Repair of left aileron of KurkiSunnuntai 18.3.2018 - Member of Tuesday Club The rotten parts of the left wing of I.V.L.K.1 Kurki have been under restoration in the Tuesday Club already for a month and a half. An additional project was launched to repair the aileron which had also been badly damaged. The aileron is located in the area of the wing which has been damaged during the 90 years of storage: water has been dripping on the plywood covering of the wing and aileron and caused rotting and moulding. The Tuesday Club will remove the rotten parts of the plywood covering of the aileron and rebuild the covering using new 1.2 mm thick plywood. Also the inner structures of the aileron will be repaired.

The work was started by defining which parts of the aileron covering needed to be dismantled. Then the plywood was cut along the marked line using a Dremel cutter blade. The rotten plywood was removed and it actually almost fell off from the aileron ribs, end and leading edge. The remaining fragments of the plywood were chiselled off the leading edge. When the plywood had been removed, further damage could be seen: parts of the aileron ribs and the rib plywood sides were partly badly rotten and will have to be renewed.

When the plywood covering had been dismantled, the attaching nails and screws remained on the leading edge, ribs and end batten. The plywood had originally been glued on the aileron structure and gluing had been reinforced with rows of nails and brass screws at 10 cm intervals. The team tried to pull out the rusted nails but only some came out and others broke. The broken nail stubs were either filed down to the wooden surface or struck into the wood using a punch. The brass screws were easy to remove.

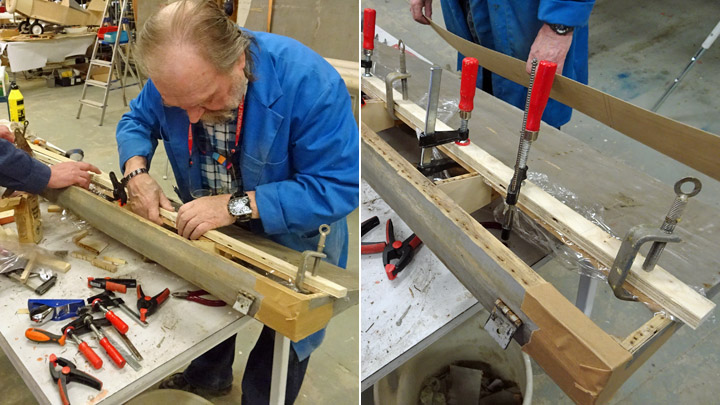

The dismantled area is covered with new plywood so that the new material is attached on the aileron ribs, leading edge and end batten and meets the existing covering in a butt joint. A new joining batten is installed between each rib and under the edge of the old plywood, reaching a couple of centimetres outside the edge. These battens form the structure under the butt joint seams of the old and new material. The wooden batten was cut to measure to fit between the ribs. Before gluing the battens into place, old protecting varnish had to be buffed out from the lower surface of the covering plywood. The battens were glued in place under the edge of the covering using Erikeeper Plus glue. A protecting plastic foil was spread over the edge of the plywood and a long wooden batten placed on top. The batten on top was an assisting element when squeezing the plywood edge and glued battens together using clamps. The plastic foil was necessary to keep the additional batten from attaching to the plywood in case some glue seeped out from the seam.

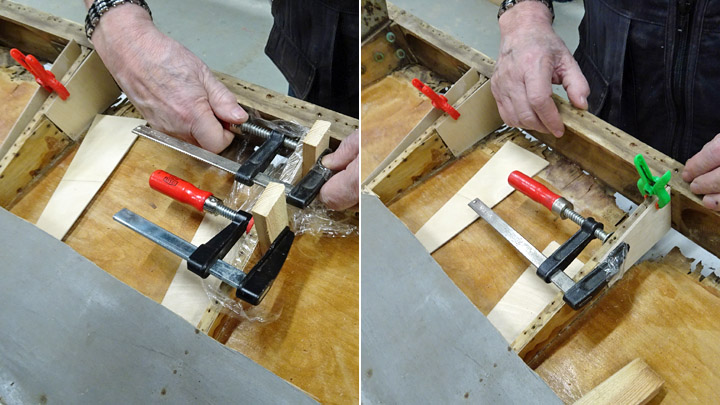

The repairs on the rotten aileron ribs has also been started. The plywood sides of the ribs, especially at the front ends, were so rotten on many ribs that the rotten parts had to be cut off and replaced using new plywood.

When the inner structures of the aileron have been repaired and the supporting battens for the butt joints of the new and old plywood covering are ready, the actual installation of the new plywood covering can be started in the dismantled areas. |

|

Avainsanat: aviation history, restoring, old aircraft, I.V.L. K.1 Kurki |