Work on the nosewheel and wing filletsKeskiviikko 31.5.2023 - Erja Reinikainen On Wednesday, May 31st, the Caravelle assembly team worked at Turku airport in windy weather, concentrating on smaller and less impressive, but nevertheless important details.

Photos by Erja Reinikainen The assembly of the wing to fuselage fillets was continued. In the wing root there are several fillets, of different shapes and sizes, fastened with rivets and screws. The assembly team spent all day fitting these fillets into place, on top of the wing and below it. Fasteners, which had been drilled out in Arlanda had to be removed, holes were opened, and countersunk edges drilled. New fasteners were installed, screws with cup washers and pop rivets. Probably hundreds of pop rivets were used during the day. Unfortunately the bottleneck in the assembly work was that there was only one battery-driven pop rivet gun in use.

Photo by Erja Reinikainen The nose landing gear has been retracted since Arlanda as the fuselage has been on supporters on the floor. Now an external hydraulic pump was connected to the actuating cylinder of the nose landing gear and using the emergency manual unlock mechanism the landing gear was extended. The nose was lifted a little with the jacks under the front fuselage and now the aircraft looks as if it is positioned on the nose wheels, although its weight is still on the jacks. In the future a support will be made for the nose landing gear to take the weight off the wheels.

Photo by Erja Reinikainen During the day scaffolding was built around the tail for the assembly of the stabilizers. On Thursday, June 1st, the horizontal and vertical stabilizers will be transported from Pansio to the airport. The aim is to lift the horizontal stabilizer from the trailer on the Caravelle’s tail. It remains to be seen whether this is possible or not if the wind is as strong as it was today.

Photos by Jouko Tarponen While the riveting of the wing fillets was going on at the airport, the Pansio hall was cleared. The hall contract ends on June 1st and all the parts, tools and accessories which are still there will be brought to the airport in a sea container. In the coming weeks the Pansio team will go on with the remaining painting and polishing work at the airport. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird |

The fuselage is installed on the wingTiistai 30.5.2023 - Erja Reinikainen The Caravelle’s fuselage was transported from Pansio to Turku airport during the night, May 29th-30th. The load on the trailer was so tall that the Ahola truck had to do quite a detour to get to the airport. On Tuesday morning the Caravelle trailer was waiting for the assembly team to arrive.

Photos by Jouko Tarponen

Photo by Janne Salonen In the morning there was a mobile crane with two hooks and a “hiab” loader crane, on which the free-turning cable pulley system was fastened. This made it possible to lift the fuselage and to turn it around all its axes. First the fuselage was lifted from the trailer and supported by the cranes. The assembly team placed groups of three jacks on plywood boards under the fuselage, one group in front and another in the rear. Then the fuselage was lowered slowly into its position on the wing.

Photos by Erja Reinikainen The fuselage was carefully manoeuvred downwards, inch by inch, guiding it to meet the assembly points on the wing and the front and rear edges of the wing joint. The final inches required accuracy from the crane operators when the fuselage had to be turned towards the road or towards the forest, the nose or the tail had to be lowered or the whole fuselage rolled slightly. Fortunately there were calm professionals on the crane controls as well as in the assembly team and eventually the fuselage settled into place. This phase took about one hour.

Photos by Erja Reinikainen Getting the bolts connecting the wing and the fuselage into place took more time. The fuselage was still supported by the crane slings when the position of the fuselage was manoeuvred so that the bolts could be fastened. The first fasteners were easy to get into place but the attachment bolts in the fuselage keel tunnel area and especially the front lower fittings were the most difficult to install. To get the bolts into place the position of the aircraft was inched by using the tripod jacks, changing the position of the wings, and trying to get weight into the tail. A couple of times all members of the assembly team climbed into the tail section as weight load. By lunchtime all bolts had been installed.

Photos by Erja Reinikainen In the afternoon a large tripod jack was brought under the tail to support it, assembly work in the keel tunnel was continued, and the assembly of the wing leading edges and the wing to fuselage fillets was started. During the disassembly in Arlanda the leading edge, flaps and wing root fillets of the left-hand wing had been removed – and now they will be installed back into place. A lot of fasteners will be needed, and there will be demand for the fasteners which were cleaned in the ultrasonic washer in Pansio. A leak was observed in the hydraulic system of the integral stairway, now it was repaired, and the stairway is operating again.

Photo by Erja Reinikainen Members of the Pansio team and of the airport staff came to see the Caravelle and to take pictures. There were also curious visitors who had read about the aircraft in the local paper, Turun Sanomat. There will be more to see on Thursday when the vertical stabilizer is lifted into place. |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird |

Caravelle towbar restoredLauantai 27.5.2023 - Tuesday Club member The original towbar for Caravelle III (SE-DAF), acquired from Sweden by Aviation Museum Society, was brought along. It was used by SAS. The towbar was abandoned by SAS along with the termination of the Caravelle fleet’s career. The towbar had lain decades at Arlanda Airport along SE-DAF.

The towbar was taken under restoration at the Tuesday Club in the autumn of 2022, in a similar fashion as the derelict Super Caravelle towbar was restored, used by Finnair. The SAS towbar is of the first version made by the Sud Aviation industries. For its part the Super Caravelle towbar used by Finnair is of the third and last version. The differences between these towbars are minimal and concern mainly the wheel rack of the towbar.

Along with the spring all the parts of the towbar were refurbished and painted. The last job before assembling the towbar was to repair the wheel rack to working order. When the towbar wheel rack was dismantled in the autumn season, it was noticed that the rim of the other wheel was so far gone that it was unusable. The other wheel’s rim was sound enough to be usable with a bit of welding. A new tyre and inner tube were bought for it and one of the bearings, which had broken when the wheel was dislocated from the axle of the wheel rack. When the rim had received its blue colour, the inner tube and the tyre were fitted in place.

To replace the unusable wheel, we managed, after a spot of searching, to find a wheel with an inner tube looking like the original wheel, and fitting the towbar’s 25 mm axle. A majority of the “wheelbarrow” wheels on sale were made for a 20 mm axle. When the rim of the new wheel had also been painted blue you could hardly tell them apart. The wheels were attached on to the wheel rack’s axles, after which the test assembling of the towbar could be commenced.

The test assembling will be necessary, because the towbar will be transported in parts to the Turku Airport area, where it will be assembled on show next to the ex SAS Caravelle SE-DAF, now being restored as the Finnair “Bluebird”. By test assembling it will be ensured that the assembling in Turku will take place without surprises.

The towbar test assembly was started by setting against each other the flanges of the halves of the towbar. We had to do some thinking, because the guiding pins for the flanges of the towbar halves didn’t line up with their holes so that the lifting handles are in the same line. We established that the towbar halves must have been 180 degrees out of line of each other already when they came to Finland.

This we hadn’t noticed when dismantling the towbar, because the towbar lacked the lifting handles, which would have indicated the position. If they had been there, we would have noticed that one handle was beneath the towbar, the other one above. So our conclusion is that the towbar was wrongly assembled at Arlanda. An indication of this is that in the photos we took before the dismantling of the towbar, the metal support of the towbar which should touch the ground is sticking to the skies.

To solve the problem of test assembling we sawed off the guiding pins and pressed the flanges of both the bar halves against each other so that the lifting handles were above the towbar and lined up properly with each other. After this the flanges were locked to each other with two locking collars around them. The collars were tightened fast by their brackets with bolts. This way the towbar halves had been connected.

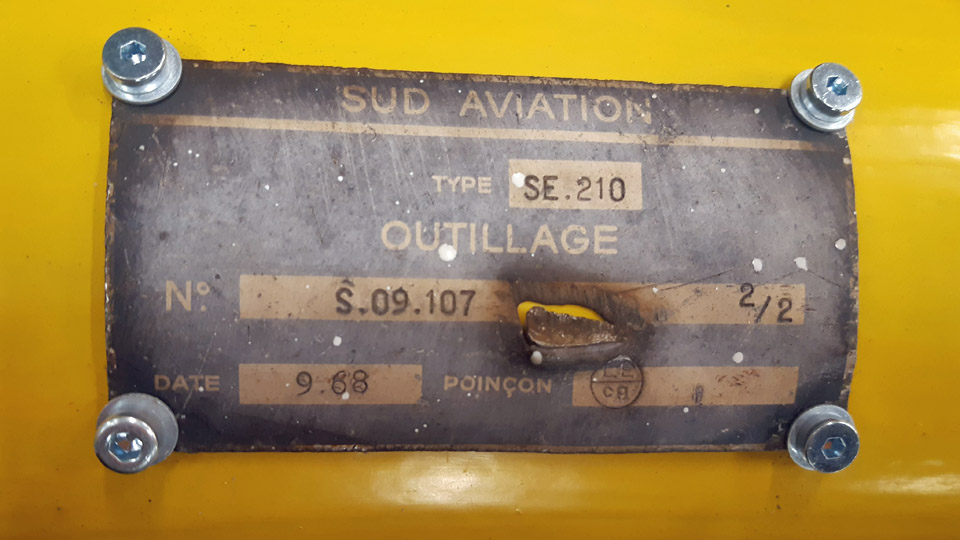

Now it was time to attach the wheel rack to the towbar. The wheel rack was attached to the towbar by its attachment collars. The rack wasn’t attached in the middle of the towbar, but some way on the pull loop end side of the centre of gravity. Thus the aircraft towhead end, which connects with the nose gear, weighs down and leans on the ground by its support. Finally we attached the manufacturer’s plaque on the side of the towbar. The towbar is still lacking the Caravelle logo, which will be painted on its side before it will be ready to be delivered to Turku.

The derelict towbar underwent a complete transformation at the hands of the Tuesday Club. It changed from the rusty and partly damaged towbar into a renewed one, resembling the towbars used by the Finnair Caravelle fleet. It received the same appearance as the Finnair Super Caravelle towbar we restored a year ago. Photos by Lassi Karivalo Translation by Matti Liuskallio |

|

Avainsanat: aviation history, restoration, Caravelle, SE-DAF, Sven Viking;OH-LEA, Sinilintu, Bluebird;Tuesday Club |