Reinforcing fabrics for plywood seams on Myrsky's wingSunnuntai 22.11.2020 - Tuesday Club member The C-type wing of the Myrsky-fighter (VL Myrsky II) has plenty of plywood seams which are reinforced with linen fabric strips. The purpose of the fabric is to protect the plywood seams from problems caused by moisture. There are fabric strips e.g. on the edges of the aileron and flap compartments, on the leading edge of the aileron, on the edges of the landing gear wells and on the wing tips. The tips of the horizontal stabilizers have also been reinforced with fabric. Originally the Myrsky’s wings didn’t have these fabric strips to prevent moisture problems. The aircraft factory started planning these for the wing in late 1944 when the whole Myrsky series had already been built. The reason for this were the problems in the plywood seams, caused by moisture, and due to which some glued plywood seams on the wings had opened. In the same modification the structure of the rear wing spar was changed, and the Myrsky C-wing was created. The first series production aircraft the A-type wing. It was replaced by the B-wing, then the B1-wing and eventually in 1945 by the C-wing. The construction of the VL Myrsky II meant continuous improvements and modifications.

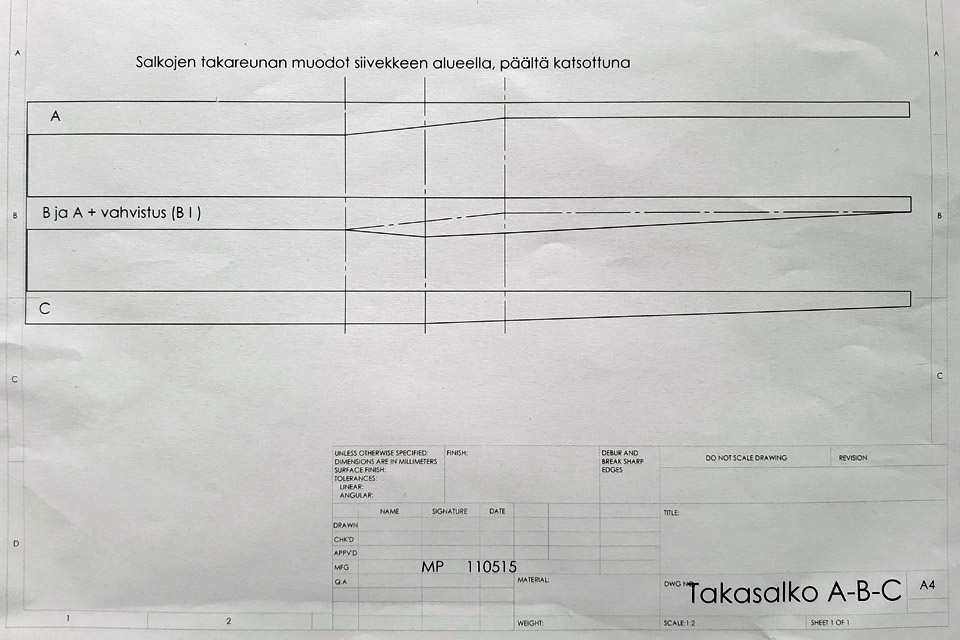

The structure of the Myrsky’s A-, B- and C-wings differed mainly in the rear spar. In the A-wing the rear spar became thinner at the seam of the aileron and the flap, thinning steeply towards the wing tip. This point proved to be weak and led to the breaking of the wing. This is why the rear spars of the A-wings were reinforced by adding a strengthening piece on the side of the spar – and this is how the B-wing was created. This was not a good solution either. That is why a new rear spar was designed, it thins linearly towards the wing tip. The wing with the new kind of rear spar was called the C-wing and the aim was to replace the Myrsky’s B-wings with the new type. Only about a dozen C-wings were built during 1945 and they were only installed on a couple of Myrskys before the aircraft type was written off. Obviously the MY-5, the MY-41 and the MY-50 were the only ones which had the C-wing. The MY-14, which is under restoration, had a B-wing. In December 1945 the aircraft got a new wing at the Lentorykmentti 1 (Flight Regiment 1) Depot in Pori. It is not known what kind of wing was installed. Around the same time a C-wing was installed on the MY-5. So it can be speculated whether the MY-14 got a C-wing, too. The MY-14 will get a C-wing when it is being restored. The steering committee of the Myrsky restoration project decided that building a C-wing for the MY-14 is both justifiable and appropriate. This solution was chosen mainly because the drawings that are available for the restoration work represent the C-wing and, excluding the rear spar, the wing resembles the B-wing. It can be speculated, as shown above, whether the MY-14 had a C-wing in 1945 or not.

During the autumn the Tuesday Club team has fastened linen fabric strips on the plywood seams of the wing, i.a. the edges of the flap compartment on the port wing. The work was started by cutting the saw-toothed fabric strips for all the edges of the flap compartment from 105 g/m2 linen fabric using ”zig-zag” scissors.

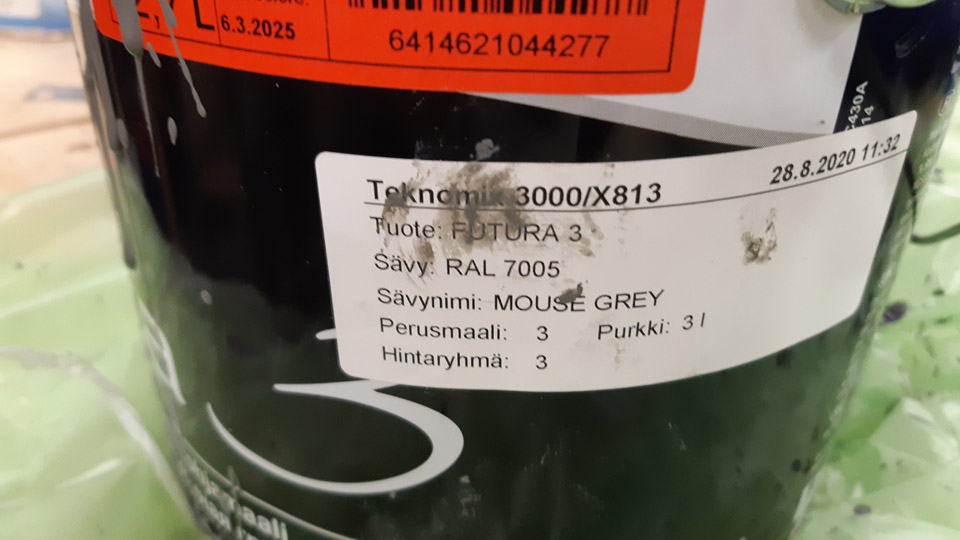

The fabric strips will be glued on the edges of the compartment with grey Futura 3 undercoat paint, hue RAL 7005, which is the same undercoat paint with which the whole MY-14 wing will be painted. The fabric strips are glued on the clean plywood surface before the plywood covering is painted. This was not the procedure with the fabrics on the leading edge of the aileron. The team was too eager to get the work done and the first layer of undercoat paint had already been applied on the ailerons before the fabric strips were remembered!

Before gluing, areas matching the width of the fabric strip were drawn on the edges of the flap compartment. Above the plywood edge the paint was applied with a roller and below the edge with a small brush. The layer of paint was the adhesive surface for the fabric. Now the saw-toothed fabric strip could be pressed against the wet paint surface. When the fabric had been smoothed tightly against the painted surface with fingers, a layer of paint was applied on it with a roller and a brush so that the whole fabric strip was covered with paint.

At the moment the fabric strips have been installed on the edges of the flap and aileron compartments, the edges of the landing gear well and the seams of the wing tip on the port and starboard wings. The strips protect the seams from moisture. The surfaces of the strips will be honed smooth before the wing gets its undercoat paint.

The both wing halves of the Myrsky MY-14 are practically ready for the undercoat painting of the wings’ plywood surfaces. The plywood surfaces have already been honed smooth. Before applying the first layer of undercoat paint, the plywood surfaces will be washed to remove any grease and oil. A solution containing 50% Sinol and 50% water will be used. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |