couple of new machines were bought during the day and in the afternoon more people were able to participate in the actual polishing.

Photo by Reino Myllymäki. Until then part of the volunteers were involved in other tasks: tearing old sheets into polishing rags, painting and repairing a hole in the cabin floor with a piece of plywood. There were probably also other jobs, which the writer doesn’t remember, sorry about that!

A challenging task: the writer trying to decide what to have for lunch. In some mysterious way some of the black dirt on the aluminium surface ended up on the polisher’s face…

Photo by Reino Myllymäki In the afternoon one side of the horizontal stabilizer had been polished and it should have been turned around for more polishing, so the work party moved to the inner flaps. One of the flaps was completed on the upper surface and the other one was otherwise ready on Saturday, but the Nushine 2 was missing. The polishing of the other flap was finished on Sunday.

Photo by Reino Myllymäki. Polishing was done also on top of the Caravelle’s fuselage because there is a narrow, polished surface on the dorsal fin. The fin polisher was secured on the crane hook by his harness.

On Saturday the polishing of the lower part of the Caravelle’s fuselage was started. This turned out to be very heavy work because the polishing machine must be supported upwards and pressed on the surface which is being polished.

Photo by Janne Salonen. On Sunday the polishing work on the lower fuselage was continued.

On Sunday the polishing of the wings was also started, concentrating mainly on the wing fences.

Photo by Janne Salonen. On Saturday there were 15 volunteers at work, on Sunday 11. The total amount of working hours during the weekend was 150. If you feel badly about not participating, don’t worry! There will be another work party on the first weekend in May (May 6th – 7th).

Photos by Jouko Tarponen. Above there are some pictures which were taken on Monday, after the work party. The results look good, and you can look at your reflection on the aluminium surface! The Caravelle restoration work continues in the Pansio port hall until the end of May, when the aircraft parts and the assembly and restoration work move to Turku airport. Photos by Ismo Matinlauri unless mentioned otherwise. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

The Caravelle restoration works before EasterLauantai 15.4.2023 - Erja Reinikainen In the weeks before Easter the Caravelle restoration team in Pansio has been busy doing the remaining sanding work on the wing and vertical stabilizer. The lower part of the fuselage has not been sanded yet because the fuselage is now resting on low trestles, and it is impossible to work under the fuselage. The technical team decided that the fuselage will not be lifted higher at this point, mainly to save time. The parts of the fuselage sides, which will remain visible, can be quite well sanded in this existing position.

Polishing work has been practised on the engine air intake rings. Polishing the leading edge of the wings and flaps is also under way. In polishing it is easy to see that the quality of work does not get better by increasing the amount of polishing agent, quite the contrary. Polishing of the fuselage will be started in the riveted areas of the tail. Polishing a jet airliner requires time and effort, so more volunteers are needed. A polishing work party is organized on the weekend April 22nd-23rd, 2023. You can participate on either day - or both. No special skills are needed. More information and registration on the Aviation Museum Society Finland website.

The painting work has progressed to a point where several small aluminium parts have been painted. Some painted fairings and panels have already been assembled around the engine nacelles and in the wing roots. So far we have been painting with rollers and brushes in the semi-heated rooms of the hall. When the weather gets warmer, we will be able to paint also in the large unheated hall. Major painting work will not be started before the stored boats are moved out from the rear section of the hall. This will take place in the beginning of May.

In the cabin clearing and cleaning has been continued, and the functioning of the doors has been tested. The aft stairway was repaired some weeks ago and it operates on its own hydraulics when some changes were made in the system. The original operating mechanism of the front door has been damaged and probably can’t be repaired. Alternative solutions for operating the front door have been investigated.

Photo by Ismo Matinlauri. During the decades the Caravelle’s windows have cracked and become opaque. The technical team has been trying to find a feasible way to repair or to renew them. Repairing them proved to be burdensome and time-consuming, and having new windows made for the whole cabin is expensive. So the decision was that now there is nothing to be done about the windows. Their renewal can naturally be considered in the future.

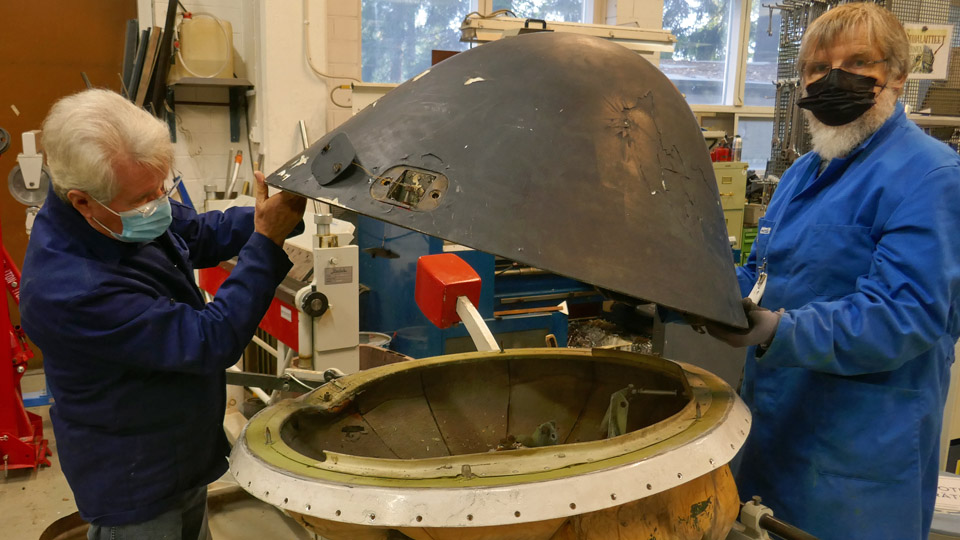

The Caravelle’s radome and the nose bulkhead behind it have been repaired by Aviation Museum Society Finland’s Tuesday Club. The work is ready, and the parts have been brought to Pansio to wait for assembly. The search of Caravelle’s missing flight instruments and radio panels has been going on in Finland and abroad. The inquiry online brought some results, but a lot is still missing. All instruments which have been received have been installed into place. Aviation Museum Society’s chairman Janne Salonen has been visiting colleagues in Sweden over Easter, and we hope he will be able to bring some new supplies to the instrument panel. The previous inquiry brought, however, a donation of several flight instruments, which we can’t use on the Caravelle but which can maybe be traded when acquiring the right kind of instruments. Minor details but important elements in the appearance of the aircraft are the registration, airline name and country colours which are painted on its surface. These are among the last tasks during the finalizing phase, but the technical team has already been evaluating the alternatives how to make them. When the aircraft is brought to Turku airport, its rudder and elevators will have to be locked into place so that they are not moved by the wind. How to accomplish this detail has also been investigated during the winter. The technical team is already planning how to move the aircraft parts to the display site at the airport, how to lift the parts into place and eventually assemble them there. Before the aircraft is brought there, concrete slabs will have to be dug into the ground under its landing gear. The details of the transportation and lifting procedures will have to be carefully planned so that everything goes smoothly and without problems. The display site is right on the edge of the airport area, which brings an extra challenge for traffic arrangements and cranes, among other things. There will be more blogs about this phase later. Photos by Jouko Tarponen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Caravelle salvage crew, part 1Sunnuntai 9.4.2023 - Erja Reinikainen Several blogs have been written about the Caravelle III aircraft which is under restoration in Pansio, about its history and the progressing of the work. Without enthusiastic volunteers there wouldn’t be any activity, so it is time to talk about the people behind this project. This blog introduces an overview of the tasks which are needed before the aircraft is ready for display. I hope to continue with some personal interviews in the following blogs.

Photo by Reino Myllymäki In the early phases of the project Janne Salonen, the chairman of Aviation Museum Society Finland had a key role. He has good connections to Jan Forsgren, who is a member in the voluntary organisation Arlanda Aviation Museum’s Friends (Arlanda Flygsamlingars Vänner). In spring 2020 Jan informed Janne that the owners of the Arlanda Aviation Museum, the representatives of Swedish National Maritime and Transport Museums, had decided to give up the Caravelle. The first assessments on bringing the aircraft to Finland were carried out by the board of Aviation Museum Society Finland. Also the official decision on launching this project was made by the board.

Photo by Raímo Korpi The seven members of the board have supported and promoted the Caravelle project all along, without reserve. The project outlines and the major acquisition decisions have been made by the board. The rental agreement of the Pansio port hall and the final display site at Turku airport have been negotiated by the chairman and the board. Also the details including major costs, such as the transportation of the aircraft parts, have been negotiated and approved by the board. Finding funding for the project has been a long and challenging effort. Funding and sponsoring arrangements are negotiated by the chairman and board members.

Photo by Raímo Korpi Aviation Museum Society’s board member Reino Myllymäki is responsible for the public relations of the project. He is assisted by two or three bloggers and by Jouko Tarponen, who is responsible for photographing the project’s progress in Pansio. All blogs and Caravelle news in the society’s Feeniks magazine are published also in English and this task is taken care of by two volunteers.

Photo by Raímo Korpi The members of Aviation Museum Society Finland were informed about the Caravelle project at an early stage. In the beginning of year 2021 the search for the technical team members was launched. During the spring the former Finnair mechanics Markku Ahokoski, Martti Saarinen and Kari Nyman answered the challenge. During the winter 2021-22 they led the discussion and assessment on how the aircraft could be disassembled and transported to Finland. This team has now been working in the project for a couple of years.

