MY-14 got propeller control and throttle leversTorstai 29.6.2017 - Reino Myllymäki VL Myrsky II fighter has a VLS 8002 constant-speed propeller. According to name, the propeller keep the rotational speed by changin the blade pitch.

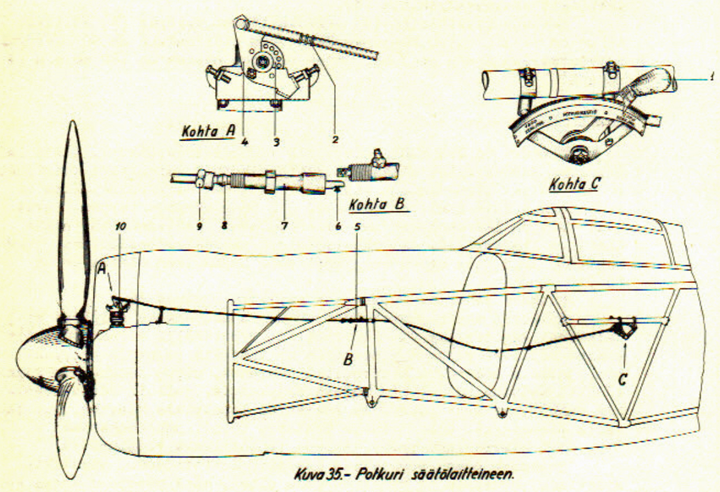

The object on the gear box is the constant-speed unit. Notice the quality of the leading edge of the NACA ring. Photo: The Finnish Aviation Museum. VLS 8002 in a propeller construction of the State Aircraft Factory. It has three wooden blades with Hamilton Standard 3 E 50 hub. The hub is not made by Hamilton: it is finished in Finland by using Swedish preform. The constant-speed unit is designed by Hamilton and it can change the blade pitch between 27 and 47 degrees.

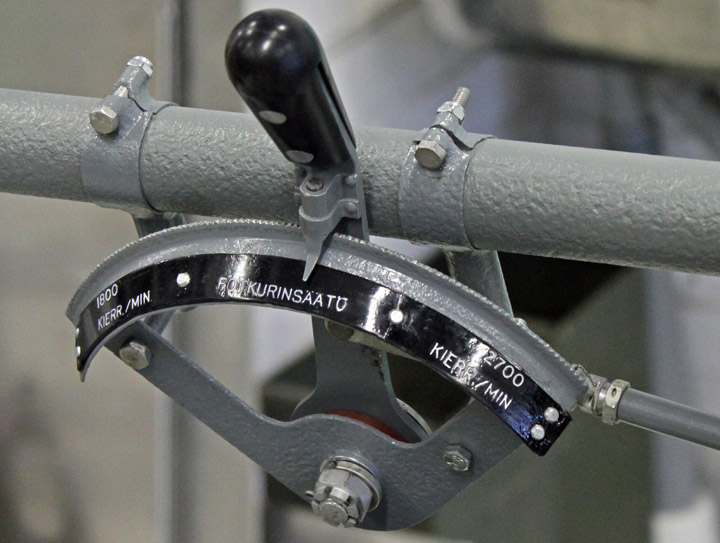

The blade pitch can be adjusted by a control lever in the cockpit. In front the blade pitch is decreasing and the rotational speed is increasing. In back vice versa. The lower pitch is used in the climbing and the higher pitch in the cruising. The propeller control lever of MY-14 was very corroded. The friction plates and knob were disappeared and the parts of the control levers of the MY-5 and the MY-5 had to be utilised. The steel parts were glass ball blasted and painted by Isotrol primer and paint. The duralumium parts were cleaned by oxalic acid. The new friction plates were lathed by using original Parkesin as a material. The Parkesin is trade mark of nitrocellulose called to "lusto" in Finland. In addition, the knob was lathed from black Parkesin and fixed by aluminum rivets. The original instruction plate of the control lever has preseved but in three parts. The material of the plate was Paxolin plate. Paxolin is fenol laminated paper. The paint was removed machanically and repainted by Miranol paint. The parts were glued together by epoxy resin and the result was fixed by aluminium rivets.

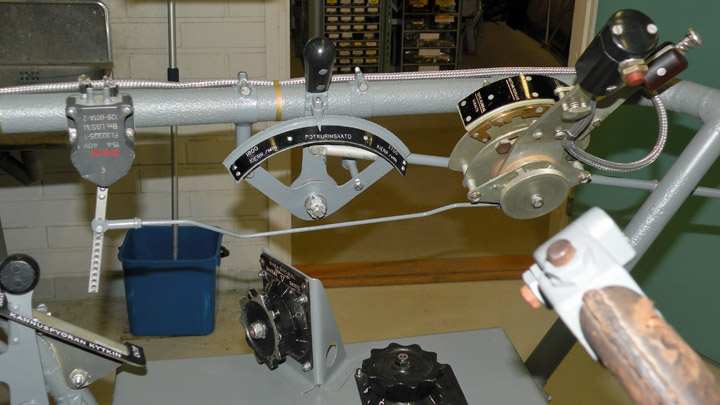

The casing pipe of the Teleflex wire of the propeller control system was cleaned by steel wool and some spacers' nuts were substituted by original parts. The steel casing pipes were so corroded that they had to be renewed. Since the engine is not yet installed, the Teleflex wire was not installed. In addition to that, the front part of the casing pipe system is still lacking. The throttle lever system consists of two levers. One controls the mixture and another is the essential throttle lever. There is a push-to-talk switch in the knob of the lever. In all, the throttle lever system is not a simple system since there are adjustable restrictors and a bar to enable the whole control range at the high altitude. All three throttle lever systems of the MY-5, the MY-9 and the MY-14 were in so poor condition that using an original spare part was a good idea. Unfortunately it was not complete. The throttle lever system was disassembled. The plywood friction plates were grinded until the system ran correctly. The steel parts were painted and a new knob were made. The push-to-talk switch was substituted by an original spare part. The wiring was renewed but the fastenind bands were original spares.

Finally, the levers were fixed. The result is excellent, isn't it? Histotical photo: The Finnish Aviation Museum. Other photos: The Finnish Air Force Museum. |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |