Preparations for the MiG 21 BIS cockpit into a simulator at an endLauantai 15.4.2023 - Tiistaikerholainen Aviation Museum Society Finland received the cockpit section of the MiG-21BIS (MG-111) fighter in conjunction with the scrapping of the aircraft. The cockpit will be transformed into a MiG-21BIS cockpit simulator for the Finnish Aviation Museum. I’ve written about this in my earlier blogs. Before the simulator equipment can be installed, the cockpit and the equipment spaces in front and behind it had to be emptied of all the equipment, instruments, and wires.

This work has been going on at the Tuesday Club from the autumn. At times there were difficulties how to cut the bundles of wires to be dismantled, nearly as thick as wrists. At present the necessary dismantling and other work to transfer the cockpit into a cockpit simulator are more or less completed. The cockpit will be moved to the Middle Hall of the Finnish Aviation Museum at the end of April, for the simulator equipment to be installed. There it will have a permanent place as a simulator.

At least six removal boxes filled to overflowing have been dismantled from inside the cockpit and the equipment spaces in front and behind it. It is still unclear what to do with the dismantled things. There might be gadgets which could interest MiG-21BIS enthusiasts.

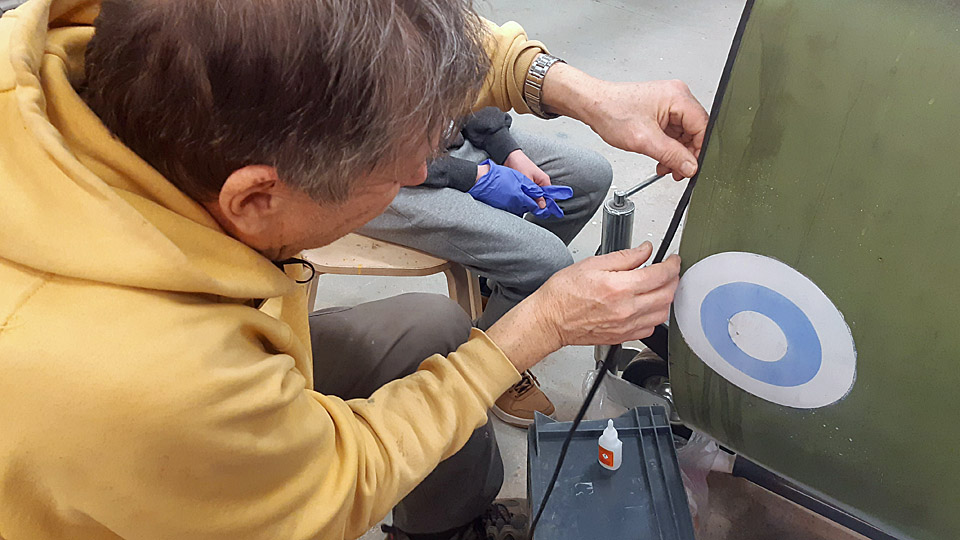

Photo by Juha Veijalainen. Apart from emptying, the cockpit frame has been prepared otherwise for the public use of the simulator. The apertures for the engine air ducts on both sides of the cockpit have been closed with plates of plexiglass, to prevent especially small children to crawl into them. Some sort of cover was also needed for the aperture for the nose gear well in the front wall of the cockpit. It was covered with a piece of furniture plywood, sawn into form and painted with greyish green paint. The tone of the paint was defined from the grey colour of the inside surfaces of the cockpit inspection hatches.

Photo by Osmo Väisänen. The fuselage edges were dangerously sharp after the cutter because the cockpit section was cut off the fuselage of MG-111. The sharp edges were ground and shielded by gluing protective tapes made of rubber on them. As glue we used strongly adhesive Gorilla Super Glue. The front and rear walls of the cockpit and the space for equipment in front were cleaned and painted neat with suitable greyish green Teknos Kirjo Aqua paint. The cockpit front and rear spaces will be covered with fairings. The seams between the fairings and the cockpit frame were covered with thick and derelict rubbery sealing mass. These masses were ground off with a band grinder.

The MG-111 cockpit windscreen and side glasses had become opaque and non-transparent. There was doubt whether they could be buffed and polished clear. So we bought from Motonet some conditioner for polishing the windscreens of motorboats. With the conditioner and a soft cloth disc the cockpit windscreen and glasses were buffed and polished to a fairly good condition. We’ll be buffing and polishing the cockpit canopy with the same method. This won’t be done until the cockpit has been transferred from the restoration shop to the Middle Hall. On the starboard side of the cockpit there was the subsonic pitot tube of the aircraft. It was rusty on the surface. We sanded the rust off and polished it till it shone like a mirror.

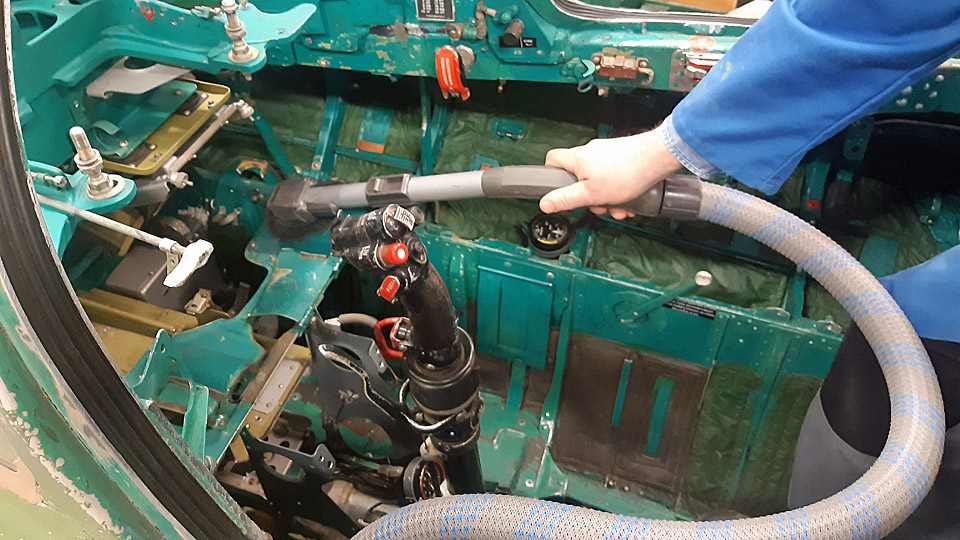

After having vacuum-cleaned the cockpit, now devoid of equipment and wires, it could be stated that the preparatory work of the Tuesday Club to transform the Mig 21 BIS MG-11 cockpit into a Mig 21 BIS cockpit simulator was concluded. Well, there’s still the bufffing and polishing of the opaque cockpit canopy… Photos by Lassi Karivalo except if otherwise mentioned. Translated by Matti Liuskallio |

|

Avainsanat: aviation history, restoration, MiG-21BIS, MG-111 |

Detaching the MiG-21BIS fighter's pilot seatTorstai 2.2.2023 - Tuesday Club member In conjunction with the scrapping of the Mig 21 BIS fighter, the cockpit section was received by the Aviation Museum Society – and now it has been prepared at the Tuesday club to become an MiG 21 BIS cockpit simulator. The external equipment of the cockpit have already been detached, but the dismantling of the cockpit interior gadgets and wiring to make way for the simulator mechanisms, is still under work.

Photo by Pentti Kuusisto The dismantling of the cockpit section interior equipment has been hindered by the pilot’s KM-1 ejection seat, which is still in place. To dislocate the seat we received from the Karelian Wing Guild a special tool and a bar, with which the seat locking could be freed and subsequently lift the seat out of the cockpit. A retired Mig 21 BIS ejection seat mechanic from the Karelian Wing Guild paid us a visit and gave us instructions how to detach the seat.

After the start of the Tuesday Club’s spring season we turned our attention to the seat. Armed with the instructions and tools we had received from the Karelian Wing Guild together with the MiG 21 BIS manual, which we fetched from the archives of the Finnish Aviation Museum, we started to detach the seat.

With the aid of the unlocking tool we managed to disconnect the locking under the seat. To lift the seat from its place, the metal bar used to unlock the seat was attached to it with cargo straps. Then the Museum forklift was driven by the cockpit, so that the forks raised to the upper position reached over the cockpit and the bar attached to the seat.

Photo by Juha Veijalainen. The bar was tied to the forks with straps, after which the seat could be hoisted out of the cockpit, hanging from the forks. It was a close shave whether the forks could be lifted high enough, because the restoration workshop ceiling beam was just above the cockpit and there was only centimetres of extra space. However, we managed to swing the seat over the cockpit side with a bit of manual help, and lowering the forks settled the seat onto a wooden pallet on the restoration workshop floor. Thus the MiG- cockpit was freed of the seat and we gained plenty of space to carry on with dismantling the wiring and gadgets to make way for the simulator equipment.

Photos by Juha Veijalainen. Because there was no further restoration or maintenance work planned for the seat at this stage, it was attached with straps to the pallet and taken to storage into the container at the Museum yard used for DC-3 (DO-5) parts. Translation by Matti Liuskallio. Photos by Antti Laukkanen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Tuesday Club, MiG-21BIS, MG-111 |

The spring season 2023 for the Tuesday Club got startedLauantai 21.1.2023 - Tuesday Club member After a well-earned Christmas break work continued on January 10th, 2023 from where it was left on going for the break.

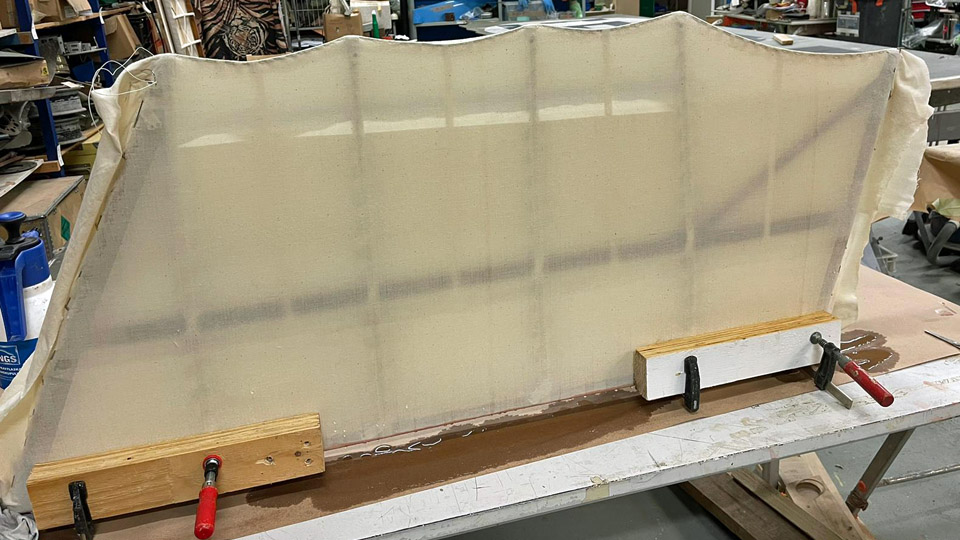

Photos by Reijo Siirtola The repair of the Caravelle III (DAF) nose radome damage was started by making an opening for the cover for the attachment bolt in the damage point, which was laminated over. An opening was sawn according to the measurements of the cover with a keyhole saw, after which a rabbet was laminated along the edges of the opening, against which the cover will be pressed and locked to the frame of the attachment bolt. Simultaneously the straightening of the damage to the nose pressure bulkhead outer circle was started. The crushed bulkhead circle has to be straightened in order to get the radome edge to be pressed tightly against the bulkhead circle and locked in place with three bolts.

Photo by Heikki Kaakinen By the beginning of the summer the starboard wingtip and the starboard horizontal stabilizer damages have to be repaired, so that everything will be ready when the Caravelle III (OH-LEA , ex SE-DAF) ) called “Bluebird” in Finnair colours will be transferred from the Pansio hall in Turku to close proximity of the Turku Airport terminal.

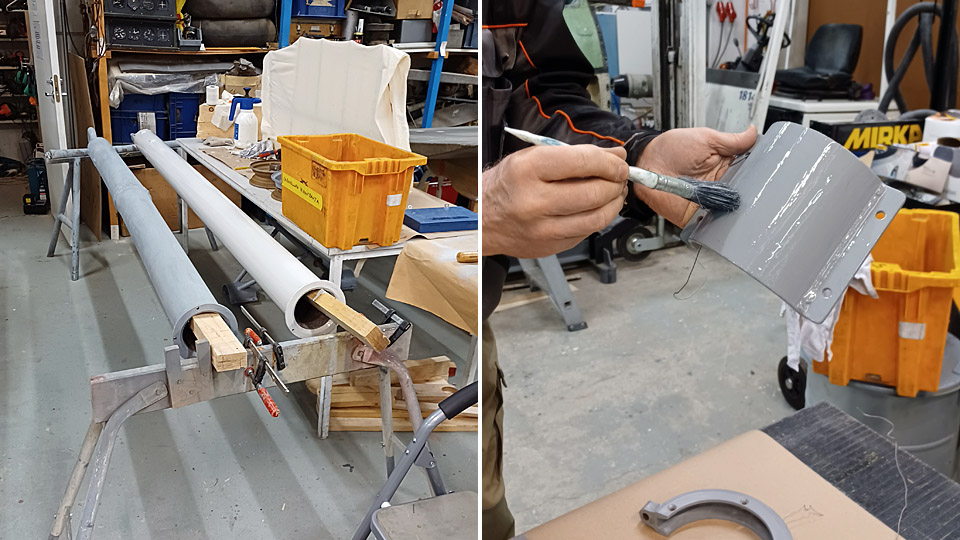

Photos by Juha Veijalainen The surface handling of the parts of the Caravelle towbar, which was brought along with the Caravelle III from Arlanda, is underway. The towbar used by SAS will be restored to the livery of the towbars used by Finnair. The sandblasted parts of the towbar are being painted with the grey Isotrol primer. The surface colour will be “Finnair blue”, apart from the towbar ends, which will be painted with yellow high visibility paint.

Photo by Antti Laukkanen

Photos by Juha Veijalainen

Photo by Osmo Väisänen We finally managed to dislocate the pilot’s seat from the cockpit of the MiG 21 BIS (MG-111), which will be transformed to a cockpit simulator. The dislocation was made possible by a dislocation bar, instructions and a manual received from the Guild of the Karelian Wing. Lots of original wiring still needs to be removed from the cockpit, before we can have access there to install the actual simulator equipment. The covering of the engine air intake duct openings in the cockpit rear and front bulkheads with plexiglass is underway.

Photo by Heikki Kaakinen Work continues with the Caudron C.50 (CA-50) aircraft. The re-covering of the fully restored port elevator with linen fabric was started and the unsatisfactorily tightened patches on lower wings were continued to be replaced with modern Oratex-material. The winter season barely allows any work on the interior of the DC-3 (DO-5) fuselage owned by Aviation Museum Society Finland. Work will continue with the warmer spring weather. Well, we have achieved something; the door between the cockpit and the cargo hold has received a new coat of paint. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, MY-14, VL Myrsky, Caudron C.59, CA-50, MiG-21BIS;MG-111 |

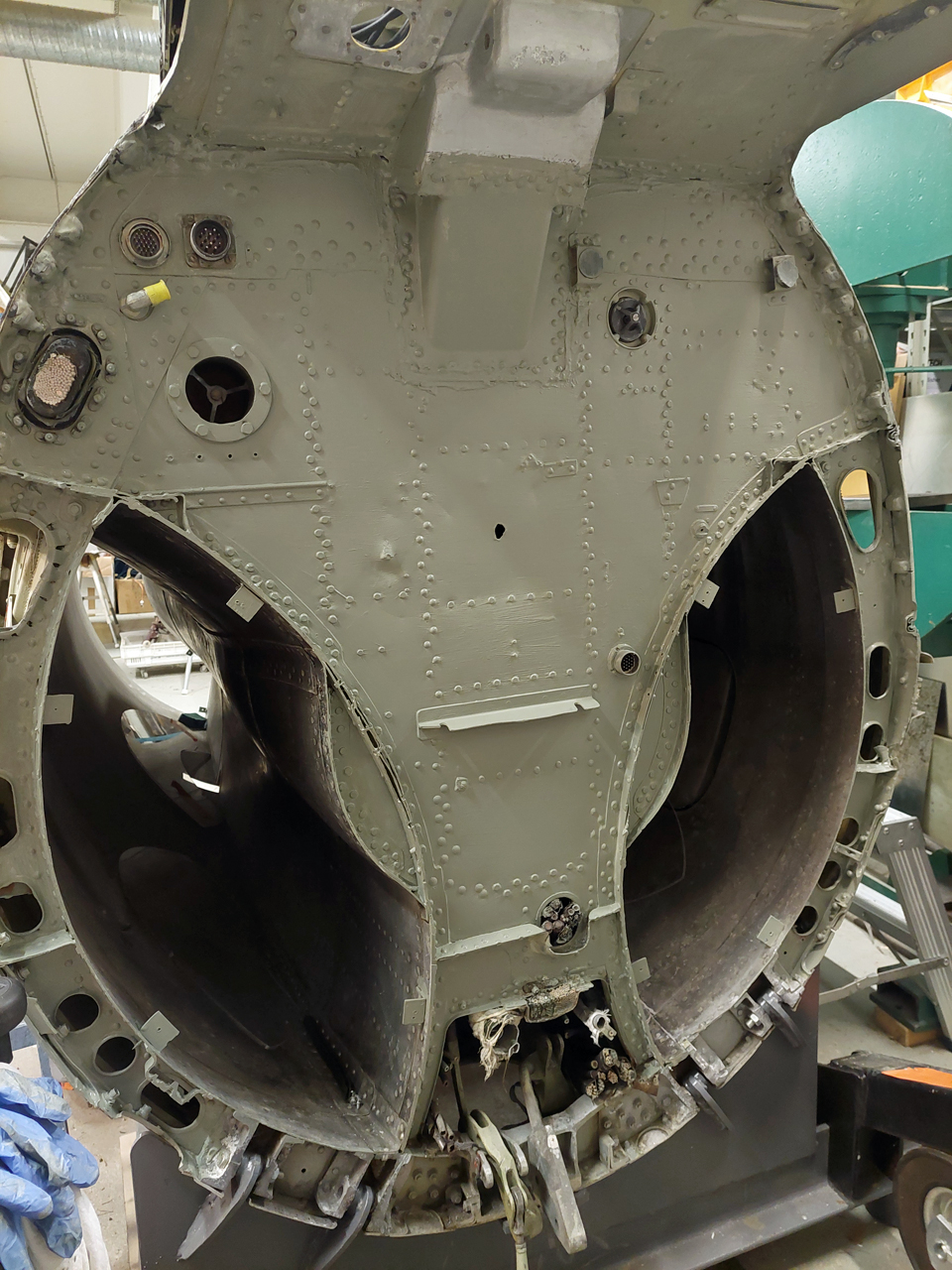

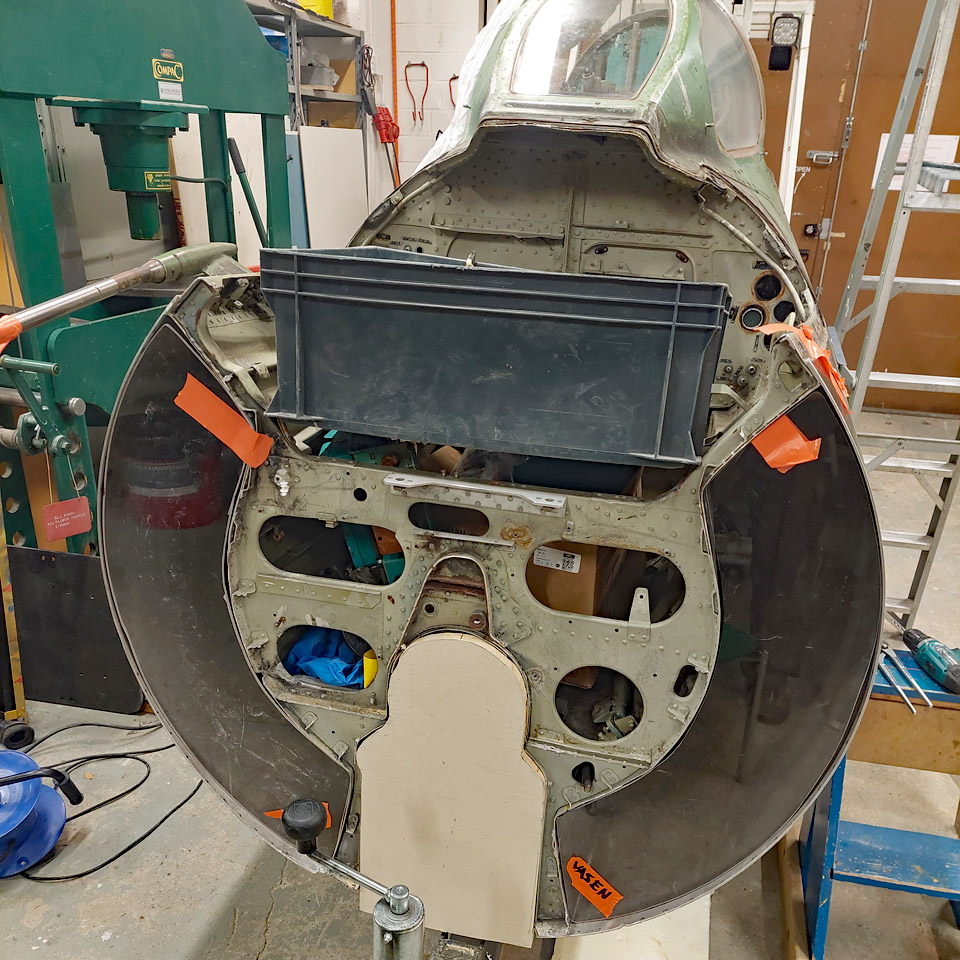

Washing the MiG-21BIS cockpit entity rear bulkhead and covering of the air ductsTorstai 22.12.2022 - Tuesday Club member Suomeksi Preparations to transform the cockpit entity of the MiG-21BIS (MG-111), owned by Aviation Museum Society Finland, into an experience simulator have been going on at the Tuesday Club during the whole autumn season. Clearing the cockpit interior of instruments and wires to make way for the simulator equipment is still going on. Along with that we have concentrated on the work with the external surfaces of the cockpit entity. Later the term simulator will be used instead of cockpit entity in this blog.

The simulator rear bulkhead has been cleared of all the wires and gadgets. After that the bulkhead was cleaned with Tikkurila Oy paint cleansing liquid, prior to the actual painting of the bulkhead. For the cleansing the simulator was pushed out of the Finnish Aviation Museum’s restoration workshop into the yard. Paint cleansing liquid was sprayed with spraying bottles onto the bulkhead and the surface was brushed clean. After that the cleansed surfaces were rinsed thoroughly with water using the museum restoration workshop’s fire hose.

The MiG-21BIS simulator rear bulkhead will be painted to the shade of the faded green exterior surface. This way it will visually match the simulator’s original faded green colour. The front bulkhead will be painted with the same colour. To obtain the colour we went to the Vantaa branch of Pintaväri, carrying one fairing with a faded surface. The shade of green was defined from the fairing (NCS S5010G5OY) and accordingly Teknos Ltd KIRJO paint was mixed for painting the rear and front bulkheads.

However, we decided to postpone the painting of the cleansed rear bulkhead until the air duct openings in the rear bulkhead had been covered. Closing the rear and front bulkhead air ducts is primarily a safety issue. The ducts are large enough for a museum visiting small child and also a bigger one to crawl inside the duct. In the simulator’s front bulkhead there’s also the opening of the nose wheel well.

We decided to cover the air ducts with sturdy transparent plexi glass plates. This way one can see inside the duct. The assembly of the plexi glass covers will be done so that the pieces aren’t easily detachable, so that the museum visitors wouldn’t be tempted to take them off, but in such a way that they could be easily removed if necessary. We started to make the plexi glass covers with the left air duct opening in the rear bulkhead. With this opening it can be tested how to cut, shape, and implant the plexiglass cover into the duct opening. Only after this plexiglass cover has been fitted into the air duct opening, will we start making the right air duct plexiglass lid.

In the Finnish Aviation Museum’s material container we found suitable 5 mm thick polycarbonate plexiglass. It can be easily sawed and shaped and is not prone to crack when worked on.

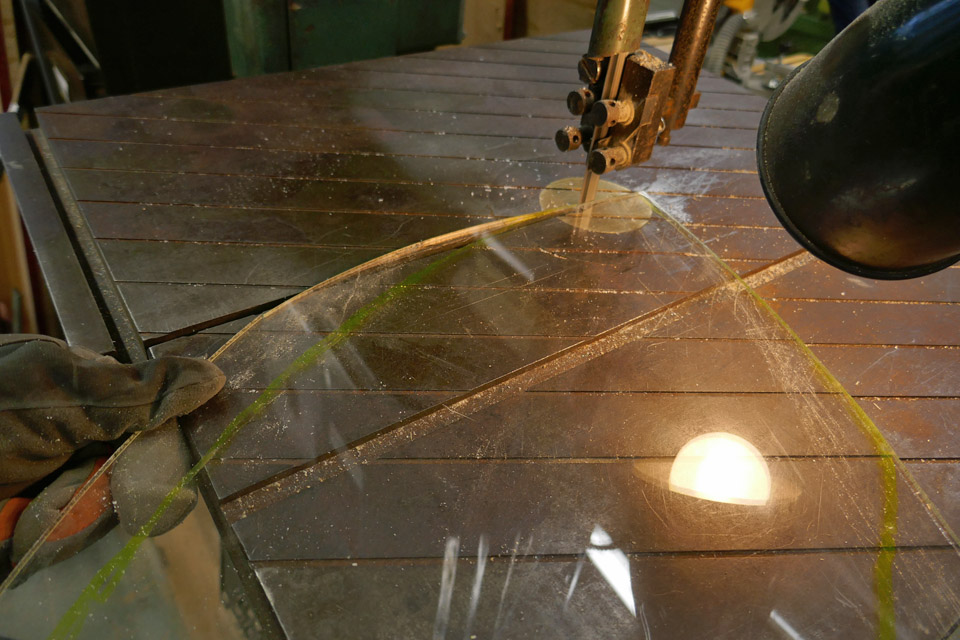

A piece of plexiglass was placed on the opening of the air duct and the shape of the duct was drawn on it. After that the plexiglass was sawed with a band saw along the drawing line to its preliminary shape. By fitting the piece of plexiglass on the opening it was moulded phase by phase to the shape of the air duct rim. The aim was to achieve a shape where the plexiglass sits suitably tightly inside the rim of the duct. Eventually the plexiglass was shaped so that it fitted into the duct opening.

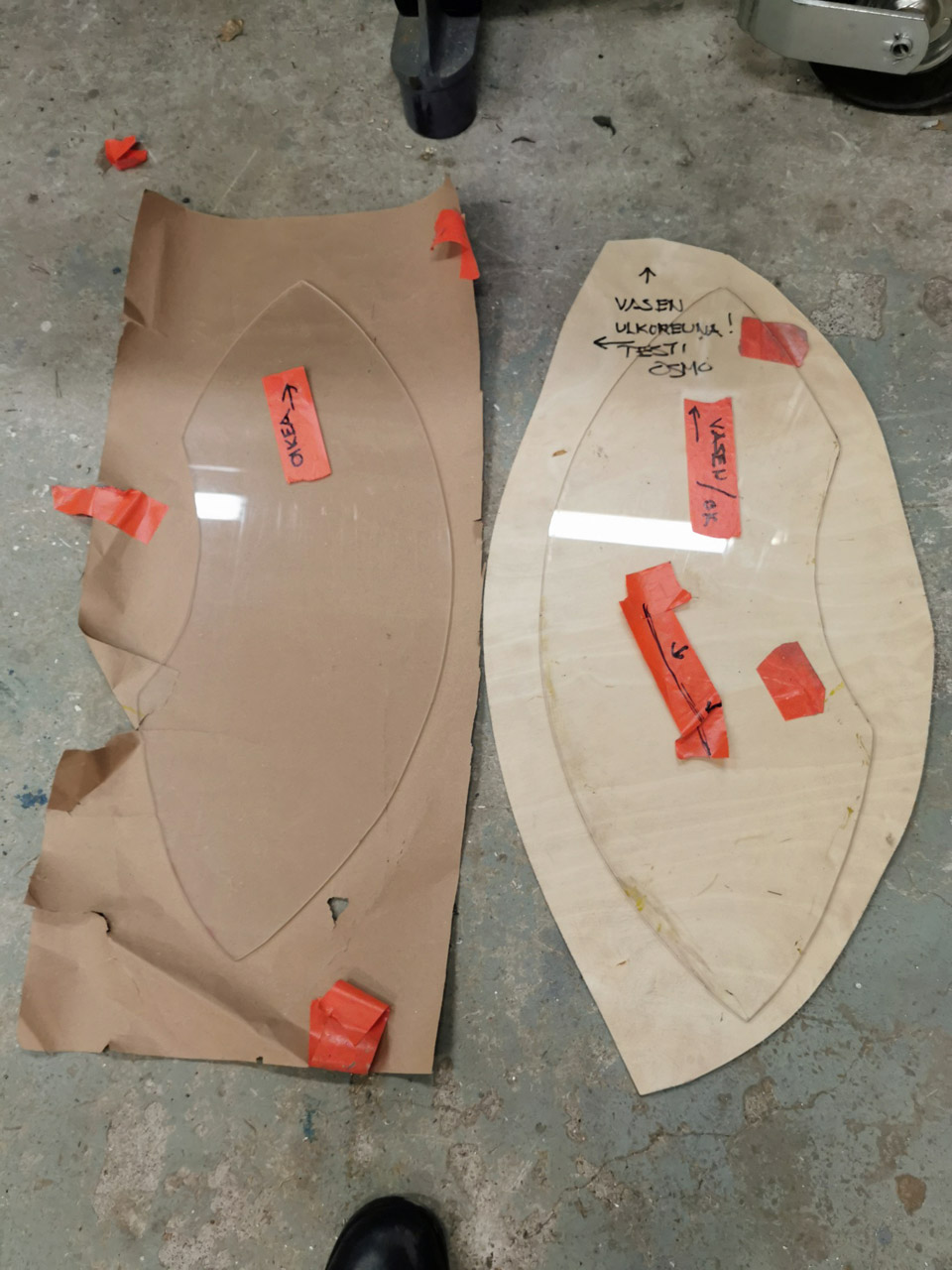

We used the left lid as a template for the right air duct, albeit as a mirror image. We assumed that the ducts would be identical. After having cut the plexiglass for the right air duct and tried it on the opening, we found out that the ducts weren’t fully identical – oh well, “big country, big tolerances”. After some additional shaping the plexiglass it fitted snugly to the inside rim of the duct. Now both the lids of the simulator rear bulkhead were ready to be fastened.

To fasten the plexiglass lids we decided to use L-shape holders. One end of the holder would be fastened to the plexiglass cover, the other to the rim of the air duct. For making the holders, strips of aluminium were cut off to suitable pieces and bent into L-shape. Fastening the plexiglass covers will take place after the Tuesday Club’s Christmas break.

Along with the rear bulkhead plexiglass covers, work went on with covering the front bulkhead landing gear well. Unlike the engine air intake ducts, the cover to the landing gear opening will be made out of laminated wood. First we made a template the shape of the landing gear opening out of easily workable insulation board. According the insulation board template, the cover of the landing gear opening was sawed out of 15 mm thick laminated wood. The shaping of the cover to its final form and fastening it into place is postponed to the Tuesday Club’s spring season. |

|

Avainsanat: aviation history, restoration, Tuesday Club, MiG-21BIS, MG-111 |

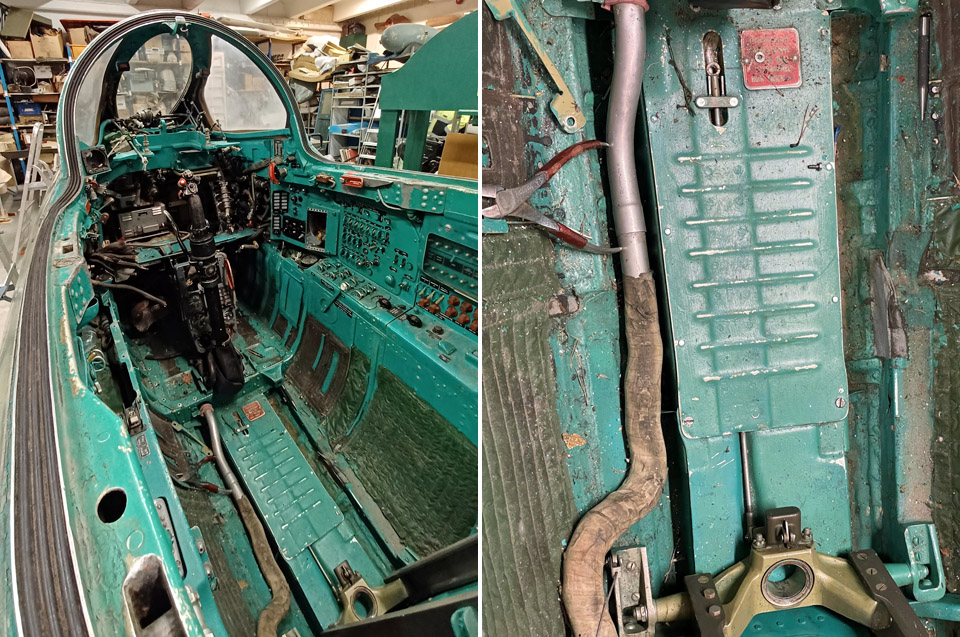

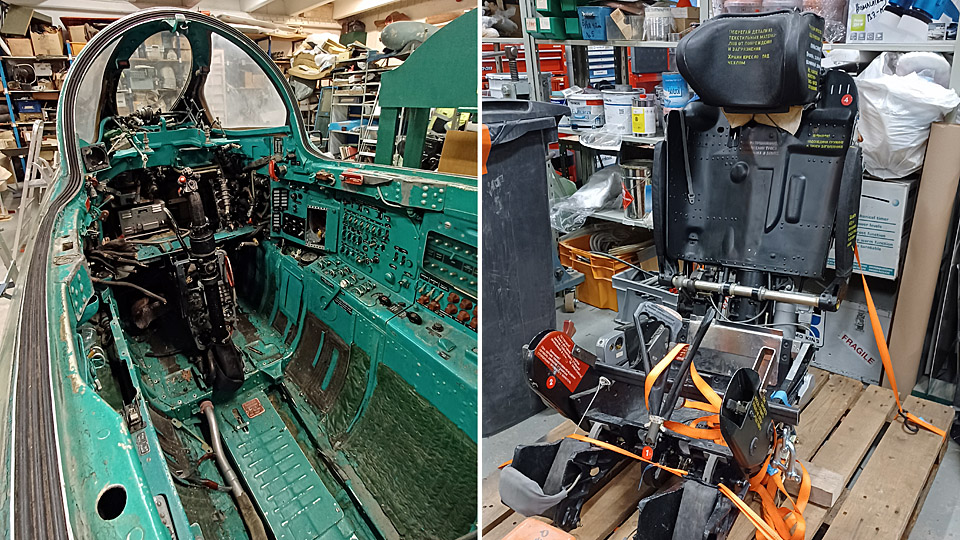

Dismantling the MG-111 cockpit interior for the simulatorMaanantai 5.12.2022 - Tuesday Club member Work on the MiG-21BIS MG-111 cockpit to transform it into an experience simulator continues at the Tuesday Club. When the MG-111 was scrapped, Aviation Museum Society Finland received a part of the fuselage, containing the cockpit, to be modified to an experience simulator. To achieve that, most of the equipment of the cockpit entity will be dismantled. In their place the simulator equipment will be installed, but part of the original equipment and parts will also be reinstalled.

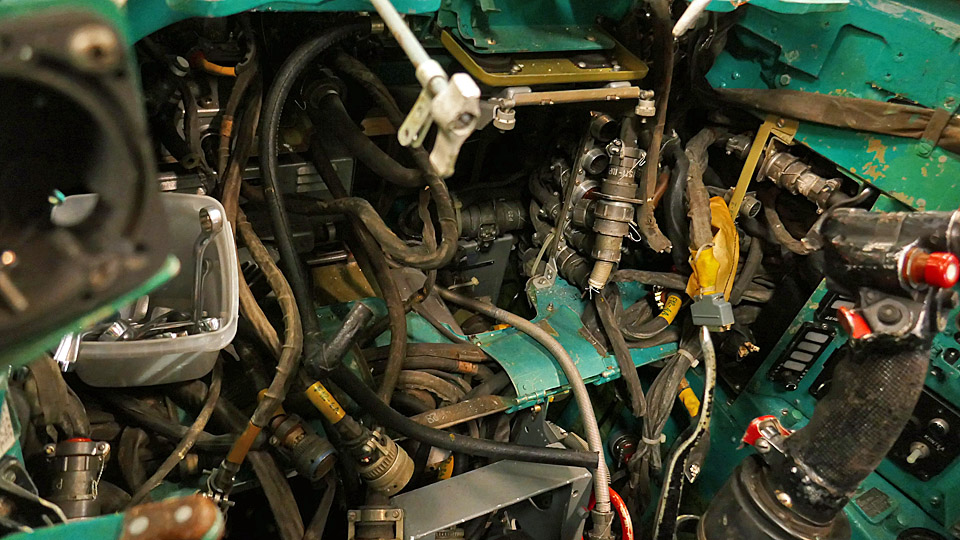

Most of the wiring and equipment from the space in front of the cockpit, as well as the wiring from the bulkhead behind the cockpit, were already dismantled at the yard of the Aviation Museum. After this the cockpit part was taken to the restoration workshop of the Aviation Museum, to dismantle the equipment and wiring within the cockpit.

First the space in front of the cockpit and the rear bulkhead were stripped off the last wires and equipment racks and holders there. So both spaces are now empty. The empty front space will at its time house the simulator equipment of the MiG-21BIS cockpit simulator. The rear bulkhead will be tidied and painted and the large openings of the engine air intake channels that are visible there will be covered with plexiglass.

Photo: Juha Veijalainen. For emptying the cockpit of its equipment, we wanted to detach the pilot’s seat because removing the seat would provide space for working in the cockpit, both during the removing the equipment and installing the simulator equipment. Before we set to removing the seat, we detached the cockpit canopy.

Photo: Ari Aho. To remove the seat, we received expert guidance and the necessary lifting lever from the former MiG-21BIS mechanics at Rissala. Detaching the seat didn’t, however, succeed because we couldn’t find the release catch under the MG-111 seat, where it normally is. It is possible that the release catch wasn’t reinstalled when the seat was removed when the MG-111 was struck off charge and reinstalled after the detonation charges belonging to the ejection seat had been removed. Well, we’ll try again to remove the seat in December, when we’ll hopefully get a mechanic from Rissala to come and visit and ponder about the thing with us.

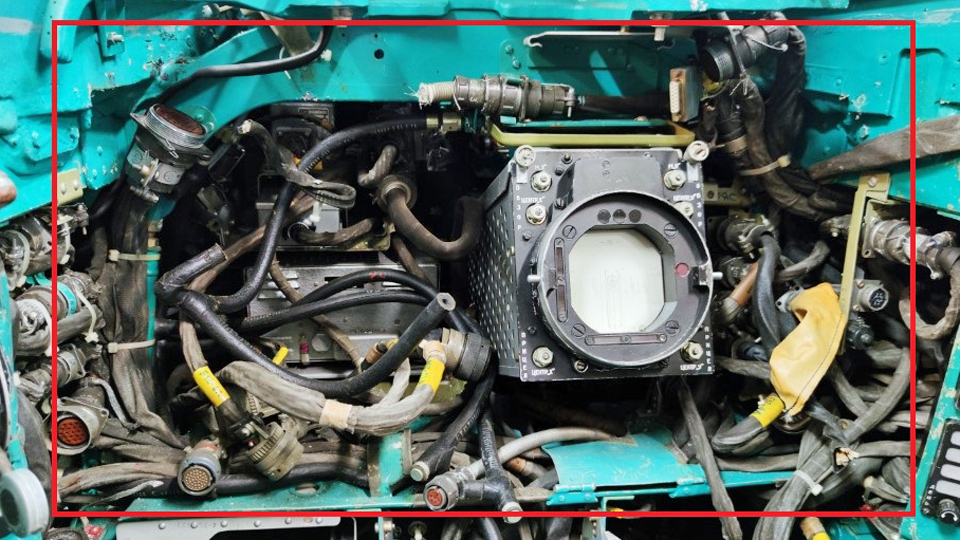

Photo: Juha Klemettinen. Although we couldn’t detach the pilot’s seat, we started to dismantle the interior of the cockpit according to Juha Klemettinen’s advice to transform the cockpit of MiG-21BIS MG-111 into a simulator. Juha removed the instrument panels and other switchboards himself. Our task was to dismantle, as advised by Juha, the space behind the instrument panel of the radar screen and the numerous wires criss-crossing there. How on earth could there be so much wiring!!

We started the work on the cockpit first by removing the radar and then turning our attention to the wires. It wasn’t so much about single wires, but bunches of wires inside a skin. Some of them could be disconnected from their connectors and removed. Disconnecting the wires from their connectors was awkward, because the connectors were either hidden on unobtainable. It came to mind that our Russian colleagues hadn’t paid a thought to easing the work of mechanics when positioning the wires.

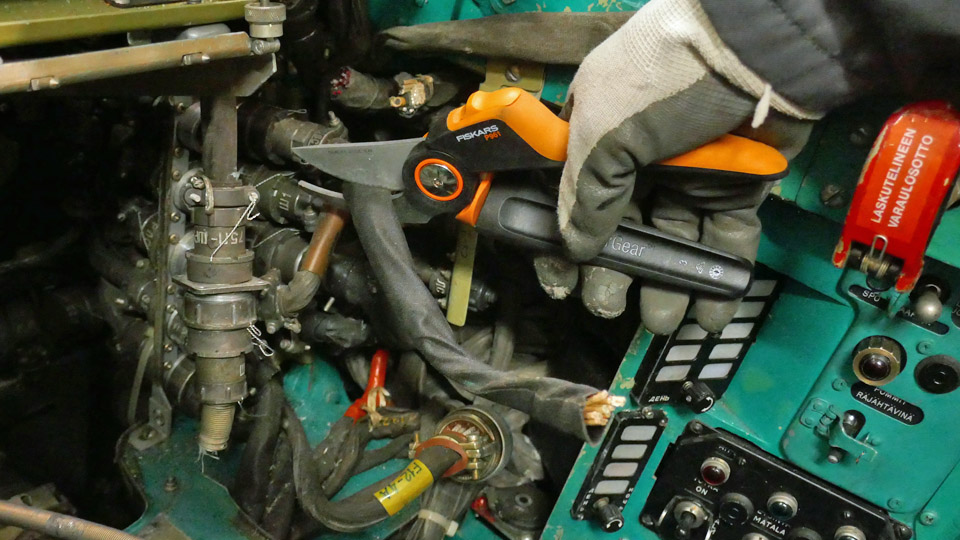

At the end there was no other option left but to cut the wires. Juha gave us permission to do that. Cutting the thick wires was no mean feat, because the thick bundles containing many wires were very tough nuts to cut.

Someone had the bright idea to acquire a pair of Fiskars garden secateurs (branch cutters) to cut the thick bundles of wire. If the Fiskars secateurs cut 20-30 mm thick branches easily, they should cut through the Russian wires. So we bought a pair of Fiskars branch cutters and they worked very well in cutting the wire bundles. The box containing cut off wires began to fill with wires of various length removed from the cockpit. We still have our work cut out for us before the space behind the instrument panel has been completely emptied.

Simultaneously, as we worked inside the cockpit, we dismantled the multi-pin connecting plugs that ran through the bulkhead between the cockpit and the space in front of it. The shackles that fastened the plugs to the bulkhead could be turned open. After that the plugs were pushed through the bulkhead, to the cockpit, to be drawn out from there. It wasn’t possible to push them into the cockpit very much, because the thick wires didn’t yield. It will probably be possible to remove the plugs with their wires, after a sufficient amount of wires have been removed from the cockpit. In good time the wires from the simulator mechanism will be drawn through the openings in the bulkhead between the cockpit and the space in front of it, where the simulator equipment will be installed. Photos: Lassi Karivalo except if otherwise separately mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, MiG-21BIS, MG-111 |

MiG-21BIS MG-111 cockpit is modified into experience simulatorSunnuntai 9.10.2022 - Tuesday Club member The MG-111 was the first MiG-21BIS fighter which was taken into use by the Finnish Air Force in 1978. This individual differed in certain characteristics from the BISes which the Air Force later received. In the first photograph the MG-111 is at the Oulunsalo shooting camp in June 1990. Notice the two little red Draken silhouettes on its vertical stabilizer, symbolizing the air victories over Drakens at the shooting exercise before the shooting camp.

Photo: Perttu Karivalo The MG-111 flew its last flight in 1993. In 1994 the aircraft was moved to the Finnish Aviation Museum to be stored. The last years the MG-111 stood outside, and in 2016 it was eventually cut to pieces as “canning material” on the museum yard. During the cutting process it was observed that the MG-111 was still in quite good condition. It is a pity that Finland’s first MiG-21BIS got an end like this.

However, not everything ended up as raw material for cans. The fuselage was cut in front and behind the cockpit and the cockpit part was preserved, the plan being that the cockpit is modified into a MiG-2BIS experience simulator. Aviation Museum Society Finland owns the cockpit and its modification work into an experience simulator has started.

Modifying the cockpit into a simulator means that the equipment and wires outside the cockpit and also partly inside it will have to be dismantled. The dismantling is necessary because space is needed for the simulator hardware and for its assembly.

The task for the Tuesday Club was to dismantle wires and equipment in the fuselage, in front of the cockpit and behind it. The dismantling began on May 24th. The work progressed well but it had to be interrupted for the summer break. The dismantling was continued on August 30th when Tuesday Club started its autumn season.

Emptying the equipment compartment in front of the cockpit of all the clobber was a time-consuming job. In a way this was easy too, because the order had been to disassemble and dismantle everything in the best possible way, without a second thought. This is why cutters, and even a hacksaw were used, in addition to the various kinds of screwdrivers and wrenches.

Some work was also needed when the various parts and wires were unfastened from the wall behind the cockpit and from the compartments behind the panels on the sides of the fuselage. Soon there were several boxes filled with disassembled clobber. The cut edges of the fuselage behind the cockpit were dangerously sharp. The edges were filed smooth to avoid injuries.

When the equipment and wires outside the cockpit had been disassembled, the cockpit part was towed with a forklift to be washed outside the Finnish Aviation Museum’s restoration workshop. Before using the pressure washer, the feed-through holes to the cockpit were plugged to keep the water outside the cockpit. The wash of the cockpit section was finished using brushes and cloths.

Photos: Antti Laukkanen. Now the cockpit section is waiting to be moved into the Finnish Aviation Museum. There the work will be continued by unfastening the instrument panels and the pilot’s seat, among others. When the simulator equipment is eventually assembled, the unfastened cockpit panels and the pilot’s seat will be returned into their places. Photos: Lassi Karivalo except separately otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, MiG-21BIS, MG-111 |