Mil Mi-8T (HS-4) helicopter tail boom stabilizers' covering with thin aluminium sheetSunnuntai 29.10.2023 - Tuesday Club member The tail boom stabilizers’ covering of the Mil Mi-8T helicopter, situated in the Karelian Aviation Museum, has started briskly. As was told in an earlier blog about the HS-4, the stabilizers will be covered with a thin aluminium sheet, instead of covering fabric. This is because the aluminium sheet stands much better to weather. And we must remember that HS-4 stands outdoor at the Museum yard most of the time and it’s not airworthy anymore. The covering of the stabilizers got really started after they had been stripped off tattered and rotten fabric and the faded aluminium surfaces were ground and waiting for painting after covering.

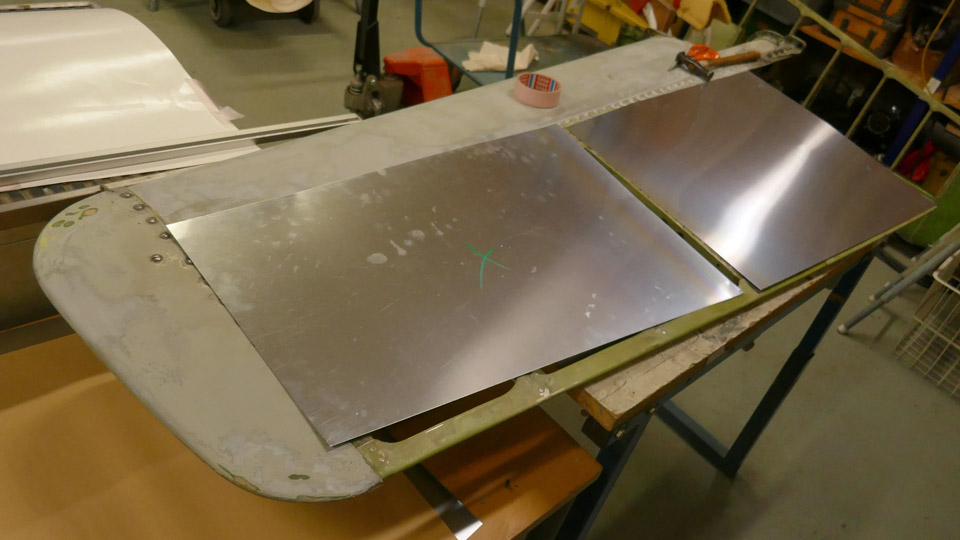

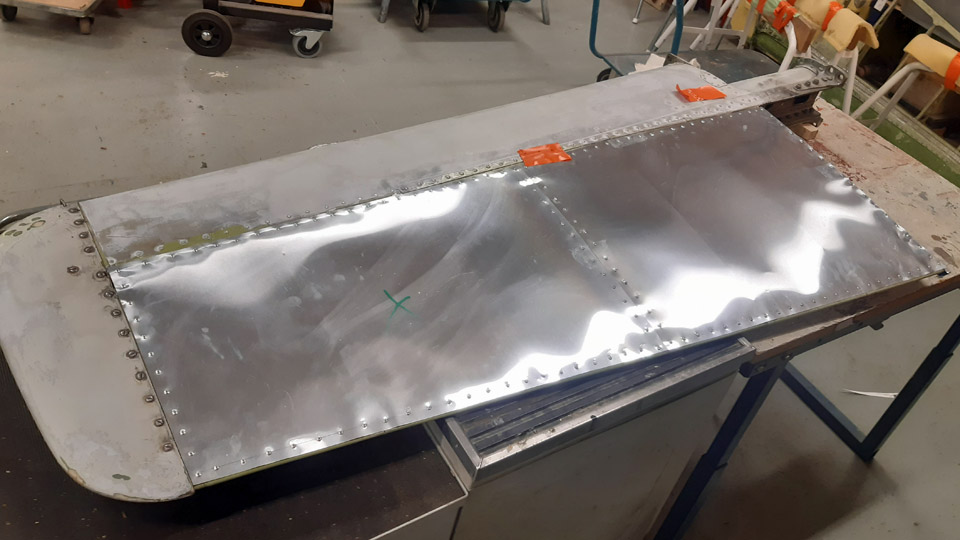

We decided to start the covering from the underside of the right-hand stabilizer. The covering will be done with 0,3 mm thick aluminium offset-printing sheets that were donated to us. Because one printing sheet isn’t enough to cover the whole area, both sides of the elevator will be covered with two aluminium sheets, joined to each other with edge joints.

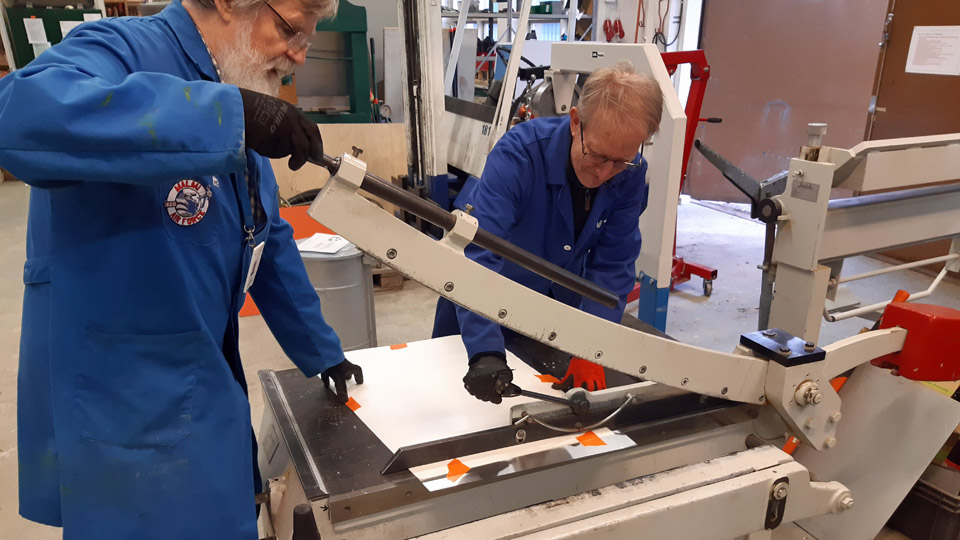

We drew the area to be covered from the stabilizer stem and tip onto cardboard and cut the cardboard with a cutter to serve as models for the stem and tip aluminium covering sheets. Then we put the cardboard models on the aluminium sheets and attached them to the sheet with tape. This way the cardboard models stuck to the sheet when the aluminium sheets were cut to form with a cutter.

The edge joint of the stem and tip sheets is made on the centre rib of the stabilizer. Therefore a 5 cm wide aluminium support strip was riveted on the rib. The edge joint of the aluminium sheets will be placed in the middle of the support strip and the sheets will be riveted into the strip at the edges. Now the covering sheets could be placed on the stabilizer to their final form. The edges were formed, however, in such a way that the sheets are equally wide at the joint and their top edge joins tightly with the edge of the steel reinforcement on the surface of the stabilizer.

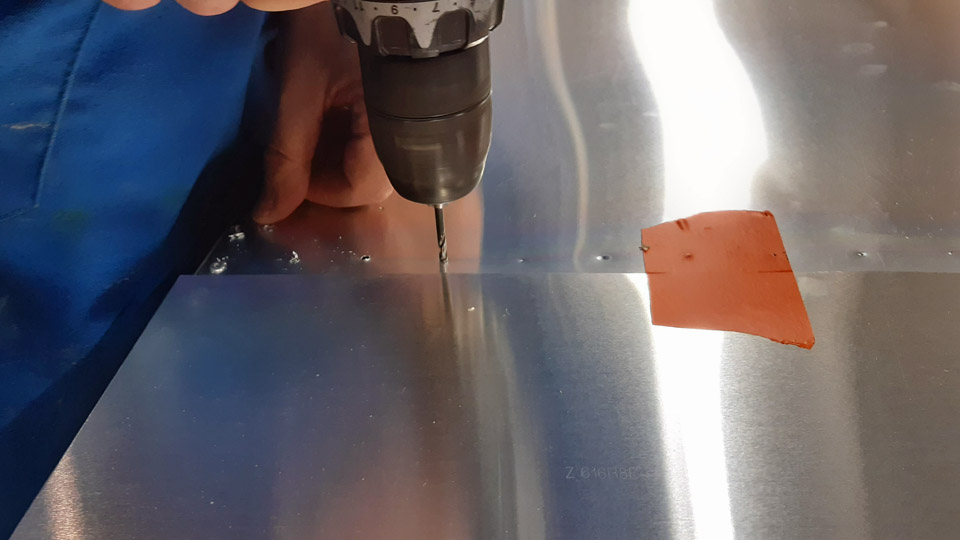

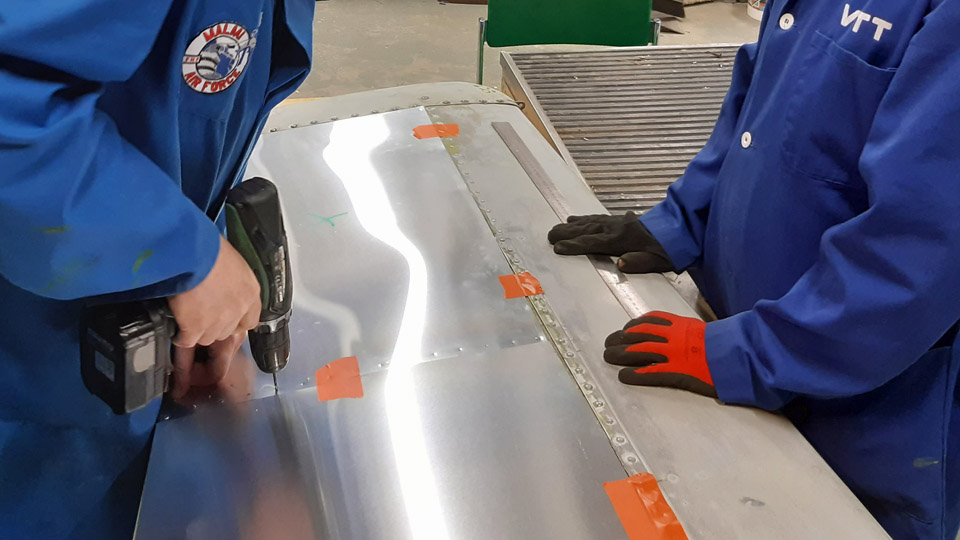

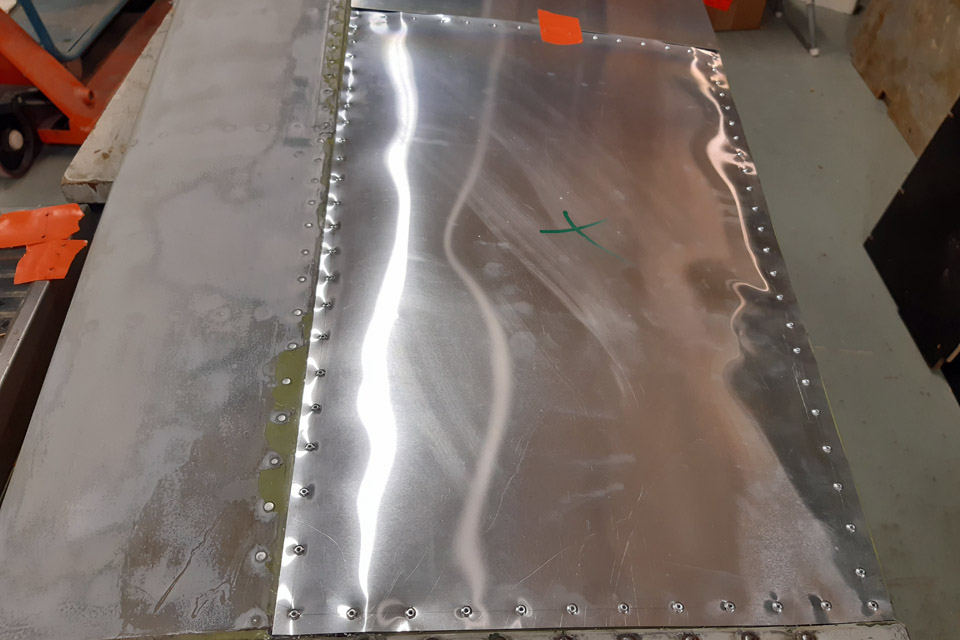

When the underside sheets had been shaped into place, the riveting was commenced from the tip sheet. The sheets will be riveted to the stabilizer at their outer edges with 3,2 x 6,0 mm blind rivets or pop rivets. First the places of the rivets were marked with a pen at three cm intervals at the edges of the sheets. Then the marks for drilling the rivet holes were snapped with a spike. The drilling took place with a 3,2 mm bit.

After the holes on one side were done, the pop rivets were riveted in place one after the other. The rivet was tightened with rivet pliers through the covering sheet into the structure of the stabilizer. After the stabilizer tip sheet had been riveted at its edges to the stabilizer underside, the stabilizer stem covering sheet was riveted to its place.

Because the aluminium sheets were only riveted at their outer sides, the contact surface of the rib and aluminium sheet was seamed with silicone. That way the aluminium sheet glues itself to the rib and won’t resonate in strong winds.

After the undersurface of the right-hand stabilizer was covered, the upper surface covering could be continued in similar manner. The procedure will be the same, when covering the left-hand stabilizer of the HS-4 tail boom with thin 0,3 mm thick aluminium sheet. When both stabilizers have been covered with aluminium sheets, it’ll be time to move on to the painting phase of the stabilizers, and that, as Kipling put it, is a different story. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |