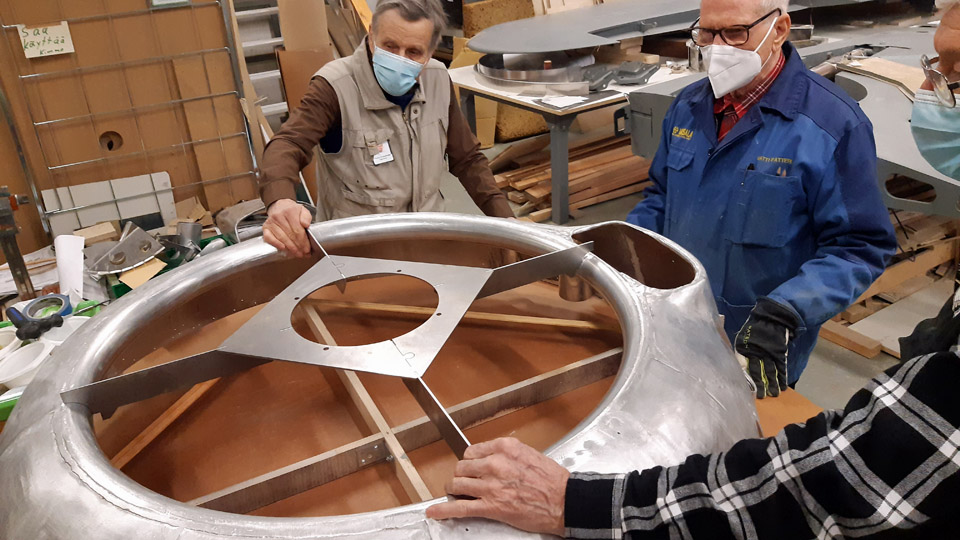

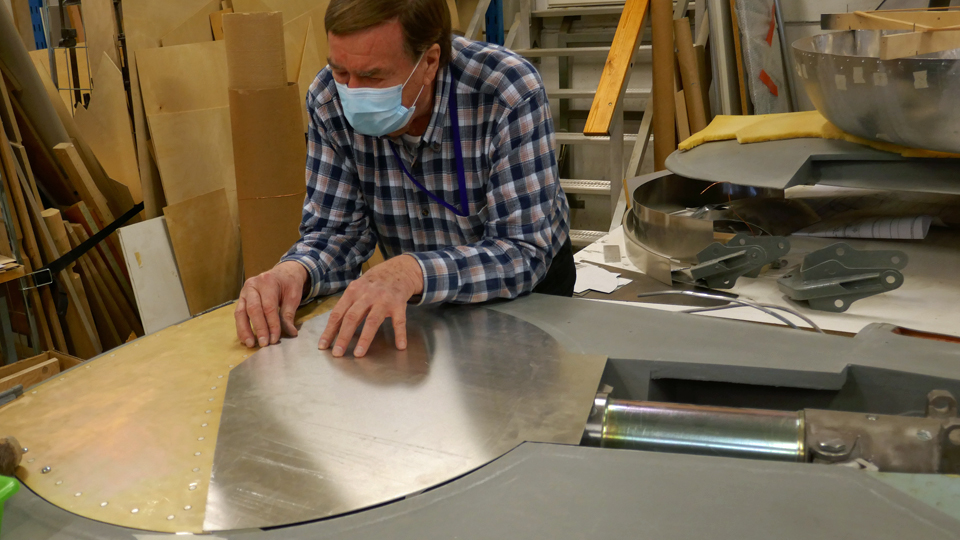

Tuesday Club started its spring season with full capacityTiistai 1.3.2022 - Tuesday Club member Suomeksi The Tuesday Club was not able to start its spring season in January because the amount of people allowed to work in the restoration workshop of the Finnish Aviation Museum was still limited due to the Covid-19 pandemic. Only the restoration work on the Myrsky MY-14 could be continued in January. Only half a dozen Tuesday Club members could work at a time, wearing masks. In the beginning of this year the Myrsky project has concentrated on the NACA-ring and the port wing landing gear doors, as well as finishing the Myrsky demo-wing before the Myrsky restoration exhibition will be opened.

