Stories from the Caravelle's winterSunnuntai 11.2.2024 - Jouko Tarponen ja Hannu Hedman There are several Caravelle veterans among us. During coffee breaks and in different conversations colourful stories have been told from those days. Below two personal experiences. My first trip by air in a CaravelleWhen we were 13-14 years old, my friend and I were real aircraft fans. We lived in Raisio and we came often to Turku airport or the nearby Sikovuori nearby to see airplanes. Mainly we came there by bike but sometimes our parents drove us there.

In spring 1982 my friend and I saved money to travel by air from Turku to Helsinki, the aim was to fly in a Super Caravelle which Finnair was about to remove from service. I was already then a Caravelle fan, which must be because it was probably the first aircraft I was able to recognise as a child. In those days a weekly charter flight from Turku to Heraklion was flown by a Caravelle. The Finnair Super Caravelle flew a scheduled flight from Helsinki to Turku on Saturday evening and the departure time to Heraklion was 9.15 pm - if I remember correctly. The return flight to Turku landed on Sunday morning at 7.15 am. The great day was Sunday, May 23rd, 1982. We bought tickets for the morning flight from Turku to Helsinki, departing at 7.45. The aircraft was Super Caravelle and the ticket cost 70 Finnish marks. We returned home by taking a bus from Helsinki-Vantaa airport to the Helsinki railway station and from there by train to Turku. I felt very nervous and thrilled about flying because I had never experienced it before. In the morning we left Raisio in sunny weather, taken to Turku airport by car by our parents. When we got there, the information display said that the aircraft will return from Heraklion almost two hours later than scheduled. Then we drove back home to Raisio and returned to the airport about one hour and a half later.

Finnair’s Super Caravelle OH-LSD ”Oulu” from Heraklion landed in Turku at 9.10, full of passengers. When the passengers had disembarked, and the aircraft had been refuelled, there was an announcement: “departure on Finnair flight AY204 to Helsinki, gate 1”. At that point I felt for a moment that the situation was almost insuperable.

I felt slightly better when my friend and I started to walk from the gate to the aircraft. I was a first-timer in air travel, my friend wasn’t. I could only look at the floor, during take-off the uneven surface of the runway could be felt inside the aircraft, and this was a new experience for me. When we were in the air, the travelling became smooth.

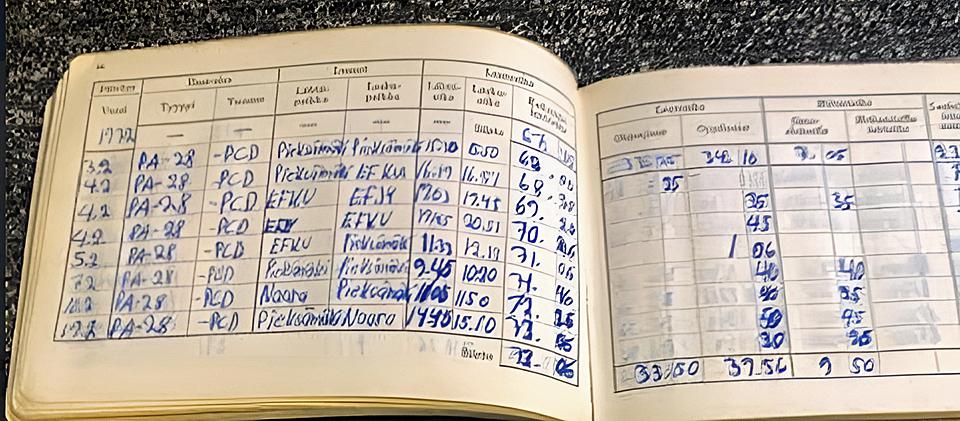

Soon I looked out of the window for the first time. That was something new and awesome. I don’t remember being afraid anymore, except when the aircraft was turning when coming in for landing. I was 14 and my friend was 13. The whole experience of the first flight was and still is one of my most memorable experiences. At that time air travel was rather luxurious, compared today. Travelling south on holiday was not that common then. This was really a great experience and overcame my fear of flying. Now I knew what flying was about. It was really safe in those days too. An encounter in the darkIn this poor-quality picture you see a page from my pilot’s logbook from more than 50 years ago. At that time I was on a night VFR and basic instrument course in Kuopio. We were flying training flights and solo flights in the dark. I flew my first solo flight at night on February 4th, 1972. At that time the evening flight AY555 from Helsinki to Kuopio was flown on a Super Caravelle.

On these late flights I was often in the air at the same time with the Caravelle. Once flight controller Kalle Linden in the Kuopio tower warned me when I was heading south by the Kurkimäki masts: “OH-PCD, look around, the Finnair Fiver (555) is ahead”. The Caravelle acknowledged: “We can see the small one”. That was when I noticed there was an enormous pool of light flying on my left side. After that I was more careful, and we met often in the air in the Kuopio APP area. It was rather stirring that the tower cleared my plane on the ramp close to the Finnair Caravelle. I had to go round and kick the wheels on my plane to make myself important. And yes, the guys waved from the Caravelle’s window. First story: Jouko Tarponen, the photographer from the Turku team and documenter of the Caravelle restoration project Second story: Hannu Hedman, also from the Turku Caravelle team and a pilot with his heart and soul. He also likes to wear a red robe before Christmas… |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

