Painting of the Mi-8 helicopter tail boom stabilizersTiistai 16.1.2024 - Tuesday Club member The restoration of the Karalian Aviation Museum situated Mil Mi-8T (HS-4) tail boom stabilizers has been concluded. It started at the Tuesday Club in the autumn season 2023. The decayed covering fabrics of the stabilizers of aluminium structure were removed and the stabilizers were covered with weatherproof thin aluminium sheets instead of fabric. Because it was decided to paint the stabilizers all round, the worn paint surfaces were ground ready for painting. The priming of the stabilizers has been described in an earlier blog.

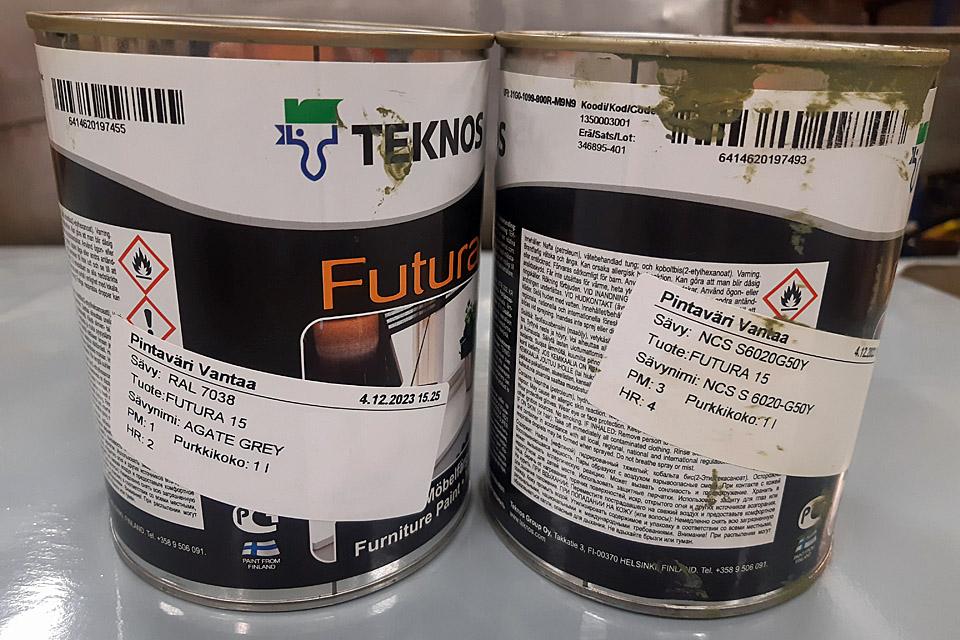

The stabilizers of the tail boom will be painted according to the paint scheme used in Mi-8 helicopters in the Defence Forces. The upper surfaces will get a camouflage colour AN 22 green (Light bronze green), which compares to the NCS-shade map NCS S6020-G50Y. The under surface will be light grey (Light aircraft gray), which corresponds to the RAL shade map RAL 7038. As the surface paint the Teknos Futura 15 outside furniture paint was chosen. Corresponding to the aforementioned shades, the grey and green paints were bought at the Pintaväri Vantaa branch.

The painting was started from the upper surfaces with the green Futura. The smooth surfaces were painted with a narrow mohair roller. Uneven surfaces like the rivet studs, the stabilizer stem and the strut were painted with a brush. The first time over gave a fairly good coverage, but to achieve a good surface the stabilizers have to be painted twice over.

After the green paint had dried, the under surfaces were painted once over with the light grey Futura. This paint, too, gave laudable coverage with the first painting. However, the under surfaces were painted a second time over after the paint had dried, to achieve an even and well protecting surface.

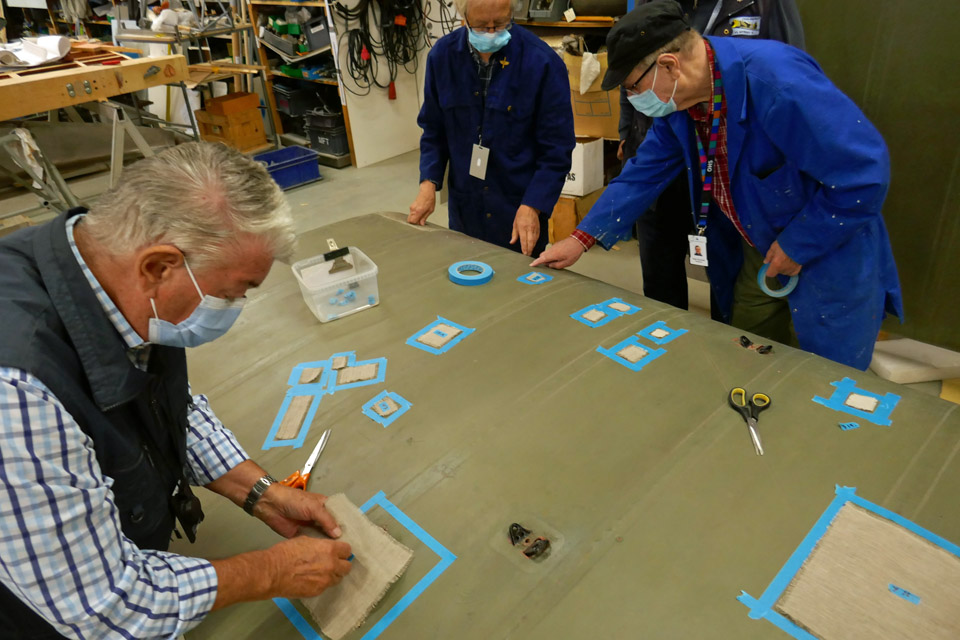

We still had to paint the stabilizers’ upper surface for a second time. The painting of the upper surface for the second time was left last, because at the seam of the upper and under surfaces of the stabilizer, the green paint gives a good coverage over the light grey paint. In this context the green and grey border surface of the stabilizer was taped over with painter’s tape. Another option would have been to paint the border area with a roller without masking. However, we ended up with masking, because it produces a neat and tidy straight border between the grey and green paint.

When masking is used in painting, it’s important to take off the masking tapes immediately, before the paint dries. If you leave the tape in place till the paint is dry, when taking the tape off it easily tears dried paint along, and the neat border that was meant to be achieved by masking, will be lost.

The Mil Mi-8T helicopter of the Karelian Aviation Museum has now had its tail boom stabilizers restored and they are ready to be delivered to Lappeenranta. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

Priming the HS-4 tail boom stabilizersTorstai 30.11.2023 - Tuesday Club member When both the fabric covered areas of the Mil Mi-8T (HS-4) helicopter tail boom stabilizers had been covered with thin 0,3 mm aluminium offset printing sheet, we could move on to priming these new aluminium surfaces. Obviously, the decayed fabric coverings were renewed with aluminium sheets instead of fabric.

Right hand side photo by Mårten Juslin. The first phase in priming is to remove grease and dirt from the surface to be painted. KUSTOM-anti grease agent was used to remove the grease. The agent was applied to clean cloth and both stabilizers’ new aluminium surfaces were meticulously wiped with it. The anti-grease operation for other surfaces of the stabilizers will be done in conjunction with the paintwork because their surfaces are already set up for the paintwork.

Photo by Mårten Juslin. The next step is the graining of the new aluminium surfaces to be adhesion-primed, especially as the HS-4 tail boom stabilizers’ new surfaces are smooth like a mirror.

Photo by Mårten Juslin. The graining of the new aluminium surfaces was done with a traditional scouring pad. After graining, the graining dust was wiped off the surfaces with a clean cloth. It was noticed that more dirt had accumulated to the cloth used for wiping off the grease and dirt than to the cloth used for wiping off the graining dust. This goes to show, how important part of the priming, the removal of grease and dirt is.

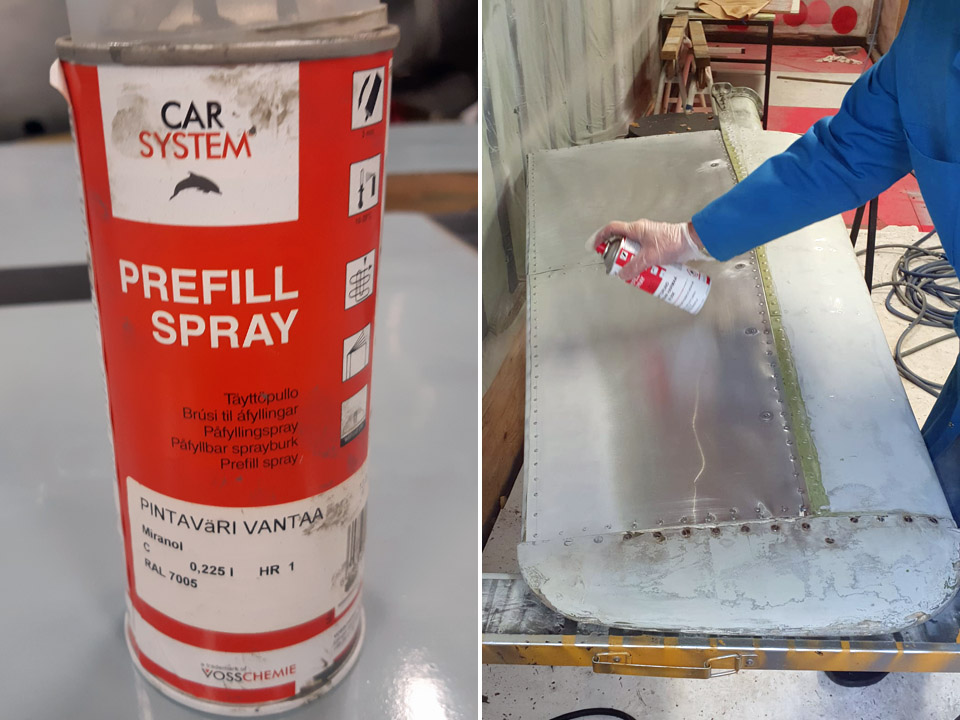

Right hand side photo by Ari Aho. As a primer or adhesive primer we chose the handy spray paint (Car System Prefill Spray Miranol) and its tone (RAL 7005). Light grey is in this case a good tone for the adhesive primer, because the stabilizers’ undersurfaces will be painted light grey (Light aircraft grey).

Photo by Mårten Juslin.

The stabilizers that were ready for priming, were taken to the painting tent at the yard of the Finnish Aviation Museum. There the primer was misted on the stabilizers’ surfaces as a thin, but engulfing veil. The stabilizers are now ready for the paintwork. Photos by Lassi Karivalo except if otherwise separately mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

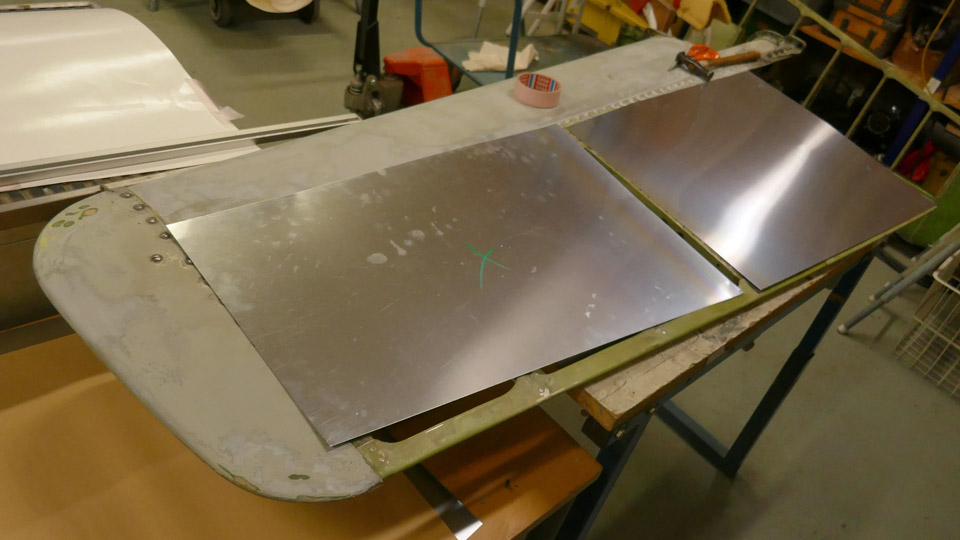

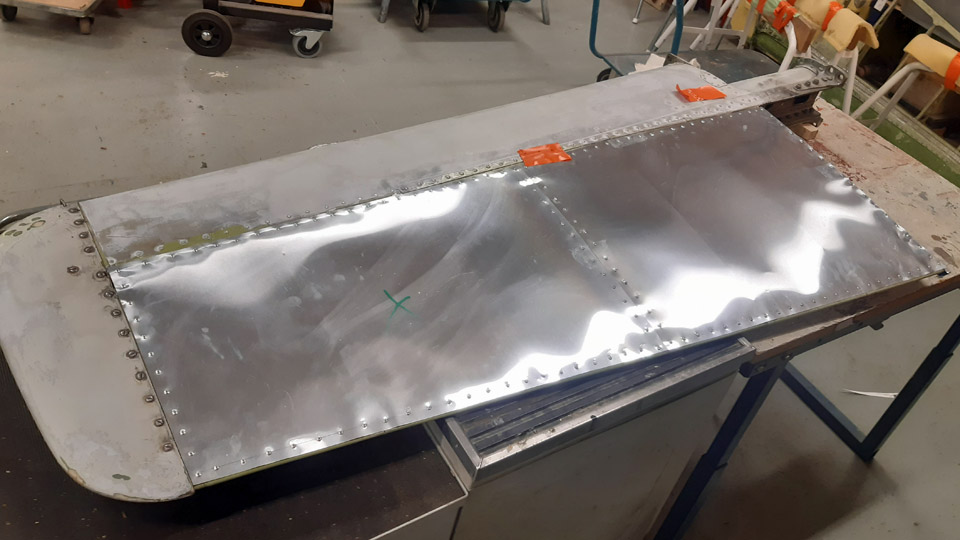

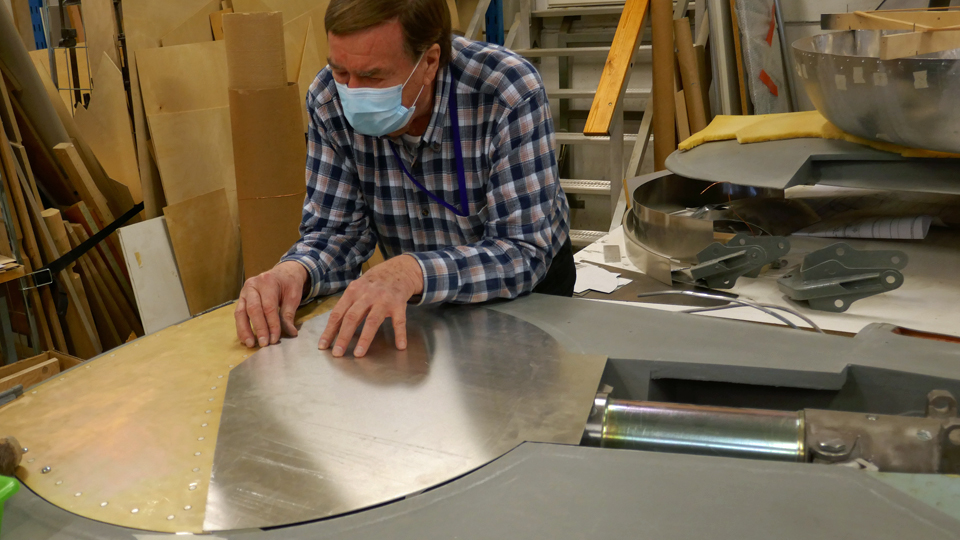

Mil Mi-8T (HS-4) helicopter tail boom stabilizers' covering with thin aluminium sheetSunnuntai 29.10.2023 - Tuesday Club member The tail boom stabilizers’ covering of the Mil Mi-8T helicopter, situated in the Karelian Aviation Museum, has started briskly. As was told in an earlier blog about the HS-4, the stabilizers will be covered with a thin aluminium sheet, instead of covering fabric. This is because the aluminium sheet stands much better to weather. And we must remember that HS-4 stands outdoor at the Museum yard most of the time and it’s not airworthy anymore. The covering of the stabilizers got really started after they had been stripped off tattered and rotten fabric and the faded aluminium surfaces were ground and waiting for painting after covering.

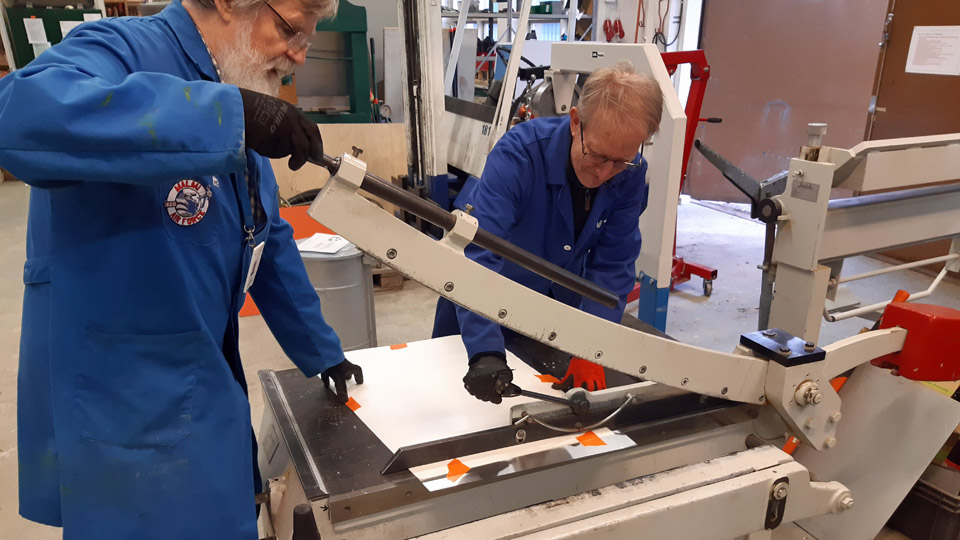

We decided to start the covering from the underside of the right-hand stabilizer. The covering will be done with 0,3 mm thick aluminium offset-printing sheets that were donated to us. Because one printing sheet isn’t enough to cover the whole area, both sides of the elevator will be covered with two aluminium sheets, joined to each other with edge joints.

We drew the area to be covered from the stabilizer stem and tip onto cardboard and cut the cardboard with a cutter to serve as models for the stem and tip aluminium covering sheets. Then we put the cardboard models on the aluminium sheets and attached them to the sheet with tape. This way the cardboard models stuck to the sheet when the aluminium sheets were cut to form with a cutter.

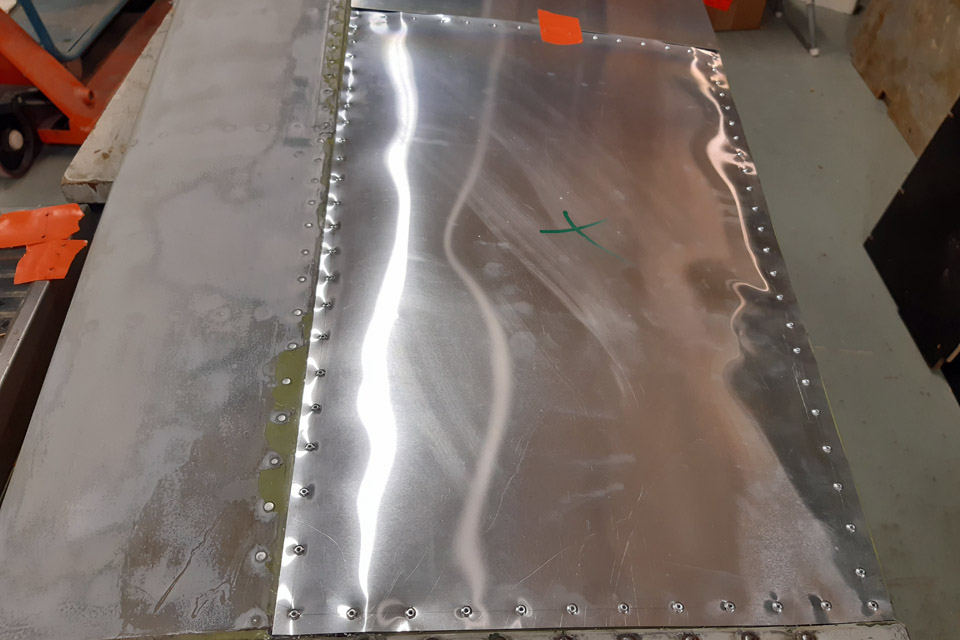

The edge joint of the stem and tip sheets is made on the centre rib of the stabilizer. Therefore a 5 cm wide aluminium support strip was riveted on the rib. The edge joint of the aluminium sheets will be placed in the middle of the support strip and the sheets will be riveted into the strip at the edges. Now the covering sheets could be placed on the stabilizer to their final form. The edges were formed, however, in such a way that the sheets are equally wide at the joint and their top edge joins tightly with the edge of the steel reinforcement on the surface of the stabilizer.

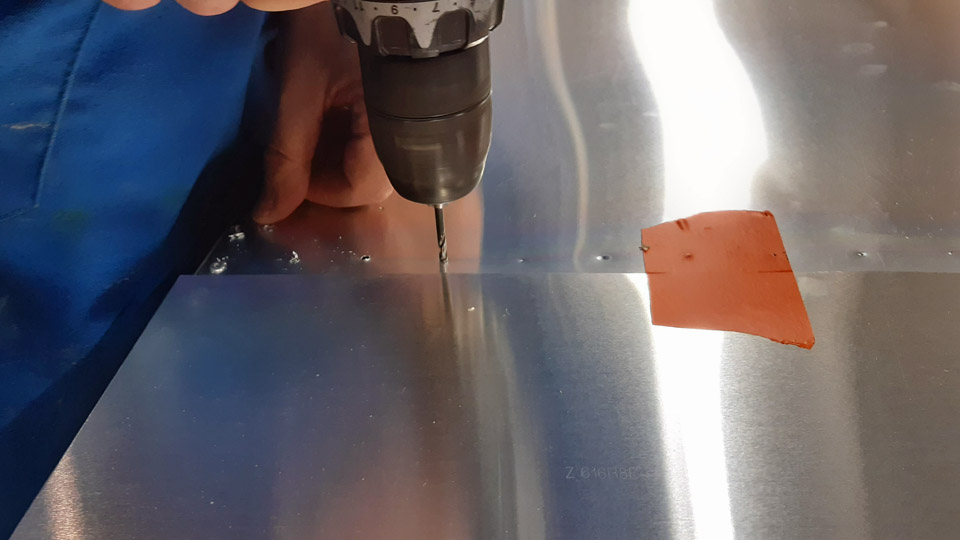

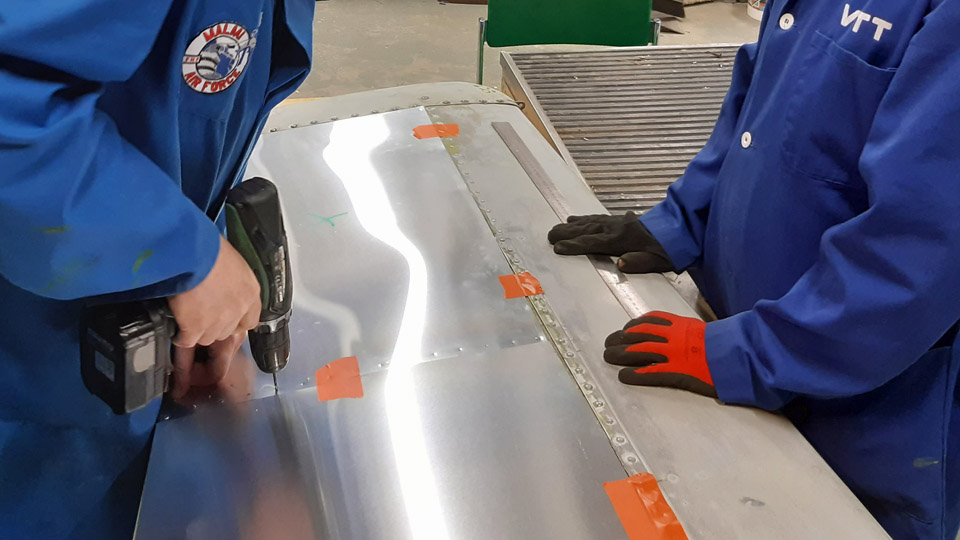

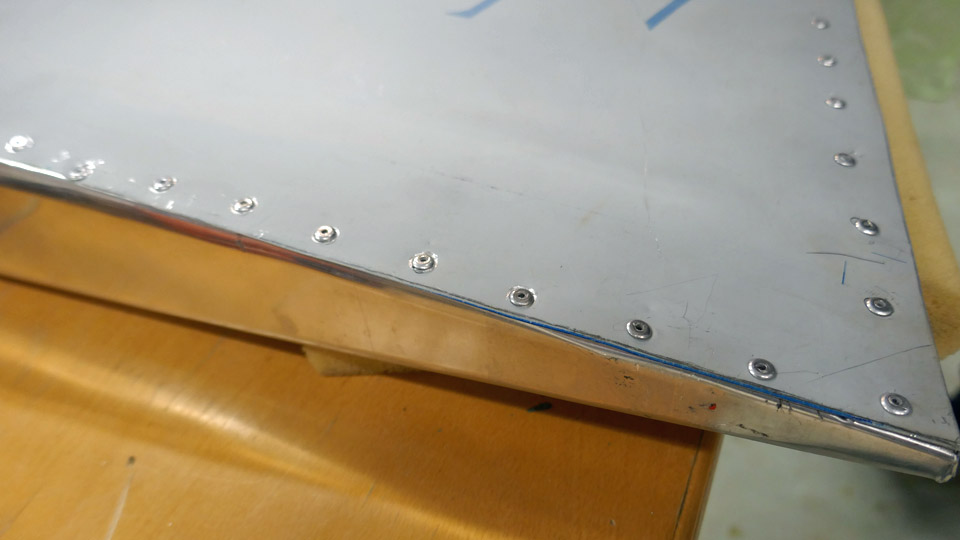

When the underside sheets had been shaped into place, the riveting was commenced from the tip sheet. The sheets will be riveted to the stabilizer at their outer edges with 3,2 x 6,0 mm blind rivets or pop rivets. First the places of the rivets were marked with a pen at three cm intervals at the edges of the sheets. Then the marks for drilling the rivet holes were snapped with a spike. The drilling took place with a 3,2 mm bit.

After the holes on one side were done, the pop rivets were riveted in place one after the other. The rivet was tightened with rivet pliers through the covering sheet into the structure of the stabilizer. After the stabilizer tip sheet had been riveted at its edges to the stabilizer underside, the stabilizer stem covering sheet was riveted to its place.

Because the aluminium sheets were only riveted at their outer sides, the contact surface of the rib and aluminium sheet was seamed with silicone. That way the aluminium sheet glues itself to the rib and won’t resonate in strong winds.

After the undersurface of the right-hand stabilizer was covered, the upper surface covering could be continued in similar manner. The procedure will be the same, when covering the left-hand stabilizer of the HS-4 tail boom with thin 0,3 mm thick aluminium sheet. When both stabilizers have been covered with aluminium sheets, it’ll be time to move on to the painting phase of the stabilizers, and that, as Kipling put it, is a different story. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

Mil MI-8T HS-4 tail boom stabilizer covering beganKeskiviikko 27.9.2023 - Tuesday Club member An example of a Mil MI-8T helicopter, used by the Defence Forces and registered as HS-4, is situated in the Karelian Aviation Museum. The tail boom stabilizers’ covering fabric is rotten and partly lacking altogether. Two thirds of the area of the stabilizers is covered with fabric and one third with sheets of aluminium. The aluminium surfaces are still in good condition, apart from a worn-out coat of paint.

Photo by Kimmo Marttinen In the spring the Karelian Aviation Museum offered the covering work of the stabilizers to Aviation Museum Society’s Tuesday Club. We agreed, because we had earlier covered the tail boom stabilizers of HS-6, which stands at the yard of the Tuulonen shopping centre. We promised to start the work in the autumn. For the covering a permission from The Finnish Defence Forces Logistics Command (FDFLOGCOM) was needed, because the helicopter is still in their possession. Permission was granted and in such a form, that we could cover the stabilizers with fabric as they originally were, or alternatively with thin aluminium sheet.

We agreed with the Karelian Aviation Museum that the stabilizers would be covered with a weatherwise better thin aluminium sheet, instead of fabric, as we had done with the HS-6 stabilizers last year. At the same time it was decided that after the covering the stabilizers would be painted all round, ergo the upper surfaces greyish green and the undersurfaces light grey, according to HS-4.

The Museum detached the HS-4 tail boom stabilizers in April, after which they were delivered to the Finnish Aviation Museum in Vantaa. At the beginning of the Tuesday Club’s autumn season the removal of the remaining rotten pieces of fabric was started. The last bits were removed with the tip of a knife. In the same manner we scratched off the thick layer of paint on the stabilizer’s steel reinforcements. Before the grinding of the HS-4 tail boom stabilizers’ faded and dirty aluminium surfaces could be started, the tone of the colour of the stabilizers’ upper and under surfaces was defined. At the Vantaa branch of Pintaväri the light greyish green of the upper surfaces was defined as the Defence Forces camouflage light green paint, code AN 22. With an electronic tone gauge the stabilizer’s faded green coat of paint was defined to be the greenish tone SG010-G9OY. The light grey of the undersurface was defined as S2500-N. We also defined the tones of the stabilizers’ aluminium surface, using the colour maps at the Finnish Aviation Museum. According to them the upper surface green was RAL 6013 Reed Gray. The undersurface light grey is closest to RAL Effect 830-1. According to the camouflage scheme of the Defence Forces for Mi-8 helicopters, the tone of the stabilizer upper surface is Light bronze green, and the undersurface is Light aircraft gray. We’ll take a closer look at this tone-of-paint-puzzle before the actual painting phase of the stabilizers.

The grinding of the faded paint surfaces was done by a random orbital grinding machine, using P180 and P240 grit sanding discs. Our aim wasn’t to grind the faded coats of paint to pure aluminium. It’s sufficient when dirt and loose paint have been removed from the surfaces and the stabilizer steel reinforcements cleaned of rust. When grinding the stabilizer surfaces, darker green adhesive primer appeared. On some uneven parts pure aluminium surface appeared.

There are roundhead rivets on the stabilizer and the stabilizer’s tip, made of glass-fibre reinforced plastic, has been attached with roundhead screws with grooves. When working on the rows of rivets and screws, the random orbital grinding machine wasn’t the best tool. So we used a grinding brush fixed to a power drilling machine to clean the rivet and screw stubs, which was very suitable for the purpose. Both the HS-4 tail boom stabilizers are ready now for the actual covering. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

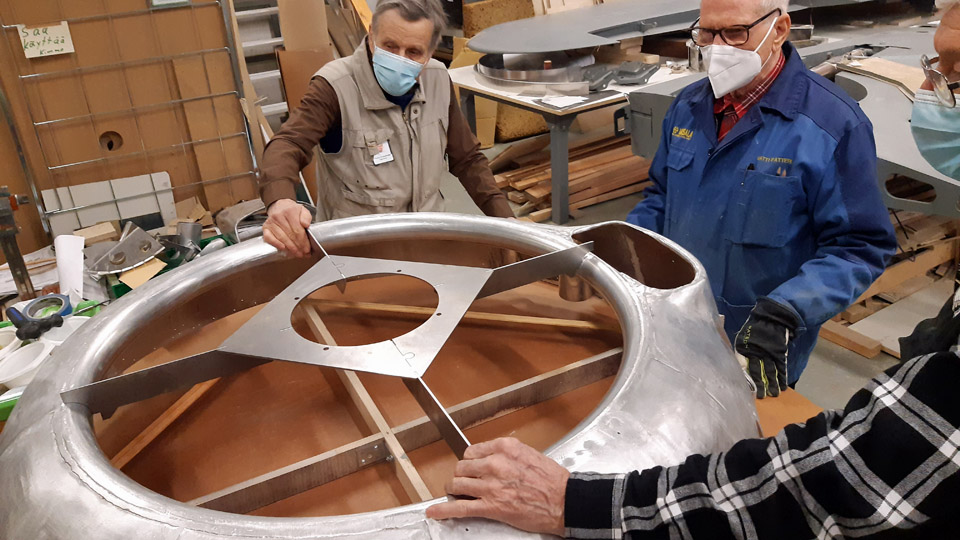

Tuesday Club started its spring season with full capacityTiistai 1.3.2022 - Tuesday Club member Suomeksi The Tuesday Club was not able to start its spring season in January because the amount of people allowed to work in the restoration workshop of the Finnish Aviation Museum was still limited due to the Covid-19 pandemic. Only the restoration work on the Myrsky MY-14 could be continued in January. Only half a dozen Tuesday Club members could work at a time, wearing masks. In the beginning of this year the Myrsky project has concentrated on the NACA-ring and the port wing landing gear doors, as well as finishing the Myrsky demo-wing before the Myrsky restoration exhibition will be opened.

Along with the Myrsky restoration work, a couple of Tuesday Club members have been working to finish the painting of the Mil Mi-8P (HS-6) helicopter tail boom stabilizers and to take the large parts of the Super Caravelle towbar to be sandblasted. The tyres of two 1920s aircraft wheels have also been dismantled so that the wheels can be repaired. These wheels have been received from the Finnish Air Force Museum to be assembled on the Caudron C.50 (CA-50) aircraft.