Along with the Myrsky restoration work, a couple of Tuesday Club members have been working to finish the painting of the Mil Mi-8P (HS-6) helicopter tail boom stabilizers and to take the large parts of the Super Caravelle towbar to be sandblasted. The tyres of two 1920s aircraft wheels have also been dismantled so that the wheels can be repaired. These wheels have been received from the Finnish Air Force Museum to be assembled on the Caudron C.50 (CA-50) aircraft.

As the national Covid-19 restrictions have been lifted due to the decreased health risks caused by the pandemic, it was agreed with the Finnish Aviation Museum that the number of people working in the restoration workshop can be increased. This enables us to launch other Tuesday Club activities in addition to the Myrsky work. On February 23rd we continued from where we stopped before Christmas, particularly with the Caudron C.59 conservation and the Super Caravelle towbar restoration. We still work in two groups of 10 Club members, one group on Tuesdays and the other on Wednesdays. The Myrsky team, with less than 10 members, is working on Tuesdays, Wednesdays and Thursdays.

The coming weeks will be spent in cleaning the parts which were dismantled from the Caudron’s fuselage, and after that the parts will be painted. Two landing gear wheels were received from the Finnish Air Force Museum for the Caudron. The wheels and spokes are cleaned from dirt, grease and rust. Mechanical and chemical methods are applied.

The Caravelle towbar has been dismantled and all dismantled parts have been cleaned of rust, either with phosphoric acid or by sandblasting, and the painting work can be started. Before painting, the sandblasted parts were washed to remove the sand dust, which remained on the surface. Then the parts were carefully dried, using compressed air. Some parts have already been painted with clear Isotrol varnish which will prevent rust. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, Caudron C.59, CA-50, Mil Mi-8P, HS-6, Super Caravelle |

Lower side of Mi-8?s port side tail boom stabilizer has been coveredSunnuntai 17.10.2021 - Tuesday Club member The covering of the Mi-8P helicopter’s tail boom stabilizers is on the way at the Tuesday Club. The helicopter with the identification HS-6 was used by the Finnish Air Force and Army during 1978-2007. The HS-6 would have ended up being scrapped if a place hadn’t been found for it at the Tuulonen shopping centre. The tail boom stabilizers were originally covered with aluminium sheet on the leading-edge side of the spar. On the trailing-edge side the stabilizers are fabric-covered. The HS-6 has been stored outdoors for almost fifteen years and the fabric covering on the tail boom stabilizers has decayed and needs to be replaced. The rotten fabrics have been removed at the Tuesday Club and the work on the new covering has been started. The new covering will be made of aluminium sheet, not fabric, as the leading edge already has. The reason for this is that the HS-6 will be on display outdoors also in the future, so using a more weather-resistant material for covering the stabilizers is preferred. This is a good reason, especially as the aircraft is not a museum item. When repairing and restoring a museum item, the aim is to use original materials and work methods. The covering material is 0.30 mm thick, used offset plates, made of aluminium. They are excellent for this purpose, with good workability. They are printing plates, so they already have an adhesive surface for the future painting work.

The first surface to be covered with the sheet metal was the tail boom’s port side stabilizer’s lower surface. First the root end of the stabilizer was covered. Its fabric covering had been removed and a piece matching the shape of the fabric was cut from the aluminium sheet. The cutting was done so that the piece of aluminium was about 10 mm larger at its edges than the piece of fabric. This was necessary because the edges of the sheet will be bent over the butt rib’s lower and upper edges. Eventually the bent edges will be covered by the metal sheets, which cover the upper and lower surfaces of the stabilizer and are riveted on the butt rib.

A mould was made from plywood for bending the root sheet edges. The mould is triangular and matches the size of the removed piece of fabric. After the edges of the sheet had been bent, the finalizing work was done with a file. When the root sheet was ready, it was riveted on the butt rib with a couple of flathead rivets.

The next step was to make a cardboard model of the stabilizer’s surface which was to be covered. The Tuesday Club team realized that the aluminium offset plates were not large enough for cutting one single sheet which would cover the whole surface which needed to be covered. The upper and lower side of the stabilizer will both have to be covered with two aluminium sheets, which are joined together with a butt joint. The joint will be on top of the rib located in the middle of the stabilizer. An aluminium plate 5 cm wide was riveted on top of this rib to form a base for the butt joint.

The cardboard model was used when the new covering sheet for the stabilizer’s root section was drawn on the aluminium sheet. The covering sheet for the stabilizer’s tip section was drawn on another aluminium sheet. Then the sheets were cut and fitted on the stabilizer. It was noticed that both covering sheets were slightly too wide and a strip a couple of millimetres wide had to be cut from their trailing edge. Now the sheet edges were exactly on the level of the trailing edge.

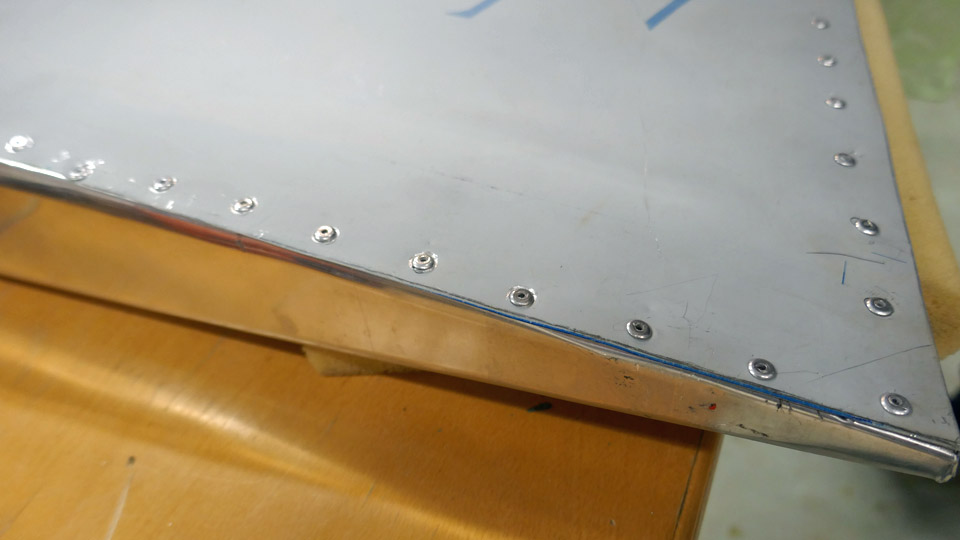

The covering sheets were riveted on the stabilizer and this work was started on the root section. The covering sheet was placed on the stabilizer ribs and locating holes were drilled into its corners. Locating pins were placed in the holes to keep the sheet in place during the riveting work. The following phase of work was to mark the places for the rivets on each rib and on the trailing edge batten. For the marking a perforated galvanised steel fixing strap was used (i.e. a strap for supporting ventilation ducts). This is a good method for marking the rivet holes nicely at even distances. Then a metal point and a hammer were used for making a starting point for drilling at each rivet location. Then the rivet holes were drilled.

Pop rivets were used when riveting the aluminium sheets into place. The pop rivet was pushed into the drilled hole and squeezed tight using a pop rivet hand tool. When the aluminium sheet on the tail boom port side stabilizer’s lower side root section had been riveted, the same procedure was used when riveting the sheet on the tip section. The lower side of the tail boom port stabilizer has now been covered and the next phase will be the covering of the stabilizer’s upper side. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, Mil Mi-8P, HS-6 |

Tail boom stabilizers of Mil Mi-8P (HS-6) are being coveredTiistai 14.9.2021 - Tuesday Club member The tail boom stabilizers of the Mil Mi-8P (HS-6) helicopter, which is on display on the yard of the Tuulonen shopping centre, have been brought to the Tuesday Club to be repaired. The HS-6 helicopter was on display outside the Finnish Aviation Museum for a long time then, some years ago, it was moved to Vesivehmaa, to stand in front of the Päijät-Häme aviation museum hall. The helicopter was approaching scrapping, but fortunately a place was found for it at the Tuulonen shopping centre. The shopping centre has quite a remarkable collection of different aircraft on display: Saab 35FS Draken (DK-247) and MiG 21 BIS (MG-124) fighter jets on the yard and Douglas DC-2 (DO-1) “Hanssin Jukka” and Focke Wulf Fw 44 Stieglitz (SZ-18) indoors. The shopping centre can already be called a small aviation museum.

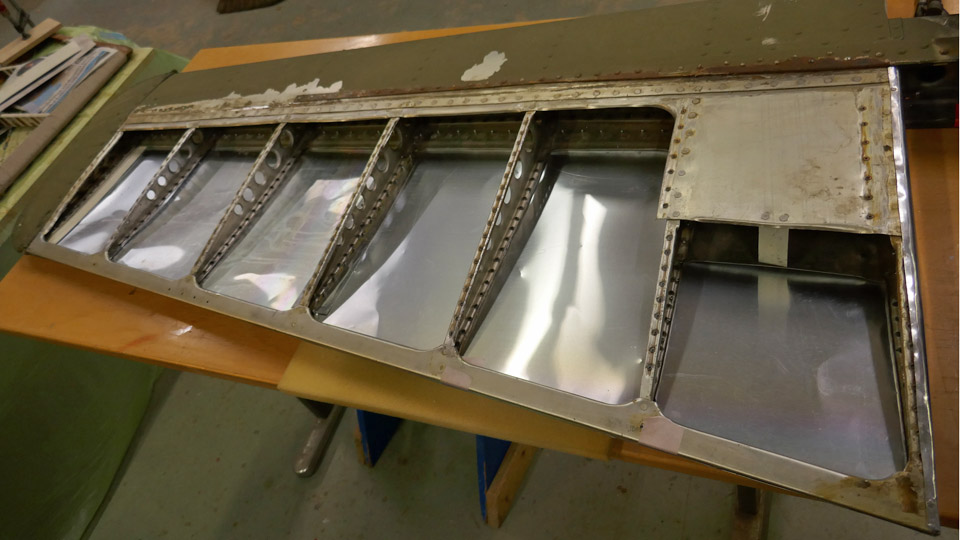

The tail boom stabilizers of HS-6 consist of an aluminium frame and are half covered with fabric. The fabric covers the area between the stabilizer’s trailing edge and the spar, about half of the stabilizer’s area. The fabric areas have been badly damaged because the HS-6 has been standing outside since the Defence Forces removed it from service in 2007.

The task of the Tuesday Club team is to remove the decayed fabric covering and to replace it with a thin sheet of aluminium. The Mi-8 can’t be considered an actual museal artefact anymore and the fabric covering would rot again as the helicopter is permanently on display outside the Tuulonen shopping centre.

The work was started by removing the rotten fabric from the stabilizer. The aluminium ribs and other surfaces, which had now been revealed, were cleaned. The stiffening steel batten, running parallel to the stabilizer’s spar, had rusted and it was cleaned. The paint on the stabilizer’s aluminium surface had partly flaked off. The flaked paint was removed, and the surface was cleaned to clear aluminium.

A cardboard model was made of the stabilizer’s surface which will be covered with a sheet of aluminium. The covering sheets will be cut from aluminium plate according to the cardboard model and riveted on the upper and lower side of the stabilizer. The cardboard model was fitted on the upper and lower surfaces of both stabilizers. It turned out that the Russian helicopter engineers has designed the stabilizers to be symmetrical. This means that the cardboard model can be used for cutting adequately accurate aluminium sheets for the upper and lower surfaces of both stabilizers. Photos: Lassi Karivalo |

|

Avainsanat: aviation history, restoration, Mil Mi-8P, HS-6 |

Tuesday Club activities are continuedTiistai 7.9.2021 - Tuesday Club member During the Covid-19 pandemic a small Tuesday Club team has been working on the VL Myrsky restoration project. Tuesday August 31st was a day of joy: finally, after a break of about 18 months, the other Tuesday Club activities could be continued. The main work item is the restoration of the Caudron C.59 trainer fighter, which is now in the restoration space of the Finnish Aviation Museum.

Photo: The photo archive of the Finnish Aviation Museum. However, there are still some restrictions and Covid-19 instructions from the Finnish Aviation Museum and the Tuesday Club is not able to start with full capacity. The number of workers in the restoration space is still limited and everybody working there is still wearing a mask.

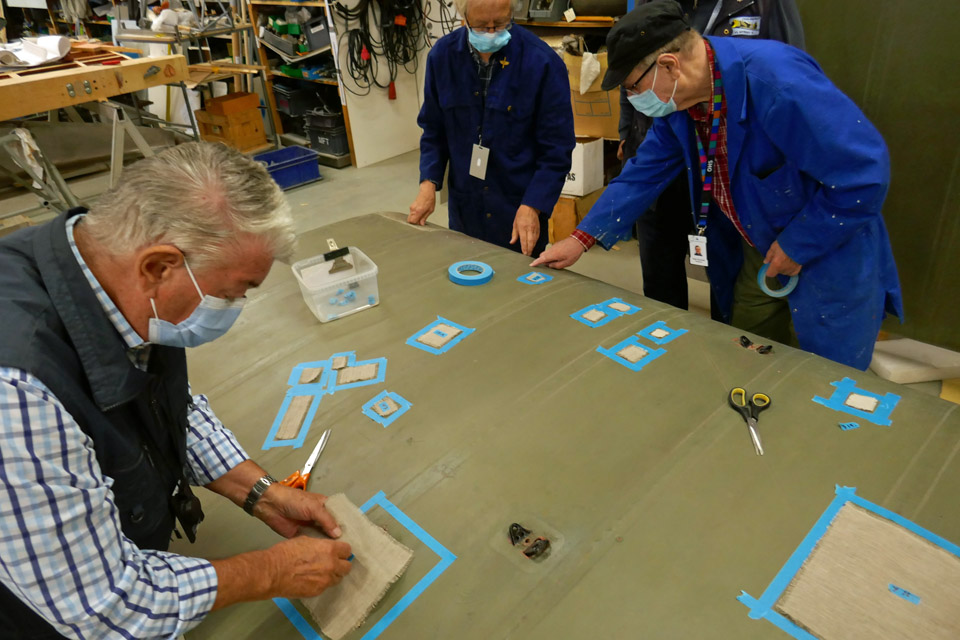

In order to involve as many Tuesday Club members as possible in the Caudron restoration work, the team has been divided into two groups and works in the restoration space on Tuesdays and Wednesdays. This allows about twenty club members to work on the Caudron and on other projects, too. The Myrsky team continues to work on three days a week. The Caudron C.59 restoration is continued, now the holes on the lower wings are being repaired. About 18 months ago the lower port wing was patched and the patches were made for the starboard wing – then the Covid-19 pandemic interrupted the Tuesday Club activities. Now the patching of the starboard wing is in progress again.

The tail boom stabilizers of the Mil Mi-8P (HS-6) helicopter, which is on display on the yard of the Tuulonen shopping centre, have been brought to the Tuesday Club to be repaired. The stabilizers are partly covered with fabric and the fabric has decayed, because the helicopter has been on display outdoors since it was removed from service in 2007. The fabric covering will be renewed by the Tuesday Club team.

One of the most unique projects the Tuesday Club has come across is the preparation of a DC-3 instrument panel for a movie. A proper DC-3 instrument panel will not be made, but a reasonably plausible version anyway. Photos: Lassi Karivalo except if separately otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caudron C.59, CA-50, Mil Mi-8P, HS-6, DC-3 |