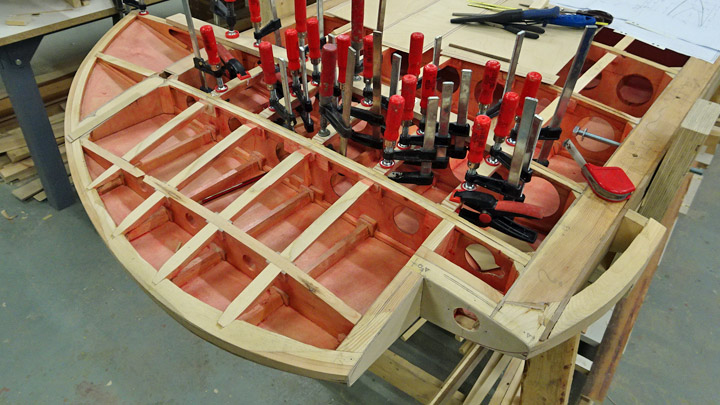

Ongoing activites at Myrsky wingtipSunnuntai 28.10.2018 - Member of Tuesday Club In the restoration work of VL Myrsky II the installation of the navigation lights is under way. When the tip of the wing was built, a gap was left on the front corner of the wing so that the navigation lights could be installed later.

The navigation light on the wingtip consists of a transparent aerodynamically designed plexiglass cover and its frame, made of aluminium, which attaches the cover onto the wing structure. The actual navigation light bulb is inside the cover, surrounded by a small red or green plastic cover.

The plexiglass cover of the navigation light is made in a vacuum moulding machine. The heated 2mm pvc plexiglass plate is pressed on a mould which has the shape of the navigation light cover. When the plexiglass has cooled on the mould, it is cut into shape.

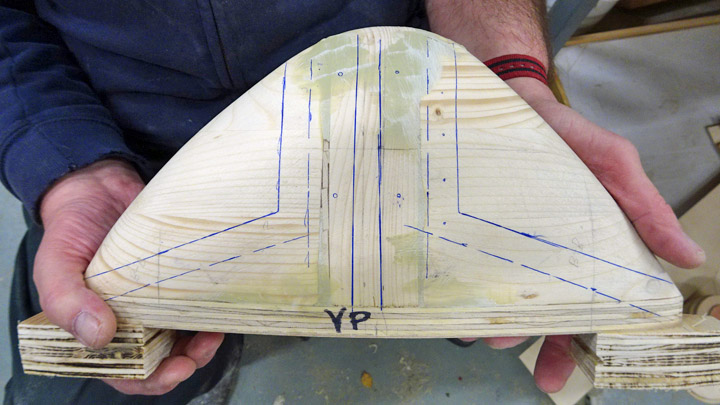

The mould for the navigation light cover was made from wood. Pieces of wood were glued together to form a piece large enough for the moulds of the navigation light covers on both wings. The piece of wood was cut and milled following drawings so that it had the shape of two navigation light covers, back to back. When the desired shape had been reached, the piece was cut into two parts. Now the moulds for the two light covers were ready.

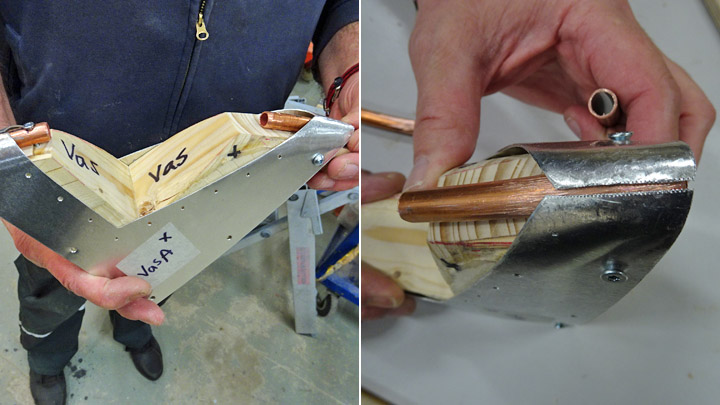

The cover is assembled into the gap at the wingtip using a frame made of aluminium sheet. For the making of the frame a mould is needed, following the shape of the plexiglass cover. The aluminium frame is made of two halves, upper and lower, which are welded together around the mould. Also in this case the mould was made from wood, matching the shape of the navigation light cover.

The upper and lower halves of the aluminium frame were screwed onto the wooden mould and the ends of the two halves met correctly. A piece of copper tube was placed under the ends of the frame halves to protect the mould from excessive heat when welding the parts together. The tube also forms a solid base under the frame edges when the welding is done.

Some additional work is still required before the navigation light cover mould is ready: it needs a supporting structure before it can be attached to the vacuum moulding machine. The mould for the aluminium frame is ready and the halves can be welded together to form the frame. |

|

Avainsanat: aviation history, restoring, old aircraft, VL Myrsky II, MY-14 |