Photo by Reino Myllymäki The disassembling (and re-assembling) of a passenger jet airliner means that a huge number of details need to be planned. The technical team has faced the task undaunted by the scale of the job. The task has included decisions on the main issues (how to disassemble the fuselage off the wing?), practical solutions (how to lift and turn the aircraft using the bridge cranes in the hall?), taking care of the small odds and ends (how to keep track of the origin of all screws and bolts which have been unfastened?), not to mention all kinds of issues which we ordinary non-technical people are not even aware of. These tasks have required good professional skills and the ability to foresee problems, and furthermore, also cool-headed decision making when something needs to be done which hasn’t been done before.

Photo by Ismo Matinlauri In the spring 2022 Ismo Matinlauri joined the technical team. His work has included recruiting the team of volunteers in Turku as well as coordinating the restoration work. Ismo has also managed all kinds of fixing and acquisition tasks. For Ismo the Caravelle project is almost a full-time job when the Turku team works in the hall three days a week and the remaining two days are spent running errands and acquiring material.

Photo by Ismo Matinlauri During the project several people, many of them former technical staff from Finnair, have participated in solving technical problems and dismantling or restoration work. A group of enthusiastic volunteers without aircraft work experience has also joined the project, wanting to have a part in making aviation history. In summer 2022 there were about twenty volunteers from Aviation Museum Society Finland (and one or two volunteers from Sweden) disassembling the aircraft in Arlanda. This group is invited to join the Caravelle polishing session which will be arranged in Pansio this spring.

Photo by Jouko Tarponen A team of about ten Turku area volunteers have been restoring the aircraft during the winter, working on three days a week. I take my hat off to these volunteers, they have been cleaning and sanding Caravelle’s surfaces for several months now! The sanding work is finally approaching the end and there is polishing and painting ahead.

Photo by Lassi Karivalo In addition to Pansio, Caravelle restoration work is ongoing also in Vantaa, where two or three people have been preparing for sheet-metal work and repairing parts which have been brought from Pansio. The Tuesday Club of Aviation Museum Society has also participated in the project by repairing e.g. the damaged Caravelle’s radome and nose bulkhead.

Photo by Jouko Tarponen Based on the estimations presented in this blog, it can be estimated that about 40 people have participated so far in the Caravelle project, some of them joining the team of volunteers for a single effort (such as the disassembling), others working on the project almost daily. Warm thanks to you all! Without volunteers this project would never have been possible. Hopefully in the following blogs we can read why they joined the team. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu, Bluebird |

Bolts and screwsMaanantai 3.4.2023 - Erja Reinikainen In Arlanda the main parts of the Caravelle were disassembled so that the fuselage, wings and stabilizers could be placed on special trailers before transporting them to Finland. The engine nacelles were also dismantled along with a number of smaller parts and equipment, such as the wing root fairings, inner flaps and equipment from the landing gear wells. This means that thousands of screws, bolts, nuts and rivets were unfastened in Arlanda, and they need to be put back into place when the aircraft is reassembled in Turku in early June. This blog tells about a small but an important part of the Caravelle’s restoration project: about the different kinds of fastening accessories. Kari Nyman from the Caravelle technical team has been interviewed for this blog. An additional challenge to the jigsaw puzzle of the fastening accessories is caused by the Caravelle’s special feature: the screws and bolts for the aircraft’s structural parts have metric dimensions, but the majority of them are a special design from the Sud Aviation aircraft factory which don’t follow the standard types and sizes. This can be seen in the aircraft’s technical specifications, which have dozens of pages defining the different “210.-series” fastening accessories. Here the 210. refers to the type of the aircraft. France has been a strong supporter of the metric system and the competition in developing a passenger jet airliner has played a significant part in these choices. The various system equipment in the Caravelle were mainly produced in the United States or Great Britain, so their fastening parts are naturally based on the standards of their country of origin, and having in this case usually US or imperial sizes, i.e. inch based sizes. For example, the hydraulic system pipes, flexible tubes and fittings are based on the American AN standard. This means for the disassembling and reassembling work that the fasteners which may look similar may have metric or imperial dimensions and the tools to be used have to be chosen accordingly.

Photo by Reino Myllymäki The disassembling work in Arlanda went surprisingly smoothly. The parts which had to be disassembled could be unfastened without major difficulties or damages. However, some screws had to be drilled out and there was more work needed especially on the underside of the fuselage. There the screws have corroded and rusted more than in average. The most difficult fasteners had to be treated with rust removing chemical and eventually all necessary joints could be opened.

Photo by Reino Myllymäki In Arlanda all disassembled fastening accessories were collected into separate plastic bags, based on their origin. Each bag was marked clearly with the information where this batch of screws was from, for example: rudder lifting point cover screws, LH wing innermost leading edge section, horizontal stabilizer, etc.

Photo by Erja Reinikainen In Pansio we have a small ultrasonic cleaner where all disassembled fastening accessories will be cleaned. Originally, we aimed to put into the cleaner only a bagful of items at a time, separated as they had been packed in Arlanda. This would have been an ideal procedure to keep track of the origin of each batch of accessories. However, the ultrasonic cleaner proved to be so slow that for time saving reasons several bags of fasteners had to be put into the cleaner’s basket at the same time. This leads to the need to sort these “mixed batches” after cleaning. The “mixed batch” screws, for example, have been sorted by their length for future use. Larger labelled batches of accessories can be cleaned one or two bags at a time and in these cases their origin is known. If the origin is known, after cleaning the accessories are put into new plastic bags which are marked with the location, for example: nose bulkhead screws, LH engine nacelle fairings and supports, LH wing upper side panel, etc.

When the Caravelle is eventually re-assembled, there will be new and old fastening accessories in use. The aircraft will never fly again, so it will be possible to build some details in a different way than it has been. All joints and seams which will be visible, are fastened using original screws or screws resembling the original ones, if possible. In the locations which won’t remain visible, and which possibly will never be opened again, pop rivets will be used to speed up the re-assembly. There are some fairings, visible ones, which have originally been riveted and now they have been fastened with pop rivets, and the appearance is quite like the original one.

Photo by Jouko Tarponen One of the most difficult details in re-assembling the aircraft will be getting the panel under the wing joint back into its place. There the original screws have been mainly drilled out, the original flange nuts have been damaged and the panel metal has corroded. Will the new and old fasteners look different on the re-assembled Caravelle? The aircraft will hardly be examined so close up that the difference could be seen. The new screws have a yellowish corrosion protection and the old ones are oxidized and darker, so both are different from their surrounding surface. The ultrasonic cleaner doesn’t remove rust or oxidized surface. This means that in painted areas the screw heads will have to be sanded before painting so that the paint sticks on them in the same way as on the surrounding aluminium surface. We managed mainly to drill out the tricky screws quite nicely, but in the vertical and horizontal stabilizer the drilled holes will have to be repaired during the re-assembly. Cup washers will be placed in the drilled holes to cover the damaged hole edges. Aircraft fasteners can’t be bought in an ordinary hardware store, nor in a car accessories store. Usually the countersunk screws on aircraft have a different countersunk angle than the ones used in cars. US standard inch-based screws are still available in the same dimensions as the originals and they can be found on the US market. However, the special Sud Aviation’s own screws are difficult to be replaced with new ones resembling the original. For example, the panel covering the main wing joint is a part of the fuselage bulkhead, and it has been fastened using metric French screws with a countersunk angle of 120 degrees. This is different from all other countersunk screws on the aircraft and similar new screws can’t be found. Ronema Oy has provided valuable help in aquiring inch-dimensioned fasteners. They represent the American company Aircraft Spruce, which imports spare parts and pilot accessories. Through them we have ordered screws from the US. Naturally one had to ask if such special screws are very expensive when they are imported for the Caravelle. Mainly they are not, we talk about 10-30 (euro) cents per screws. So with a hundred euros you already get quite a lot. The Caravelle technical team has also investigated whether it would be possible to have the metric special screws specially made for the purpose. Yes, it would be possible but we haven’t got the cost information yet. Re-assembling the Caravelle will be a challenging jigsaw puzzle, but the fastener team is prepared, and they will do their best to foresee all coming details of the hectic assembly week in June. Photos by Ismo Matinlauri expect if otherwise separately mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu |

Caravelle III OH-LEA "Sinilintu" ("Bluebird")Keskiviikko 29.3.2023 - Erja Reinikainen Suomeksi The Caravelle III, which was brought from Arlanda to Finland by Aviation Museum Society Finland, served in the SAS fleet with registration SE-DAF and name Sven Viking. In Pansio the aircraft is being restored to Finnair colours as its first Caravelle OH-LEA, Sinilintu (Bluebird). This blog tells about the long and colourful history of this aircraft.

Photo by Finnish Aviation Museum photo archive / Ilmailu magazine In 1958 the Finnish airline Aero Oy (later Finnair) ordered three Caravelle IA passenger jets from the French Sud Aviation aircraft factory. The Finnish airline was one of the forerunners of air travel and was the fourth airline to order the new passenger jet type, after Air France, SAS and the Brazilian Varig.

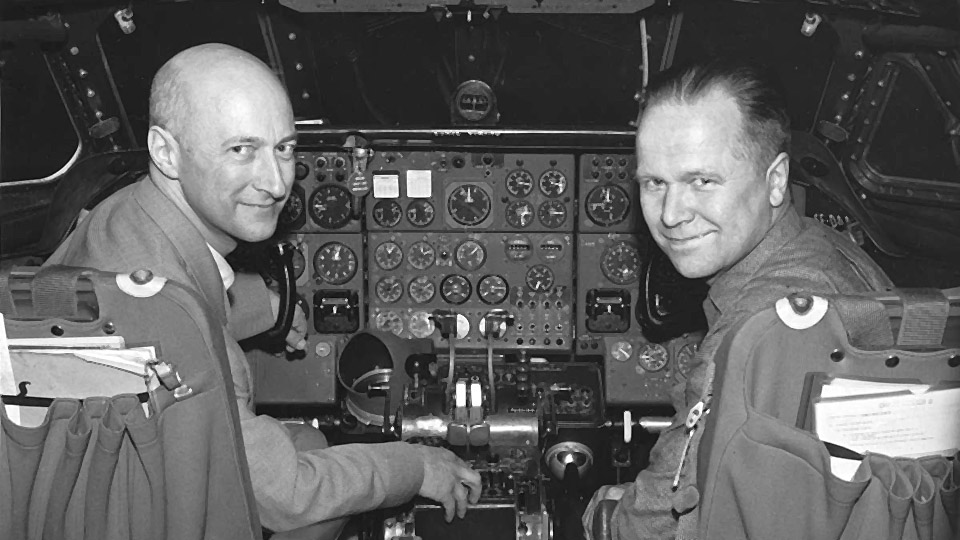

Photo by Finnish Aviation Museum photo archive / Börje Hielm. The first jet aircraft in Finnish civil aviation was Sud Aviation Caravelle IA, which got the registration OH-LEA and was named Sinilintu (Bluebird). It was handed over in Toulouse on February 21st, 1960, and it arrived in Finland on February 22nd, 1960. The aircraft was flown to Finland by Olli Puhakka, who was a former fighter pilot and Knight of the Mannerheim Cross. The co-pilot on the flight was Olavi Siirilä, also a former war pilot. Among the guests of honor on the flight were minister of transport Arvo Korsimo, Aero Oy’s managing director Leonard Grandell, chief editor of the Helsingin Sanomat newspaper Yrjö Niiniluoto and maritime counsellor Antti Wihuri.

Photo by Finnish Aviation Museum photo archive / Börje Hielm. During the spring 1960 the Bluebird was followed by Sinisiipi (Bluewing, OH-LEB) and Sininuoli (Blue Arrow, OH-LEC). These three aircraft were later modified to type Caravelle III. The fourth aircraft was already a Caravelle III when it was purchased in 1962. It was named Sinipiika (Blue Maid, OH-LED).

Photo by Finnish Aviation Museum photo archive / Ilmailu magazine

Photo by Finnish Aviation Museum photo archive / Ilmailu magazine During its service in the Aero fleet the Bluebird appeared in three different paint schemes. It was delivered in its first appearance, where the rudder was blue, and the name Aero was written in large on the upper part of the vertical stabilizer. In the second paint scheme the rudder was blue and a blue cross on the vertical stabilizer replaced the text. Otherwise the paint scheme was identical to the first one. The third painting was done when the aircraft was updated to type Caravelle III. This is the appearance into which the former SAS SE-DAF will now be restored. The paint scheme can be seen in the visualization image on the front page of the Caravelle-project. When Finnair celebrated its 40th anniversary, a special anniversary logo and text were added on the aircraft.

OH-LEB. Photo by Finnish Aviation Museum photo archive / Finnair Oyj In the Finnair fleet the Caravelle had 16 seats in the first class and 75 in the tourist class. Starting from April 1960, the Caravelles operated on routes to European cities. In the beginning the destinations were Stockholm, Copenhagen and Frankfurt, followed by several other cities during the coming years. The Caravelles replaced the Convair 440 Metropolitan piston engine aircraft in Europe, and they were transferred to domestic routes. In late 1961 Oulu was the first domestic route operated with passenger jets.

Olli Puhakka and Olavi Siirilä in the cockpit of Eskil Viking (SAS). Photo by Finnish Aviation Museum photo archive / Ilmailu magazine A Finnish speciality was flying the Caravelles with only two pilots, when other airlines had two pilots and a mechanic in the cockpit. Another remarkable difference was the surrounding and existing environment, which was why the Aero Caravelles had a brake parachute installed. The Caravelle III had Rolls Royce Avon engines and there was no reverse thrust in them to assist in the braking. The brake parachutes were only used when the friction conditions on the runway were really poor. The pilot opened the brake parachute by pulling a handle during the landing run. When the aircraft left the runway, the parachute was released by pulling the same handle. The technical ground crew then collected the parachute for reassembly.

OH-LEB “Sinisiipi” (“Bluewing”) uses drag chute. Photo by Finnish Aviation Museum photo archive / Ilmailu magazine. The OH-LEA Bluebird flew its first flight on February 11th, 1960. It belonged to the Finnair fleet in 1960–61 and logged 9091 hours. The aircraft was sold back to Sud Aviation on December 4th, 1962, and it was flown to France on September 20th, 1964. The following user of the Caravelle was the German LTU, which got the aircraft on February 12th, 1965. It was registered as D-ABAF and named Nordrhein-Westfalen. The next user was Transavia Holland. It rented the aircraft between January 30th, 1969, and April 16th, 1970, as PH-TRM.

F-BSSR in August 1978. Photo by Michel Gilliand via Wikimedia Commons. From the Netherlands the aircraft returned to France, where it was registered as F-BSRR in Air Inter’s fleet where it flew from March 19th, 1971, until December 1980. During this time the Caravelle was rented to Royal Air Maroc and SNIAS, among others, having different registrations. Air Inter sold the aircraft to Altair in Italy, where it was registered I-GISA. It was removed from service in September 1983 with 37 532 hours on its log. But the story doesn’t end here. From Italy the aircraft was bought to Congo by IAC Airlines. In Congo it was registered 9Q-CPS and it was named Santeny. The last airline to use the Caravelle was Air Transport Service, which flew it until 1994. The Caravelle was scrapped in 1996 at the N’djili international airport in Kinshasa, Congo. As we can see, OH-LEA was an individual with a long history. It served for 36 years, and it had more user airlines and operators than any other first generation Caravelle. Following sources have been used for this blog:

|

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking, OH-LEA, Sinilintu, Bluebird |

Caravelle Sanding Closing to the EndMaanantai 27.3.2023 - Ismo Matinlauri During the past week we have been climbing on the top of the fuselage in Pansio. The aim is to sand the last area on top of the fuselage which we have not been able to reach from the ladders. We also cleaned the bolt and rivet holes in the stabilizer.

We rented industrial ladders which allow us to step easily on the fuselage. However, working safety issues required some thinking. How could we step on the fuselage and safely sand and do other repairs as needed? The issue was solved by using the overhead crane’s hook as a fixing point for the personal safety harness. The harness would safely prevent the possible falling.

The vertical stabilizer’s leading edge will be polished and in the autumn we installed protective tape on it for the future painting work. However, the painting wasn’t done due to the cold weather. The tape was left on the stabilizer to wait better times but now it had to be removed due to the changes in the work process. This turned out to be a burdensome job. In addition to hard work it required both mechanical scraping and use of chemical solvents to be removed.

Many thanks to Martti Peräaho, who did the main part of the climbing and grinding work on top of the fuselage while others helped on the ladders as needed.

This week we also started polishing smaller parts. When the weather warms up, hopefully after Easter, we can focus on polishing work. We also intend to organise a polishing workshop on a couple of days where volunteers from outside the Turku area can join us in the polishing work. At the same time they can get acquainted with the project and contribute in realizing the project. Photos by Jouko Tarponen. Translation by Ismo Matinlauri and Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |

Caravelle's inside worksMaanantai 20.3.2023 - Erja Reinikainen Last week the Caravelle’s sanding work progressed in Pansio, but also new work areas were started. The preliminary preparations inside the aircraft were started and the first experiments in painting are also under way.

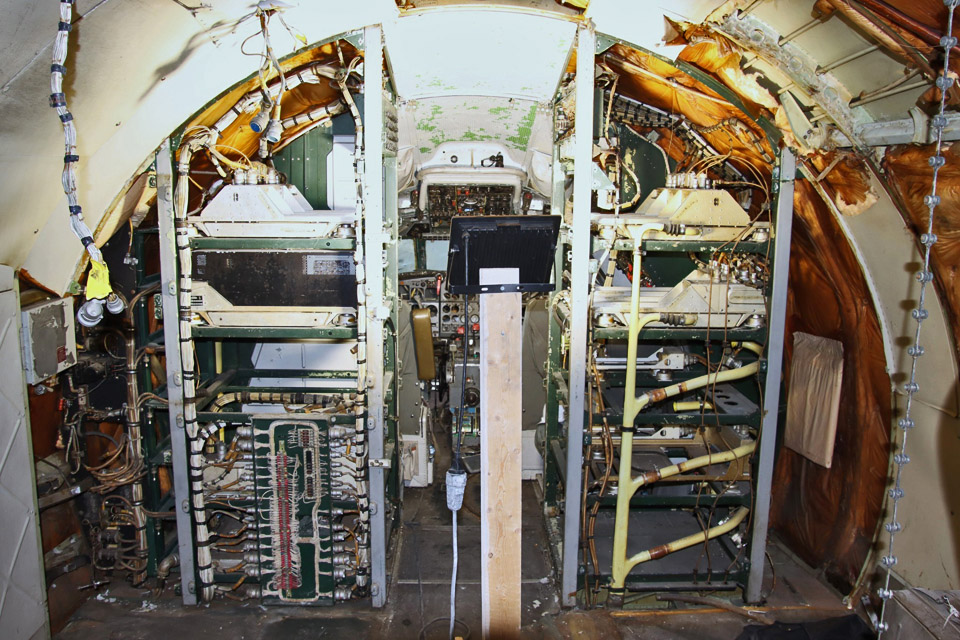

Panels were dismantled from the wall between the cabin and cockpit. They were taken to the Tuesday Club in Vantaa to be cleaned and restored. In the cockpit the shading cover above the instrument panel proved very difficult to unfasten. A small part, but very tightly fastened.

The torn insulation material and its plastic covers hanging from the cabin ceiling were removed together with some tubes and wires hanging above the aisle. Some old and dry tape lines were removed from the cabin floor. A couple of kilos of small bolts, nuts and washers were vacuumed from the cabin floor. They have probably been used for fastening either the passenger seats or the cabin panels on the walls and ceiling.

Photo by Erja Reinikainen. Two maintenance panels in the cabin floor were opened to allow future work on the aircraft’s doors. Photos by Jouko Tarponen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |

Caravelle SE-DAFSunnuntai 19.3.2023 - Jan Forsgren These blogs talk about the Sud Aviation Caravellle III SE-DAF. We think it is appropriate to tell something about what has happened to the SE-DAF before it arrived in Pansio to be restored. The original article “SE-DAF to Finland” about SE-DAF was written in English by Jan Forsgren / Arlanda Flygsamlingars Vänner, the summary has been edited by Erja Reinikainen. The whole article was published in Aviation Museum Society Finland’s aviation history magazine Feeniks, 3/2022. One of the first operators, and, in fact, the first airline to use the Caravelle in regular service was Scandinavian Airlines Systems (SAS). In SAS service, the Caravelle proved to be extremely popular among crews and passengers alike. Between 1959 and 1974, SAS operated on the European and Near East routes a total of 21 Caravelle I, IA and III variants. The Caravelle I and IAs were later modified to Caravelle III standard. The fifteenth Caravelle III SAS purchased has the serial number c/n 112. After roll-out from the Sud Est factory at Toulouse, Caravelle III c/n 112 was temporarily registered as F-WJAO prior to the first flight on February 8th, 1962. On February 17th, 1962 the Caravelle was flown to Arlanda airport just north of Stockholm. On March 5th, 1962, it was registered as SE-DAF for AB Aerotransport (ie the Swedish part of SAS). Later the same month, the aircraft was named Sven Viking. Most of the SAS Viking names used were of historical individuals from the Viking era. Sven was Sven Haraldsson, better known as Sven Tveskägg (in English; Sweyn Forkbeard). He ruled Denmark, southern Norway and England around year 1000 AD.

Photo by Wikimedia Commons.

Photo by Wikimedia Commons. Taken in December 1964.

Photo by Lars Söderström via Wikimedia Commons. Taken in 1966. When Flygvapnet (the Swedish Air Force) bought two Caravelles from SAS in 1971, it had originally been planned to buy a third aircraft as well for use in the personnel transport, and as (later on) a source for spares. As it was only possible to take Swedish-registered Caravelles into consideration, this third Flygvapnet Caravelle was to have been SE-DAF. However, for various reasons, SE-DAF remained with SAS.

Photos via Wikimedia Commons. Taken in 1971 on Oslo Fornebu Airport. The 1973 oil crisis saw a rapid increase in fuel prices. With the Avon engines being very ’thirsty’, the SAS Caravelle fleet was withdrawn from use earlier than originally planned. The last flight of SE-DAF, between Copenhagen and Arlanda, took place on September 23rd, 1974, with the registration SE-DAF being cancelled on December 3rd, 1974. A total of 27 321 hours were logged.

Photo by Peter Bakema via Wkimedia Commons. Taken in 2004. After being withdrawn from use, SE-DAF was donated to Luftfartsverkets historiska samlingar (The Swedish CAA Historical Collection). The engines were removed, with the cabin seats and interior also being largely removed. Some of the cockpit instruments were also removed. A preservative coat of Tectyl was then applied to the fuselage to prevent corrosion. Originally parked at Ramp Kalle, the Caravelle was later towed to Ramp Ivar, which was located outside the security area. It is believed that the damage to the right wingtip was sustained when towed to Ramp Ivar. Members of AFV took care of filling air in the tires every sixth month, as well as moving about 30 cabin seat frames (mainly from Caravelle 10B1R SE-DEC) into the cabin. However, a multitude of other projects, as well as a constant lack of resources, meant that no proper work in restoring the Caravelle to her former glory could be accomplished.

Photo by Juha Klemettinen. Taken in 2011. Due to Ramp Ivar being located near a taxi runway, literally thousands of airline passengers could see the Caravelle. Due to the rather worn and tatty SAS colour scheme, SAS paid for over-painting this in white. SE-DAF appeared briefly in the 2013 movie Monica Z, about the singer Monica Zetterlund. In the movie, SAS colours were applied digitally to SE-DAF during postproduction, but not painted on the actual aircraft. Shortly afterwards, the aircraft was towed back to Ramp Kalle. It was to remain there for the next eight years.

Photo by Ulf Nyström. Taken in 2020. After SMTM took ownership of Arlanda Flygsamlingar in January 2018, Le Caravelle Club, following negotiations, received permission in late 2019 to remove certain parts of the interior from SE-DAF, including some of the overhead luggage shelves, and the galley in order to restore SE-DAI back to SAS colours. In the spring of 2020, the owners of Arlanda Flygsamlingar, Statens Maritima och Transporthistoriska Museer (National Maritime and Transport Historical Museums, SMTM), decided to dispose of the Caravelle due to lack of resources, and the onslaught of the Corona Pandemic. To scrap the aircraft would have cost SEK 200,000. It was obvious that an alternative solution had to be sought. A volunteer member of Arlanda Flygsamlingars Vänner (Friends of Arlanda Flygsamlingar, AFV), Jan Forsgren, contacted Janne Salonen, tentatively asking if IMY would be interested in acquiring the Caravelle. Janne Salonen responded quickly to Jan Forsgren’s e-mail, saying that IMY were indeed interested in obtaining the Caravelle for preservation in Finland. And the rest is history. Blog was shortened by Erje Reinikainen from Jane Forsgren's article. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |

About Caravelle's sandingMaanantai 6.3.2023 - Erja Reinikainen Caravelle’s sanding work is progressing well in the port hall in Pansio. During the autumn season work methods were developed and now the best practices are producing results. The first phase in cleaning the Caravelle’s surfaces was to remove the black tar streaks and blotches left by rainwater and air pollutants during the decades when the aircraft stood outside at Arlanda airport. After some experimenting it was noticed that persistent scratching was the best work method. Different chemicals for removing graffiti and even oven cleaner foam were tested, but the results were not mentionable. Angle grinders have been used in the sanding work, starting with coarse sanding discs, and progressing to finer ones. Sanding discs P240 grit have been used for removing old paint. The surfaces which will be painted are left to this sanded coarseness, which is sufficient for the new paint to cover the surface well. The surfaces which will be polished have been sanded first using discs with P500 grit and then with P1000 grit.

The most burdensome areas for sanding have been the round head riveted painted areas on the rear fuselage and flaps. There the first grinding phase has been to use a steel-wire brush before moving to sanding discs.

The sanding work was started on the left side of the fuselage and on the lower side of the right side. After the transportation from Sweden, for some time the fuselage was resting tilted 45 degrees to the left, and this made it possible to restore the bottom on the right side and sand the left side at the top of the fuselage. The fuselage was lifted upright in the beginning of November. Before the Christmas break the 18 cm wide white strip of SAS-paint scheme white paint under the windows was sanded away on the left side, below the window line. It has been agreed that the aircraft will be painted to the 1960s Finnair paint scheme used on the Caravelle OH-LEA. There the lower side of the fuselage is polished up to the window level and the top part of the fuselage and the vertical stabilizer are painted white. The window area is painted blue with a narrow white line below. On the other side of the fuselage the paint-removing work was finished in the beginning of February. Also the sanding of the horizontal stabilizer, vertical stabilizer and engine nacelles was finished in early February.

Now also on the upper sides of the wings the middle sections have been sanded. The wings’ middle sections will be painted, and the leading edges and flaps will be polished. There the sanding work is under way. The lower sides of the wings were cleaned with dry-ice blasting, and they are ready for painting.

Before polishing, the finer grit discs (P3000 or P4000) are used at the final phases of sanding, when necessary, to remove the scratches caused by sanding. On a surface which is in poor condition, or which hasn’t been polished before, there are microscopic “hills” and “valleys” and these differences on the surface are smoothed out by moving material from the high points to the low ones (this is called compounding). This surface processing requires a lot of polishing power and therefore a rotary polisher and a wool disc are used. After using a rotary polisher the surface has a bright finish, but the wool disc has left thin spiralling scratches on it. To remove these the final polishing must be done using a double-disc random orbital polisher, “cyclo”. As you can see, there is a lot of polishing ahead before all Caravelle’s surfaces are shining bright. The use of polishing abrasives requires a temperature of +5…+10°C, so polishing work in Pansio will have to wait for spring weather. Translation with help of Martti Saarinen. Photos by Jouko Tarponen |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking |