Myrsky's starboard wing half was turned for installing landing gearSunnuntai 13.6.2021 - Tuesday Club member The assembly of the landing gear has been started on the wing halves of the VL Myrsky II (MY-14), which is under restoration at the Tuesday Club. Thorough test assembly has already been done on the test wing which was prepared in the Myrsky-project. The test wing is a 2,5 metres long root piece of the wing, meant mainly for testing the landing gear installation. The landing gear will first be assembled on the starboard wing half.

The wing halves were painted with undercoat paint and after this work they remained on the worktable the upper side up. First the starboard wing had to be turned so that the landing gear well is facing upward, and the landing gear can be installed. The wing halves have already been turned around several times during the different work phases. For this purpose steel supports have been made for the wing tip and the wing root and they are used to support the wing when it is lifted and turned.

Two lower photos: move the cursor over photo and you will see more photos! The turning supports were fastened on the wing tip and the wing root. Then a lifting device was moved to both ends of the wing and the lifting devices were connected to the steel supports with cargo straps. Then the lifting devices were pumped, and the wing was lifted in the air, supporting it manually all the time. When the wing had been lifted high enough, the wing was tilted in order to turn it around. The wing was carefully manoeuvred onto one side by supporting it from the other side. When the wing had been turned, it was lowered back on the worktable and it was placed horizontally by supporting it at the ribs.

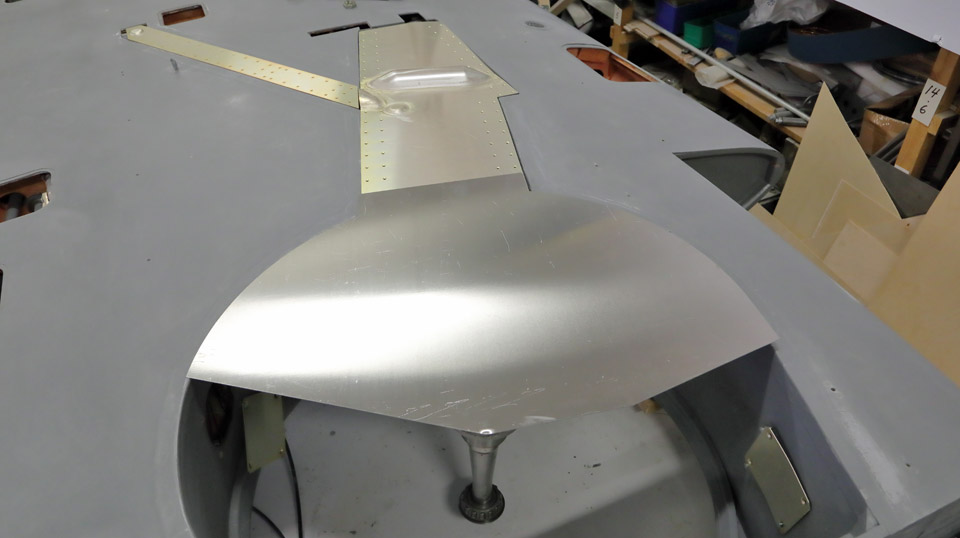

Photos: Jorma Laakkonen. Photo: Jorma Laakkonen. Now the landing gear well was facing upwards, and the landing gear assembly could be started, following the procedure developed when testing the gear on the test wing. The first preliminary test was to place the landing gear oleo strut in the well with its wheel hub and axle. At the same tame the wheel well doors were fitted into place. These include the diagonal support door, the oleo strut door, the wheel hub door and the opening door, which is fastened on the fuselage side edge of the wheel well. All parts seemed to settle nicely into their places.

Photo: Jorma Laakkonen. Now there is ahead the demanding work of fitting all the hinges and fastenings of the starboard landing gear into place so that the landing gear extends and retracts smoothly. The aluminium covers will also have to be assembled into place on the diagonal support, on the oleo strut and on the wheel hub. Another challenge is to fit into place the aluminium cover on the fuselage side of the wheel well and to make its opening and closing mechanism work as planned. This door is opened automatically by a spring lever when the landing gear is taken out. When the landing gear is retracted the wheel presses against a pin in the mechanism and closes the door. Photos: Lassi Karivalo except if otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |