A busy weekend at Caravelle at Turku airport during July 13th and 14thMaanantai 15.7.2024 - Ismo Matinlauri This weekend was the busiest we have had so far this year at our Caravelle. In this blog you will find some photos from the successful events. Saturday, July 13thOn Saturday there was a display of French vintage car technology beside the Caravelle.

Club Renault de Finlande is celebrating its 40th anniversary this year. They started their Finland Tour from Turku airport on July 13th. For Renault 2024 is a year of celebration as well, the company was established 125 years ago. Below some photos from the sunny Club Renault de Finlande event. The weather conditions were favourable, and the temperature climbed to +26 degrees Centigrade.

There was a nice collection of vintage Renaults on display.

The day was successful also for Caravelle as we had well over 50 visitors. Sunday, July 14thOn Sunday morning it was rainy in Turku and the temperature was much lower than on Saturday, only +18 degrees Centigrade. Despite the drizzle, we celebrated the National Day of France and hoisted the flag appropriately. In the staff room “Café Caravelle” there were naturally fresh croissants available for our volunteers.

There were less visitors than on the previous day, probably due to the weather. However, there were more than a hundred visitors during the weekend, and we can be very satisfied with these summer events. Next week we will have the main effort of the summer as Caravelle will be open to the public during the Tall Ships Race event in Turku. The aircraft is open daily from 10 am to 3 pm from Thursday to Sunday, July 18th – July 21st. If you are in the Turku area next week, come and visit us at the airport! Photos by Ismo Matinlauri Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Caravelle's holiday seasonLauantai 6.7.2024 - Ismo Matinlauri The Caravelle Turku team volunteers finished their spring season at the end of June. The team members started their well-earned holiday at their cottages, travelling or being active in other hobbies. In the beginning of August they will return to Caravelle restoration work. During the spring season the Turku team and the assisting technical team totalled almost 850 hours of voluntary work. Some news about the most recent work in June are shown below. Furthermore, the polishing of the lower part of the aircraft’s fuselage was continued whenever weather permitted. The officeRamirent Oy (the equipment rental company) donated us two modular containers which were joined and assembled beside the Caravelle. Now we have a combined office and shop on site.

A power supply was installed, and the office was furnished. Everything is ready inside and outside and we can use our new space during the summer season. A housewarming event will be arranged in August. Also our unofficial “Café Caravelle” (i.e. the Turku voluteers’ coffee break facility) was moved from the aircraft cabin into the new office. Now there is more space for the future interior work, and it is also easier to move in the cabin as there is less material and furniture. The passenger door and cabin partitionsThe left-hand side passenger door’s complicated opening and counterbalancing mechanism was repaired during the spring. This was quite an effort and a series of four blogs was written about it earlier. The repaired door mechanism works fine, and the passenger door is open during the visiting hours.

The partitions in the front part of the cabin are fitted into place in the two photos. The passenger door is open to confirm the correct location of the partitions so that the door opening mechanism is not disturbed. The partitions will be resurfaced in August, using material which resembles the original one, and then assembled into place. Electrical installationsThe electrical installation work is almost completed. Power outlets are already in place and connected. The wiring for lighting is almost ready, too. In August when the work continues, LED lighting will be installed on the flight deck and in the toilets and galley area in the rear section.

A LED-strip will be installed in line with the upper edge of the cabin overhead hat rack. The photo shows its wiring, waiting for the ceiling surface material installation. After that the LED-strip mounting can be assembled.

The last photo shows the white main distribution board which will be installed into the former equipment rack behind the flight deck, on the left-hand side. Wiring from the distribution board is located under the cabin floor. The wiring was being installed when the photo was taken. Before going on holiday we collected all tools and tidied up inside the aircraft for the visitors’ events. The Caravelle will be open to the public on several occasions in July. Our volunteers will be on site to introduce the aircraft and its history. Photos by Ismo Matinlauri. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Caravelle's passenger door mechanism is repaired - Part 4Maanantai 27.5.2024 - Erja Reinikainen ja Martti Saarinen The reparation procedure of the left-hand side passenger door’s complicated opening and counterbalancing system has been described in the previous blogs and the story is completed in this one. During our previous reparation visit the door was already functioning in the desired way but after a long working day the last adjustments and final inspection were not done. Therefore the door could not be taken into use yet. In the week before our latest visit to Turku we asked the Turku team to check whether the bungee ropes are still tight when the door is closed. The reply was reassuring, they are tight all right. This meant that nothing had failed or broken while the counterbalancing system had been carrying a full load for a week while the door remained closed. After arriving we lifted the cabin floorboards and checked the bungee ropes in the side tunnel under the floor. The ropes were still tight, so everything was ok. The polishing team was working outside, polishing the lower section of the passenger door and we had to wait for a while before we could open the door. It could be opened without problems.

Photo by Ismo Matinlauri. When the door was open and in its highest position, we could see that the bungee ropes had slackened a little. This we had expected to happen. There is a convenient adjustment at the far end of the each bungee cord attachment cable: the fastener pin is moved on the connecting piece into the hole where the desired tightness of the bungee rope is achieved. The adjustment was done in a couple of minutes and the door operation was tested again. Everything worked fine. After this the last installations were done, and the final inspection was completed.

The Turku team members were given user training on how to operate the door. Now it can be used safely and there is no need to go back and forth through the small and low service door. The passenger door was open for the visitors during the weekend opening hours on May 25th – 26th.

Meanwhile, work on the flight deck was continued to have the side windows replaced. The small triangular windows had already been replaced and now the large rear windows were under work. The windows are the emergency exits for the flight deck crew, so they are easy to remove by opening the locking levers and lifting the window away.

However, this was easier said than done after the aircraft had been standing outside for almost fifty years. A lot of gun oil and some patience were needed to open the locking mechanisms but eventually they could be opened. Installing the new window on the left-hand side went smoothly but the right-hand side was more difficult. Some machining was needed and two assistants helping before the window was in its place. Photos by Martti Saarinen except if otherwise mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

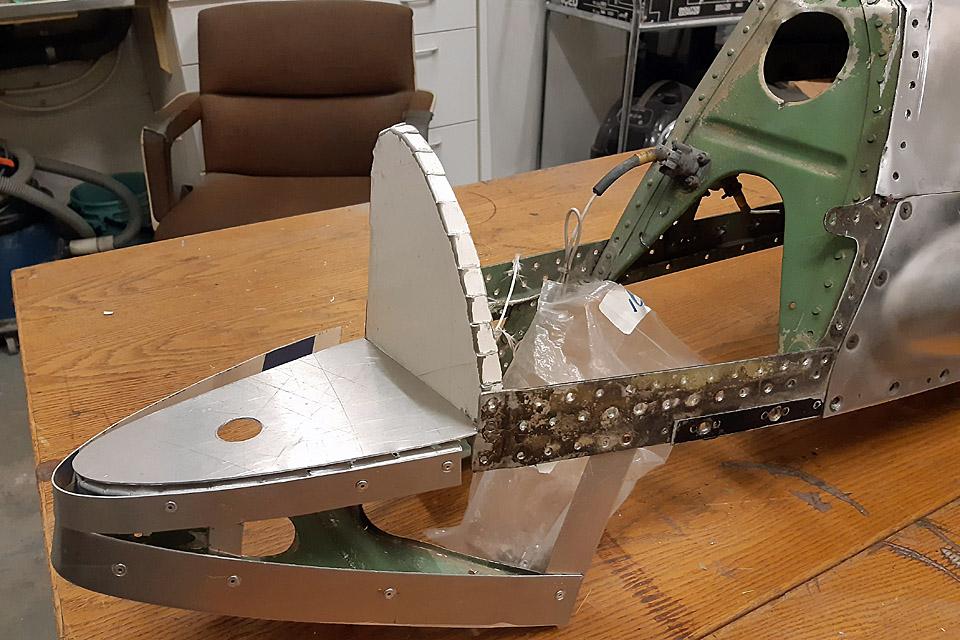

The right-hand side wingtip of Caravelle III "Bluebird" is delivered to TurkuSunnuntai 26.5.2024 - Tuesday Club member The Caravelle III "Bluebird" (OH-LEA), on display in Turku, has until now been without the wing tip piece of its right-hand side wing. For about a year, the wingtip has been under repair and parts of it have been rebuilt at the Tuesday Club, working at Finnish Aviation Museum. The leading edge of the wingtip had been destroyed while the Caravelle, in SAS colours at the time and carrying registration SE-DAF, stood by the edge of Arlanda airport for decades. Probably some airport vehicle had bumped into the aircraft.

The repair work of the right-hand wingtip section was completed at the Tuesday Club, but it wasn’t taken to Turku until now. The wingtip was transported from Finnish Aviation Museum in Vantaa to Turku airport, to be assembled on “Bluebird’s” wing. The wingtip section is too large to be transported in an ordinary passenger car. It was packed properly and loaded on the Aviation Museum yard on a trailer. The journey towards Turku could begin.

The vehicle was welcomed at Turku airport by the Caravelle Turku restoration team. The team unloaded the wingtip from the trailer and carried it under Caravelle’s right-hand side wing to wait for assembly.

Right-hand photo by Reijo Siirtola.

Now all Caravelle work allocated to the Tuesday Club have been completed. The work included repairing the nose bulkhead edge and the damaged radome, refurbishing and painting the wall panels of the flight deck and the corridor leading to the flight deck, repairing the glare shield above the flight deck instrument panel, building the frame for the navigation light on the right-hand wingtip and preparing the navigation light globes by 3D-printing.

Photo by Ismo Matinlauri. Furthermore, in 2022 we built stands for supporting the Caravelle’s fuselage and wings during the transportation from Arlanda to the former shipyard hall in the Pansio harbour area in Turku. We also restored the Caravelle III towbar, brought from Arlanda, which was in poor condition. The towbar is already in place, fastened on “Bluebird’s” nose wheel. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird, Tuesday Club |

Caravelle's passenger door mechanism is repaired - Part 3Tiistai 14.5.2024 - Erja Reinikainen ja Martti Saarinen The reparation procedure of the left-hand side passenger door’s complicated opening and counterbalancing system has been described in the previous blogs and the story continues in During the previous reparation effort the door could be opened with a manual winch, but the bungee ropes which were tested, were too weak to be used for opening and counterbalancing the door. There were also problems with the new roller chain and the door seemed to be slightly tilted. The technical team thought the problems might be caused by wrong adjustment of the cables or bungee ropes, or due to some part being bent in the process. Stronger bungee ropes were ordered from the US, and when they arrived it was time to try again to make the door work.

The attachment pieces at the door end of the new roller chain had been modified a little and this seemed to help to correct the door position. It now moved down without tilting on one side. Terminals made of copper tube had been prepared for the two new bungee ropes in the lifting mechanism, to fasten the bungee ropes to the sliding carriage and to the door lifting cables. For establishing the correct length of the bungee ropes, temporary fasteners were prepared for the rear end of the ropes to fasten them to the end cable of the bungee track. In the first phase the blue bungee rope in the middle was not changed, it remained as it had been in the previous testing.

The day was spent adjusting the length of the bungee ropes and cables, testing the door movement every now and then, and adjusting some detail once again. Some changes were also made on the bungee rope track. Eventually the door could be opened smoothly and rather lightly but closing it fully from its down position still required a fair bit of force. At this point terminals from copper tube were made also for the rear end of the two outer bungee ropes and the temporary fasteners were removed. The third bungee rope in the middle was replaced with a sturdier one and terminals were made for its ends. With this arrangement the door could be moved with less force but closing it fully was still difficult. After some additional adjustments the door was functioning as it should, but it was not taken into operation yet. The technical team had been working for full eight hours at this point, so it was time to call it a day. Next time the installation will be completed, and the adjustments will be checked after the bungee ropes have been under tension for a longer period when the door has been shut.

During the day there were naturally also other activities going on: The assembly of the office and visitor centre (which is a prefabricated reusable and movable small building) was continued and the space was prepared for the opening hours on the coming weekend. Tables and sales items were moved from the aircraft into the new building. The broken sealing strip on the passenger door was replaced with a new one.

On the flight deck there was a time-consuming battle to open the emergency exit windows’ locking mechanism which had rusted solid. Among the material brought from Arlanda in 2022 there are two windows for both sides of the flight deck. They are in better condition than the existing ones and they will used to replace the old ones. Eventually the rust on the mechanism began to yield and the locking of the windows can be opened.

The planning of the new padding for the passenger seats was continued. A workable solution is beginning to take shape. Photos by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Caravelle right-hand wingtip is finalized with the navigation light globeLauantai 27.4.2024 - Tuesday Club member When the new leading edge had been built to replace the destroyed right-hand side wingtip leading edge on the Caravelle III (OH-LEA Bluebird), we could begin the installation of the navigation light globe into its place on the leading edge. We don’t have the original navigation light globe because it has been destroyed together with the wingtip. We could not find a globe as a spare part either, so we had to make one. We chose to do this by 3D-printing. We used the partly broken navigation light globe from the left wing as a model. A new globe was printed for the right wing and also for the left wing navigation light.

The new navigation light globe was installed on the OH-LEA Bluebird’s left-hand wing earlier in the summer of 2023. The right- hand wing, however, had to wait until March 2024 for its new globe to be put already in early into place after the new leading edge of the destroyed wingtip had been finished.

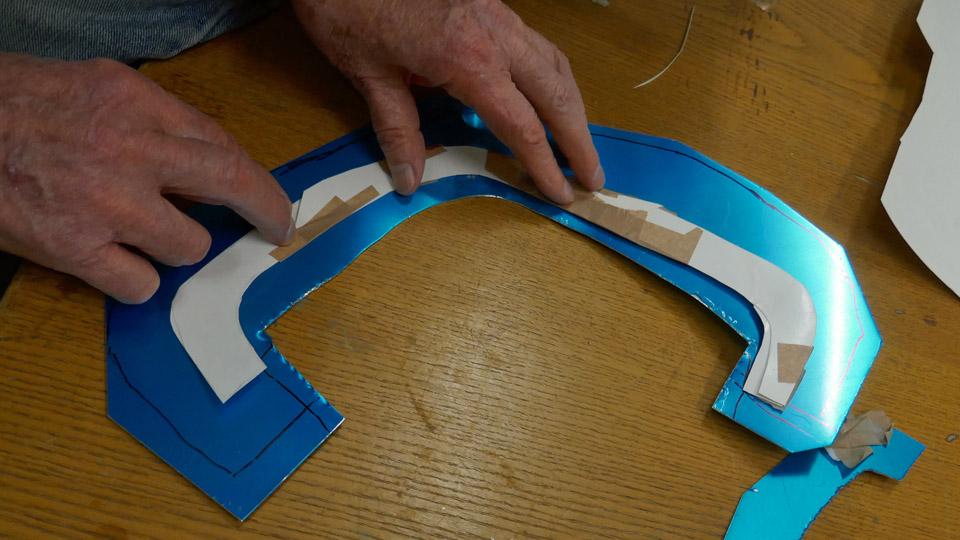

The 3D-printed navigation light globe is made of stiff plastic, and in the beginning it didn’t fit properly into place. We heated the globe with a hot air blower so that it could be moulded to fit into its mounting on the wingtip. The globe was fastened tentatively on the edges of the mounting with a couple of screws. This was necessary for holding the globe in place while making the fastening frame. The globe is fastened on the aluminium edge of its mounting with a frame. The frame has holes for screws, and it presses tightly against the sides of the globe, and the screws in the frame holes are tightened through the globe edge into the aluminium edge underneath.

Diverging from the original solution, we decided to make the fastening frame for the globe from two parts. This made it easier to build the frame. Nevertheless, the frame we made will cover the most part of the navigation globe edge. A connecting piece will be needed on the top of the globe to connect the ends of the frame.

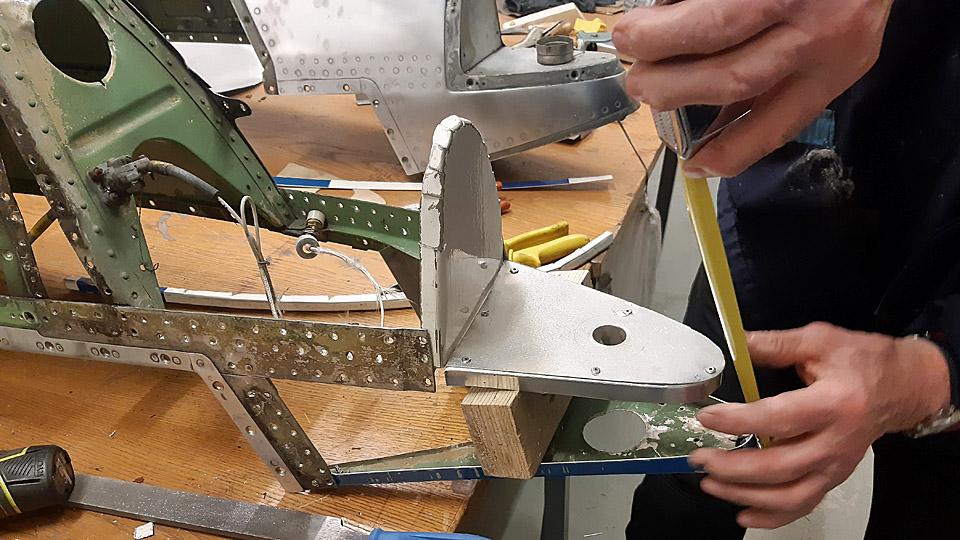

When the globe had been fastened with a couple of screws, broad paper tape was fastened on its edge. The shape of the globe frame was drawn on the tape. Based on the drawn line, a model for the frame was made of cardboard. The model was taped on a 1 mm thick aluminium sheet, which had already been pre-cut into the frame shape. After this we began to modify the sheet with a cutter to match the shape of the cardboard model.

The aluminium frame was test-fitted into place and modified several times. Gradually the frame reached its final shape and it rested against the lower edge of the globe as §planned. When the desired shape had been reached, the blue plastic film which had protected the aluminium surface was removed from the frame.

A strip of paper tape was fastened on the surface of the finalized fastening frame for marking the location of the fastening screws at regular intervals with a pencil. Holes for the fastening screws were drilled at the marked locations, then the screws were fastened one by one. This made the navigation light globe press into its place between the fastening frame and the edge of the globe mounting. Now the navigation light globe on the right-hand side wingtip was in place.

The last phase was to make the 5 cm connecting piece between the fastening frame ends on the top of the navigation light globe. First a cardboard model was made of the connecting piece. The connecting piece was cut and moulded from aluminium sheet, following the model. When the blue plastic covering had been removed from its surface, the connecting piece was fastened between the fastening frame ends, using two screws with washers. Finally the screws were tightened.

Under the globe, out of sight, is the socket for the navigation light bulb and its green glass globe. The socket was lathed from aluminium and installed into place at the Tuesday Club. The Caravelle’s right-hand side wingtip is ready for housing a powered navigation light, if there is need for it at some point.

Now the Caravelle Bluebird’s right-hand side wingtip had been completed. Re-constructing the destroyed leading edge took a whole year. The wingtip can be delivered to Turku to be assembled on the Caravelle Bluebird, which is on display near the passenger terminal at Turku airport. Photos by Lassi Karivalo. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird, Tuesday Club |

Caravelle's passenger door mechanism is repaired - Part 2Torstai 25.4.2024 - Erja Reinikainen ja Martti Saarinen Until now access to the Caravelle’s cabin has been through the small right-hand side service door and aft stairway. The passenger door operating mechanism has been damaged, and the door can’t be used before the mechanism is repaired. This blog describes the first phase of the passenger door repairs. When the passenger door is opened, it moves first straight inwards and then it is manually lifted along its rails up to the cabin ceiling. The door weighs 53 kilos, so opening and closing is assisted with a counterbalancing system. The system consists of roller chains, steel cables and three bungee cords (rubber ropes), several metres long and located under the cabin floor. There are no spare parts available for this system anymore, so the new parts have been designed and made by the technical team.

On its visit to Turku on April 12th, the technical team started the door mechanism repair work. The first phase was to install the new roller chains into the door rails (the broken chains had already been removed). The new roller chain is slightly different from the original one and some parts for it were made by order in a laser cutting company, and others ordered from abroad.

When the two roller chains were in their rails, their lower ends were fastened to the brackets on the passenger door and their upper ends to the counterbalancing cables. The roller chains and cables run through the door rails and down to the guides, which are located on the sides of the right-hand side service door. There are 4 guides on each side of the door.

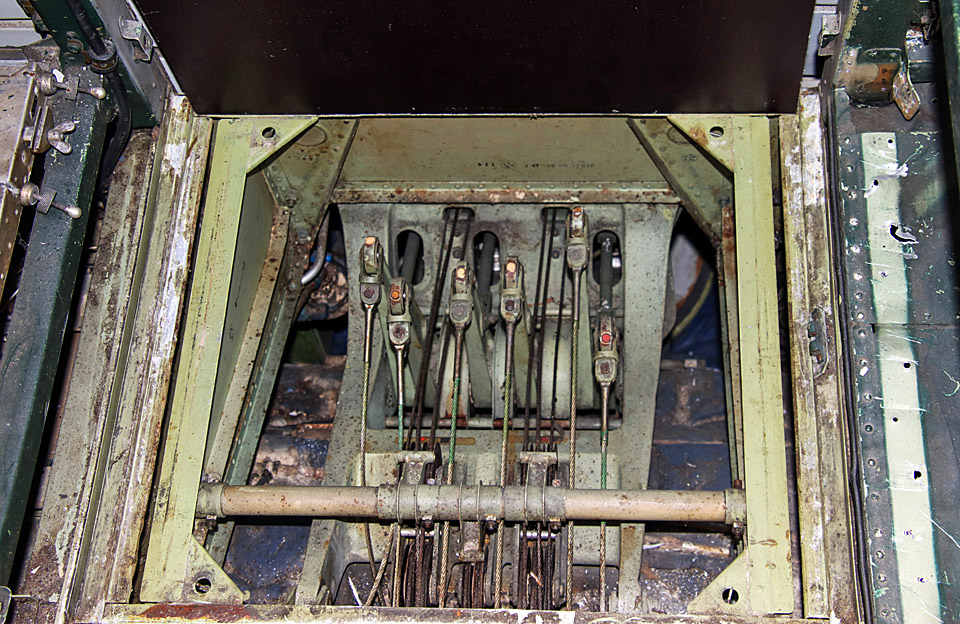

Under the cabin floor, in the side tunnel of the baggage compartment, the cables are connected to the bungee cords on a sliding carriage. The sliding carriage and its stops allow the bungee cords to operate in sequence, as the need for counterbalancing force depends on the position of the door. When closing the door, in the beginning the strength of one bungee rope is sufficient for the required counterbalancing. When the door moves downwards on the rails and is reaching its vertical position, the need for counterbalancing increases. This is when the two other bungee cords join in. The mechanism is complicated and not very reliable. When the Caravelle was in operation, the system needed regular repair and maintenance. The original bungee ropes have become brittle and can’t be used. The technical team is still looking for suitable material to replace the original ropes as the bungee ropes in the regular hardware store are too soft and slack for the purpose.

At this point the roller chain and the door function were tested without the bungee ropes by fastening the cables and the sliding carriage to a manual winch. It was not that simple to operate the winch in the cramped space under the floor. The lifting force was measured with the digital scales connected to the winch. The original bungee ropes and their supporting rollers can be seen on the upper right corner of the picture. The test arrangement worked: using the winch the passenger door could be opened, but not fully. At this point the door was secured with a couple or car tyres in the doorway.

The problem appeared to be the roller chain and cable guides, located on the sides of the service door: the new roller chain didn’t move smoothly through the guides. After some discussion the team decided to disassemble and adjust the guides. As a test, the upper guide was disassembled and cleaned, and installed back into place a little bit differently. This helped to solve the problem, so the other guides will be disassembled before the next visit of the technical team when the door mechanism repair will continue.

During the day there was also other activity in the Caravelle: three new instruments were installed into the instrument panel on the flight deck. It looks quite good already but there will be some more additions later.

The cabin curtains were unfastened from their popper slides to have them out of the way when the interior work begins. Fortunately the curtains are mainly in quite good condition, but dirty. They will be washed and ironed before putting them back. This won’t be done before the interior work has been completed.

Work was going on outside, too: the SAS prints were removed from the aft stairway before repainting. The best work method has proved to be to heat the painted area first with a blower and the scrape the paint off. Photos by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Caravelle's passenger door mechanism is repaired - Part 1Tiistai 16.4.2024 - Erja Reinikainen ja Martti Saarinen Until now access to the Caravelle’s cabin has been through the small right-hand side service door and aft stairway. The passenger door operating mechanism has been damaged, and the door can’t be used before the mechanism is repaired. This blog describes the first phase of the passenger door repairs. When the passenger door is opened, it moves first straight inwards and then it is manually lifted along its rails up to the cabin ceiling. The door weighs 53 kilos, so opening and closing is assisted with a counterbalancing system. The system consists of roller chains, steel cables and three bungee cords (rubber ropes), several metres long and located under the cabin floor. There are no spare parts available for this system anymore, so the new parts have been designed and made by the technical team. On its visit to Turku on April 12th, the technical team started the door mechanism repair work. The first phase was to install the new roller chains into the door rails (the broken chains had already been removed). The new roller chain is slightly different from the original one and some parts for it were made by order in a laser cutting company, and others ordered from abroad.