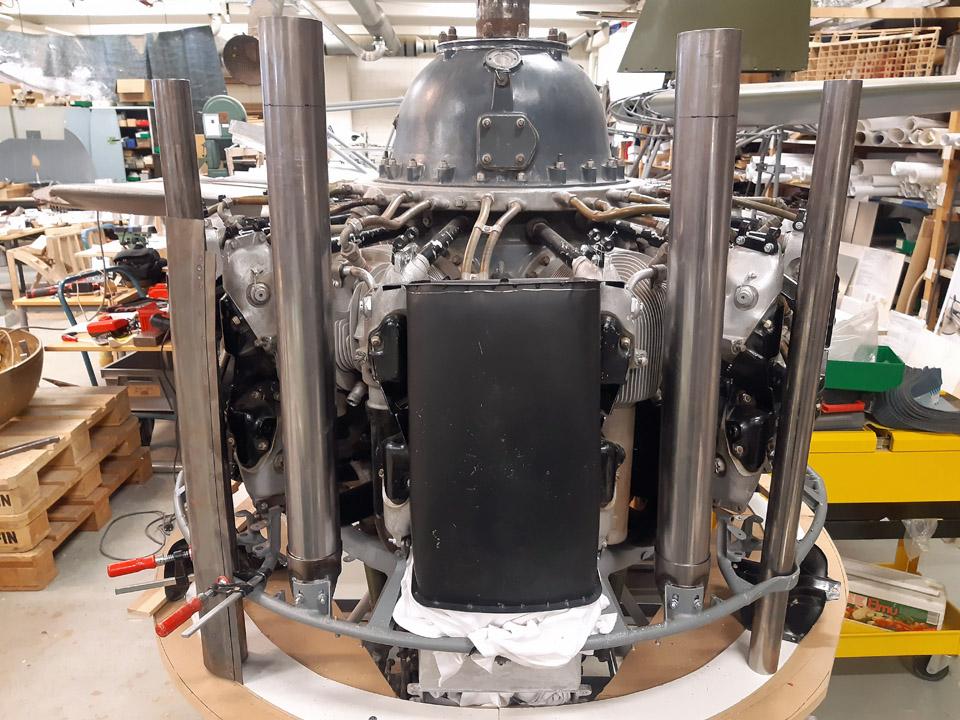

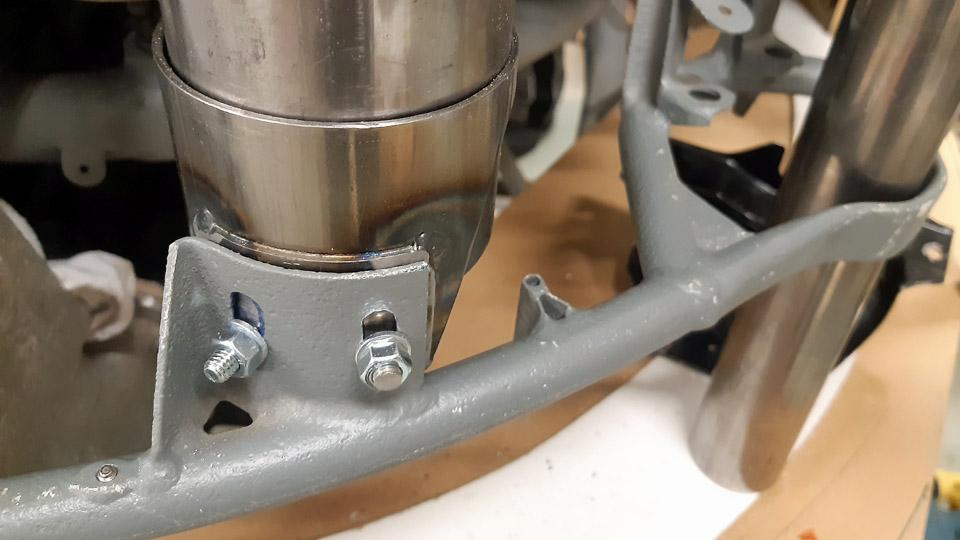

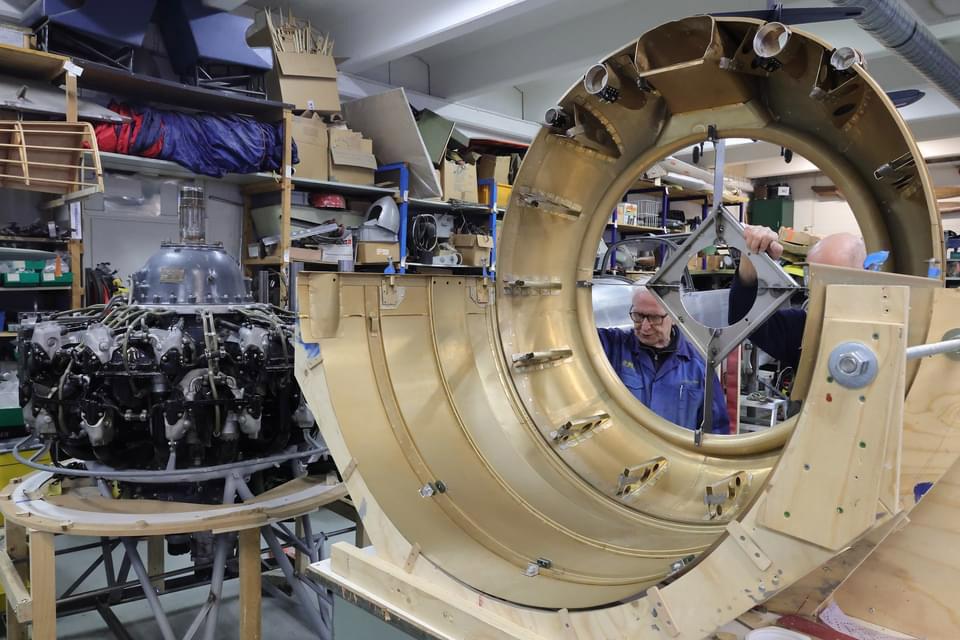

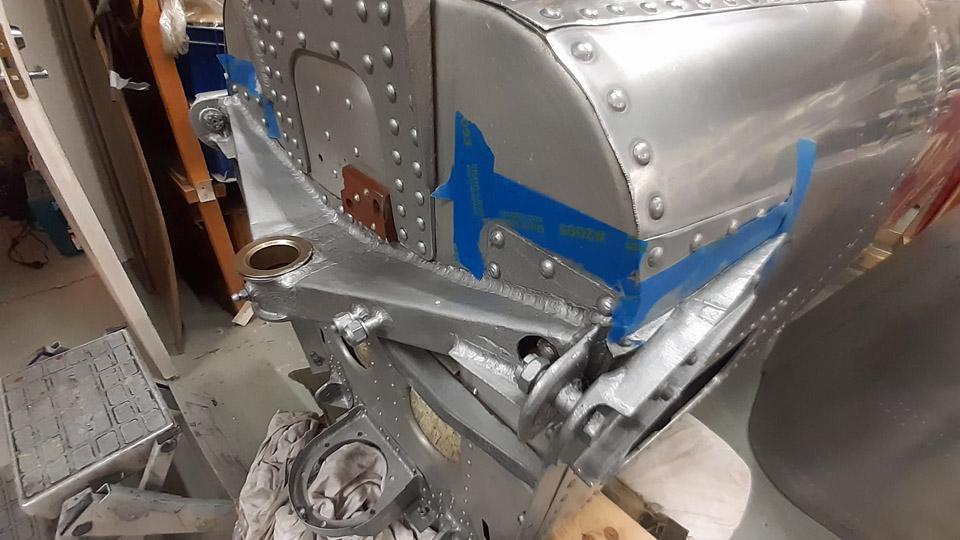

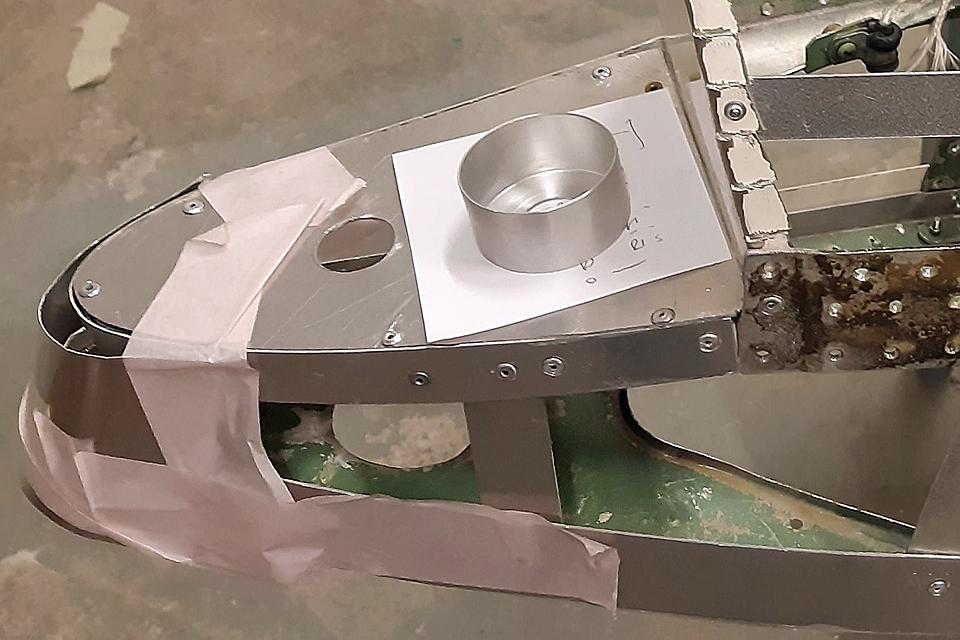

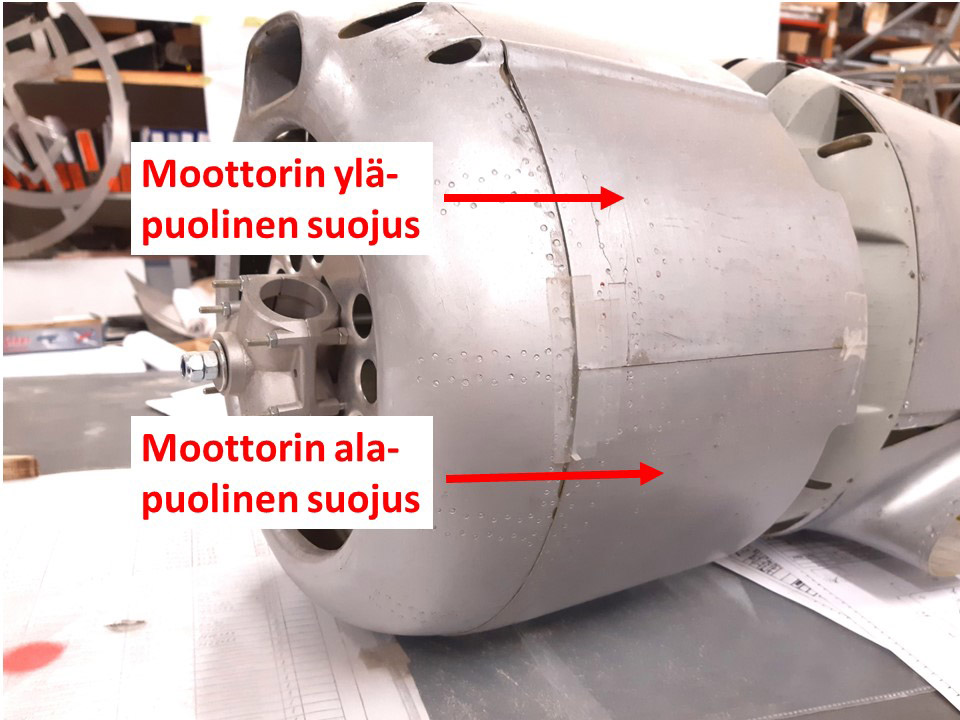

The Myrsky engine NACA-ring and lower cowling completionKeskiviikko 7.2.2024 - Tuesday Club member The engine’s NACA-ring of the VL Myrsky II (MY-14) under restoration was completed when the tightening collars, made at the Tuesday Club for the four machine gun flash tube openings at the upper part of the NACA-ring, were fitted. With the tightening collars the flash tubes made of steel will be locked to the four openings intended for them in the NACA-ring. Of the four openings the two midmost will have 70 mm flash tubes and the lateral ones will have 45 mm flash tubes. The midmost flash tubes will be fastened at their rear end to brackets on the ring of the engine cradle. The machine gun barrel will thrust itself into the rear end of the lateral flash tube, holding it in place.

The excessively long flash tubes are still “sticking out” of the NACA-ring flash tube openings. They will be cut shorter, so that the flash tube ends will only protrude to some extent out of the flash tube openings. The difference in sizes of the flash tubes is due among other things to the fact that there’s no room at the side of the engine under the upper cowling for thick flash tubes. There are shields as well made of steel plate above these narrow flash tubes. They protect the upper cowling, which is nearly touching the flash tube, from overheating when the machine gun is firing. But all the same, both sizes of the flash tubes serve the four 12,7 mm LKk/42 machine guns.

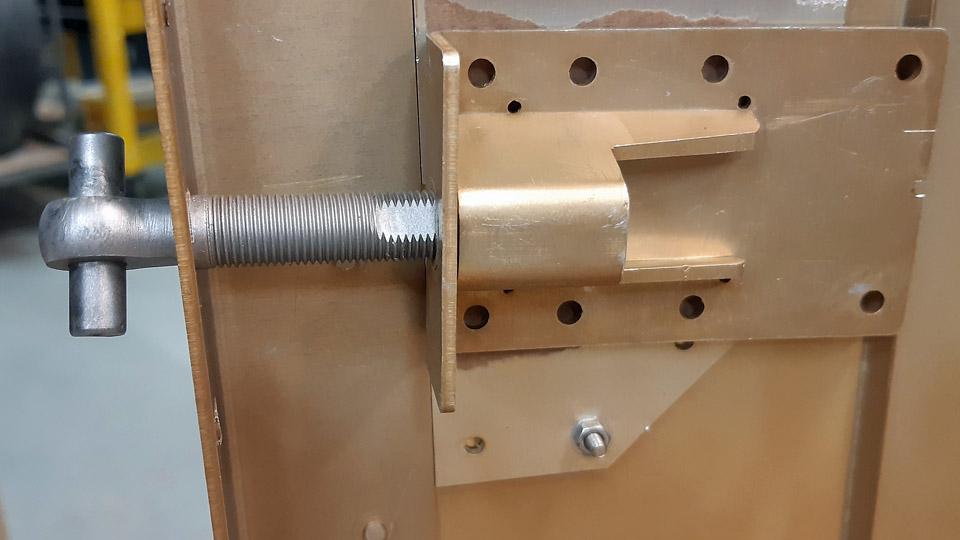

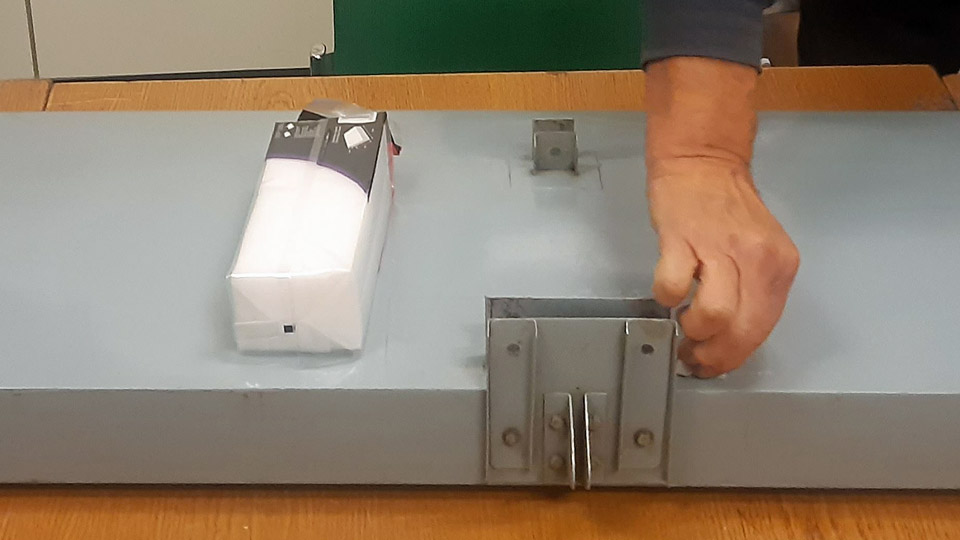

Building of the lower cowling is almost completed at the Tuesday Club. The last tasks have been the guides, which will be fastened on the cowling’s inside surface stiffening strip, the guiding pegs to the front end of the cowling, and the tightening latches, with which the lower cowling will be locked to the upper cowling. Let it be pointed out, that the MY-14 engine upper cowling will be built in the Finnish Air Force Museum.

The guides, as well as the guiding pegs, and the tightening latches were made at the Tuesday Club. Owing to the guides and the guiding pegs, the lower cowling is easy to fit into place. Three slot-formed guides were riveted on the cowling’s inner surface rearmost stiffening strip. With the aid of these slot-formed guides the cowling “snaps” in place to the fastening ring of the rear part of the engine.

Photo by Jorma Laakkonen. The three guide pegs of the cowling’s front edge were riveted on the inner surface of the cowling’s front edge. The guide pegs of the front edge push into the holes drilled in the NACA-ring hem, thus fastening the cowling from its front edge on the NACA-ring. An insulation strip made of fabric was glued to the hem of the NACA-ring to separate the two metal surfaces from each other.

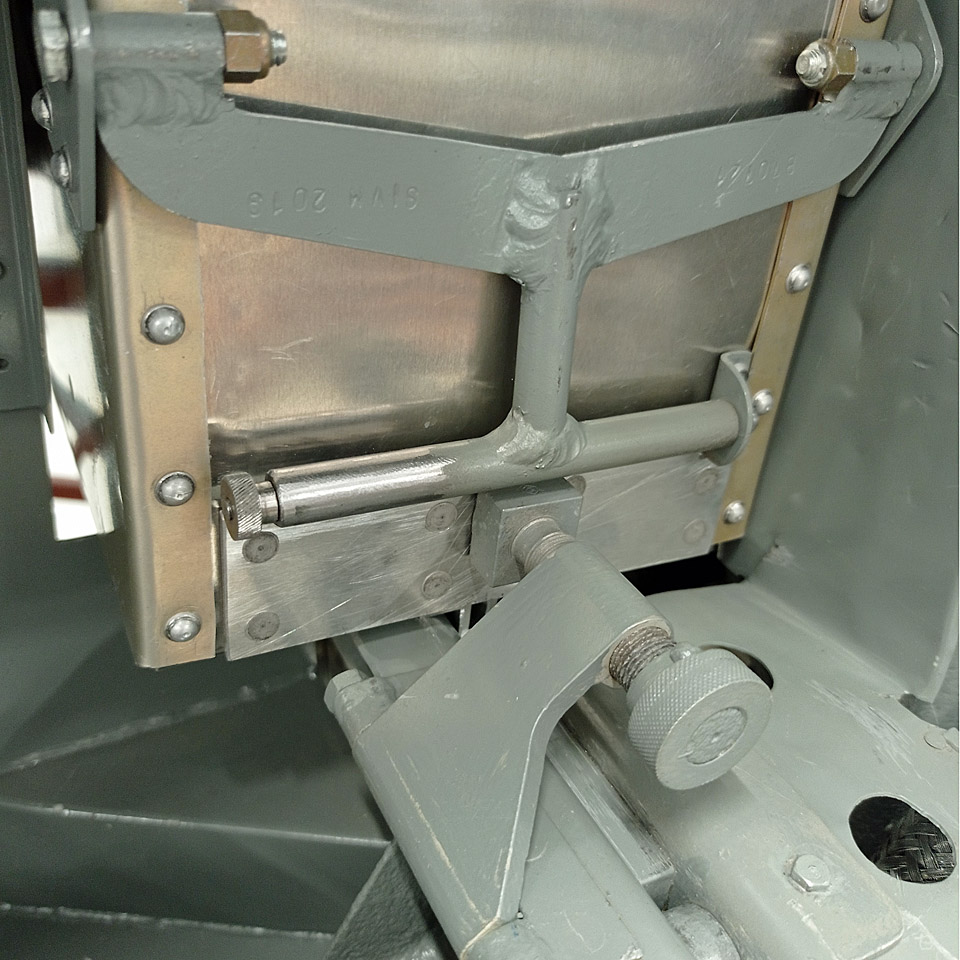

The upper and lower cowlings are locked to each other with four tightening latches. These four complicated tightening latches were built at the Tuesday Club, according to Myrsky blueprints. With adjustable tightening latches the upper and lower cowling can be locked to each other to suitable tightness. The parts of the latches with springs will be fastened to the upper edge of the lower cowling and the parts with levers to the upper cowling. The parts of the latches with springs are tentatively in place, waiting to be riveted.

After the guides and guiding pegs had been fastened on the cowling, the cowling’s fastening to the NACA-ring was tested. The testing was done while the cowling was still fastened on the last where it was built. It was noted that the guiding pegs fitted expectedly to the holes drilled in the hem of the NACA-ring. Thus the NACA-ring was fastened in place on the Pratt & Whitney R-1830 Twin Wasp engine, after which the lower cowling was fastened from its upper edge to the NACA-ring and from its lower half to the fastening ring of the rear part of the engine. The engine is beginning to resemble that of the Myrsky fighter. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, MY-14, VL Myrsky, Tuesday Club |

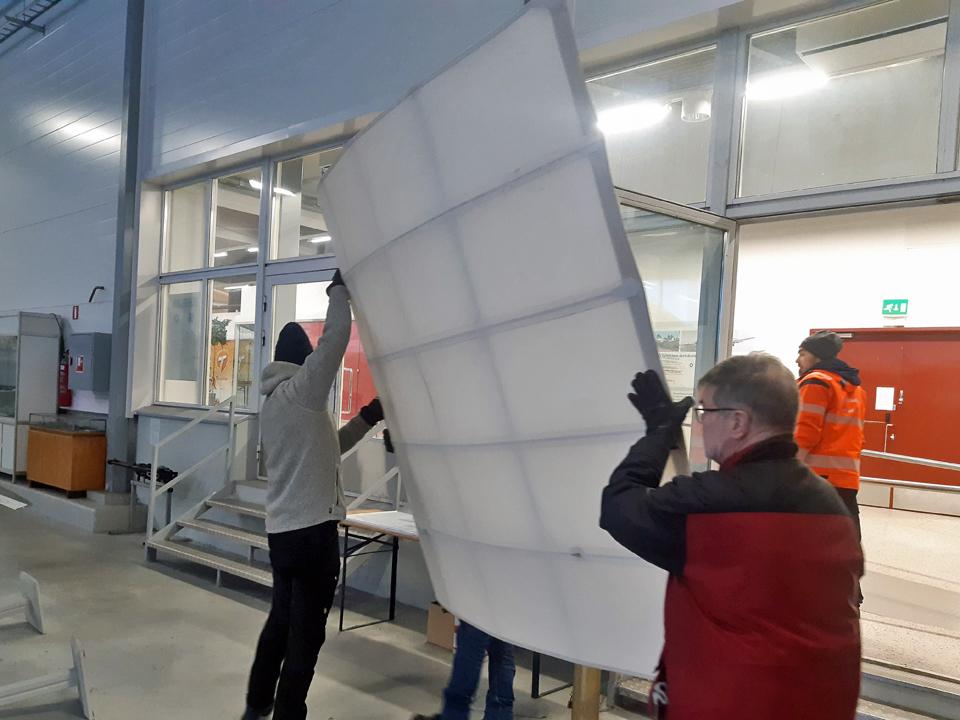

Demoiselle on show to the Shopping Centre TuulonenTiistai 6.2.2024 - Tuesday Club member The Shopping Centre Tuulonen’s small aviation museum received a new aircraft, when the Santos-Dumont n:o 20 – La Demoiselle was assembled on show along he DC-2 Hanssin-Jukka. La Demoiselle was donated by Museum Centre Vapriikki to Aviation Museum Society Finland. The display in the Hanssin Jukka hangar had been agreed between the Hanssin-Jukka heritage foundation and Aviation Museum Society. This Demoiselle is a replica and was built at the change of the Millenium.

The Demoiselle replica arrived by road transportation from Tampere to Tuulonen on Monday February 5th. Without the outer wing panels the fuselage with the centre wing fitted well on a closed-bed lorry. After the transportation arrived at Tuulonen, the outer wing panels were carried straight into the Hanssin-Jukka hangar. The Demoiselle fuselage with its mid-wing section were drawn out of the transportation and wangled inside through the double doors and to the shopping centre corridor. There it was noted that the fuselage with its mid-wing will not fit through the Hanssin-Jukka hangar double doors. Thus the mid-wing section had to come off.

Photo by Juha Veijalainen.

The unfastening of the wing posed no problem to the Tuesday Club members who were present. The two parts of the mid-wing were unfastened from their struts. After that it was easy to draw off both halves of the mid-wing from their fastening pegs in the fuselage. The left-hand and right-hand side wing halves were carried into the hangar.

Photo by Ari Aho.

Photo by Ari Aho. After that the mere Demoiselle fuselage was lifted with the shopping centre personnel engine first over the rails in front of the hangar doors, and from there carried into the hangar. There the fuselage was carried tail first into an area bordered by Hanssin-Jukka’s right-hand wing, fuselage and the horizontal stabilizer.

The original idea was to place the Demoiselle on show hanging from the ceiling, as was the case at the Museum Centre Vapriikki. It was, however, found that the floor level beside the Hanssin-Jukka was a much more presentable place. There the Demoiselle will be very well visible from the windows of the shopping centre and the aircraft wouldn’t obstruct the view to the Hanssin-Jukka. Thus the Demoiselle was decided to be reassembled right away.

Reassembling the Demoiselle replica was fairly straight forward. The Demoiselle’s use in shows with numerous dissembling and assembling has clearly been taken into account when building the aircraft. First the left- and right-hand halves of the mid-wing were pushed into the support pegs in the fuselage and the struts were fastened into the brackets situated on the wing under surface. Now the outer wing panels could be pushed into the fastening pegs in the mid-wing and tightened into place with overwing and underwing steel wire braces. When the propeller had also been fitted, the Demoiselle replica had been reassembled on show.

The Demoiselle replica, expertly built by a voluntary group in Tampere, is a resplendent sight, even though it’s not an original Demoiselle. The aircraft gives a good idea of the early 1900s aircraft and in this particular case of the Santos – Dumont n:o 20 – La Demoiselle type of aircraft. Adolf Arno of Tampere tried as the first Finn to get airborne in 1911 in a similar type - although failing in the attempt. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Santos-Dumont, La Demoiselle |

A report on the Tuuli III (TL-1) fuselage restaurationSunnuntai 28.1.2024 - Tiistaikerholainen At the beginning of the autumn season we carried on with the restoration work of the fuselage of the Tuuli III in the storage tent at the Finnish Aviation Museum’s yard. First we emptied the cockpit from the stored and packaged Tuuli parts. While doing this we noticed that the temporary cockpit floor plywood panels, that we had installed about five years ago for the period of the restoration work, were covered with mould. We disposed of them and made new ones out of 9 mm film plywood to the measurements of the original Tuuli floor panels, which were in storage. The floor panels were installed to the cockpit.

We started to clean the dirty cockpit walls and floor surfaces. We removed the surface dust with a vacuum cleaner nozzle and a brush. However, the surfaces had still to be washed clean. At first we used the steam cleaner, which had been acquired to the museum, but it turned out to be ineffective particularly in cleaning the oiled and sticky floor surfaces. The best cleaning agent for oiled and dirty surfaces proved to be a car brake cleaning liquid, Motip Brake Cleaner. The cleaning liquid was put into a spray bottle, from which the liquid was sprayed onto the surface to be cleaned and the surface was wiped clean with a rag. The cold autumn weather forced us to move indoors, so the Tuuli fuselage was towed by a lift fork from the storage tent to the Finnish Aviation Museum’s restoration workshop.

At the restoration workshop we started to work on the canopy frames, with the future glass bead blasting in mind. The completely opaque plexiglass panes had already earlier been unfastened from the frames. Our job was to strip off the sloppy rubber seals. We tried different methods for this. The best way proved to be one where we heated the seal with a hot air blower, loosening the seal simultaneously with a broad chisel. Thus we managed to get rid of the rubber seals and the frames were now waiting to be glass bead blasted and subsequent painting.

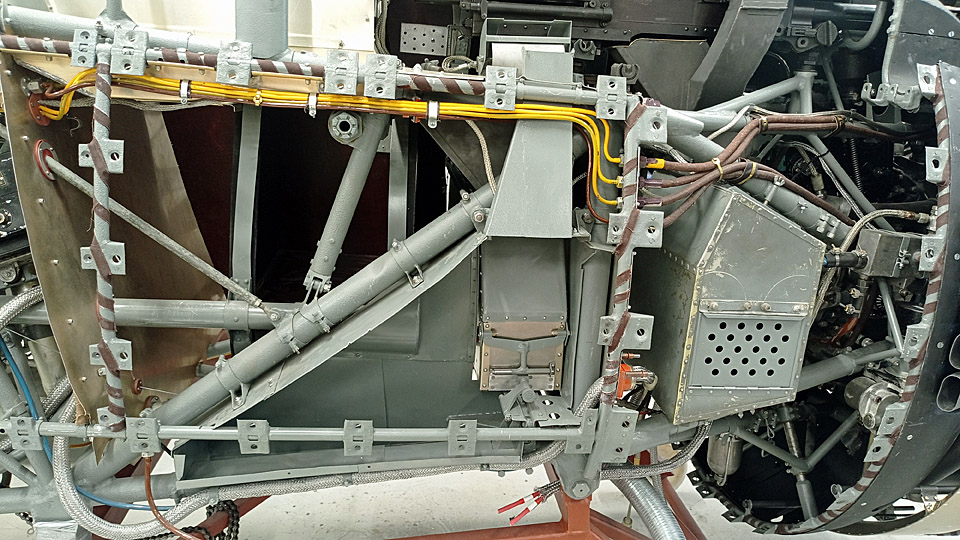

Simultaneously with working with the frames we started the cleaning of the Tuuli engine bay surfaces. For that purpose the upper engine cowling was detached. Before we could get to cleaning the surfaces, we had to dismantle wires and gadgets from the fire wall between the cockpit and the engine bay.

As the wires and gadgets were dismantled, they were marked and put into bags or boxes. The parts were also photographed before unfastening to facilitate their refitting. Part of the gadgets in the firewall were fastened with bolts through the firewall. These bolts, too, and with them the gadgets could be unfastened, when one of the club members crawled into the cockpit under the instrument panel, and reached and held the nut in place, when the bolt was wrenched open from the other side. Thus all the parts fastened to the firewall could finally be detached. The exhaust tubes going below the fuselage were unfastened from the engine bay bottom.

The engine bay surfaces were now ready for cleaning. First we vacuum-cleaned the surfaces from dust and dirt. After that the surfaces were cleaned with Motip Brake Cleaner. Now the cleaning liquid was acquired in spray form. The cleaning of the surfaces was advanced by small steps. First the cleaning agent was sprayed onto the surface. Then the dirt was taken off with a paintbrush or a small brush and finally swept clean with a piece of cloth.

The Tuuli fuselage is without the tailplane. At the end of the cut off fuselage, there is a bulky metal support for the rudder axle. It’s covered with thick rust. The initial thought was to unfasten it for cleaning. Because the metal support is fastened to the end of the fuselage with rivets, we gave up the idea.

The surfaces of the metal support, and other rusty parts had their surfaces ground with a scouring pad, when most of the rust came off. Then the parts were dealt with an anti- grease substance and painted with aluminium-coloured rust-protecting Isotrol-paint. You can also apply Isotrol on a rusty surface because it penetrates the rust to the surface of the metal, preventing the corrosion from continuing. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Valmet Tuuli III, OH-XTL, TL-1 |

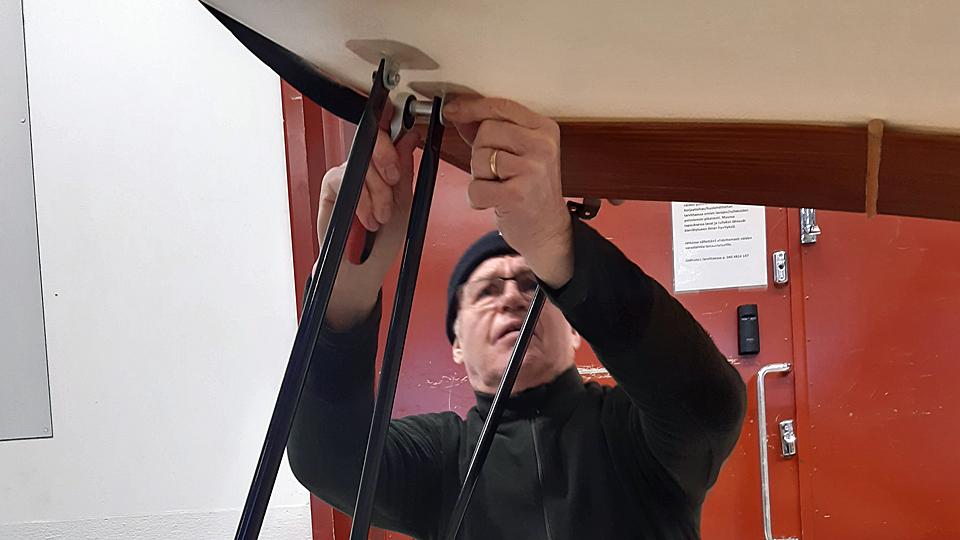

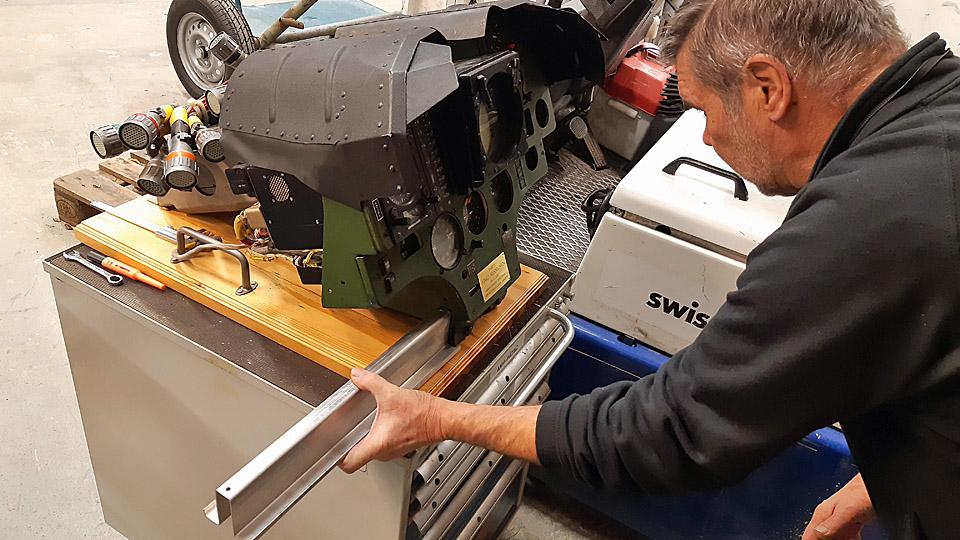

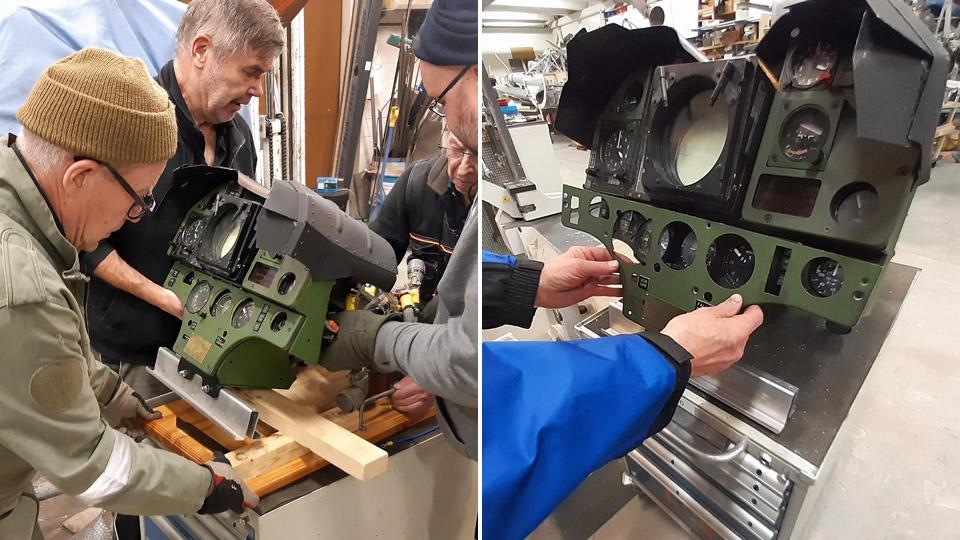

The Draken instrument panel into display artefactSunnuntai 21.1.2024 - Tuesday Club member Aviation Museum Society Finland received as a donation, a Saab J 35 Draken instrument panel entity, which was fastened to a sturdy wood panel. The society decided to make it into a showpiece that could be presented at Aviation Museum Society’s stands at fairs or airshows. Other times the instrument panel would be on display beside the Draken in no 1 Hall of the Finnish Aviation Museum. So far it’s not known to which sub-type of the Saab J 35 Draken the instrument panel belongs to.

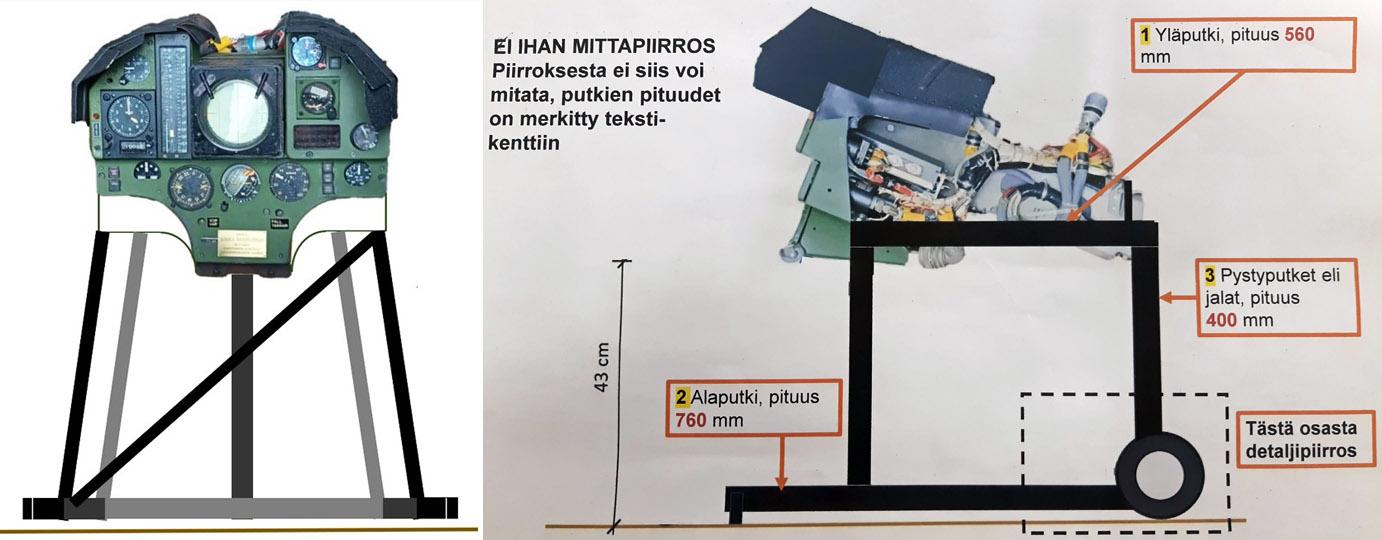

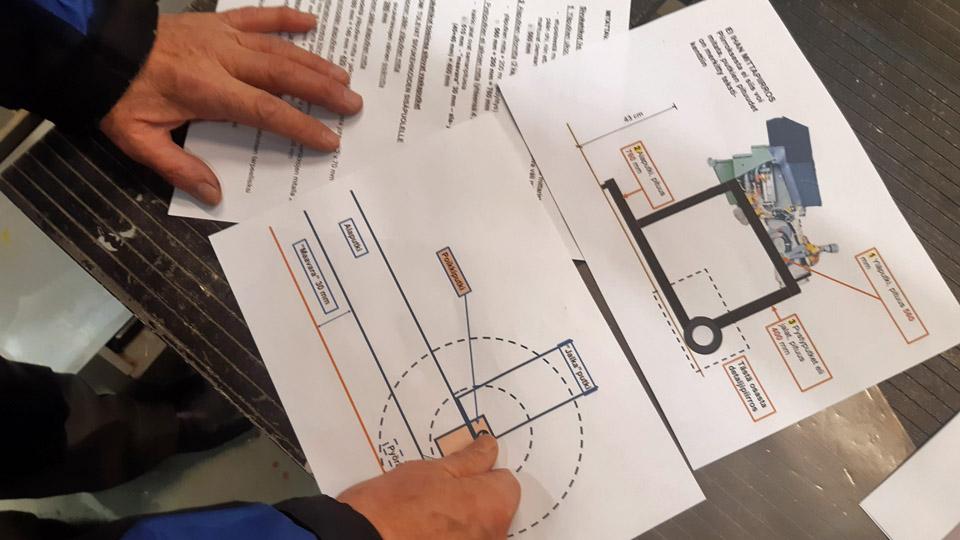

Making a display artefact requires that a safe rack must be built for the very heavy instrument panel entity. The rack will be built of metal and into such a form, that when sitting in front of the instrument panel with feet under it, the visitor can look at it just like the Draken-pilot would do in his cockpit.

