Covering the DO-5 tail openingsSunnuntai 12.11.2023 - Tuesday Club member The rain covers for Aviation Museum Society owned Douglas C-47 (DO-5) tail openings were finished in October. The tail has been without vertical and horizontal stabilizers and the tail cone for donkey’s years. Due to that rainwater and snow have penetrated into the fuselage. The building of the covers out of aluminium plate has been reported already earlier in a Tuesday Club blog.

A strike force of Tuesday Club members set off from the Finnish Aviation Museum to Turku Airport to fasten the covers to the DO-5 tail at the end of October. The covers and other equipment came along in a trailer. The DO-5 fuselage is on display beside the Caravelle III, restored as Finnair’s “Bluebird” (OH-LEA) in the vicinity of Turku Airport Passenger Terminal. After arriving at the Airport we got the covers made of aluminium plate and other necessary tools and a ladder out of the trailer got on with the job.

We divided into suitable work groups. One of them fastened the ILS look-alike antenna and the thermometer probe we had brought with us for the DO-5. These were fastened in their original places on the undersurface of the nose cone.

Another working duo started to fasten the covers for the openings of the right- and the left-hand side horizontal stabilizers. The third pair concentrated on fitting the covering shields for the tail cone. The fourth pair was tasked to fit in place the covering case we had built to cover the vertical stabilizer fastening point and to fasten in place the shaped hood, made of thin aluminium sheet, to protect the front end of the case and the fixed fuselage fin at their seam.

The fitting advanced rapidly, because the covers made at the Museum’s restoration workshop according to blueprints, settled in place as we had planned. The horizontal stabilizers’ covers were fastened to the edge of the opening at their top edge with stainless steel screws. Holes were drilled through the covers into the fuselage for the screws. After this the cover was fastened to the fuselage also from its lower edge. We used stainless steel screws deliberately, so that they won’t start leaking rusty streaks along the fuselage surface as time goes by. An extra bit had to be cut off from the rear end hem of the left-hand horizontal stabilizer’s cover, to get the cover to press tightly along the edges of the horizontal stabilizer’s opening.

When thinking about the way to fasten the covers, it occurred to us that we could have utilized the existing holes in the fuselage. However, it would have been extremely difficult to match exactly the fastening holes in the cover with the holes of the horizontal stabilizer fastening screws. That’s why we ended up with the above-mentioned method, which produced a few extra holes in the fuselage. If the DO-5 were to be made airworthy, the method would have certainly been different.

The tail without the tail cone was protected with two separate aluminium covers. We had to shape the edges of the upper cover a bit before it clicked into place and was fastened with a few screws. We also had to shape with a hand drill the curved opening in the lower cover, so that we could get the protuberant strip in the fuselage to “pop out” through the opening and press the cover tightly against the end of the fuselage. This cover, too, was fastened with a few stainless-steel screws. The edges of the lower cover shielding the rear fuselage were bent at 10 cm width to an angle of 90 degrees. This way the sides of the cover could be pushed under the covering sheet of the horizontal stabilizer’s rear end and linked to it with a couple of screws.

The vertical stabilizer’s fastening point wasn’t covered with just an aluminium cover, like the other openings, but a nearly three metres long covering case was made for it. The seams of the aluminium sheets were covered with duct tape, after which the case was lifted to place on the low support braces of the fastening point. It was noticed that the case settled in its place as planned. The rear end of the case’s aluminium sheet was bent from its lower edge to form a canopy against rain on the rear end of the fuselage. Despite the case being fairly heavy, it was fastened by its hem with a few screws to the fuselage. Thus not even a strong gust of wind gets to throw it from its place.

Photo by Mikko Jaakkola

Photo by Esko Ruohtula When the protecting case of the vertical stabilizer’s fastening point was in place, we started work on the final shaping of the hood, covering the joint of the case and the fixed fin. The hood had been bent to its preliminary shape from 0,3 mm thick aluminium sheet at the Museum. We had to shorten it quite a bit before it was the right size to protect the joint. The hood was fastened from its lower edge to the fuselage with a few screws and the sharp head of the hood was shaped round.

Photo by Mikko Jaakkola The openings for the DO-5 horizontal stabilizers, vertical stabilizer and the fuselage rear end had now been protected against the weather, and we could start the home journey to the Finnish Aviation Museum, satisfied with our work. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio |

|

Avainsanat: aviation history, restoration, Tuesday Club, DC-3, C-47, DO-5 |

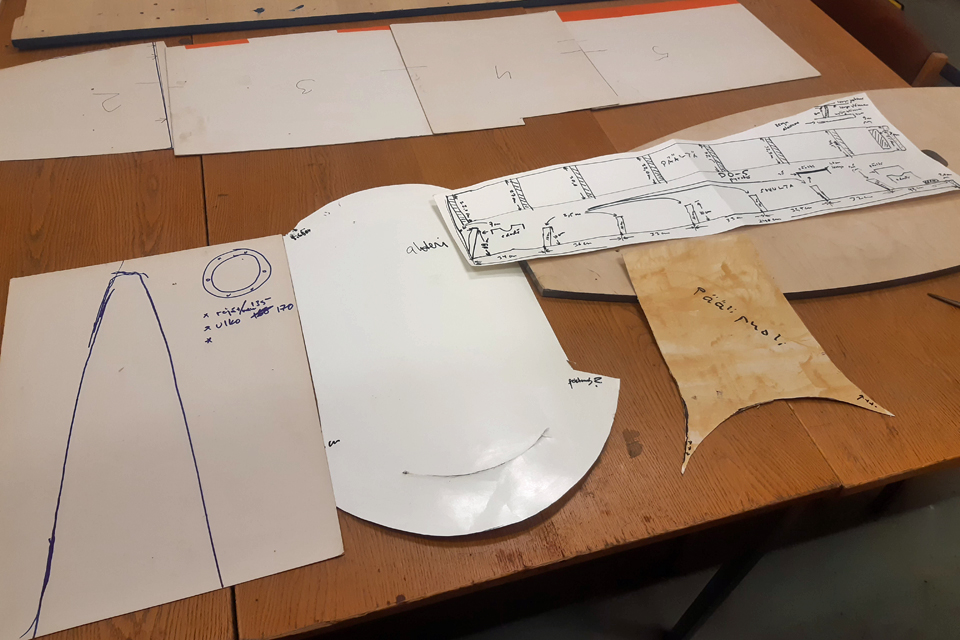

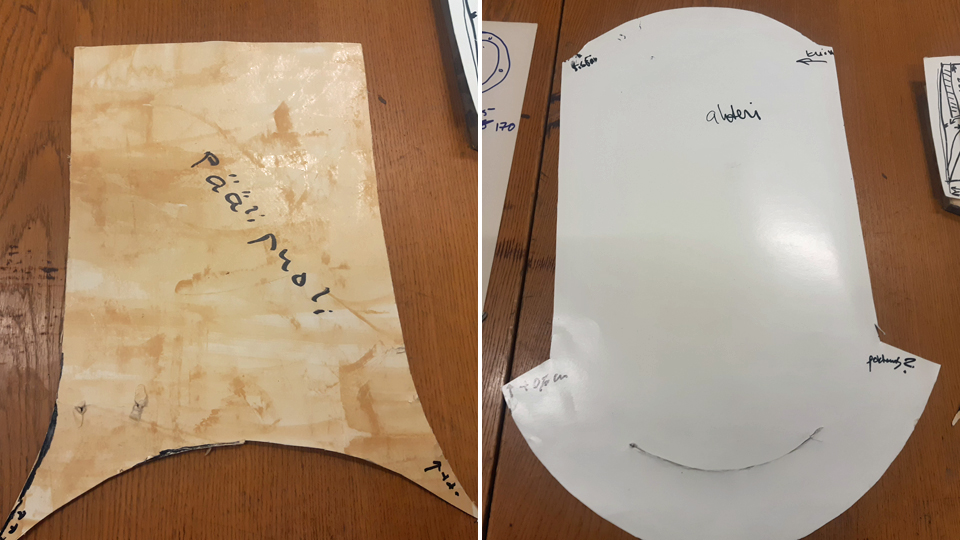

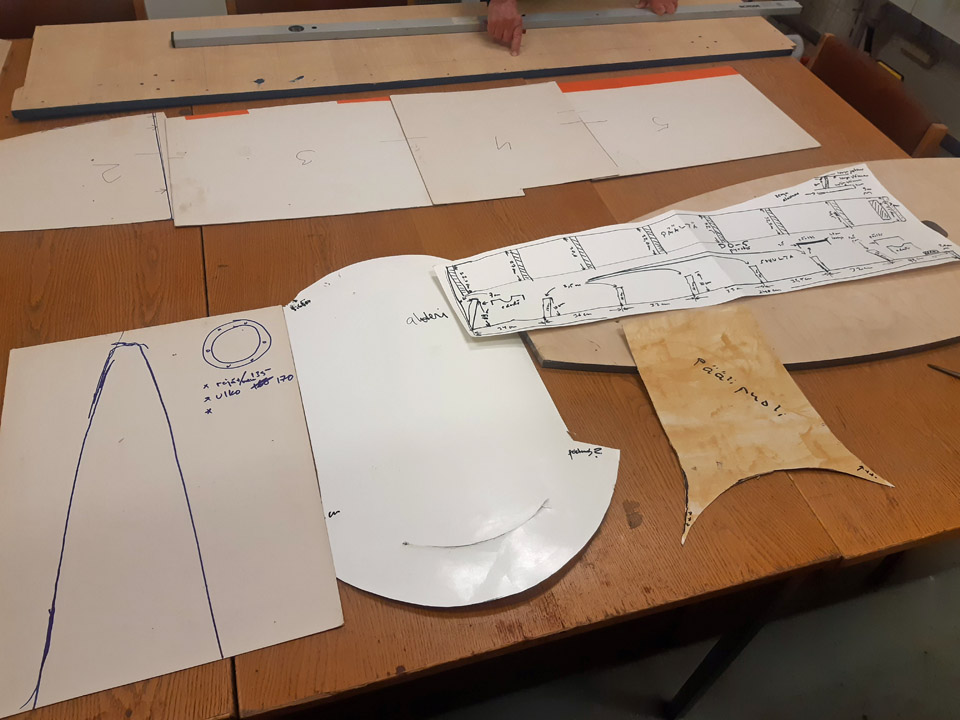

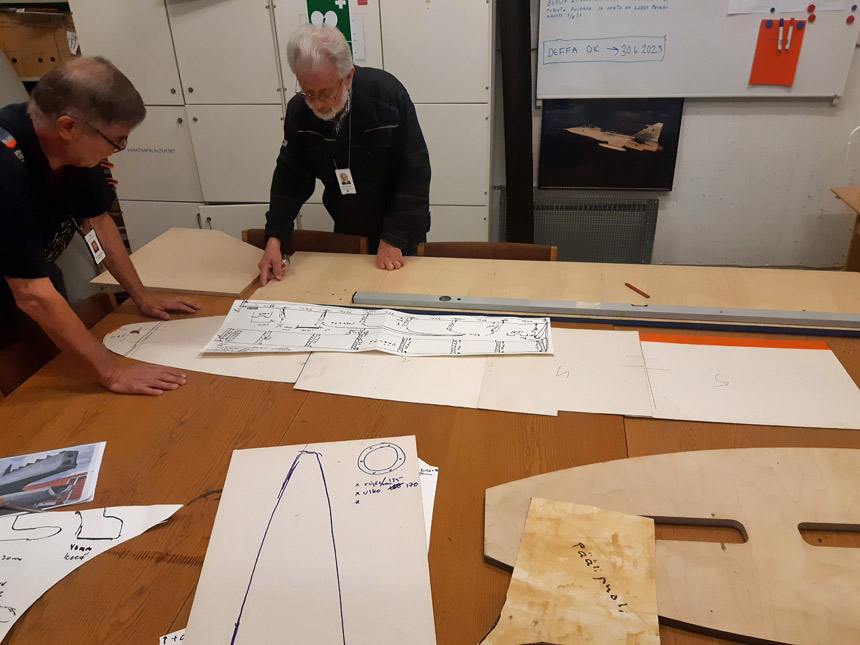

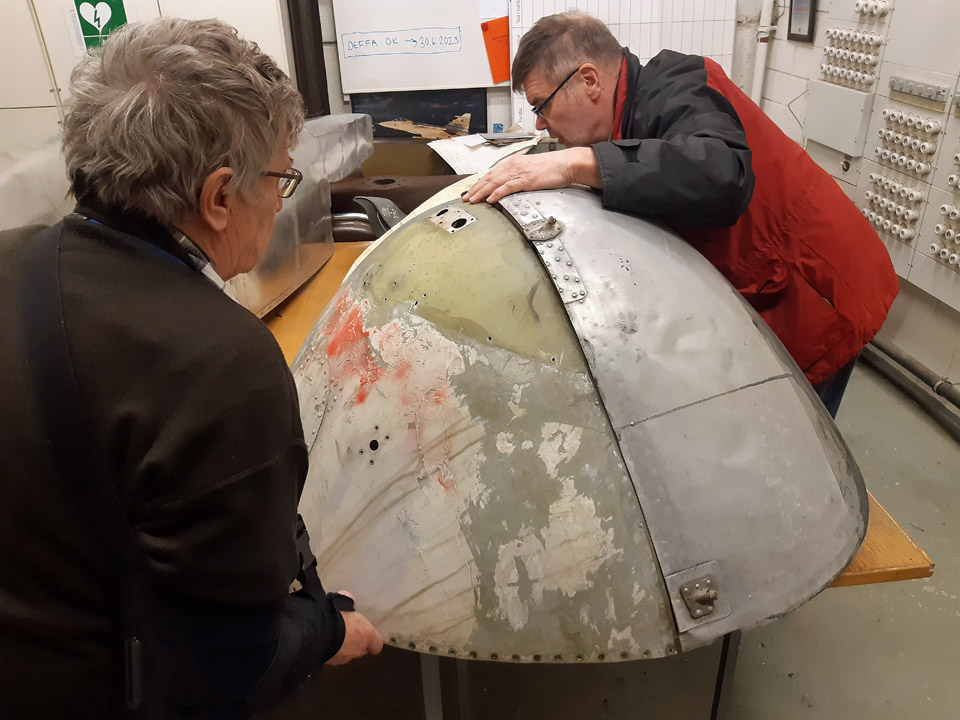

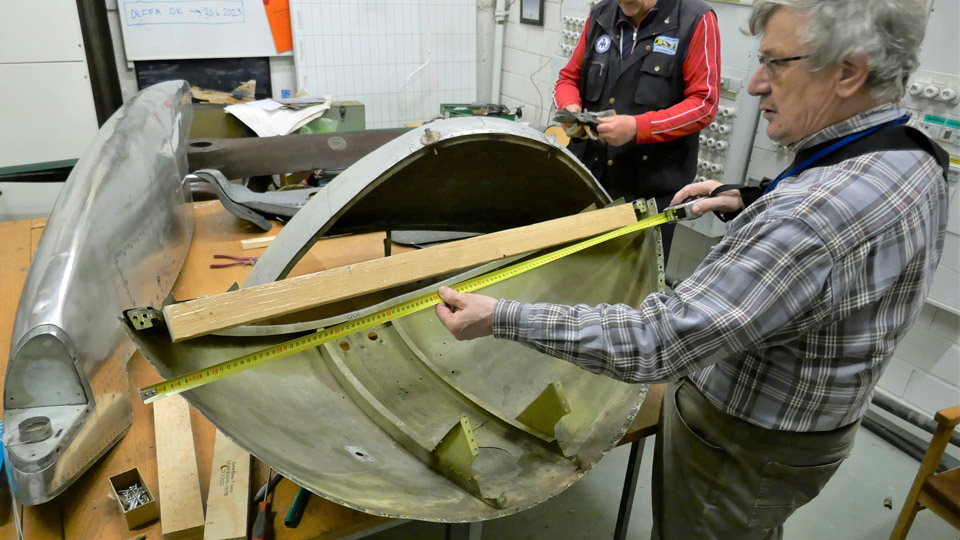

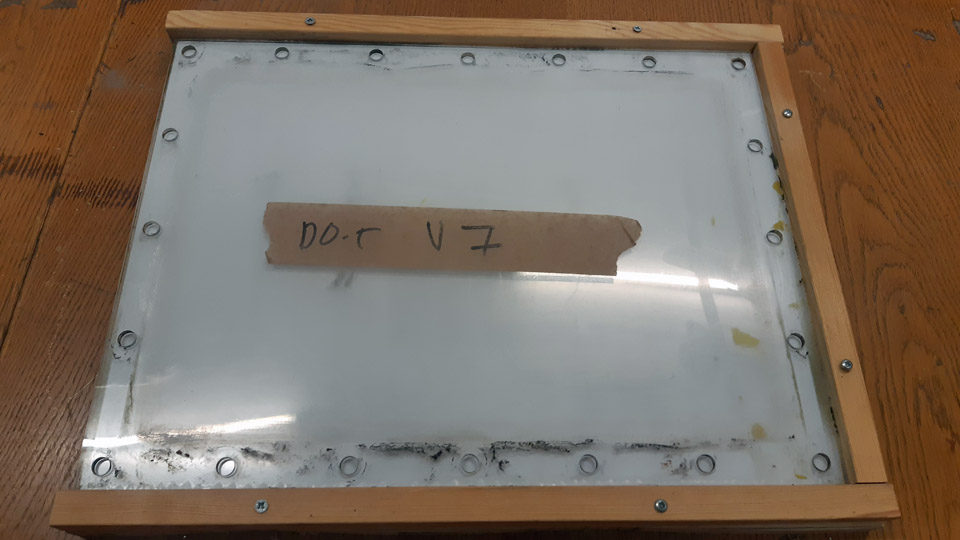

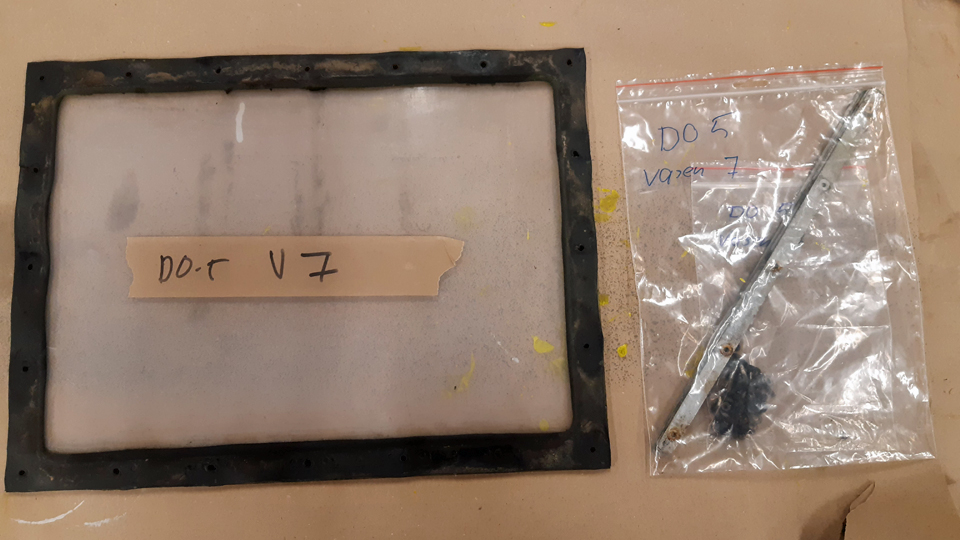

Constructing the weather shields for the stabilizer openings for the DO-5 (Douglas C-47)Lauantai 4.11.2023 - Tuesday Club member The fuselage of the Douglas C-47 (DO-5) owned by Aviation Museum Society is situated in vicinity of the Turku Airport passenger terminal, close to the Caravelle III, magnificently restored as Finnair “Bluebird”. The DO-5 tail has no elevators or rear cone. That’s why rainwater and snow blizzards have penetrated into the fuselage for years, to play havoc inside. Now we can get rid of this problem when the Tuesday Club has made shields to cover the openings. To build them we visited Turku to measure the sizes of the openings and cardboard templates were made. (see the blog from Sep.21st 23)