When the two roller chains were in their rails, their lower ends were fastened to the brackets on the passenger door and their upper ends to the counterbalancing cables. The roller chains and cables run through the door rails and down to the guides, which are located on the sides of the right-hand side service door. There are 4 guides on each side of the door.

Under the cabin floor, in the side tunnel of the baggage compartment, the cables are connected to the bungee cords on a sliding carriage. The sliding carriage and its stops allow the bungee cords to operate in sequence, as the need for counterbalancing force depends on the position of the door. When closing the door, in the beginning the strength of one bungee rope is sufficient for the required counterbalancing. When the door moves downwards on the rails and is reaching its vertical position, the need for counterbalancing increases. This is when the two other bungee cords join in. The mechanism is complicated and not very reliable. When the Caravelle was in operation, the system needed regular repair and maintenance. The original bungee ropes have become brittle and can’t be used. The technical team is still looking for suitable material to replace the original ropes as the bungee ropes in the regular hardware store are too soft and slack for the purpose. At this point the roller chain and the door function were tested without the bungee ropes by fastening the cables and the sliding carriage to a manual winch.

It was not that simple to operate the winch in the cramped space under the floor. The lifting force was measured with the digital scales connected to the winch. The original bungee ropes and their supporting rollers can be seen on the upper right corner of the picture.

The test arrangement worked: using the winch the passenger door could be opened, but not fully. At this point the door was secured with a couple or car tyres in the doorway.

The problem appeared to be the roller chain and cable guides, located on the sides of the service door: the new roller chain didn’t move smoothly through the guides. After some discussion the team decided to disassemble and adjust the guides. As a test, the upper guide was disassembled and cleaned, and installed back into place a little bit differently. This helped to solve the problem, so the other guides will be disassembled before the next visit of the technical team when the door mechanism repair will continue. During the day there was also other activity in the Caravelle: three new instruments were installed into the instrument panel on the flight deck. It looks quite good already but there will be some more additions later.

Photo by Jouko Tarponen. The cabin curtains were unfastened from their popper slides to have them out of the way when the interior work begins. Fortunately the curtains are mainly in quite good condition, but dirty. They will be washed and ironed before putting them back. This won’t be done before the interior work has been completed.

Photo by Jouko Tarponen Work was going on outside, too: the SAS prints were removed from the aft stairway before repainting. The best work method has proved to be to heat the painted area first with a blower and the scrape the paint off. Photos by Erja Reinikainen except if otherwise mentioned. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Caravelle's overhead storage shelf is movedTiistai 2.4.2024 - Ismo Matinlauri The interior work of Caravelle III, restored as Finnair OH-LEA Bluebird, started in March after the winter break. The first work item was to move the rear part of the left-hand side overhead storage compartment to the front RH side. (In this case the compartment is actually a shelf, and it will be called that in this blog.) On the right-hand side all overhead storage shelves and the ceiling structure have been dismantled in Sweden for the needs of the local Caravelle III SE-DAI. Our aim is to build a part of a passenger cabin to the front part of the fuselage, with four rows of seats. For this purpose the overhead storage shelf had to be disassembled from the rear part and installed to the other side in front. The rear part of the cabin will be an open space for future events and exhibitions. Disassembling the overhead storage shelf proved to be an arduous operation. This seems to be the first area in the Caravelle where screws have not been used sparingly. Obviously the shelf has not been meant to be disassembled regularly during maintenance work. Dozens of small screws had to be unfastened and on top of that, four locking bolts had to be unfastened through the passenger service unit. We had to build a long-handled tool specifically for this purpose.

Fastening battens for the overhead storage shelf were fastened on the RH side, starting from the service door. The lower aluminium batten could be moved but the upper batten proved impossible to unfasten and move, so we decided to use a wooden batten instead.

Reassembling the overhead storage shelf happened as the disassembly but in reversed order. First we fastened the row of air conditioning and loudspeaker panels into place.

The fasteners of the overhead storage shelf had to be modified to fit into their new location. The original spacing of the fasteners didn’t fit because the shelf had to be turned around to assemble it to the other side.

The final fastening of the shelf was done through the passenger service unit (PSU). This time the fastening bolts were replaced with self-drilling screws. We decided not to move the brackets for the fastening bolts, we estimated the screws to be sufficient.

Above the overhead storage shelves we stretched the covering material we had taken down from the other side. Now the front part of the cabin looks identical on both sides. Finally we installed the metal grilles to cover the air-conditioning and loudspeaker panels.

We had been doubtful about moving the overhead storage shelves because of the amount of work and breaking the existing structure. Actually disassembling the shelf proved to be the most difficult and the most time-consuming phase. After that the reassembly into the new place was quite straight-forward. There will be a partition at both ends of the shelf so that the cut ends of the shelf will be covered. Building the partitions will be another story and we will come back to that later. Photos by Ismo Matinlauri. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

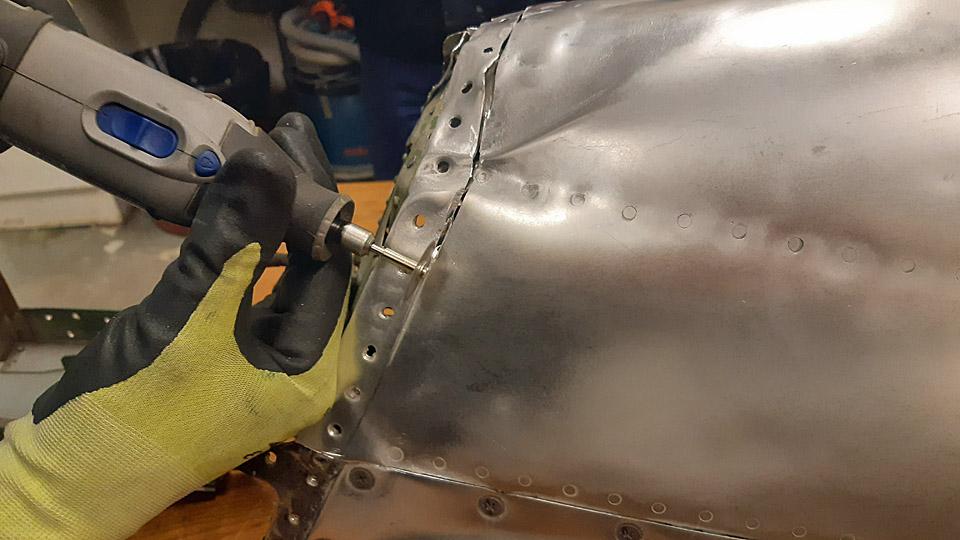

The Caravelle right-hand wingtip leading edge is completedKeskiviikko 27.3.2024 - Tuesday Club member Owned by Aviation Museum Society Finland and now on display at Turku Airport, the Caravelle lll (OH-LEA Sinilintu, Bluebird) has had its damaged right-hand wingtip leading edge restoration completed. The wingtip in the Caravelle is a separate entity, which can be detached from the wing. For the sake of simplicity, I’ll use the term wingtip for this structure in the future.

The last task in building the new leading edge for the wingtip was to rivet the edges of the upper and lower covering sheets to the centre line of the leading edge. The edges of the covering sheets meet at the centreline of the leading edge. Otherwise the covering sheets of the new wingtip had already been riveted in the wingtip structure.

To be able to rivet the covering sheet edges on the leading edge centreline, the sheet edges were tightened against the leading edge using a cargo strap, tied around the wingtip. After this, rivet holes were drilled at both ends of the sheets and the edges were riveted on the centre line with pop rivets.

It was noticed that a gap of 1-4 mm was left between the edges. The edges of the sheets therefore didn’t reach each other to form a butt joint. It was decided to cover the gap with an aluminium covering strip, running along the leading edge centre line.