As the national Covid-19 restrictions have been lifted due to the decreased health risks caused by the pandemic, it was agreed with the Finnish Aviation Museum that the number of people working in the restoration workshop can be increased. This enables us to launch other Tuesday Club activities in addition to the Myrsky work. On February 23rd we continued from where we stopped before Christmas, particularly with the Caudron C.59 conservation and the Super Caravelle towbar restoration. We still work in two groups of 10 Club members, one group on Tuesdays and the other on Wednesdays. The Myrsky team, with less than 10 members, is working on Tuesdays, Wednesdays and Thursdays.

The coming weeks will be spent in cleaning the parts which were dismantled from the Caudron’s fuselage, and after that the parts will be painted. Two landing gear wheels were received from the Finnish Air Force Museum for the Caudron. The wheels and spokes are cleaned from dirt, grease and rust. Mechanical and chemical methods are applied.

The Caravelle towbar has been dismantled and all dismantled parts have been cleaned of rust, either with phosphoric acid or by sandblasting, and the painting work can be started. Before painting, the sandblasted parts were washed to remove the sand dust, which remained on the surface. Then the parts were carefully dried, using compressed air. Some parts have already been painted with clear Isotrol varnish which will prevent rust. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, Caudron C.59, CA-50, Mil Mi-8P, HS-6, Super Caravelle |

Lower side of Mi-8?s port side tail boom stabilizer has been coveredSunnuntai 17.10.2021 - Tuesday Club member The covering of the Mi-8P helicopter’s tail boom stabilizers is on the way at the Tuesday Club. The helicopter with the identification HS-6 was used by the Finnish Air Force and Army during 1978-2007. The HS-6 would have ended up being scrapped if a place hadn’t been found for it at the Tuulonen shopping centre. The tail boom stabilizers were originally covered with aluminium sheet on the leading-edge side of the spar. On the trailing-edge side the stabilizers are fabric-covered. The HS-6 has been stored outdoors for almost fifteen years and the fabric covering on the tail boom stabilizers has decayed and needs to be replaced. The rotten fabrics have been removed at the Tuesday Club and the work on the new covering has been started. The new covering will be made of aluminium sheet, not fabric, as the leading edge already has. The reason for this is that the HS-6 will be on display outdoors also in the future, so using a more weather-resistant material for covering the stabilizers is preferred. This is a good reason, especially as the aircraft is not a museum item. When repairing and restoring a museum item, the aim is to use original materials and work methods. The covering material is 0.30 mm thick, used offset plates, made of aluminium. They are excellent for this purpose, with good workability. They are printing plates, so they already have an adhesive surface for the future painting work.

The first surface to be covered with the sheet metal was the tail boom’s port side stabilizer’s lower surface. First the root end of the stabilizer was covered. Its fabric covering had been removed and a piece matching the shape of the fabric was cut from the aluminium sheet. The cutting was done so that the piece of aluminium was about 10 mm larger at its edges than the piece of fabric. This was necessary because the edges of the sheet will be bent over the butt rib’s lower and upper edges. Eventually the bent edges will be covered by the metal sheets, which cover the upper and lower surfaces of the stabilizer and are riveted on the butt rib.

A mould was made from plywood for bending the root sheet edges. The mould is triangular and matches the size of the removed piece of fabric. After the edges of the sheet had been bent, the finalizing work was done with a file. When the root sheet was ready, it was riveted on the butt rib with a couple of flathead rivets.

The next step was to make a cardboard model of the stabilizer’s surface which was to be covered. The Tuesday Club team realized that the aluminium offset plates were not large enough for cutting one single sheet which would cover the whole surface which needed to be covered. The upper and lower side of the stabilizer will both have to be covered with two aluminium sheets, which are joined together with a butt joint. The joint will be on top of the rib located in the middle of the stabilizer. An aluminium plate 5 cm wide was riveted on top of this rib to form a base for the butt joint.

The cardboard model was used when the new covering sheet for the stabilizer’s root section was drawn on the aluminium sheet. The covering sheet for the stabilizer’s tip section was drawn on another aluminium sheet. Then the sheets were cut and fitted on the stabilizer. It was noticed that both covering sheets were slightly too wide and a strip a couple of millimetres wide had to be cut from their trailing edge. Now the sheet edges were exactly on the level of the trailing edge.

The covering sheets were riveted on the stabilizer and this work was started on the root section. The covering sheet was placed on the stabilizer ribs and locating holes were drilled into its corners. Locating pins were placed in the holes to keep the sheet in place during the riveting work. The following phase of work was to mark the places for the rivets on each rib and on the trailing edge batten. For the marking a perforated galvanised steel fixing strap was used (i.e. a strap for supporting ventilation ducts). This is a good method for marking the rivet holes nicely at even distances. Then a metal point and a hammer were used for making a starting point for drilling at each rivet location. Then the rivet holes were drilled.

Pop rivets were used when riveting the aluminium sheets into place. The pop rivet was pushed into the drilled hole and squeezed tight using a pop rivet hand tool. When the aluminium sheet on the tail boom port side stabilizer’s lower side root section had been riveted, the same procedure was used when riveting the sheet on the tip section. The lower side of the tail boom port stabilizer has now been covered and the next phase will be the covering of the stabilizer’s upper side. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, Mil Mi-8P, HS-6 |

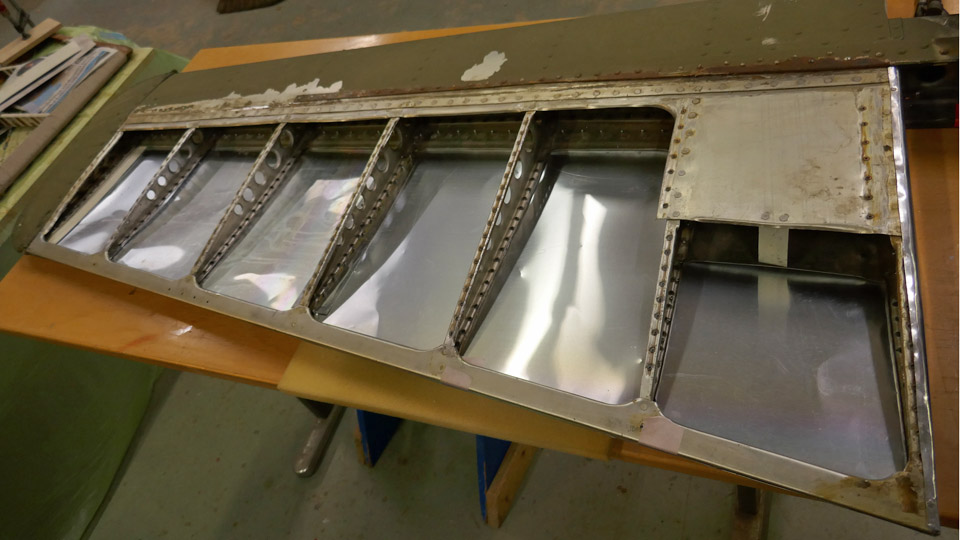

Tail boom stabilizers of Mil Mi-8P (HS-6) are being coveredTiistai 14.9.2021 - Tuesday Club member The tail boom stabilizers of the Mil Mi-8P (HS-6) helicopter, which is on display on the yard of the Tuulonen shopping centre, have been brought to the Tuesday Club to be repaired. The HS-6 helicopter was on display outside the Finnish Aviation Museum for a long time then, some years ago, it was moved to Vesivehmaa, to stand in front of the Päijät-Häme aviation museum hall. The helicopter was approaching scrapping, but fortunately a place was found for it at the Tuulonen shopping centre. The shopping centre has quite a remarkable collection of different aircraft on display: Saab 35FS Draken (DK-247) and MiG 21 BIS (MG-124) fighter jets on the yard and Douglas DC-2 (DO-1) “Hanssin Jukka” and Focke Wulf Fw 44 Stieglitz (SZ-18) indoors. The shopping centre can already be called a small aviation museum.

The tail boom stabilizers of HS-6 consist of an aluminium frame and are half covered with fabric. The fabric covers the area between the stabilizer’s trailing edge and the spar, about half of the stabilizer’s area. The fabric areas have been badly damaged because the HS-6 has been standing outside since the Defence Forces removed it from service in 2007.

The task of the Tuesday Club team is to remove the decayed fabric covering and to replace it with a thin sheet of aluminium. The Mi-8 can’t be considered an actual museal artefact anymore and the fabric covering would rot again as the helicopter is permanently on display outside the Tuulonen shopping centre.

The work was started by removing the rotten fabric from the stabilizer. The aluminium ribs and other surfaces, which had now been revealed, were cleaned. The stiffening steel batten, running parallel to the stabilizer’s spar, had rusted and it was cleaned. The paint on the stabilizer’s aluminium surface had partly flaked off. The flaked paint was removed, and the surface was cleaned to clear aluminium.

A cardboard model was made of the stabilizer’s surface which will be covered with a sheet of aluminium. The covering sheets will be cut from aluminium plate according to the cardboard model and riveted on the upper and lower side of the stabilizer. The cardboard model was fitted on the upper and lower surfaces of both stabilizers. It turned out that the Russian helicopter engineers has designed the stabilizers to be symmetrical. This means that the cardboard model can be used for cutting adequately accurate aluminium sheets for the upper and lower surfaces of both stabilizers. Photos: Lassi Karivalo |

|

Avainsanat: aviation history, restoration, Mil Mi-8P, HS-6 |

Tuesday Club activities are continuedTiistai 7.9.2021 - Tuesday Club member During the Covid-19 pandemic a small Tuesday Club team has been working on the VL Myrsky restoration project. Tuesday August 31st was a day of joy: finally, after a break of about 18 months, the other Tuesday Club activities could be continued. The main work item is the restoration of the Caudron C.59 trainer fighter, which is now in the restoration space of the Finnish Aviation Museum.

Photo: The photo archive of the Finnish Aviation Museum. However, there are still some restrictions and Covid-19 instructions from the Finnish Aviation Museum and the Tuesday Club is not able to start with full capacity. The number of workers in the restoration space is still limited and everybody working there is still wearing a mask.

In order to involve as many Tuesday Club members as possible in the Caudron restoration work, the team has been divided into two groups and works in the restoration space on Tuesdays and Wednesdays. This allows about twenty club members to work on the Caudron and on other projects, too. The Myrsky team continues to work on three days a week. The Caudron C.59 restoration is continued, now the holes on the lower wings are being repaired. About 18 months ago the lower port wing was patched and the patches were made for the starboard wing – then the Covid-19 pandemic interrupted the Tuesday Club activities. Now the patching of the starboard wing is in progress again.

The tail boom stabilizers of the Mil Mi-8P (HS-6) helicopter, which is on display on the yard of the Tuulonen shopping centre, have been brought to the Tuesday Club to be repaired. The stabilizers are partly covered with fabric and the fabric has decayed, because the helicopter has been on display outdoors since it was removed from service in 2007. The fabric covering will be renewed by the Tuesday Club team.

One of the most unique projects the Tuesday Club has come across is the preparation of a DC-3 instrument panel for a movie. A proper DC-3 instrument panel will not be made, but a reasonably plausible version anyway. Photos: Lassi Karivalo except if separately otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caudron C.59, CA-50, Mil Mi-8P, HS-6, DC-3 |