Photo by Ismo Matinlauri

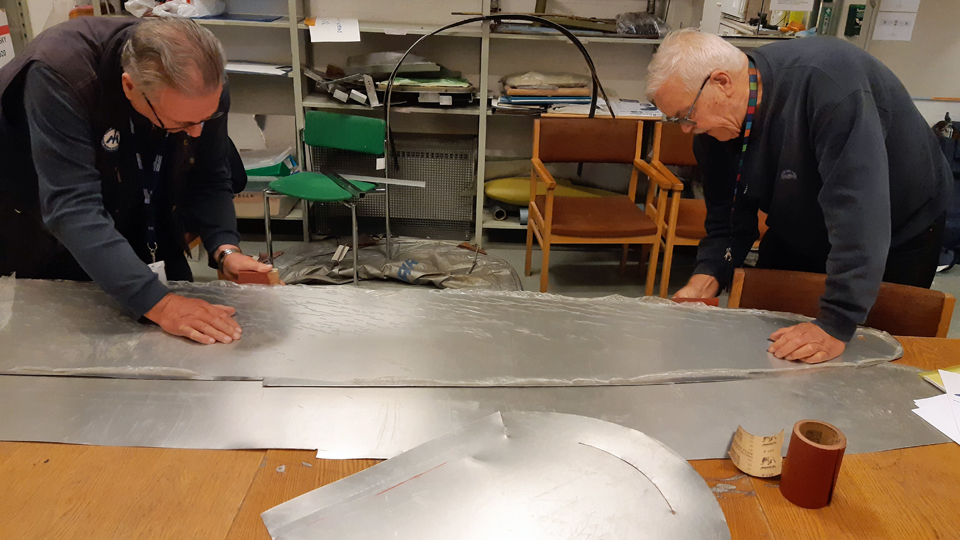

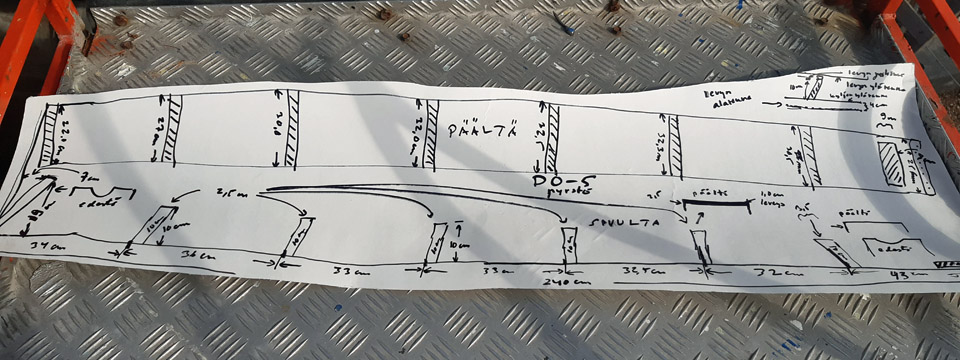

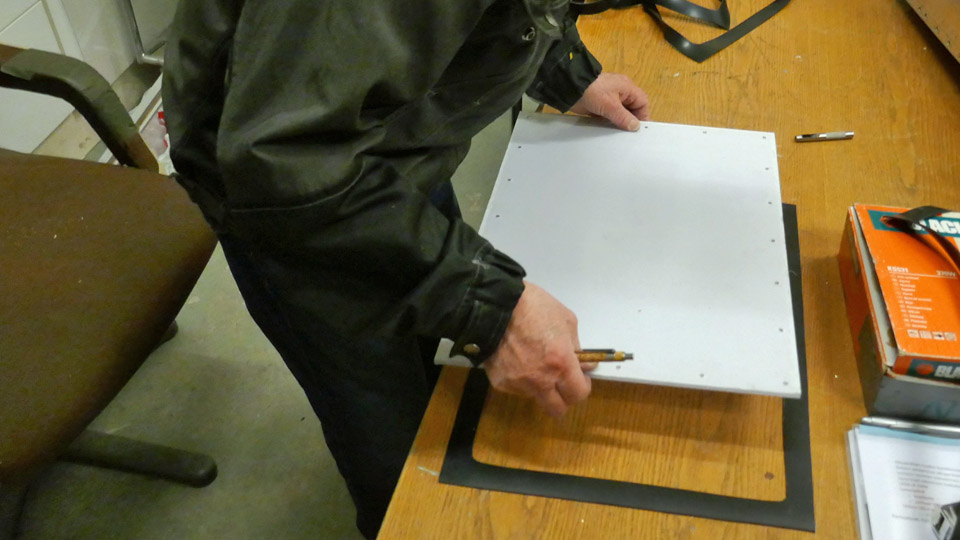

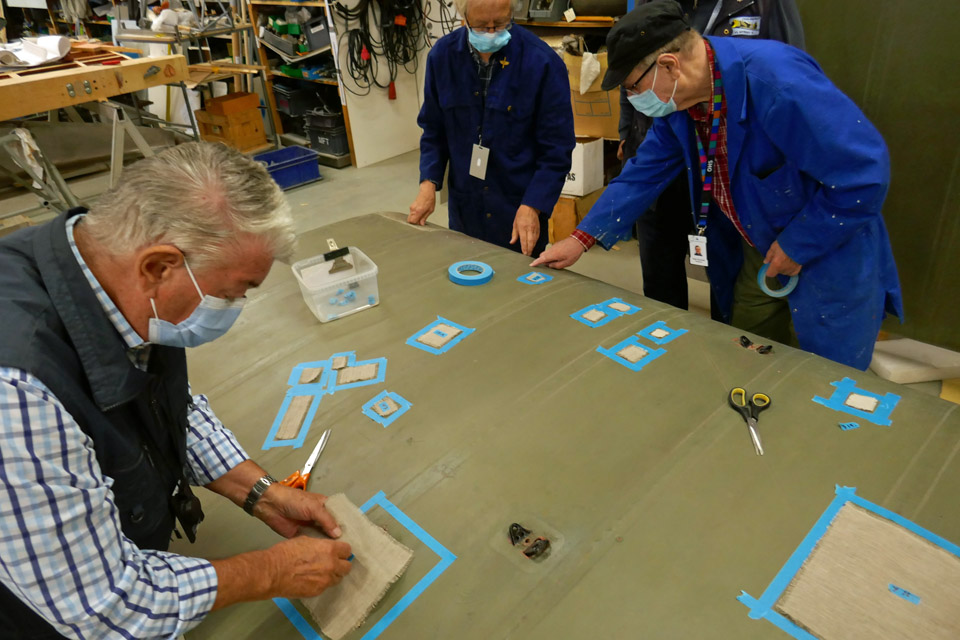

When we were starting to build the covering shields, we contemplated, whether we’d build the shields from plywood, or thin aluminium sheet. We ended up with a compromise, where we would build a plywood case covered with aluminium to shield the vertical stabilizer’s fastening point. The openings of the horizontal stabilizers and the rear openings we would shield with aluminium sheets. Building the vertical stabilizer covering caseThe fastening point of the vertical stabilizer is built in such a way that it can’t be covered with a shield alone. That’s why we’ll be building a covering case from plywood, which can just be pressed into place, supported by the fastening point’s 10 cm high supporting brackets. The top of the case will be built from sturdy plywood plate. The sides will be from thin plywood. Because the plywood we use isn’t weatherproof, we’ll cover the plywood case with thin aluminium offset-press sheet, which goes well with the aluminium fuselage of the DO-5.

The construction of the covering case of vertical stabilizer fastening point was started from the top, which duplicates as the frame of the case. To make that we used sturdy 12 mm thick plywood plate. We had to build the top from two joined pieces, because the length of the plywood plate at our disposal wasn’t enough to cover the 240 cm length of the vertical stabilizer’s fastening point.

We cut two pieces of plywood, which were a bit broader than the fastening point of the vertical stabilizer. The pieces were joined with a 30 cm long plywood joint piece. The form of the fastening point was drawn according to the blueprint on the more than 240 cm long case top. After that the extra bits according to the drawing line were sawn off, so that we had the finished piece of plywood for the top of the case.

The sides of the case were made from 3 mm thick aviation plywood. 15 cm broad ”strips“ were cut, using a cutter, from the plywood plate to form the sides of the covering case. A 15 cm broad plywood side shields well the vertical stabilizer’s fastening point. The plywood strips were fastened from their upper side to the side of the roof plywood with 20 mm nails. They were joined to one another with a lap joint, so that the ends of the plywood overlapped 10 cm.

When the vertical stabilizer’s covering case was structurally ready, it was covered with 0,3 mm thick offset printing sheets. From 100x70 cm aluminium sheets at our disposal, we cut off strips that were 1 cm broader than the sides of the case. That way the covering strip reaches a bit past the plywood side forming a “dripping edge”, preventing rainwater from rising into the plywood under the aluminium sheets. The aluminium strips were nailed with 20 cm nails to the edge of the 12 mm thick top plywood edge. The strips were joined with lap joints overlapping about 5 cm. The lap joint will be covered with aluminium tape when the covering case is fitted into place.

After the sides of the case had been covered, the case roof was covered. Three one-metre-long pieces were cut from the offset sheets. The sheets were cut about 5 cm broader than the case roof. This is because the edges of the aluminium sheets will be bent over the roof edge to cover the roof/side plywood joint. As the roof covering sheet had been fastened in place, its edges were bent with gentle beating with a hammer onto the top edge of the side sheets. The overlapping edge of the offset sheet was fastened to the roof edge with a few sheet metal screws. The case covering the vertical stabilizer joint was finished. To shield the front end of the covering case, there will be a tapered “hood”, which will be formed from aluminium sheet. This hood will cover the joint of the vertical stabilizer’s front part (fin) and the covering case. The hood was made from 0,3 mm thick offset sheet and it was bent into form with a bending machine. The so far oversized hood will be formed to its final shape when fitting the vertical stabilizer covering case to the DO-5. Making the horizontal stabilizer opening covers

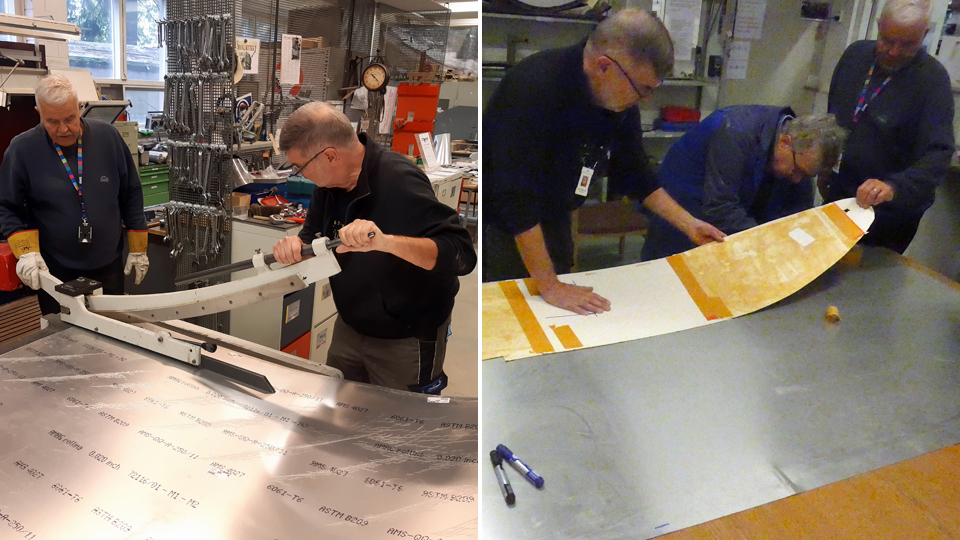

The covers for the DO-5 horizontal stabilizer openings were made from 0,7 mm aluminium sheet. A piece was cut, big enough for both the openings of the horizontal stabilizers. The cardboard template of the openings was fastened on the aluminium sheet with adhesive tape. The outline of the template was drawn on the sheet with a felt pen, along which a billet to cover the opening was cut with a cutter and tin snips. Because the cutter and tin snips left the edges of the aluminium piece jagged and sharp, the edges were smoothed with a file. In a similar way the other cover was also cut using the cardboard template. We presume that the covering pieces we cut, are mirror images and will fit either of the two openings.

At the leading-edge head of the stabilizer opening there’s a fixed pipe for the stabilizer’s anti-ice rubbers’ pressure hosepipe. A hole was cut in the covering shield for the hosepipe. Now we were ready to remove the protective plastic sheets on the covering piece. Any traces of the plastic were washed off with white spirit.

The horizontal stabilizers’ opening covers, cut from 0,7 mm aluminium sheet, are very flexible, so it was decided to stiffen them with strips of plywood. From 3 mm plywood panel about 10 cm wide plywood strips were cut with a cutter. They were glued on the inside of the horizontal stabilizers’ covers using the Sikaflex 221.This way the covers gained suitable stiffness, which facilitates their fitting in place to shield the openings of the horizontal stabilizers of the DO-5. The tail end covering plates

The DO-5 tail is without the tail cone, so the rear end of the fuselage is prone to rain. The rear end will be covered with two aluminium plates, of which the upper is small compared with the lower one. A template from cardboard we had made was placed on the 0,7 mm aluminium plate and the outlines of the templates were drawn on the plate with a felt pen. Covers for both of the rear fuselage openings were cut from the plate. The edges were smoothed with a file. A curved slit a few mm wide had to be made to the lower shield, through which a solid protuberance on the fuselage “peeps” out. That slit was made by drilling a hole to the end of the slit and then drilling the slit open with a keyhole saw.

The covers for the vertical and horizontal stabilizer openings, as well as the rear fuselage, were ready to be fitted to the fuselage of the DO-5. The fittings will be completed yet before the winter sets in. Photos by Lassi Karivalo except if otherwise mentioned. Translated by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

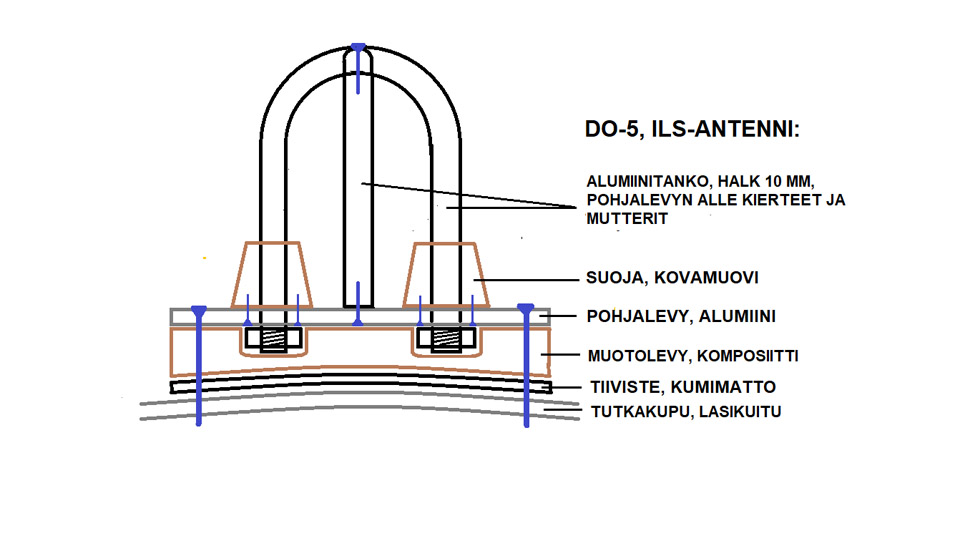

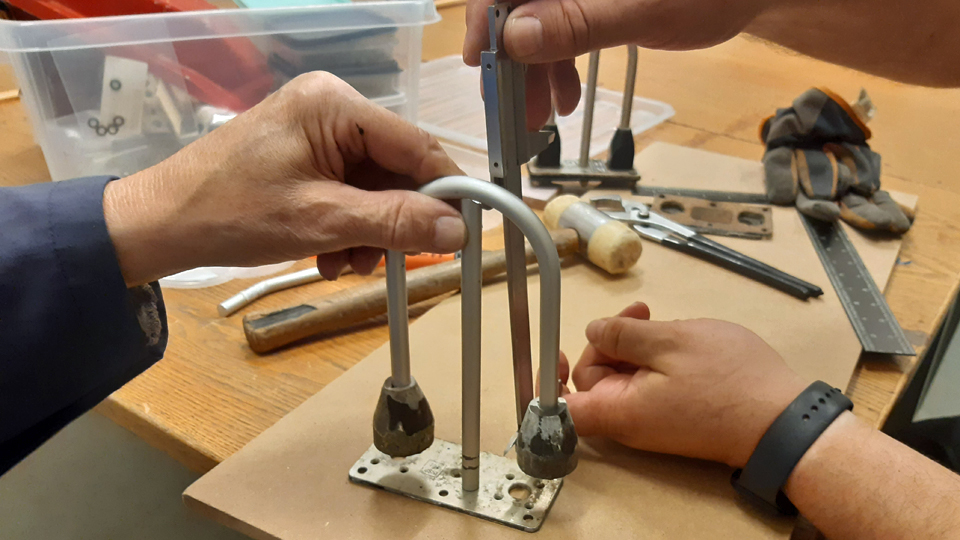

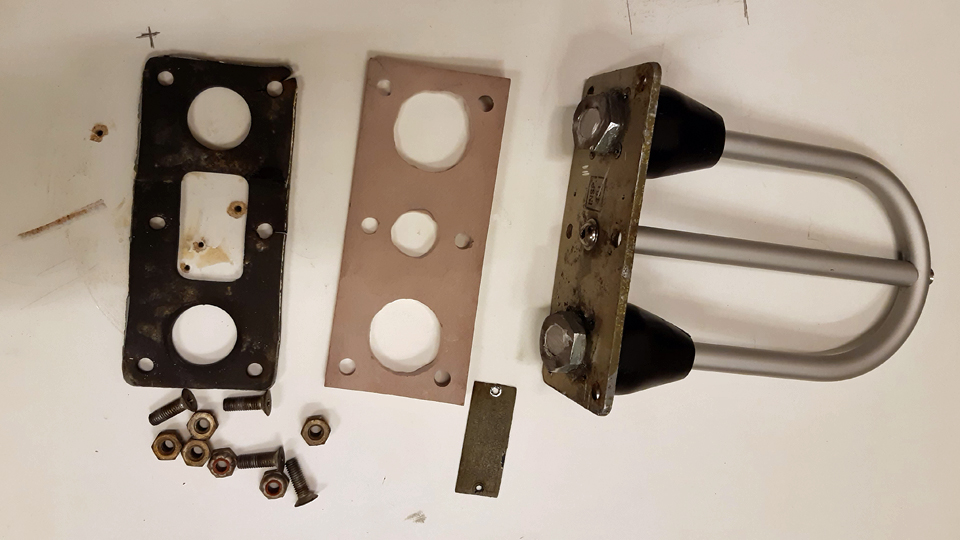

Making a look-alike ILS-antenna on the DO-5 noseSunnuntai 8.10.2023 - Tuesday Club member Last spring the missing lower part of the nose cone was made of glass fibre to the C-47 (DO-5), owned by Aviation Museum Society Finland. To make the nose appear real, it should include an Instrument Landing System glidepath antenna. It consists of the antenna arch, made of 10 mm thick aluminium tube, a vertical support in the middle of the arch, the antenna stem shields, a base plate, a wedgelike form plate and a rubber seal. With the aid of the form plate it’s possible to fasten the antenna tightly and at the right angle on the curved surface of the nose cone. Both ends of the antenna arch penetrate the stem shields, reaching the underside of the base plate, where at both ends of the antenna tube there’s a connector for the antenna’s electric wire.

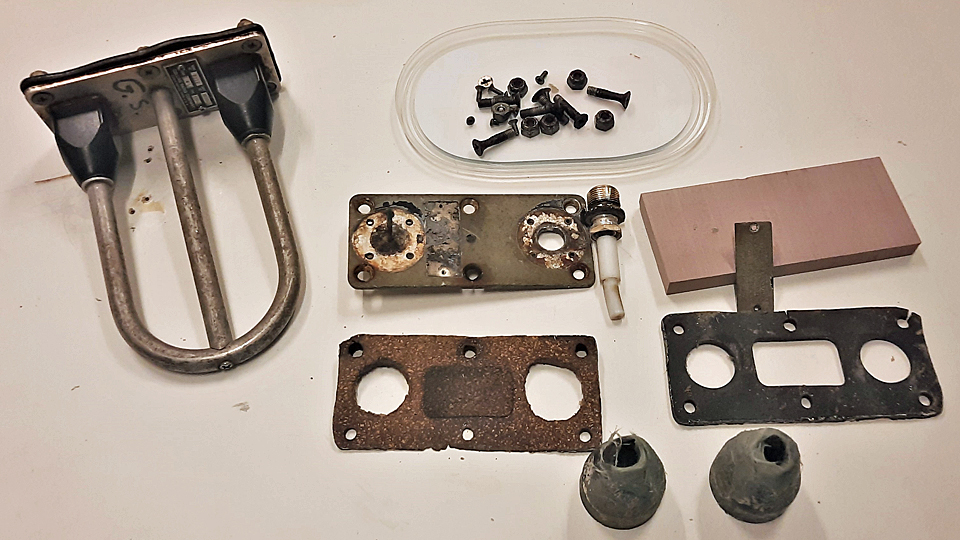

We don’t have this antenna to fit on the DO-5. So we decided to make a look-alike copy of the antenna, because the DO-5 will not be made airworthy. We were lucky to get an original antenna for making the look-alike copy, although it is without the form plate made of cork and the rubber seal belonging to the antenna. At the same time, however, we got a broken base of the antenna to be used as model, on which to make the look-alike copy. The base still had the form plate and the rubber seal in place. We are obliged to return the form plate, so it, too, has to be done.

Picture by Reijo Siirtola. To make a look-alike copy we made a model drawing, which is on the outside looks like the original antenna. The difference from the original antenna is that we replace the original antenna made of aluminium tube with a solid 10 mm thick aluminium bar. The fastening of the antenna arch to the base plate also differs. Because our antenna will not be functional, we’ll fasten the antenna arch to the base plate with nuts. For that purpose the ends of the antenna arch will be pushed with their shields 10 mm past the underside of the base plate and the ends will be threaded for the nuts. We’ll have to make a new form plate, too. We’ll make it out of mass plate that can be reshaped, instead of cork.

Photo by Reijo Siirtola.

We started making the look-alike antenna by dismantling the antenna base we had. The antenna end shields, made of hard plastic, which were attached to the base plate with small screws, were broken. They were mended with epoxy putty. After the putty had dried, the shields were formed to their original shape and painted black. At the same time holes were opened through the shields, to enable the ends of the aluminium rods, modelling the antenna arch, to be pushed through the shields.

Photo by Juha Veijalainen.

To make the antenna arch, we cut an overlong piece of 10 mm thick round aluminium rod. To bend the antenna to its original form, we built a bending device. With it we bent the aluminium rod to the exact arched form of the original antenna. We pushed the overlong ends of the antenna arch through the antenna shields to cut them to exact length. For that purpose we measured from the original antenna the distance from the top of the arch to the surface of the base plate and added the necessary 10 mm, the distance that the antenna ends reached below the base plate. We cut off the extra bits from the antenna arch ends, after which the ends were threaded for the fastening nuts.

To make the vertical support in the middle of the antenna arch, we cut off from 10 mm aluminium rod an also overlong piece for the centre support. We shaped the top end of the rod as concave, for it to press tightly against the top of the antenna arch. We measured the necessary length for the centre support and marked the lower end of the rod accordingly and cut off the extra. The centre support is fastened at the top with a small bolt through the antenna arch and at the bottom end with a small bolt through the base plate.

Then we marked the attachment point for the centre support on the antenna arch and drilled a hole for the top fastening bolt. There’s already a hole in the original base plate for the bottom end bolt. After the holes have been drilled in the top and bottom ends of the vertical support, inside threads were made with a threaded pin, and the vertical support for the antenna arch was ready for fitting in.

A new form plate to replace the original one made of cork had to be made. We made this form plate out of easily workable mass plate. The mass plate was ground wedgelike from the sides. The side against the base plate was left straight, but the side against the nose cone was worked as concave, according to the original model. Finally holes were drilled in the new form plate for the antenna arch nuts.

It was time to assemble the antenna. We pushed the ends of the antenna arch in their shields in such a manner that the vertical support in the middle of the arch settled nicely between the antenna arch and the base plate. We turned into place the bolts to the ends of the vertical support. Then we fastened the antenna shields to the base plate with four small screws through the base plate. That done we tightened the antenna arch into place with the nuts at the arch ends. The vertical support worked as a stiffener when fitting the antenna arch into place. When the form plate with its rubber seal was fitted, the glidepath antenna look-alike copy of the DO-5 instrument landing system (ILS) was finished. The next thing to do will be to go to Turku and install the antenna look-alike copy onto the upper edge of the DO-5 nose cone’s lower part made of glass fibre. The DO-5 is situated by the Turku Airport Terminal, beside the Caravelle “Bluebird”. We can measure the exact position of the antenna from the original “DAK” nose cone, so according to that we’ll drill the necessary holes into the upper edge of the lower half of the DO-5 nose cone made of glass fibre and install there the ILS-antenna look-alike copy we made. We’ll go and install the antenna still before the winter sets in. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, DC-3, C-47, DO-5 |

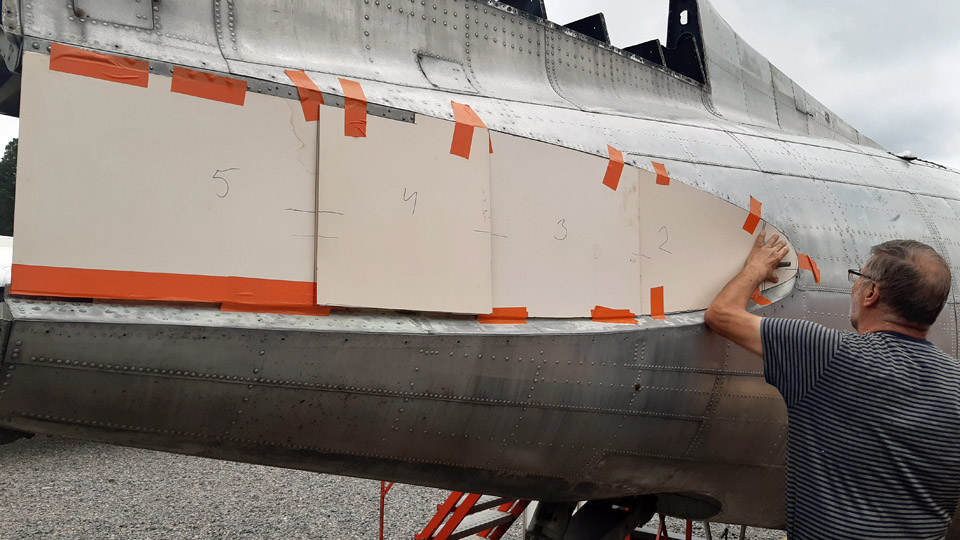

Covering the DO-5 openings for the stabilizersTorstai 21.9.2023 - Tuesday Club member When in June we were preparing the C-47 (DO-5) fuselage, owned by Aviation Museum Society Finland, for display at the Turku Airshow, the working list included covering the DO-5 tail openings for the stabilizers with aluminium plates. The reason for the covering being to prevent rainwater from getting inside the fuselage. At the time we didn’t have time to make the covers to shield the openings. At the beginning of the Tuesday Club’s autumn season we included the covering of the stabilizer openings on our work list.

Photo by Janne Salonen. At the moment, the DO-5 fuselage is situated by the Turku Airport, next to the Caravelle III or OH-LEA “Bluebird, which is the object of restoration and owned by Aviation Museum Society Finland. That’s why we had to go to Turku to measure the covers for the stabilizer openings. On Monday, September 4th, we headed for Turku.

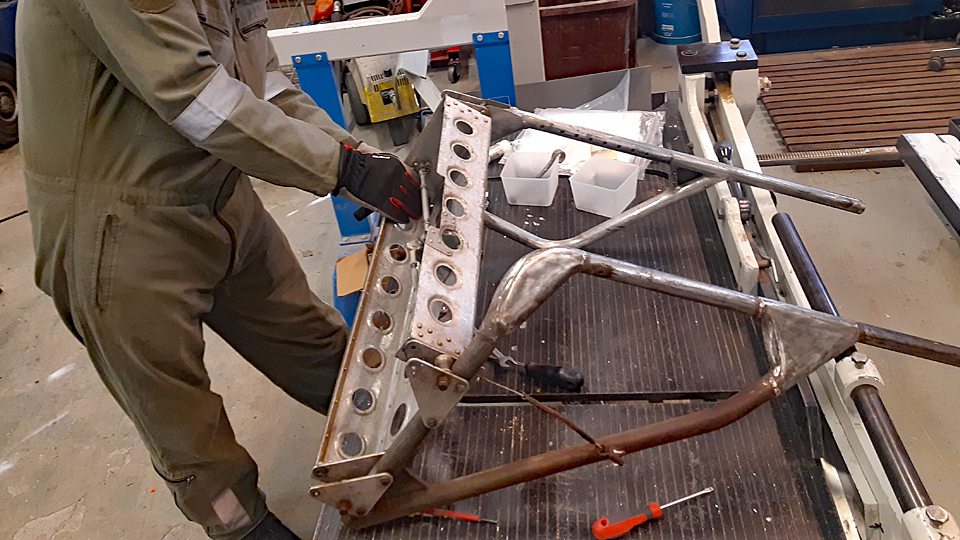

Photo by Jouko Tarponen. Measuring the sizes of the openings on the DO-5 and making cardboard templates of them took quite a few hours. Our work was facilitated by the fact that we had at our disposal a high enough worktop, given to us by the Caravelle restoration project, on which we could reach to measure the vertical stabilizer’s opening, which was highest up. Or as a matter of fact, the vertical stabilizer’s attachment point isn’t an opening at all, like the horizontal stabilizers’, but the vertical stabilizer is attached from its lower part to aluminium attachment brackets rising from the fuselage.

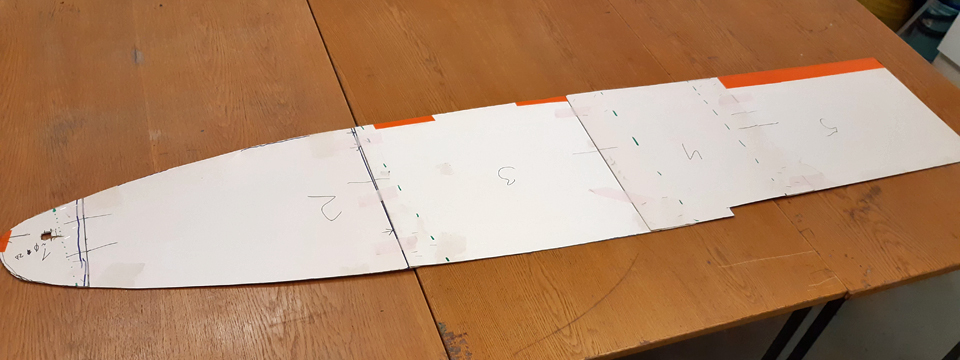

We started with the right-hand side horizontal stabilizer opening in the tail. A cardboard template was made by shaping and attaching to the stabilizer opening several numbered cardboard panels, one after the other. Finally we shaped a cardboard template of the curved leading edge of the stabilizer opening. Because we assume that the right- and left-hand side openings are symmetrical, we only made a cardboard template of the right-hand side stabilizer opening.

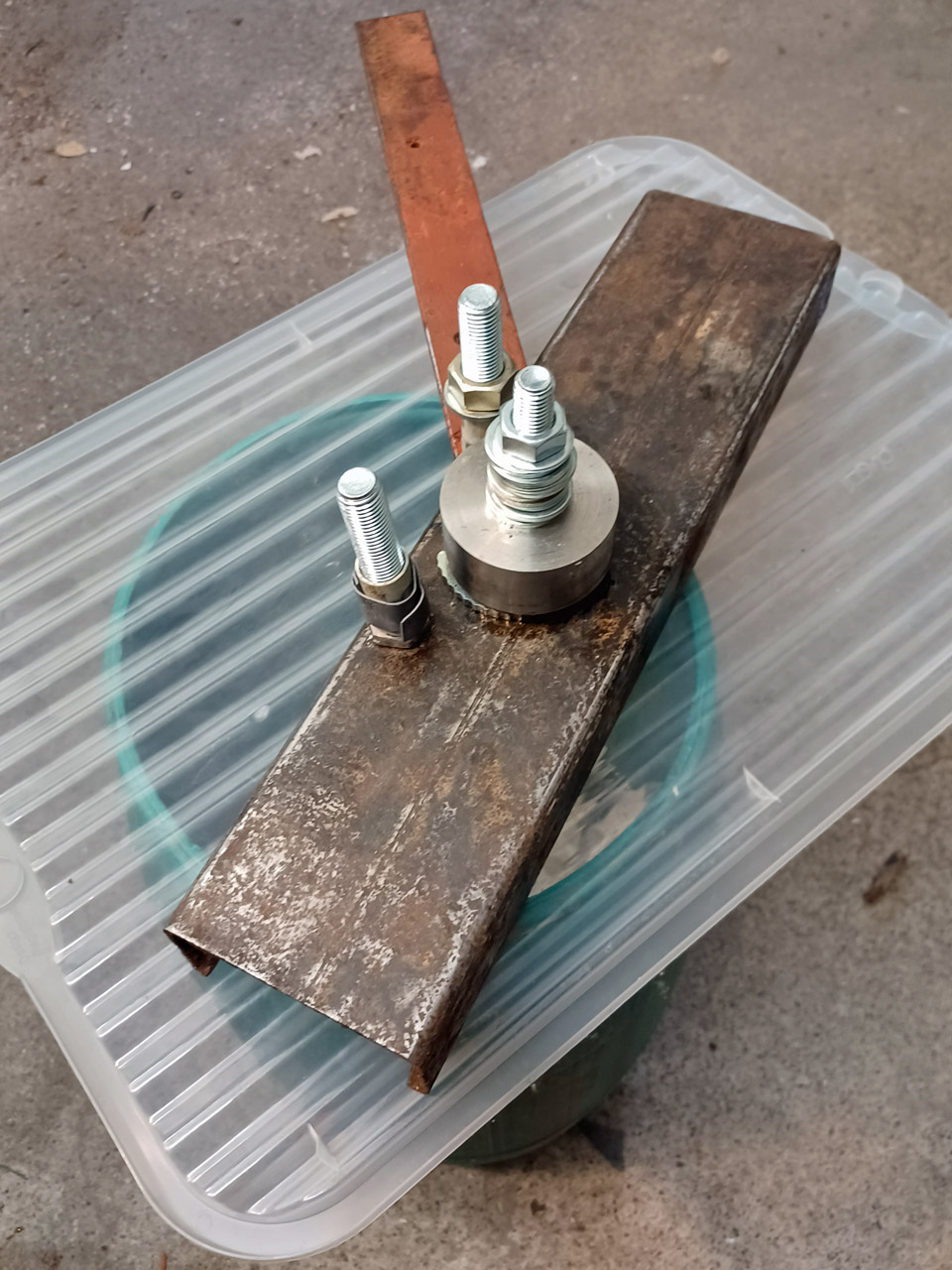

A cardboard template of the vertical stabilizer’s attachment point wasn’t made, because it isn’t an opening in the fuselage like those of the horizontal stabilizers. At the vertical stabilizer’s attachment point, from the top of the “cut off” tail, seven rectangular 10 cm high solid attachment brackets, made of aluminium, are sticking up stretching 240 cm in distance. The vertical stabilizer is attached to these brackets with screws, and from its hem to the side of the fuselage.

Photo by Reijo Siirtola. We ended up sheltering the vertical stabilizer’s attachment point with a rainproof case. The case would be pressed on the 10 cm high attachment brackets. The top of the case would be of sturdy plywood, covered with a sheet of aluminium. The sides of the case will be made of sheets of aluminium. They will be attached from their top rim to the edge of the plywood cover, so that the top rim remains under the downward bent edge of the aluminium sheet on top of the case. This will guarantee that the joint becomes watertight. The bottom sides of the case overlap the top of the fuselage by 4 cm. Thus the rainwater running along the case’s sides can’t get inside the fuselage.

To build the case covering the attachment point of the vertical stabilizer, a sketch was made, where all the relevant details to build the case were measured.

Photos by Ismo Matinlauri.

Because the DO-5 tail cone isn’t fixed to the fuselage, the tail cone opening must also be protected from the rain. The opening will be protected with two aluminium sheets, because of the structure of the tail’s cross-section. So we made individual cardboard templates of the top-and lower halves of the fuselage of the DO-5 without the tail cone.

The covering of the DO-5 tail stabilizer openings was started with the case protecting the vertical stabilizer. First the plywood top will be built. It will act as the frame for the case. There was suitable, sturdy plywood in the material storage of the Finnish Aviation Museum. We will have to make the top plate out of two halves, though, because the length of the plate at our disposal isn’t enough to cover the whole 240 cm length. The measures for the vertical stabilizer taken in Turku, were transposed to the plywood plate, which became the case’s top. Next the top plate will be sawn into measure. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

The DO-5 fuselage on display at the Turku AirshowPerjantai 23.6.2023 - Tuesday Club member The fuselage of the Douglas C-47 A, registered DO-5, owned by Aviation Museum Society Finland was on display at the Turku Airshow as part the Aviation Museum’s stand. The DO-5 fuselage, which was used by the Finnish Air Force for training paratroopers in the 1960’s, was refurbished enough in the Aviation Museum Society’s Tuesday Club for the fuselage to be brought on display to Turku. The Airshow visitors could be allowed inside the fuselage to see how the aircraft was used in training the paratroopers.

Photos by Janne Salonen

Photo my Lassi Karivalo The DO-5 fuselage was transported from the Aviation Museum’s yard at Vantaa to Turku Airport on the Thursday before the Airshow weekend. The Aviation Museum Society’s stand was situated in the Airshow area close to the mighty Boeing C-17 Globemaster. So there they were in close vicinity, the USA Air Force Air Transport aircraft from the 1930’s and the 1990’s, albeit in different calibre.

Photos by Lassi Karivalo The Society had also brought on display the “Snoopy” aircraft donated to the Society and awaiting full restoration. This experimental aircraft from 1969 was constructed by the brothers Ari and Esko Hietanen from Turku.

Photo by Janne Pauni The DO-5 fuselage drew great interest among the Airshow visitors. On both show days, Saturday and Sunday, people poured into the DO-5 to hear about the history of this individual aircraft and about the refurbishing projects done by the Tuesday Club, including the full-sized photo in the cockpit of the instrument panel of the Kar-Air DC-3 OH-VKB, which is situated in the Aviation Museum.

Photo by Juha Veijalainen

Photo via Jarmo Kaipainen We told the visitors in particular how the DO-5 was used at Utti as a jump aircraft to train paratroopers and after it was taken off from flying, how the fuselage was utilized on the ground as a dry run platform before the first real jump as a paratrooper. We didn’t keep count how many persons visited the interior of the DO-5, but we estimate that the number is nearer 2000 than one thousand. It was a pleasant incident, when someone visited the aircraft and said that he had jumped from this very aircraft in 1963 on his conscript time, when it still served as a jump aircraft. Those who visited the aircraft were also very interested in the Aviation Museum Society’s DO-5 project in itself. They thought it was commendable that Aviation Museum Society Finland saved from the scrap yard an aircraft used by the Air Force in the 1960’s, with the cabin still in its original paratrooper training attire. Our project isn’t solely to preserve a C-47 because there are plenty of them still flying in the world, including converted airliner flying “Dak”, the OH-LCH, owned by Airveteran Oy. In preserving the DO-5 we’ll be able to save for the future generations Air Force history from the 1960’s concerning paratrooper training. We at the Tuesday Club can be proud as Punch for what we have already done to refurbish the fuselage. Without our input the fuselage wouldn’t have been in such a condition that it could have been put on display. There’s still a lot to do with the DO-5, but time will show how far we can go. The positive feedback we received at the Turku Airshow only confirmed how important our idea was, from the point of aviation history, to save the DO-5 used by the Air Force in training paratroopers more than 50 years ago. We, inside the DO-5 telling the visitors about the history and use of the aircraft, were literally in a hot spot. The scorching weather and the sun blaring from a cloudless sky heated the interior really hot. The temperature must have been nearly +50 degrees Celsius, even though we had installed a few fans to ease our existence. We did survive the hours’ long “sauna” of both airshow days. It must be admitted that cases of mineral water and Coke relieved the situation in preventing dehydration. The positive attitude of the visitors motivates Aviation Museum Society Finland to carry on with the refurbishing of the DO-5. From the point of view of the Tuesday Club the situation is problematic, because for the time being the DO-5 remains in Turku and our club operates in the Finnish Aviation Museum’s premises in Vantaa in co-operation with the Museum.

Photos by Janne Salonen After the Airshow the DO-5 fuselage was transported to Turku Airport to the vicinity of the Caravelle III, which was restored as Finnair’s “Bluebird”, and is owned by Aviation Museum Society Finland. There the Old Lady DO-5 can stay by the little younger Old Lady the “Bluebird” on public display.

Photos by Janne Salonen The former SAS Caravelle (SE-DAF) presently in Finnair colours, outside the actual Airshow area also interested the Airshow visitors very much. So about 1300 people popped in to get acquainted with the Caravelle “Bluebird” on their way from the Airport terminal bus-stop to the gates of the Airshow area. It was well worth getting acquainted with, because the newly painted Finnair “Bluebird is a truly resplendent sight. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

Tuesday Club's DO-5 work completedKeskiviikko 21.6.2023 - Tuesday Club member The hard work of the Tuesday Club members was instrumental in getting the fuselage of the type C-47A DO-5, owned by Aviation Museum Society Finland, into sufficient shape for putting it ready for showing before the Turku Airshow. It was touch and go because the last tasks weren’t finished until two days before the fuselage of DO-5 was transported from the yard of the Finnish Aviation Museum to Turku Airport on June 15th, 2023. The last significant project was to install new plexiglass panes for the cockpit. The Air Force DO-5 hasn’t had original panes in the cockpit for decades. Part of the windows lacked panes altogether, resulting rainwater and snowstorms ruining the cockpit badly, whilst the fuselage lay forgotten for decades in the Utti forests. Because the original cockpit panes and the large sliding panes on both sides of the cockpit weren’t available, we ended up with acquiring plexiglass panes for the window openings. On top of that we decided to attach the plexiglass panes to their frames with a mixture of glue and sealant mass. In this way the windows become watertight, preventing water to seep into the fuselage. This also meant that the big sliding panes on both sides of the DO-5 cockpit couldn’t be slid open anymore.

To acquire new 5mm polycarbonate plexiglass panes we made a template out of thin plywood for each of the window openings. For the windscreens we had already in the autumn acquired from ETRA plexiglass panes ready cut to form. Cold weather and the oncoming winter, however, put paid to carrying on with the installing of the windowpanes. We fastened then the plexiglass panes and the temporary panes in the other windows with plastic tape from their edges to wait for the warmer temperatures of the spring, when we could continue with the cockpit windows.

Photos by Lauri Veijalainen

Other tasks to refurbish the DO-5 fuselage in the spring delayed attaching the new plexiglass panes, so that we didn’t get to it until May 2023. Then the plexiglass panes for the large sliding windows on the sides of the cockpit were acquired.

Photos by Lauri Veijalainen

Each plexiglass pane was squeezed into its frame and a thin rubber strip was installed under the lower edge of the pane in order to get the pane at the right elevation in its groove. After that the edges of the panes were taped either by masking tape or with plastic tape so that there remained a suitable zone for the glue and sealant mass. The tape is to protect the rest of the surface of the pane from the sealant mass to spread and that the seam of the sealant mass will be clean.

Photo by Lauri Veijalainen After the taping, the glue and sealant mass was squeezed out along the seam of the pane and the frame. After that the mass was formed even with a plastic forming spatula. As mass we used black Soudaseal and Würth glue and sealant mass. When the seaming was ready, we extracted the protective tapes along the pane edges and the protective film on the panes. The seaming of each pane turned out to be very neat.

Photo by Lauri Veijalainen There are also small sliding windows in the cockpit that can be opened. For them we received original framed panes from Airveteran Oy. Installing them proved to be a bit problematic. Both the sliding window frames lacked a locking screw from the bottom, with which the window was pressed with its rubber seal tightly against the frame to make it watertight. On top of that, both the frames of the sliding windows we received were both for the right-hand side. Luckily the right- and left-hand side pane differ from each other little enough, so we pushed the right-hand side pane deep and tightly enough into the grooves of the left-hand side frame. There it can remain for the time being, until we’ll find a suitable pane for it.

We noticed that along the windscreen and cockpit side window frames there were empty screw holes. What for, we wondered? To stop water from leaking into the fuselage, we blocked the holes by screwing groove-headed sheet metal aluminium screws into each of them.

Photos by Lauri Veijalainen

Photo by Janne Salonen With the windows we had accomplished all the agreed tasks to refurbish the DO-5, so for our part the fuselage was ready to be transported to Turku Airport and to be on show there at the Airshow on June 17th -18th. The DO-5 fuselage left for Turku on Thursday June 15th. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

Making the lower part of C-47 (DO-5) nose coneLauantai 3.6.2023 - Tuesday Club member In an earlier blog I told that we were lent the lower half of a DC-3 (OH-VKC) nose cone to make the missing lower half of the DO-5 nose cone out of fibre glass. The DO-5 operated at its time in the Finnish Air Force as a jump aircraft for paratroopers. Aviation Museum Society managed to buy the DO-5, which was heading for scrap yard. Unfortunately the middle section of the wing is missing.

We needed the lower part of the nose cone on loan to make an outer surface fibreglass mould. With the help of the mould we’ll make the missing lower half out of fibreglass. Why do we make the lower half out of fibreglass and not of sheet aluminium? Simply because making the lower half out of aluminium is much more challenging and, on the other hand, because the fibreglass lower half of the nose cone fills its place well in the nose of the non-flying DO-5.

The lower half of the OH-VKC nose cone we loaned, and the DO-5 nose cone upper half are of the same DC-3 family, but they have been manufactured in different times and places. Because of this we still wanted to test, whether the OH-VKC lower half and the DO-5 upper half are a match. They weren’t an exact match, but close enough for us to use the loaned lower half of the nose cone to make a fibreglass mould.

The first phase in making the fibreglass mould was to stiffen the lower part of the OH-VKC nose cone so that it wouldn’t distort when under work. This was because the lower half, made of thin aluminium sheet, detached from the nose of the OH-VKC is “sloppy” and won’t retain its form. A wooden cross stiffener was made between the opposite corners of the lower half. Then curved stiffeners in the form of the lower half edges were sawn out of 20 mm thick film plywood, which were attached to the edges of the lower half of the nose cone. The stiffeners were fastened by utilizing the existing attachment screw holes in the edges. Now the nose cone lower part will stay in form when handled.

Photos by Reijo Siirtola Before making the fibreglass mould the bottom surface of the nose cone had to be cleaned into aluminium from the paint and filler covering it. The mottled history of the OH-VKC could be seen in the many layers of paint on the nose cone. An attempt to remove the layers of paint using a grinder failed because the sanding discs got choked instantly. Next a paint removing agent and scraping the paint off was tried. Suitable for our purposes proved to be Solmaster MP EKO Maalinpoisto (paint remover). Plenty of Solmaster was applied onto a restricted area of the aluminium surface and the area was covered with fabric to prevent evaporation. When the substance had worked a while, the paint could be scraped off with a wooden spatula. The wooden spatula worked well, and it doesn’t damage the aluminium surface of the lower half. Because the surface remained sticky, the final cleaning was done with thinner and xylene. In this way, phase by phase, the nose cone lower half’s surface was cleaned. Finally the surface was buffed with a nylon slip disc (Mirka nylon 60x30x6m).

Photo by Reijo Siirtola Before layers of fibreglass fabrics, impregnated in polyester resin, could be applied on the surface of the lower half of the nose cone, the surface had to be carefully sealed. The sealing is important, because the sealer prevents the resin impregnated fibreglass mat from sticking on the aluminium surface below. Five layers of Miracle Gloss 8 sealer by Kevra Oy were rubbed on the lower half’s surface. Three first layers were rubbed on the cone surface with an interval of an hour, then a 12 hour pause, and finally the last two layers again with an interval of an hour. After 24 hours the lamination could be started. As lamination mat Biltema woven fibreglass fabric 30-512 was used, and as resin Biltema Polyester resin 36-0780”. The Polyester resin was chosen because its price was a shy quarter of the corresponding epoxy resin, and it won’t stick easily on the sealed surface of the mould.

Photo by Reijo Siirtola. Before the real lamination with fibreglass fabric, a test lamination with a small piece of fibreglass fabric was made. A piece of fibreglass fabric was impregnated with polyester resin while the piece of fabric was spread on cardboard. When the white colour of the fabric changed into transparent, it was turned over and polyester resin was applied on the other side, too. The cardboard from a cardboard box is an excellent base for this purpose. It’s strong enough to withstand the fibreglass mat to be impregnated with polyester resin and the resin won’t absorb into the cardboard to any significant degree. The piece of fibreglass fabric, impregnated with polyester resin, was “squeezed” tightly with a roller onto the surface of the lower half of the nose cone. The fabric stuck on well, and what was most important, after drying the fabric came off the next day without damage. So the sealing was a success.

Photo by Reijo Siirtola Now we could start to laminate the whole of the surface of the lower half with fibreglass fabric. For that purpose three pieces covering the lower half surface were cut out of the fibreglass fabric. First the surface of the lower half of the nose cone was completely covered with polyester resin. After that the first piece of lamination fabric was impregnated with resin and it was laminated on the surface of the lower half of the nose cone. Three layers of fabric were laminated. Finally on top of the layers thick ropes were laminated with polyester resin, which after drying would form a supporting structure keeping the mould in form.

Photos by Reijo Siirtola The next day the fibreglass mould could be detached. The detaching succeeded with ease, and no traces were left on the aluminium surface – thanks to the excellent sealer. Extra bits out of the edges of the mould were cut off. Slight unevenness was noticed on the inner surface of the detached mould. The uneven patches were sanded, and the surface was spackled with Biltema’s fibreglass filler (36-0137) and buffed. Thus the fibreglass mould had been finished for the lamination of the lower half of the nose cone.

Photo by Reijo Siirtola The lamination of the lower half of the nose cone began with the sealing of the inner surface of the fibreglass mould. After sealing the lamination was started, but this time with fibreglass mat. The reason for this was that with using of fibreglass fabric some unevenness seemed to remain, which necessitated extra buffing. With the fibreglass mat, which was pressed out of short glass fibres, the fibres criss-cross with each other. That gives a very smooth surface when laminated with a roller. Due to the structure of the mat it has also a good tensile strength in every direction.

Photo by Reijo Siirtola A piece covering the inner surface of the mould was cut. Polyester resin was first applied to the surface of the sealed fibreglass mould. After that the polyester resin impregnated pieces of fibreglass mats were laminated with a roll, one after the other, onto the inner surface of the mould. After the fibreglass had dried out the laminate was detached from the inner surface of the mould. It could be seen that the surface of the lower half of the fibreglass cone was remarkably smooth, nearly ready for painting.

Photos by Reijo Siirtola Because the fibreglass lower half of the nose cone wouldn’t hold its form without support, new supports cut out of thick plywood were installed. Thus it was secured that that the new fibreglass lower half of the nose cone stays in form when fitted on to the nose of the DO-5. The surface of the fibreglass lower half was spackled and sanded and primed with grey primer. When the lower half of the OH-VKC nose cone and the fibreglass lower half were put side by side, they looked identical, as was planned.

Photo by Juha Veijalainen

The new lower half of the nose cone was ready to be fitted onto the nose of the DO-5. During the fitting it will be seen how much we’ll have to work on its edges, so that we’ll be able to get it settle the way we want, against the upper half of the nose cone. To fit the lower half of the nose cone onto the DO-5 nose, we removed a sheet metal covering plate, which had protected the “cut off” nose. Behind it all sorts of rubbish, accumulated in the nose during the decades, was revealed and had to be cleaned off.

After cleaning we installed the upper half of the DO-5 nose cone in place and started fitting the fibreglass lower half in place. When fitting the lower half we noticed that the lower half was just within the tolerances, as we had hoped it would be. Naturally the edges of the lower half and the plywood supports inside had to be modified a few times so that the lower half of the nose cone was settled in the way we hoped, against the fuselage and the upper half.

The fibreglass lower half of the nose cone was ready waiting for the finishing coat of paint. At this stage it was painted grey and is allowed to stand out from the original upper half of the cone. If the DO-5 aluminium fuselage is to be polished at some stage, the fibreglass lower half of the nose cone will be painted with a paint that will emulate the aluminium surface. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

DO-5 cabin to get new window panesTiistai 9.5.2023 - Tuesday Club member The windowpanes in the cabin of the DC-3 (C-47) – aircraft, owned by Aviation Museum Society, have gone opaque or non-transparent during the decades of storing in the woods. It has been decided to renew the panes. We’ll have time at the Tuesday Club to renew at least the port side panes before the Turku Airshow. The DO-5 fuselage will be on display at the Aviation Museum stand. The DO-5 panes will be renewed using UV-shielded polycarbonate plexiglass. It’s a lasting and easily workable material.

On both sides of the ”DAK’s” passenger cabin there are seven windows. The windowpanes are 47,7 x 34,9 cm in size. Their thickness is 5 mm. The panes have been fastened with 20 3,8 mm thick and 18 mm long roundhead grooved screws. The holes for the screws are situated in each window according to standard, at the same place. Between the frame and the pane there’s a 2 mm thick rubber seal. The seal has a speciality that it has holed rubber studs for each 11 mm hole. The studs press themselves into the screw holes so that the screws go through the rubber studs. The rubber studs prevent the screws being in direct contact with the plexiglass and operate as vibration dampers. The screws have been tightened against the plexi glass surface with nuts and washers, or instead of the washers with a supportive metal batten.

We started to renew the panes on the port side of the fuselage. At first we detached the pane from the window nearest to the door. One of the detachers was outside the fuselage and held the grooved screw in place with a screwdriver and the other one inside of the fuselage unwound the nut with care. The nuts had inch thread, so they were original. We detached all 20 nuts relatively easily and the screws were detached. The pane’s original rubber seal with studs appeared still to be in good condition, so it could be fitted back with the new pane. The empty window opening was covered from the outside with a plastic sheet fastened with duct tape. The detached rusty screws were cleaned, and their heads painted with anti corrosion paint.

When we continued detaching the panes, it was observed that that the screws of the remaining six windows had millimetre threads and were of various sizes, as if picked out of a junk box. Thus the screws aren’t original and fitted in the ”U.S of A”. Furthermore, the panes were without the rubber seals and attached only with less than ten screws instead of twenty. Because of this the window frames had empty screw holes for water to leak between the frame and the pane and to the cabin. Part of the panes were also thinner than the original ones. So it’s evident that DO-5 hasn’t flown with these panes assembled. The panes have most probably been fitted to the DO-5 cabin at Utti, when the fuselage was transformed into a ground training platform for paratroopers, or after the writing-off of the fuselage and abandoning it into the woods.

We decided to replace all the panes we had detached with 5 mm. thick plexi glass (as was the case in the original), 20 attachment screws and rubber seals. This means that we will have to buy seven panes of plexi glass, new attachment screws and some rubber mat for making the seals. Rubber seals with studs like the originals we are, however, unable to make. We bought the seven polycarbonate plexi glass panes sawn into measurements at ETRA. Because only one pane was original with original rubber seals, the 11 mm screw holes responding to the rubber studs will only be drilled to that. All the other six panes will be drilled holes for only 5 mm thick attachment screws, because these panes will be fitted with a 2 mm thick smooth rubber seal. We made a drilling frame out of a sturdy plate and battens, to drill the 20 screw holes into the panes in exactly the right spots. The drilling began into the plexiglass pane for the original window. The new plexiglass pane, still covered with a protective film, was placed under the drilling frame. On top of that was placed the original pane, which had 20 holes of 11mm in diametre for the rubber studs and attachment screws, which was meant as a drilling template. The panes were locked into the drilling frame with clamps.

To drill the holes precisely in the middle of the holes in the template pane, we lathed out of brass a drilling guide, which fits snugly into the 11 mm. hole. In the middle of the guide a hole was drilled for the 5 mm drill bit. The guide was placed into the 11 mm hole in the old pane, which was on top of the new plexi glass pane and through the guide a 5 mm preliminary hole was drilled into the pane under it. Thus a 5 mm hole was drilled into all the 20 holes. After this an 11mm bit was changed in the column drilling machine, and the template pane was removed from top of the new pane. The 11 mm bit was centred on the first 5 mm hole, and it was enlarged to 11 mm. Thus all the 20 holes were enlarged. After the drilling was done, the size of the holes was tested by fitting the rubber seal with studs from the original window to the new pane. The rubber studs fitted perfectly into the drilled holes.

The six other panes were made in a different way, because they will be fitted with a smooth 2mm thick rubber seal. Into these panes 20 holes were drilled with a 5 mm bit. This means that the panes’ screw holes will lack the vibration damping effect given by the studs, but on the other hand this DO-5 fuselage will never again fly, apart from a little shaking when moved about. When all the holes had been drilled to the new panes, it was time to make the rubber seals. A metre of 1,4 m wide rubber mat was bought from ETRA. Because the panes measure 47,7 x 34,9 cm. there’s enough material for eight seals, enough for a couple of extra ones. A funny thing happened when buying the mat; the shop assistant asked: ”would you like the smelly mat or the one without smell”? The brand without smell turned out to be double the price. To save Aviation Museum Society’s funds we bought the “smelly” brand. By Jove it did smell revolting, but soon the smell evaporated.

To cut the seals from the rubber mat for the six new plexiglass panes, a template out of plywood, exactly like the seal, was made. With the aid of the template the necessary six rectangular shaped rubber seals were cut. Now the seals lacked only the holes for the pane’s 20 attachment screws.

The screw holes were marked in each seal by using one new plexi glass pane as a template, into which 20 screw holes 5 mm in diametre had been drilled. The plexi glass pane with the screw holes was lined precisely on the rubber seal. A mark was made with a pen through each hole. After that the holes for the screws were made in the seal by using a leather piercer. This procedure was repeated on all the six seals.

We still had to find as many as possible new screws with a low round head and groove, resembling the original ones, with nuts and washers, to attach to the windows. You can’t find them in modern ironmongers’ anymore. Luckily the screws we were after could be found at Uudenmaan Pultti in Järvenpää. They were 4 mm thick and 20 mm long. With millimetre threads but being almost a match to the original 3,8 mm thick and 18 mm long screws. The heads of these new screws were painted in silvery grey, so that they wouldn’t stand out gleaming on the side of the DO-5 fuselage. Now everything is ready for the new panes to be installed to the port side windows of the DO-5 cabin. Photos by Lassi Karivalo Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

The lower half of DO-5 nose cone on loan to fabricate a new oneSunnuntai 23.4.2023 - Tuesday Club member The fuselage of the Air Force C-47 (DO-5), which had been used for paratrooper training and is currently owned by Aviation Museum Society, is lacking the nose cone. The reason being that only the upper half of the cone survived and a lower half doesn’t exist in Finland for our purposes. Probably such an item could be found abroad for a load of money, but that form of action isn’t for us.

Left hand photo via Laskuvarjojääkärikilta. After pondering various possibilities to build the lower half of the nose cone at the Tuesday Club, we ended up in building the lower half out of fibreglass. The fibreglass lower half of the nose cone wouldn’t by all means be like the original, made of aluminium sheet, but resembles the original one, however. It would certainly be better than no nose cone at all. Now we have to find on loan an original “Dak” nose cone lower half, so that we could make a fibreglass mould with the help of the original lower half. Based on it we would make the fibreglass lower half of the nose cone. When installed, it would be painted in aluminium finish and simultaneously the upper half would be cleaned and polished.

The solution to acquiring an original lower half was found when the owner of the front fuselage of the ex Kar-Air DC-3 (OH-VKC), situated in Finland, promised to borrow us the lower half of the nose cone. So a group of DO-5 project members travelled en situ to dislocate the nose cone. For the most part we managed easily to detach the screws holding the lower half in the fuselage. We were helped by the preparatory work done by the owner of the OH-VKC front fuselage. A few screws had to be loosened by drilling.

In spite of the awkward working postures and the loose talking typical to us, the lower half of the nose cone was detached from the nose of OH-VKC in a couple of hours and the journey to the Finnish Aviation Museum began.

At the museum we fitted the lower half of the nose cone on loan and the DO-5 upper half together. They did match perfectly well, even though DO-5 is of the Douglas type C-47 or transport aircraft and OH-VKC is an original passenger aircraft. We established the lower half of the nose cone on loan to be perfectly suitable for making a fibreglass mould. Before we get that far, the lower surface of the lower half on loan has to be ground clean of dirt as well as the paint and filler on its surface.

Our aim is that the complete nose cone will be in place in the DO-5 fuselage, when it will be on show at the Aviation Museum Society’s stand at the Turku Airshow on June 17th -18th. Photos by Lassi Karivalo except if otherwise mentioned Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

The DC-3 (DO-5) fuselage refurbished for displayLauantai 8.4.2023 - Tuesday Club member Aviation Museum Society Finland will bring to its stand at the Turku Airshow on Jun.17th – 18th the fuselage of the DC-3 aircraft it owns. To be precise, it’s the fuselage of a Douglas C-47 A- 80-DL aircraft. It was completed at Long Beach in 1944.

Photo via Jarmo Kaipainen. This “Dakota” designated DO-5 last served in the Finnish Air Force as a flying trainer for paratroopers and finally its fuselage was used as a ground training platform for paratroopers. After rotting away for decades in the Utti forest it was donated to Aviation Museum Society Finland. With the fuselage came the tail assembly and the outer wing panels. The fuselage is without the centre wing section. Unfortunately it has disappeared somewhere during the passing years.

Photo by Juha Ritari

Aviation Museum Society restores the fuselage for display purposes. This work is presently undergoing at the Tuesday Club. Lots of work is still ahead, before the fuselage is back at its DO-5 era operational appearance. As may easily be guessed, tens of years outdoors with leaking cockpit windows has played havoc, but we aren’t downhearted as the saying goes. Yes, and the fuselage has already been used as a stage prop for the recent Finnish films “Pertsa ja Kilu” and “ Sisu”.

The fuselage of the DO-5 will be brought on display to the Turku Airshow into the Aviation Museum Society’s stand, even though it won’t be in the display condition we aim it to be. It will still be interesting to see the configuration the DO-5 was used in training the paratroopers, because the cabin is still in the condition it was used in para training with the canvas benches along the walls and the parachute opening straps hanging on the running wire.

At this moment the fuselage is at the Aviation Museum’s yard to be restored by the Tuesday Club. Restoration work has been going on both in the cockpit and in the cabin. In the cockpit both the pilots’ seats have been detached and dismantled into parts. They are at a sorry state and partly rusted. We aim to get them restored by the summer. A real challenge are the back plates and the seat buckets which are both made of pressed cardboard. They have all gone mushy because of the rainwater leaking into the cockpit. A probable alternative is to make the back plates and the seat buckets from aluminium sheets.

The door between the cockpit and the cabin has been restored. Presently we have started to renew the cabin windowpanes, which have become opaque. The opaque panes will be replaced with clear polycarbonate ones. One of the panes has already been detached. We hope to get at least the seven panes by the cabin exit door changed into transparent ones by the Turku Airshow.

The cockpit is lacking the instrument panel and instruments. As a first aid measure we aim to install a real and full sized “Dakota” instrument panel into the cockpit copied on an aluminium sheet. The instrument panel was photographed from the Karhumäki Airways OH-VKB DC-3A-aircraft. And that’s not nearly all. There’s no nose cone on the DO-5 front end. We do have the upper half of the nose cone, but the lower half is missing. There isn’t one in Finland for us to get our hands on. The meaning is to make the missing lower part from glass fibre. To make the glass fibre mould we can borrow an original lower half of a CD-3 nose cone. If the work proceeds as planned, the DO-5 nose doesn’t have the cut off look at the Turku Airshow but has the original “Dakota” nose form. Sooner or later the DO-5 fuselage, which has now become covered with dirty grey patina, will be polished to pristine condition. As the good reader will notice, nearly all that I wrote about isn’t ready yet. Let this blog be more of an inducement to go to the Turku Airshow on June 17th -18th and to visit the Aviation Museum Society’s stand and the DO-5 fuselage, the Hawk experience centre, the OH-XEA “Snoopy” light aircraft and also the Aviation Museum Society’s OH-LEA “sinilintu-bluebird” Caravelle – jet airliner resplendent in Finnair colours, which will be assembled by the airport passenger terminal. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

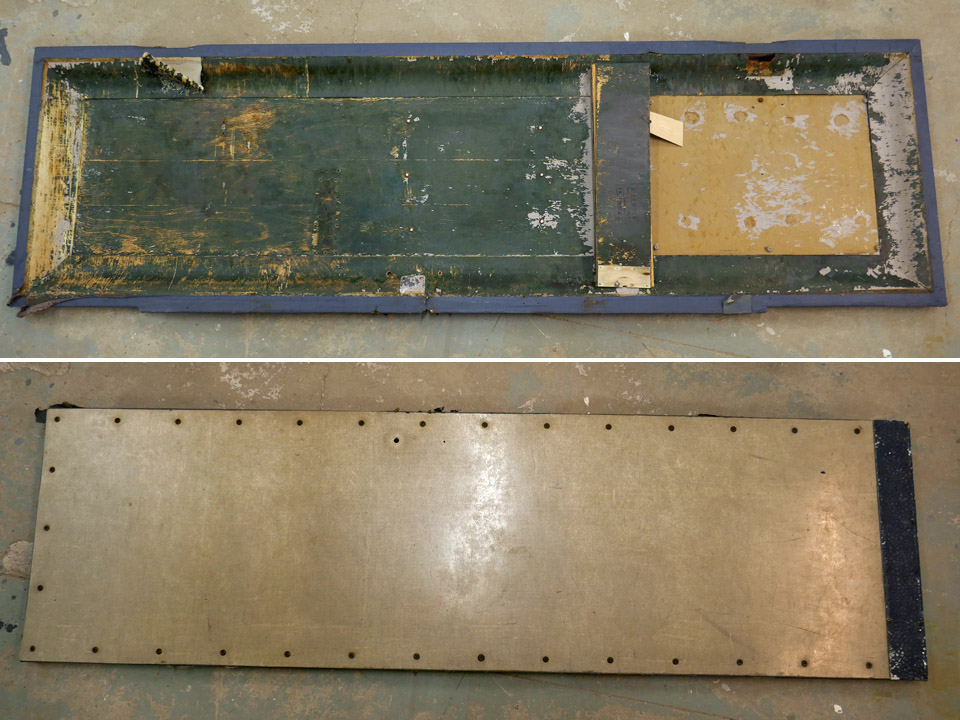

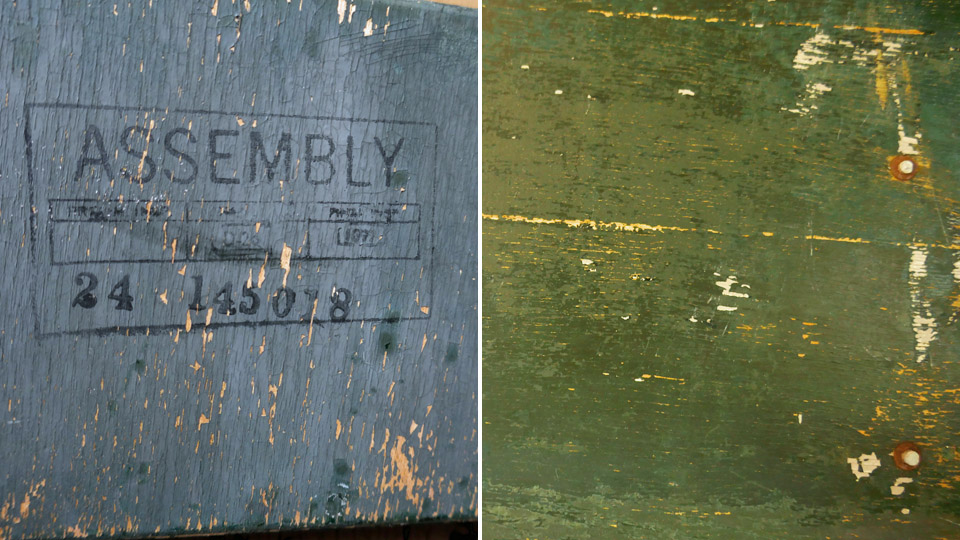

DO-5's door from the cabin to the cockpit is under restorationSunnuntai 6.11.2022 - Tuesday Club member The restoration work of the DO-5 (DC-3/C-47) fuselage, owned by Aviation Museum Society Finland, is now concentrating on the wooden door which separates the cockpit from the cabin. Structurally it is a so-called panel door. The painted surface on the cockpit side is badly worn and flaked, and it will be restored to its original condition. On the cabin side the original surface of the door has been hidden under a modern and pale hard-surfaced board. The same board has been used for covering the cabin side of the wall separating the cockpit and the cabin, and the cabin walls up to the upper level of the cabin windows. We are wondering whether the door and walls have been re-covered during the aircraft’s Lufthansa period or when it came to the use of the Finnish Air Force. We decided to leave the cabin side of the door as it is, with its new covering, to match the cabin walls. Judging from the cockpit side of the door, the door seems to be an original C-47 type door. An indication of this is a large stamp found on the plywood surface of the door. The word ASSEMBLY and serial number 24 145018 can still be read on it. There are also other numbers on the stamp, but they are not clearly distinguishable.

For restoring the door, it was disassembled from its frame and brought to the restoration workshop at the Finnish Aviation Museum. The painted surface on the cockpit side will be sanded and the plywood veneers, which have delaminated, will be glued back together. Finally the door will be repainted.

Before painting, the loose flaked paint was scraped off and the greenish grey paint surface was sanded smooth. Our aim is to paint the door and the aluminium wall surfaces in the cockpit using the original shade of green. Before that we will try to find out what the original paint and its shade might have been.

At least two different shades of green can be seen on the door. It looks as if there is a paler shade of green underneath, and it has been covered with a darker green paint. On the aluminium wall surfaces in the cockpit at least three different shades of green can be distinguished. We can only guess which of these could have been the original one – if any. After the invasion of Normandy, the DO-5 has been in civilian use in the Netherlands, French Indochina, and Germany before coming to the service of the Finnish Air Force in 1960.

I asked for advice about the DC-3 colours from the Finnish Air Force Museum. I learned that the cockpit colour, and also the colour of the door, was most likely the American “Bronze Green” or “Dull Dark Green”. In the American aircraft of that era the colour of the inner surfaces was usually dark green. Zink chromate anti-corrosion primer was used on aluminium surfaces and its shade was modified with black pigment, adding some UV-protection on the paint. However, there are still some issues to resolve before we can go and buy the paint.

The surfaces still need some preparatory work before the door is ready to be painted. We haven’t yet decided whether the door will be painted now or in the spring, together with the aluminium wall surfaces in the cockpit.

When the door surfaces had been sanded, the delaminated plywood veneers were glued into place. The veneers were pressed tightly against the surface using blocks of wood and clamps. The glue we used was EriKeeper Plus wood glue, meant for outdoor use. Photos by Lassi Karivalo Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

DO-5 cockpit seatsTorstai 20.10.2022 - Tuesday Club member Suomeksi Restoring the fuselage of the DC-3/C-47 (DO-5) into at least tolerable condition before display requires all kinds of work. The main emphasis is on the cockpit area.

When the tail sections of the DO-5 and other clobber had been moved from the fuselage into the storage container next to the aircraft and when the cockpit windows had been sealed to prevent rainwater from entering the aircraft, we could concentrate on the cockpit. The starting point was a complete disaster area: the instruments and most of the cockpit equipment were missing, the seats were tattered, the walls bare without interior panels, and there was rubbish everywhere.

Our first step was to clear the cockpit of the clobber and rubbish, which had filled it during the years. Eventually we were even able to use a vacuum cleaner for cleaning the surfaces in the cockpit. The first aim is to make the cockpit look tidy. Thinking further, it would be nice to install some of the missing instruments and equipment back into the cockpit, but now this seems to be very far away.

After cleaning our following targets were the pilots’ seats. The seat consists of the actual seat and its tube frame, on which the seat is fastened. Our aim is to restore the seats although the seat parts are badly damaged. The tube frames are still in good condition, although covered with rust.

The reason for the damage is that the whole seat part is made of multi-layer cardboard; pressed and stiffened into the shape of a seat. Due to the rainwater and humidity which has got into the cockpit, the pressed cardboard has become soggy, and the cardboard layers have disintegrated into pulp. However, the seat backs are still in reasonable condition.

The truth is that it won’t be possible to restore these original tattered seats into good condition. The seat part of both seats will have to be completely replaced, even though the seat back is still useable. We will certainly be stuck between a rock and a hard place, trying to figure out how the seat part could be rebuilt. One option would be to build it from aluminium plate, this is an alternative to be considered. The seat frame must be cleaned of rust and painted.We started the seat work by unfastening both pilot’s seats from the rails on the cockpit floor. Then the seat part of each seat was unfastened from the seat frame. The seat is fastened on the seat frame tube with brackets, which slide on the tube to allow the height of the seat to be adjusted. The seat is locked at the suitable height with lock pins which are pushed into the holes on the frame tubes. The adjusting mechanism is under the seat.

We started the dismantling work of the seat on the left. We unfastened the rusted brackets around the seat frame tube to disassemble the seat from the frame. This wasn’t easy, because the seat height adjustment locking pins were still firmly stuck in their holes on the seat frame. Some effort was needed before the adjustment system’s locking pins could be pulled out of their holes and the seat and its frame disassembled.

We dismantled the seat on the right in a similar way. It is identical to the seat on the left, but its mirror image. There we had to disassemble completely the seat height adjustment mechanism before the locking pins could be pulled out of their holes on the seat frame. Then the seat and the frame could be unfastened from each other. Both seat parts were taken to the DO-5 storage container to wait for further actions. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, DO-5;DC-3, C-47, Dakota |

DO-5 cockpit windscreens to winter proof conditionSunnuntai 16.10.2022 - Tuesday Club member Work on the fuselage of the DC-3 (C-47) DO-5, owned by Aviation Museum Society Finland, have started promisingly at the Tuesday Club. At the moment we aim to concentrate on tasks that are possible to do regardless of the weather during the cold period and winter season. The fuselage is out in the open at the yard of the Finnish Aviation Museum. Furthermore, we have prepared the fuselage, which is out in the open, for the autumn rains and the blizzards of winter.

One such measure was to get the cockpit windows sealed so that rainwater and snow wouldn’t get into the cockpit. We had already earlier in the autumn covered the cockpit windows of the DO-5 with rainproof plastic, because the plexiglass panes fixed to the frames of the windscreens were too small to keep water out of the cockpit. Both the original windscreen panes of the DO-5 have been broken at some stage and been replaced with transparent 3 mm thick plexiglass panes.

To replace those undersized windscreen plexiglass panes before winter we had to get new plexiglass ones to fit properly to the windscreen frames. Although that wouldn’t be the procedure with a flying DC-3 aircraft, but to replace a broken or otherwise unusable windscreen pane, a completely new pane with frames would have been changed as a spare part. Such spares we don’t, alas, possess.

So the undersized windscreen plexiglass panes were detached and the chutes of both windscreens were cleaned of rust and dirt with a brush disc, attached to a battery driven drilling machine. To acquire new plexiglass panes, a window shaped template was made of 1,2 mm plywood. This template was cut so, that the template of the windscreen pane could just be slid into the chute of the frame through the windscreen opening.

The plan is to glue the new plexiglass pane to the chute with silicone. In the process of gluing the plexiglass pane will be supported so that it leans with each edge a few mm against the inner side of the frame chute. Thus the plexiglass pane would cover the whole windscreen opening and the silicone seam would become watertight.

WE had ETRA cut us two windscreen panes according to the plywood templates, from 5 mm thick UV-protected polycarbonate plexiglass. When we fitted them into the DO-5 windscreen chutes, after a bit of filing, we got the panes to click into place inside the windscreen frame.

Because the autumn temperatures had sunk to about 10 degrees centigrade, we decided to postpone the gluing of the plexiglass panes to warmer weather next spring. Instead, we taped the new plexiglass panes, covered with protective plastic, on the outside of the aircraft with orange tape to the frames of the windscreens in order to stop rainwater or snow from getting into the cockpit. The tape covered completely the seam between the fuselage and the frame of the windscreen. We covered the seams of the cockpit’s side widows in the same manner, to prevent rain from penetrating into the cockpit through them.

Another preparation for winter was to cover the tail section with a protective tarpaulin. The vertical and horizontal stabilizers have been dismantled. Thus rain and snow have free access into the fuselage through the openings. We got hold of a large tarpaulin, with which we covered the tail section completely. Photos: Lassi Karivalo Translation: Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, DO-5;DC-3, C-47, Dakota |

The Tuesday club is starting to restore the DO-5 fuselageSunnuntai 11.9.2022 - Tuesday Club member Aviation Museum Society Finland owns a DC-3 (C-47) DO-5 fuselage with elevators and rudder. The wings are still lacking. The fuselage of the DO-5 came to the possession of the Aviation Museum Society in 2018, otherwise the fuselage would have ended in the scrap yard. The ex- Air Force DO-5 last served as a ground training device with the parachute jumping school at Utti. The DO-5 fuselage owned by Aviation Museum Society has already been used as prop in two movies.

The intention of Aviation Museum Society is to refurbish the DO-5 fuselage so that it could be presented in different outdoor occasions. It would then be possible to get acquainted to the interior of the aircraft. The passenger cabin of the fuselage will be preserved in its existing parachuter training appearance with the canvas benches along the walls. The fuselage will be available to film makers’ needs in the future, too.

The fuselage refurbishment of DO-5 is beginning at the Aviation Museum Society’s Tuesday Club. This is why the fuselage is on the yard of the Finnish Aviation Museum. Well, it will not be ready tomorrow by far, for the club members have their work cut out for them with the refurbishment of the fuselage. But, maybe by the end of spring 2023 the work will be so much advanced, that we could dare to take the fuselage on display at the National Air Show at Turku. Well, time will show.

The beginning of the autumn season for the Tuesday Club has been spent on preparations for the DO-5 fuselage refurbishment. One of the tasks will be the removal of the vertical stabilizer, rudder, elevators, the rear cone, nose cone and other parts of the aircraft that were stored in the cabin, to a storage container which was brought to the vicinity of DO-5. The horizontal stabilizer, which was stored under the fuselage, was also moved into the container. The parts that had been in the cabin had to be taken away, because they filled the fuselage so that moving in there was difficult, dangerous even, not to mention working in the cabin during the restoration process.

In the restoration of the fuselage, we will concentrate at first on the cockpit. There we’ll have to, amongst other things, to seal the windows and possibly replace them partly with new ones, to detach the pilots’ seats for refurbishment, to clean the cockpit surfaces and remaining equipment and to paint the wall surfaces.

We have already accomplished something in the field of restoring, when the legendary DC-3 mechanic Pauli “ Speedy” Fallström replaced the broken tail wheel with a new one. Photos: Lassi Karivalo Translation: Matti Liuskallio |

|

Avainsanat: aviation history, restoration, Tuesday Club, DO-5;DC-3, C-47, Dakota |

Tuesday Club activities are continuedTiistai 7.9.2021 - Tuesday Club member During the Covid-19 pandemic a small Tuesday Club team has been working on the VL Myrsky restoration project. Tuesday August 31st was a day of joy: finally, after a break of about 18 months, the other Tuesday Club activities could be continued. The main work item is the restoration of the Caudron C.59 trainer fighter, which is now in the restoration space of the Finnish Aviation Museum.

Photo: The photo archive of the Finnish Aviation Museum. However, there are still some restrictions and Covid-19 instructions from the Finnish Aviation Museum and the Tuesday Club is not able to start with full capacity. The number of workers in the restoration space is still limited and everybody working there is still wearing a mask.

In order to involve as many Tuesday Club members as possible in the Caudron restoration work, the team has been divided into two groups and works in the restoration space on Tuesdays and Wednesdays. This allows about twenty club members to work on the Caudron and on other projects, too. The Myrsky team continues to work on three days a week. The Caudron C.59 restoration is continued, now the holes on the lower wings are being repaired. About 18 months ago the lower port wing was patched and the patches were made for the starboard wing – then the Covid-19 pandemic interrupted the Tuesday Club activities. Now the patching of the starboard wing is in progress again.

The tail boom stabilizers of the Mil Mi-8P (HS-6) helicopter, which is on display on the yard of the Tuulonen shopping centre, have been brought to the Tuesday Club to be repaired. The stabilizers are partly covered with fabric and the fabric has decayed, because the helicopter has been on display outdoors since it was removed from service in 2007. The fabric covering will be renewed by the Tuesday Club team.

One of the most unique projects the Tuesday Club has come across is the preparation of a DC-3 instrument panel for a movie. A proper DC-3 instrument panel will not be made, but a reasonably plausible version anyway. Photos: Lassi Karivalo except if separately otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caudron C.59, CA-50, Mil Mi-8P, HS-6, DC-3 |