Other than restoration activities in Tuesday ClubMaanantai 23.3.2020 - Member of Tuesday Club The Tuesday Club of the Finnish Aviation Museum Society is mainly connected to restoring and repairing old aircraft and placing them on display in the aviation museums. Mainly this is naturally true, but the Tuesday Club is involved in various other activities which support the functions of the Aviation Museum or the Aviation Museum Society. This blog introduces some examples of these activities. Legs for large display monitorsThe Aviation Museum Society purchased six large display monitors, second-hand but functioning, to be used in different in public events connected to aviation. The bargain didn’t include legs which are needed when the display is standing on a table. Therefore the Tuesday Club team was given the task to make two legs for each display.

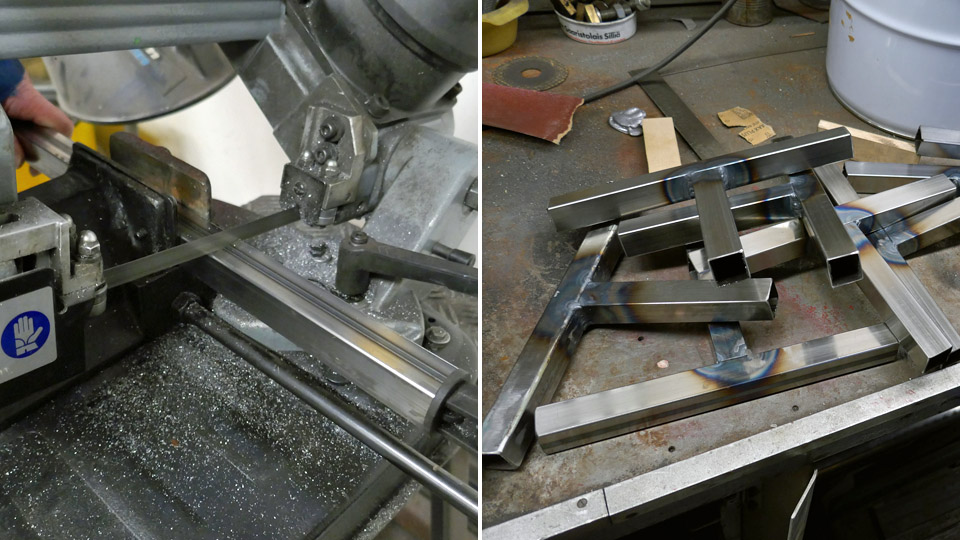

The team decided to make T-shaped legs from metal tube. The legs could be installed into the holes in the lower edge of the display and unfastened after use. The team acquired rectangular metal tube with suitable dimensions and cut it into pieces which will be welded together to form the T-shaped leg. For each display two tube pieces were needed for the horizontal legs and two pieces for the vertical supports. A total of two dozen tube pieces were cut for the six displays.

The 12 T-shaped legs were welded in the welding space outside the Finnish Aviation Museum. The welded seams and the ends of the tubes were ground smooth and then painted black. Finally the square tube ends of the legs were plugged using black plastic plugs. Now all six displays had their legs ready and they can be used in the different aviation events. Extending the guard railing of the stairsVisitor safety is important for the Finnish Aviation Museum. When inspecting the safety issues, a shortcoming was noticed on the stairs leading to the balcony of the I Hall. The guard railing of the stairs was shorter than the staircase. This may be dangerous for the visitor when the railing suddenly ends and there are still more stairs to walk. The museum decided to build extensions to the railings.

For the new railings the Tuesday Club team acquired stainless steel tube, which is strong enough and has a glossy polished surface which doesn’t need additional polishing. The tube will be connected to the existing railing tube using a lapped joint.

The lapped joint is made by cutting away the lower part of the tube at a length of about 30 cm. The open curved end of the railing tube can be pressed tightly on the original handrail and fastened with brackets on the vertical balustrade. The joint of the stainless steel tube on the original handrail will be made first on one railing to test how it works. When the joint has reached the desired form and appearance, the other three railing extensions can be made according to the model and using serial production process. The first joint is already in the testing phase.

The extended handrails will naturally need their own vertical balustrades. The balustrades will be made from ordinary steel tube which was cut into four pieces. Fastening plates were welded onto the lower end of each balustrade tube. Fastening brackets for the handrail will be welded to the upper ends of the tubes.

Now the guard railing extension project is at the phase where the joint of the extended handrail and the existing handrail is finalized and the balustrade tubes are made. However, the corona virus pandemic interrupted the Tuesday Club activities at the Aviation Museum and the work will be continued when the pandemic is over. Paint testsThe Tuesday Club is working on the restoration of the VL Myrsky II (MY-14) fighter and the Caudron C.59 advanced trainer plane and the rotor blades of the SM-1 helicopter (HK-1) are being repaired. Each project is now reaching the painting phase. The exact paint type and colour originally used on the Caudron and the helicopter rotor blades are not known. Also the fabric-covered parts of the Myrsky will require paint tests. The test is not only about paints but also different kinds of cotton and linen fabrics will be tested how they fit the needs. The Tuesday Club team decided to make a dozen wooden frames, covered with fabric, for testing the paints and different kinds of fabrics and for choosing their combination.

Suitable batten material was found in the wood storage of the restoration space and it was cut to measure. The battens were connected to form frames of 50x50 cm. The frames were covered with four different kinds of cotton fabric and a linen fabric. On some frames the fabric was properly sewn, as it would be when covering an airplane with fabric. On other frames the fabric was fastened using a stapler.

When the frames were ready, the fabric was tightened using nitrocellulose varnish. The fabric has to be tightened before the paint tests. The fabric has to be covered with the shrinking dope several times before it is tight enough. The shrinking procedure is started with thinned varnish (50% varnish, 50% thinner) and finished with plain varnish.

The shrinking process was left unfinished when the corona virus pandemic interrupted the Tuesday Club activities. Hopefully the pandemic is soon over and the team can return to their normal routines. Photos: Lassi Karivalo, translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoring, old aircraft, Tuesday Club |