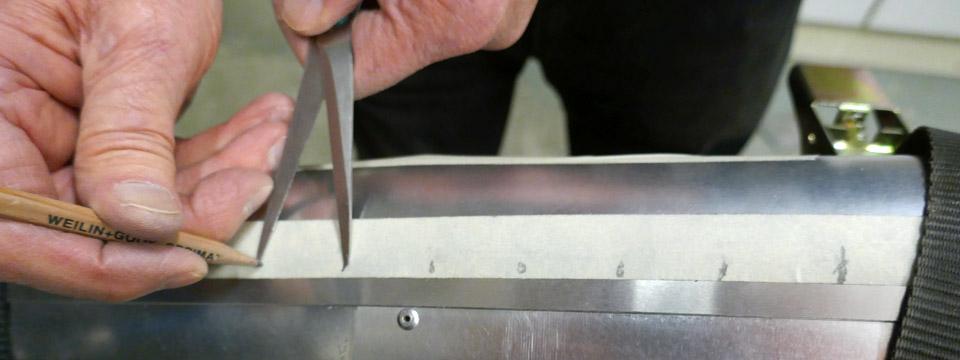

To make the covering strip, an 8 cm wide and 40 cm long aluminium strip was cut out of 1 mm thick aluminium sheet to conceal the seam between the covering sheets. The aluminium strip was shaped to the curved form of the leading edge by shaping it against a suitable size iron tube. The concealing strip was arduous to shape because the wingtip leading edge slopes to various directions. The strip was, therefore, moulded phase by phase, fitting it to place at times. Thus the concealing strip was made to press tightly against the leading edge ridge.

Now the blue plastic films protecting the aluminium sheet could be removed and start the riveting of the covering strip. For the riveting the covering strip was tightened to place at both ends with a cargo strap. Masking tape was applied to both ends of the covering strip to mark the places of the pop rivets. The places were marked on the surface of the tape at even spaces with a compass and pencil, and the holes for the rivets were drilled accordingly.

We discussed what would be the best order to rivet the covering strip, so that it would best confirm to the shape of the wingtip leading edge. We ended up in starting the riveting from the rear end of the covering strip, proceeding rivet by rivet towards the wingtip. In doing so, the covering strip riveted itself tightly to the wingtip leading edge. Finally, the edges of the covering strip were tapped with a hammer and a piece of wood to press it still more tightly to the underlying surface of the covering material.

The demanding task of rebuilding the destroyed wingtip leading edge of the Caravelle III was now ready. Let’s not forget the fitting of the 3D-printed navigation lamp cover to its place in the leading edge tip. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird, Tuesday Club |

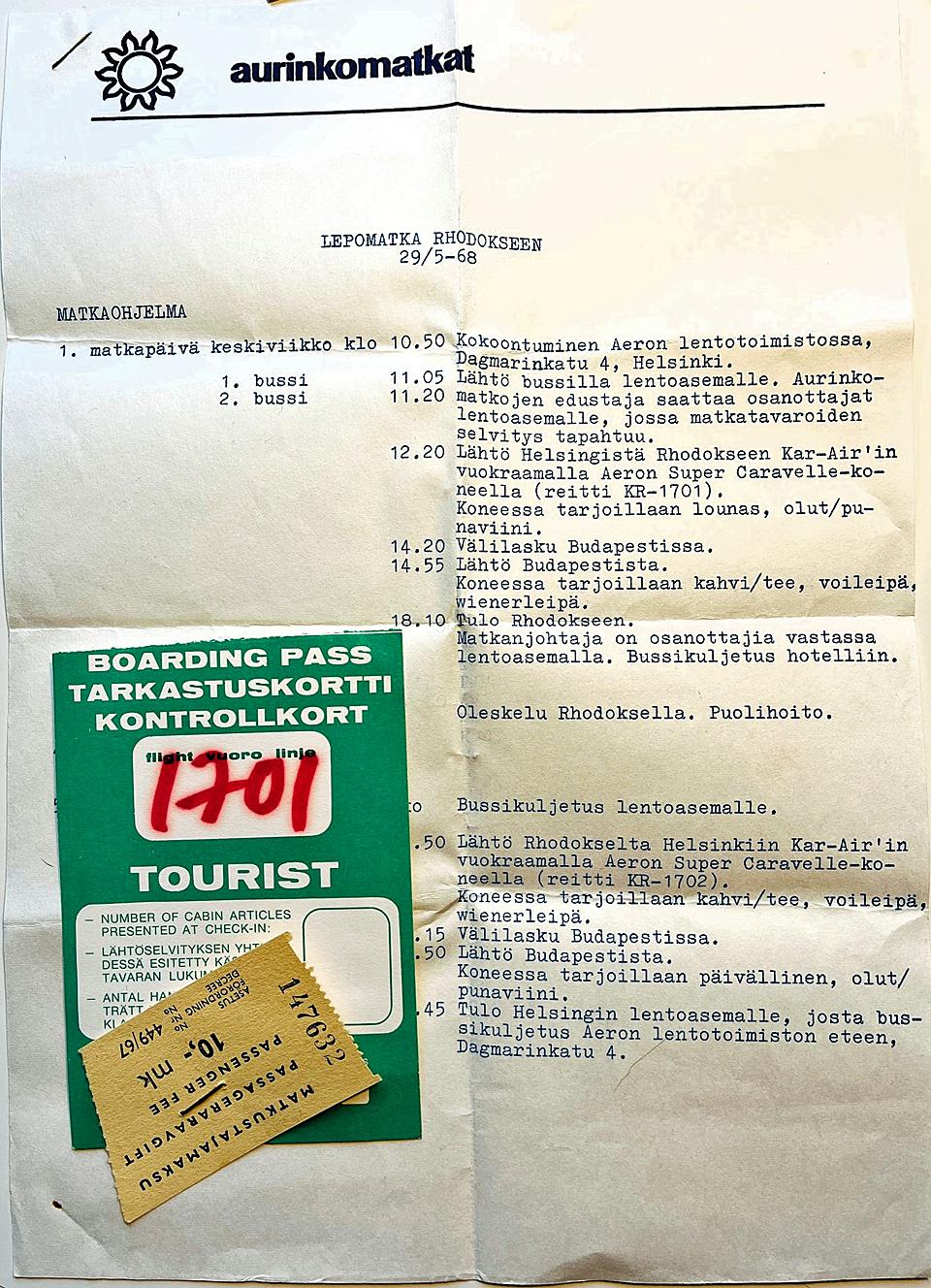

To the sunny south by Super CaravelleMaanantai 26.2.2024 - Erja Reinikainen I wrote in my travel diary on June 22nd, 1966: “The airplane is still on the ground, the engines are running. … We have been in the air for quite a while now. We had lunch and we will be in Warsaw in about 30 minutes. … We took off from Warsaw a long time ago and are flying high above the clouds. Soon we will land in Constanta. We will go by bus from the airport to Hotel Lotus”. We were on a holiday trip to Mamaia beach resort in Romania, on the Black Sea coast. I was 10 years old. The aircraft was Finnair Super Caravelle, but I haven’t noted its registration, and it can’t be seen in the photographs. On the way there and coming back we stopped in Warsaw to refuel. In the same diary there are stories from a trip on the Swedish charter airline’s Internord DC-6 from Helsinki to Naples and back in 1967. Flying over the Alps on a sunny day was an experience for a child from Finland where there are no mountains: “Ahead of us there are magnificent and beautiful mountains! The majestic Alps with their wonderful valleys glide by”. Some superlatives from a 11-year-old.

Between the diary pages there is a leaflet by Aurinkomatkat travel agency “Relaxing holiday to Rhodes, May 29th, 1968”. It shows that our flight was a Kar-Air flight, the aircraft belonged to Aero Oy. The following year we are in the air again and I write in my diary on May 29th, 1968: “Once more on a Finnair Super Caravelle. We are heading away from Seutula airport and towards Rhodes. … A map-like view opens below us with forests, lakes, and fields. The clouds drift by, soft and white. This time we will stop in Budapest to refuel. … Now we are in Budapest, but they won’t let us out. Why not?? So this is Budapest, looks very ordinary to me: a radar, an Interflug airplane and fuel trucks”.

Erja and her mother in the Rhodes harbour. This is the photo which everybody who goes there will have. In 1969 we were on the way to Rhodes again, this time the Caravelle was OH-LSB “Tampere”. I drew a picture of it in my diary. It is rather short and the windows are not triangular, but otherwise it is almost recognizable: engines on the rear fuselage, the horizontal stabilizer is almost the right size and there are boundary fences on the wings.

Drawing of Super Caravelle from 1969. Some background information for the travel stories: my father was an air force mechanic during WW2, and he wanted his family to experience what it was like to fly. I was 6 years old when we travelled from Helsinki to Tampere on a Kar-Air DC-3. In 1962-69 and in the early 1970s I travelled somewhere with my parents every year, usually by air. And I thought flying was fantastic. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Stories from the Caravelle's winterSunnuntai 11.2.2024 - Jouko Tarponen ja Hannu Hedman There are several Caravelle veterans among us. During coffee breaks and in different conversations colourful stories have been told from those days. Below two personal experiences. My first trip by air in a CaravelleWhen we were 13-14 years old, my friend and I were real aircraft fans. We lived in Raisio and we came often to Turku airport or the nearby Sikovuori nearby to see airplanes. Mainly we came there by bike but sometimes our parents drove us there.

In spring 1982 my friend and I saved money to travel by air from Turku to Helsinki, the aim was to fly in a Super Caravelle which Finnair was about to remove from service. I was already then a Caravelle fan, which must be because it was probably the first aircraft I was able to recognise as a child. In those days a weekly charter flight from Turku to Heraklion was flown by a Caravelle. The Finnair Super Caravelle flew a scheduled flight from Helsinki to Turku on Saturday evening and the departure time to Heraklion was 9.15 pm - if I remember correctly. The return flight to Turku landed on Sunday morning at 7.15 am. The great day was Sunday, May 23rd, 1982. We bought tickets for the morning flight from Turku to Helsinki, departing at 7.45. The aircraft was Super Caravelle and the ticket cost 70 Finnish marks. We returned home by taking a bus from Helsinki-Vantaa airport to the Helsinki railway station and from there by train to Turku. I felt very nervous and thrilled about flying because I had never experienced it before. In the morning we left Raisio in sunny weather, taken to Turku airport by car by our parents. When we got there, the information display said that the aircraft will return from Heraklion almost two hours later than scheduled. Then we drove back home to Raisio and returned to the airport about one hour and a half later.

Finnair’s Super Caravelle OH-LSD ”Oulu” from Heraklion landed in Turku at 9.10, full of passengers. When the passengers had disembarked, and the aircraft had been refuelled, there was an announcement: “departure on Finnair flight AY204 to Helsinki, gate 1”. At that point I felt for a moment that the situation was almost insuperable.

I felt slightly better when my friend and I started to walk from the gate to the aircraft. I was a first-timer in air travel, my friend wasn’t. I could only look at the floor, during take-off the uneven surface of the runway could be felt inside the aircraft, and this was a new experience for me. When we were in the air, the travelling became smooth.

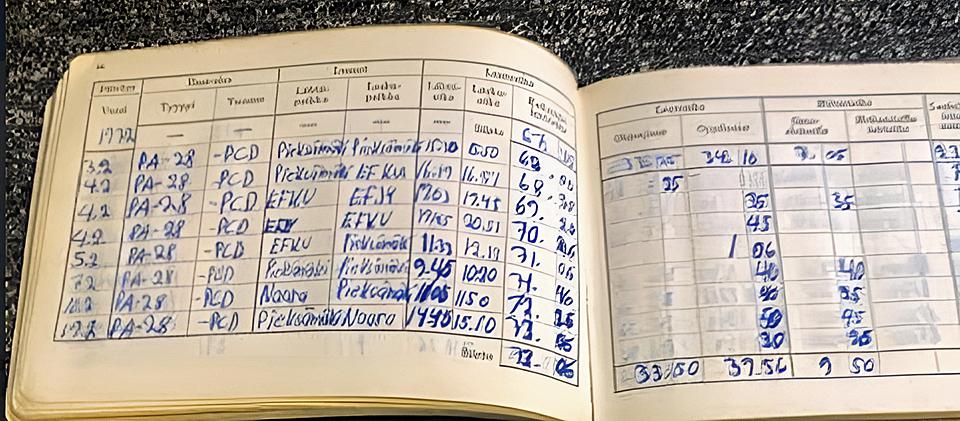

Soon I looked out of the window for the first time. That was something new and awesome. I don’t remember being afraid anymore, except when the aircraft was turning when coming in for landing. I was 14 and my friend was 13. The whole experience of the first flight was and still is one of my most memorable experiences. At that time air travel was rather luxurious, compared today. Travelling south on holiday was not that common then. This was really a great experience and overcame my fear of flying. Now I knew what flying was about. It was really safe in those days too. An encounter in the darkIn this poor-quality picture you see a page from my pilot’s logbook from more than 50 years ago. At that time I was on a night VFR and basic instrument course in Kuopio. We were flying training flights and solo flights in the dark. I flew my first solo flight at night on February 4th, 1972. At that time the evening flight AY555 from Helsinki to Kuopio was flown on a Super Caravelle.

On these late flights I was often in the air at the same time with the Caravelle. Once flight controller Kalle Linden in the Kuopio tower warned me when I was heading south by the Kurkimäki masts: “OH-PCD, look around, the Finnair Fiver (555) is ahead”. The Caravelle acknowledged: “We can see the small one”. That was when I noticed there was an enormous pool of light flying on my left side. After that I was more careful, and we met often in the air in the Kuopio APP area. It was rather stirring that the tower cleared my plane on the ramp close to the Finnair Caravelle. I had to go round and kick the wheels on my plane to make myself important. And yes, the guys waved from the Caravelle’s window. First story: Jouko Tarponen, the photographer from the Turku team and documenter of the Caravelle restoration project Second story: Hannu Hedman, also from the Turku Caravelle team and a pilot with his heart and soul. He also likes to wear a red robe before Christmas… |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

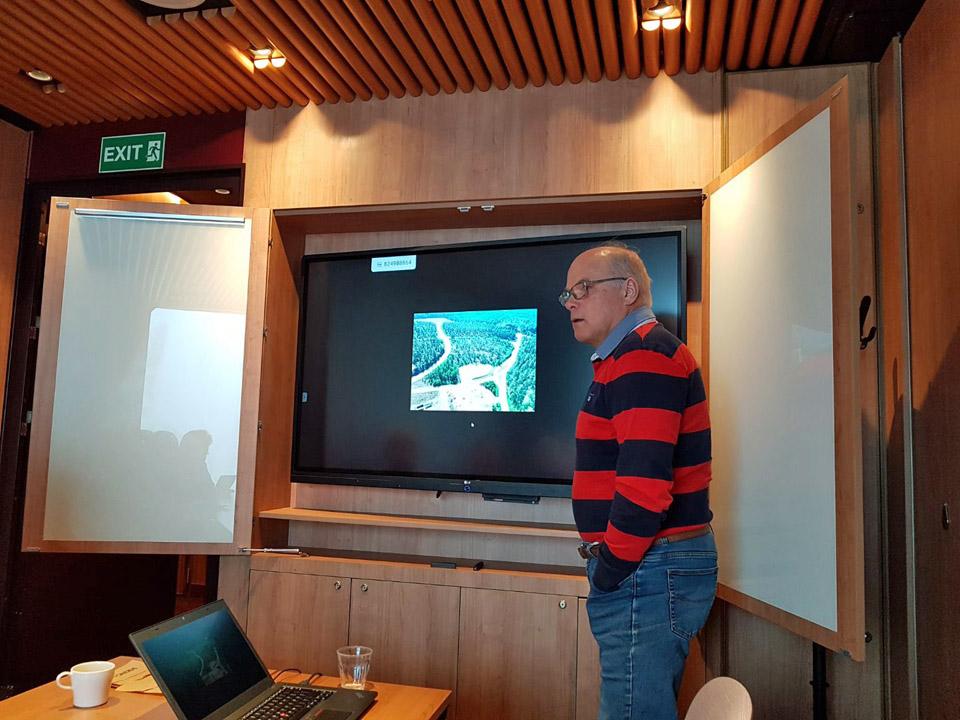

Mid-winter Caravelle news from the writing deskSunnuntai 14.1.2024 - Erja Reinikainen About six months ago Ismo Matinlauri wrote a blog on this website where he talks about the amount of work and accessories used so far for Caravelle’s restoration project. At the end of 2023 the number of working hours spent on Caravelle’s disassembly, restoration and reassembly totalled 5,653 hours.

Photo via Ismo Matinlauri. Paraphrasing Ismo’s text from last July: "Restoring the Caravelle has required a fair number of volunteers’ working hours. The job can’t be done by restoration work volunteers alone, a lot of paperwork is also needed".

Photo via Ismo Matinlauri. The successful running of the project has required comprehensive commitment from the key personnel, especially for planning, procurement, and practical arrangements before each actual phase of work. In the three years since the beginning of the project, a large number of Caravelle-related meetings have been arranged by various groups involved in the project:

A memo has been written of nearly all meetings. We can say that the project has been rather well documented for the future aviation history researchers. The background crew of the project have also taken care of informing the various stakeholders about the project, as well as of Facebook posting, press releases, media interviews, photo processing, project material filing, etc. My estimate is that there are about 8-10 of us who have been involved in the project as PR officers, writers, translators, bloggers, photographers, etc.

Photo by Erja Reinikainen. About 50 blogs have been written yearly on the Caravelle project website, and all blogs have been complemented with photographs and translated into English. The web pages went through a thorough update in October 2023. Several articles have been written about the Caravelle and the project phases, mainly for the Feeniks journal of the Aviation Museum Society, but also for other aviation history magazines. Based on an unofficial and rather freely formulated Excel spreadsheet, about 70 meeting memos have been prepared so far in the Caravelle project. About 80 person-workdays have been spent in meetings when all participants and the memo writing are considered. It can be also estimated that about 40 person-workdays have been spent on publishing all the blogs, including writing, translation, photographs, and publishing. As the year 2024 progresses and the Caravelle restoration work continues, there will be more weekly meetings, blogs, articles, and photographs – and the documenting team will be busy again… |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Repairing the Caravelle right-hand wingtipSunnuntai 14.1.2024 - Tuesday Club member Acquired from Sweden by Aviation Museum Society Finland, the Caravelle (OH-LEA) restored at Turku airport as Finnair’s “Bluebird” had had its right-hand wingtip leading edge badly damaged during its stay in Sweden. It was damaged for a distance of ca. 40 cm, and at the process the wingtip navigation light was also destroyed. Luckily the left-hand wingtip is intact, so that it can be used as a model when rebuilding the right-hand smashed wingtip. So the destroyed wingtip must be remade.

The remaking the right-hand wingtip was started by dismantling the damaged area. The rivets on the crumpled aluminium sheets were drilled away, so that the wingtip covering could be bent open, and the covering sheets detached from the wingtip support frame. We tried to straighten the detached aluminium sheets to their original shape, but they turned out to be so brittle, that they broke when straightened to their shape. So we concluded that the right-hand wingtip leading edge had to be covered with new sheets of aluminium.

We dismantled the detachable support frames of the damaged area. Part of the structure didn’t need to be detached, so it could be used as such in reconstructing the wingtip leading edge. The detached and usable frames were straightened to their original shape. They were fastened with pop rivets to their places, utilizing the intact left-hand wingtip when positioning the support frames.

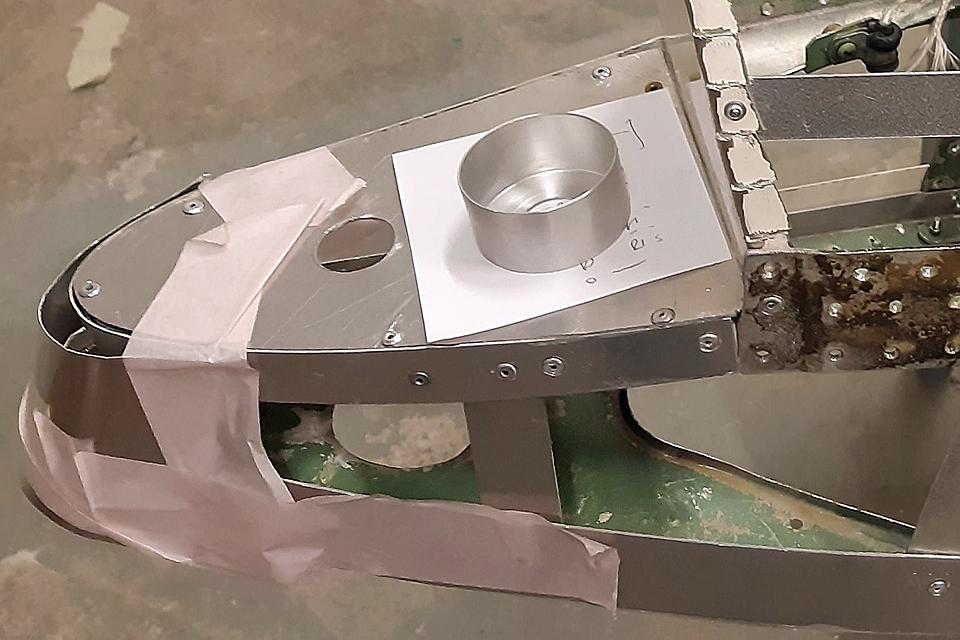

After this the back wall and bottom plate of the right-hand wing navigation light bay was constructed with the left-hand wing navigation light bay as a model. The back wall and bottom plate were cut off from 1 mm thick aluminium plate. When the navigation light bay back wall and bottom plate were tentatively in place, the wingtip leading edge was nearing its original shape.

An opening was made in the bottom plate of the navigation light for the wiring of the navigation light. Also a cup-like socket was lathed for the later fixing of the light in mind. After that the whole navigation light bay was locked from its edges to the remaining original frames of the wingtip with strips cut from 1 mm thick aluminium plate. The fastening was done with pop rivets.

The next phase was to make a support frame between the edge of the intact area in the wingtip and the back wall of the navigation light, where the original frame had been destroyed. The edge of the intact area is formed by the wingtip’s original curve. However, the curve is somewhat damaged in its upper edge, but repairable and will be hidden by the wingtip new covering.

The support frame was made of 2 cm wide strips cut off from 1mm thick aluminium plate. To be able to rivet the ends of the support frame strips to the edge of the curve, the original damaged aluminium covering which had been on the frame, was cut off with a Dremel blade. Five strips were fastened between the edge of the curve and the back wall of the navigation light. The fastening was made with pop rivets. To make the structure sturdy enough to bend and fasten the aluminium cover sheets on the frame, two additional crosswise support strips were riveted to the structure. Now we’ll be ready to start covering the right-hand wingtip leading edge with 1 mm thick aluminium sheets. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird, Tuesday Club |

Caravelle's Turku team and a nice Christmas lunchLauantai 23.12.2023 - Ismo Matinlauri On Tuesday, December 19th, the Caravelle Turku restoration group gathered for a Christmas lunch. The place was Krookila Wanha Tupa (Old Farmhouse). The history of the place goes as far back as 1490, and in the summer the farm is open to the public as a museum. We enjoyed a nice and traditional Christmas lunch in this historic and beautiful surrounding.

The group picture shows 13 members of the Turku team with Aviation Museum Society Finland chairman Janne Salonen and his mother Liisa Salonen. Liisa has participated in the Caravelle restoration project and has encouraged and cheered up the Turku team on several occasions. Our chief photographer Jouko Tarponen is missing from the picture – he was naturally behind the camera.

This team will continue its work with the Caravelle after a hopefully short winter break. If we are able to find a suitable warm workshop we will start restoring the passenger seat frames and cabin partition walls while waiting for the weather to get warmer. Photos by Jouko Tarponen Translation by Erja Reinikainen |

|

Avainsanat: ilmailuhistoria, entisöinti, Caravelle, OH-LEA, Sinilintu |

Santa Claus visited CaravelleTiistai 12.12.2023 - Ismo Matinlauri On Saturday, December 9th, we had the pleasure to welcome Santa Claus on board our Caravelle. Santa turned out to be a competent pilot and well familiar with the Caravelle’s flight deck equipment. This is understandable – after all, he has hundreds of years’ experience of flying with reindeer.

The aircraft was open to the public, too. The weather was slightly colder than during the assembly phase in the beginning of June, now it was -5 degrees Centigrade. The rear pantry was in use for the first time, serving visitors glögg and gingerbread and juice boxes to the younger ones.

During the day we had 63 visitors, including about 15 children. The visitor from farthest away came from Portugal. The visitors were genuinely excited and interested about the airliner and stayed a long time despite the cold weather.

The hydraulic system of the rear stairway had been repaired a couple of days earlier so we could have the stair open during Santa’s visit. This way the visitors could move flexibly to the aircraft’s tail and behind it, where the Rantala crane truck was parked. The truck interested especially the youngest visitors.

After the last visitors, we topped up the bags of de-icing salt to make sure the de-humidifying continues inside the aircraft. Santa’s visit was a suitable closing for this eventful year in our Caravelle.

The Caravelle team wishes our readers Merry Christmas and a Happy New Year! Photos by Ismo Matinlauri Translation by Erja Reinikainen |

|

Avainsanat: ilmailuhistoria, entisöinti, Caravelle, OH-LEA, Sinilintu |

Caravelle goes into hibernationTorstai 16.11.2023 - Ismo Matinlauri The days are getting shorter and colder even in Turku, on the south-west coast of Finland. The work period for the autumn has ended and it was time to prepare our beauty into hibernation for the winter.

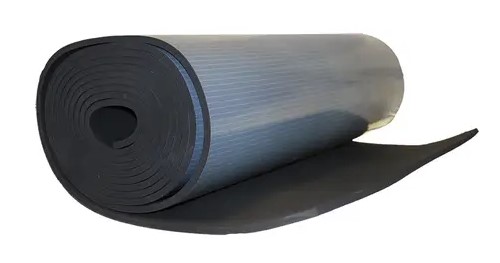

The last work item for this autumn was to finish the insulation on the cabin walls. On the left-hand side of the cabin wall and ceiling the original insulation material is still there, but on the other side of the cabin the insulation has been dismantled together with the overhead shelves, other interior items, and surface material. We tidied the cut edges of the old insulation material and after analysing different new insulation material alternatives we decided to use cellular rubber, which is available from a hardware store. It is water repelling, odourless and tasteless, and has a self-adhesive layer on one side. This makes its installation significantly simple and fast. It also acts as a vapour barrier, so no separate plastic barrier is needed, as there is on the inside of the old glass wool insulation layer.

An insulation thickness of 10 mm is sufficient for our needs, because the aircraft will not be heated in the winter, nor cooled in the summer. The material is sold in rolls, one metre wide, so it is a material which is easy to cut into suitable pieces. As the airliner has no heating, a solution for controlling humidity had to be found. We discussed the problem with several experts and decided to try two possible solutions.

Ordinary road salt (calcium chloride) was packed into three bags made of fabric, which were hung in the cabin. The salt is a hygroscopic material and absorbs water vapour from the indoor air. Buckets were placed under the bags, and they will be emptied at regular intervals when the salty water drips into them.

We are also testing a small air dehumidifier, which recirculates and cools indoor air, condensing humidity from the air. We set the target and limit value to 60% relative humidity. If the indoor humidity is lower, the dehumidifier switches itself off. When the machine is running, its electricity consumption seems to be 2,6 kWh/day when it is running. This means a monthly electricity cost of 20 euros if the dehumidifier is running all the time. The Caravelle has now gone into hibernation, but we will see if it is possible to wake her up for some Christmas events in December. Photos by Ismo Matinlauri Translation by Erja Reinikainen |

|

Avainsanat: ilmailuhistoria, entisöinti, Caravelle, OH-LEA, Sinilintu |

Gathering information for future cabin restoration workLauantai 11.11.2023 - Erja Reinikainen The members of the Caravelle technical design team visited Turku a few weeks ago (on October 25th) to find information for the future restoration work in the cabin. The visitors were Markku Ahokoski, Kari Nyman and Martti Saarinen and team assistant Erja Reinikainen. All summer and autumn access to the Caravelle’s cabin has been through the right-hand side service door and aft stairway. During the assembly phase in June also the emergency exits over the wing were used. The passenger door on the left-hand side is damaged and it can’t be opened. Lately also the aft stairway has been out of use as its hydraulic pump and cylinders are under repair. The service door is smaller than the passenger door and this has caused problems when large items (e.g. plywood boards) have been taken inside for repairs in the cabin. The passenger door needs to be repaired in the spring before any major work in the cabin is started.

When the passenger door is opened, it moves first straight inwards and then it is manually lifted along its rails up to the cabin ceiling. The door weighs 53 kilos, so opening and closing is assisted with a counterbalancing system. The system consists of roll chains, steel cables and three bungee cords (rubber ropes), several metres long and located in the cargo space under the cabin floor. The mechanism is damaged, and the door can’t be used before the mechanism is repaired. There are no spare parts available so they will have to be made and this makes the repair work a lengthy process.

During their visit to Turku Markku and Kari opened the cabin floorboards and concentrated on the passenger door’s bungee cord system. They also disassembled the broken roll chains and now their parts can be used as models when making new ones. While the others were occupied with the door mechanism, Martti was working on the flight deck installing the latest additions into the instrument panel. The panel on the captain’s side looks quite good already, on the co-pilot’s side there are more still missing. Some instruments have been donated, some have been received in an exchange, some have been bought

While the others were working inside the aircraft, Erja dug herself into the storage container to find the cabin seat covers which were brought from Arlanda. According to Murphy’s law, they had been packed into the far corner of the container, in thoroughly sealed boxes which were under other boxes at the very bottom. It turned out that there is a good number of are dark green seat covers in reasonable condition and they can probably be fitted on the seat frames we have. During the winter we can start planning how to clean and repair the seat covers.

Winter is coming and there will be a break in the restoration work for the coldest months. Along with that there will also be less blogs during the winter. Photos by Erja Reinikainen Translation by Erja Reinikainen |

|

Avainsanat: ilmailuhistoria, entisöinti, Caravelle, OH-LEA, Sinilintu |

How to Fence a CaravelleKeskiviikko 1.11.2023 - Ismo Matinlauri Since the beginning of June, the restored Caravelle has been protected at Turku airport by temporary rented fencing – providing only rather moral security. On Tuesday October 24th the permanent fence around the aircraft was completed. Fortunately during these months before the real fence was built there were no damages or accidents caused by the lack of proper fencing.

Photo by Ismo Matinlauri When the Caravelle’s location was planned in the Turku airport area, it was already obvious that a fence must be built around the aircraft. The main worry were vandals, graffiti sprayers and odd curious visitors. Secondly the fencing helps to control visitors and in other times protects the curious passers-by from accidents in the vicinity of the aircraft. Naturally the fence will not stop the most persistent trespassers, but it will, however, provide sufficient security. The purchase of the fence material started already before the Caravelle arrived in Turku. In spring 2022 Aviation Museum Society Finland bought the material for the fence and the gates. First the construction of the fence was scheduled to take place before the aircraft is moved to the site in spring 2023. Soon it was discovered that the fence will hamper the crane operations on site during the assembly and also make the actual assembly work more difficult. Therefore it was decided that the Caravelle is assembled first, and the fence is erected after that. The construction of the fence was left to a professional – that means that a contractor was hired to erect the fence. For cost saving reasons some of the work was done by the Aviation Museum Society Finland volunteers. In this case this meant assisting in setting the fence poles into concrete and in spreading the net wiring between the poles. This reduced the total cost nicely. Building the fence was an efficient procedure, completed in five workdays: • Day 1: marking and levelling the fence line, digging the holes for the concrete foundations,

Photo by Janne Salonen

Photo by Janne Salonen

Photo by Ismo Matinlauri

Photo by Jouko Tarponen

Photo by Jouko Tarponen Building the fence in late October was eventually a good thing. The weather is getting cold and there is quite a limited amount of work which can be done inside and outside the Caravelle due to the cold and wet weather, so we had plenty of time to assist in erecting the fence. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

The Finnish DC-Association's DC-3 visited TurkuSunnuntai 8.10.2023 - Ismo Matinlauri On Wednesday, October 4th, the Caravelle restoration work was interrupted in a very positive way: The DC-Association’s Douglas DC-3 OH-LCH landed in Turku and taxied to the airport terminal.

We can say that “the flying eternally youthful visited the new senior”. The DC-3 was in Turku on a training flight and the crew came to see how the Caravelle’s restoration work is progressing.

The crew members who visited the Caravelle: pilot Mikka Rautakoura, maintenance director Jussi Pakarinen, mechanic Reino Ahola and chief pilot Petri Munukka. There was a lively conversation in the cabin and on the flight deck about the technology used in the Caravelle. The visitors were particularly interested in how the acquisition of the flight instruments for the instrument panel is progressing.

Photos by Ismo Matinlauri A brief update on the restoration work: This week we installed the last new plywood boards into the floor and now the necessary areas have been replaced. Four boards of 12 mm thick waterproof plywood were needed, but now the critical areas of the floor are in good condition.

We installed a sheet of thick plexiglass in the cabin floor area above the wing-fuselage joint. In the future the visitors are able to see the details of the wing-fuselage joint. Outside the aircraft the polishing work on the fuselage has also progressed. The polishing of the front section will be completed before the autumn rain and cold weather settle in. During the following two weeks a permanent fence will be built around the aircraft. That will be the topic in the blog at the end of this month. Photos by Jouko Tarponen except if otherwise mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Photo by Puuilo

Photo by Puuilo