So it had to be defined, at which elevation the instrument panel has to be, for the before mentioned conditions to be fulfilled. We lifted the heavy instrument panel onto a transfer platform on the forks of a forklift. After that we put a chair in front of the forklift and adjusted the elevation of the platform so that the instrument panel is in the visitor’s field of vision. It was noted that 40 cm from the floor level to the lower edge of the instrument panel will be suitable.

Drawings by Juha Veijalainen.

Now structural drawings and visualization images of the instrument panel rack could be made to build the rack. A solid and safe rack will be made of 20 mm x 40 mm steel tube. To make way for the rack, a lacquered wooden platform had to be unfastened from the instrument panel. Before unfastening the platform, a metal support was fastened to the lower edge of the instrument panel. The instrument panel was lowered on this support after unfastening the wooden platform.

We also detached a plaque fastened on the Draken instrument panel, saying that the instrument panel was a retirement present. To unfasten the plaque, we had to detach the front panel of the instrument panel. In place of the detached plaque we fastened a plaque, which said the instrument panel to be “that of the Saab J35 Draken-fighters, used by the Finnish Air Force”.

To build the rack for the instrument panel we bought a couple of bars of 20x40 mm metal tube. Pieces were sawn off the tube according to the drawings. The sawn pieces of tube were welded to one another. First the lower, upper and vertical tubes of both sides of the rack were welded together. After this, the rack was tentatively put together by fastening between both sides the cross bars of the lower and upper parts of the rack with clamps. It was noted that the rack will be just as we planned it. The next phase is to weld the cross bars to the sides of the rack, after which the instrument panel rack will be structurally ready.

Photo by Juha Veijalainen.

The Draken instrument panel with its rack is heavy, so moving it about is challenging. To facilitate the moving, the rear ends of the lower bars of the rack will be equipped with wheels. On top of that, sliding shafts will be built to the front end of the upper tubes. The shafts will slide inside the tubes, so the instrument panel will be movable like a wheelbarrow. We found a suitable set of trolley wheels of 150 mm in diameter at the storage of the Finnish Aviation Museum.

The 360 degrees revolving stem of the wheel was detached from them, because on the instrument panel rack the wheels will be fixed. Both wheels were taken apart and their bearings were serviced to operating standard.

Next the rack will be welded together to form an entity, after which the instrument panel can be fastened to the rack. After the lower bars have received their wheels and the shafts have been made, the rack will be painted. After that the donation to Aviation Museum Society Finland will be ready to be moved beside the Draken in the Finnish Aviation Museum. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club;Saab J35 Draken |

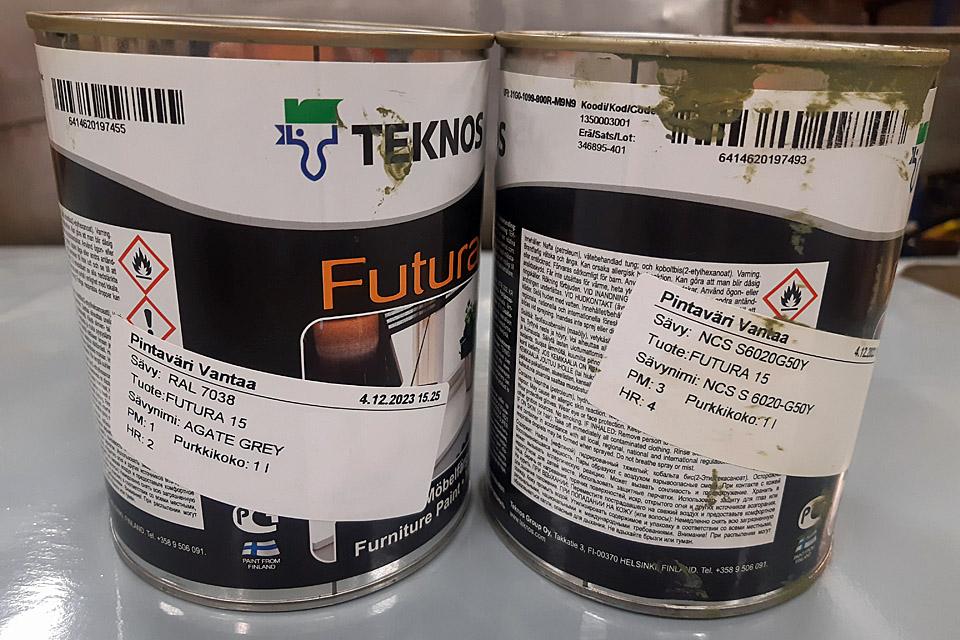

Painting of the Mi-8 helicopter tail boom stabilizersTiistai 16.1.2024 - Tuesday Club member The restoration of the Karalian Aviation Museum situated Mil Mi-8T (HS-4) tail boom stabilizers has been concluded. It started at the Tuesday Club in the autumn season 2023. The decayed covering fabrics of the stabilizers of aluminium structure were removed and the stabilizers were covered with weatherproof thin aluminium sheets instead of fabric. Because it was decided to paint the stabilizers all round, the worn paint surfaces were ground ready for painting. The priming of the stabilizers has been described in an earlier blog.

The stabilizers of the tail boom will be painted according to the paint scheme used in Mi-8 helicopters in the Defence Forces. The upper surfaces will get a camouflage colour AN 22 green (Light bronze green), which compares to the NCS-shade map NCS S6020-G50Y. The under surface will be light grey (Light aircraft gray), which corresponds to the RAL shade map RAL 7038. As the surface paint the Teknos Futura 15 outside furniture paint was chosen. Corresponding to the aforementioned shades, the grey and green paints were bought at the Pintaväri Vantaa branch.

The painting was started from the upper surfaces with the green Futura. The smooth surfaces were painted with a narrow mohair roller. Uneven surfaces like the rivet studs, the stabilizer stem and the strut were painted with a brush. The first time over gave a fairly good coverage, but to achieve a good surface the stabilizers have to be painted twice over.

After the green paint had dried, the under surfaces were painted once over with the light grey Futura. This paint, too, gave laudable coverage with the first painting. However, the under surfaces were painted a second time over after the paint had dried, to achieve an even and well protecting surface.

We still had to paint the stabilizers’ upper surface for a second time. The painting of the upper surface for the second time was left last, because at the seam of the upper and under surfaces of the stabilizer, the green paint gives a good coverage over the light grey paint. In this context the green and grey border surface of the stabilizer was taped over with painter’s tape. Another option would have been to paint the border area with a roller without masking. However, we ended up with masking, because it produces a neat and tidy straight border between the grey and green paint.

When masking is used in painting, it’s important to take off the masking tapes immediately, before the paint dries. If you leave the tape in place till the paint is dry, when taking the tape off it easily tears dried paint along, and the neat border that was meant to be achieved by masking, will be lost.

The Mil Mi-8T helicopter of the Karelian Aviation Museum has now had its tail boom stabilizers restored and they are ready to be delivered to Lappeenranta. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

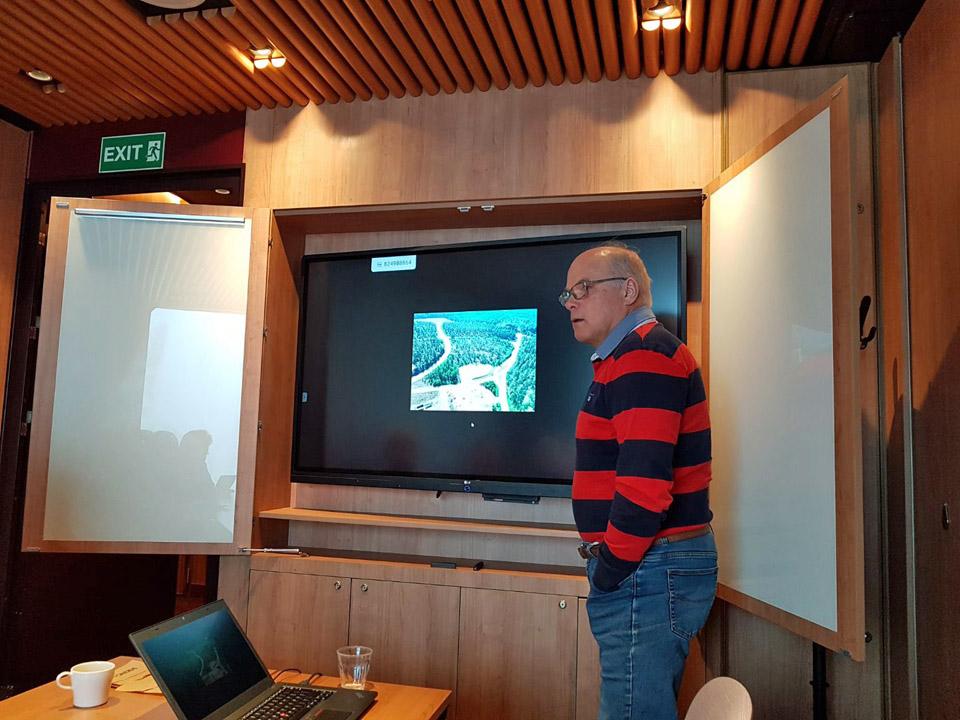

Mid-winter Caravelle news from the writing deskSunnuntai 14.1.2024 - Erja Reinikainen About six months ago Ismo Matinlauri wrote a blog on this website where he talks about the amount of work and accessories used so far for Caravelle’s restoration project. At the end of 2023 the number of working hours spent on Caravelle’s disassembly, restoration and reassembly totalled 5,653 hours.

Photo via Ismo Matinlauri. Paraphrasing Ismo’s text from last July: "Restoring the Caravelle has required a fair number of volunteers’ working hours. The job can’t be done by restoration work volunteers alone, a lot of paperwork is also needed".

Photo via Ismo Matinlauri. The successful running of the project has required comprehensive commitment from the key personnel, especially for planning, procurement, and practical arrangements before each actual phase of work. In the three years since the beginning of the project, a large number of Caravelle-related meetings have been arranged by various groups involved in the project:

A memo has been written of nearly all meetings. We can say that the project has been rather well documented for the future aviation history researchers. The background crew of the project have also taken care of informing the various stakeholders about the project, as well as of Facebook posting, press releases, media interviews, photo processing, project material filing, etc. My estimate is that there are about 8-10 of us who have been involved in the project as PR officers, writers, translators, bloggers, photographers, etc.

Photo by Erja Reinikainen. About 50 blogs have been written yearly on the Caravelle project website, and all blogs have been complemented with photographs and translated into English. The web pages went through a thorough update in October 2023. Several articles have been written about the Caravelle and the project phases, mainly for the Feeniks journal of the Aviation Museum Society, but also for other aviation history magazines. Based on an unofficial and rather freely formulated Excel spreadsheet, about 70 meeting memos have been prepared so far in the Caravelle project. About 80 person-workdays have been spent in meetings when all participants and the memo writing are considered. It can be also estimated that about 40 person-workdays have been spent on publishing all the blogs, including writing, translation, photographs, and publishing. As the year 2024 progresses and the Caravelle restoration work continues, there will be more weekly meetings, blogs, articles, and photographs – and the documenting team will be busy again… |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

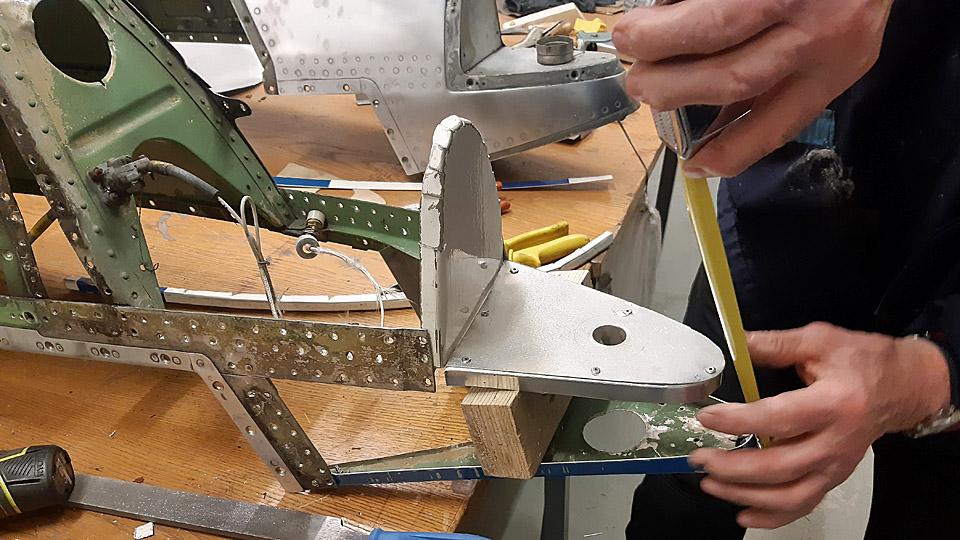

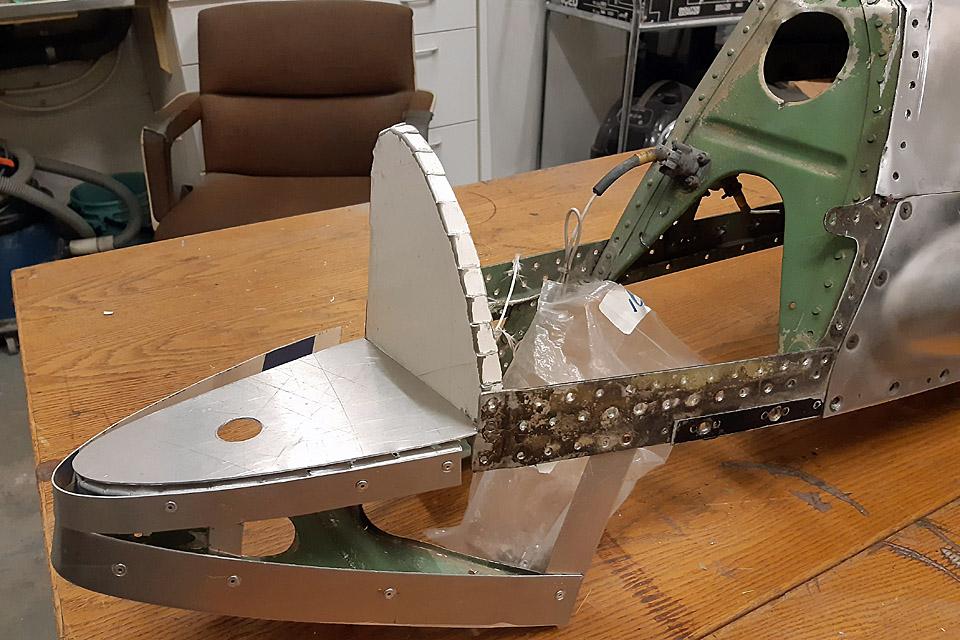

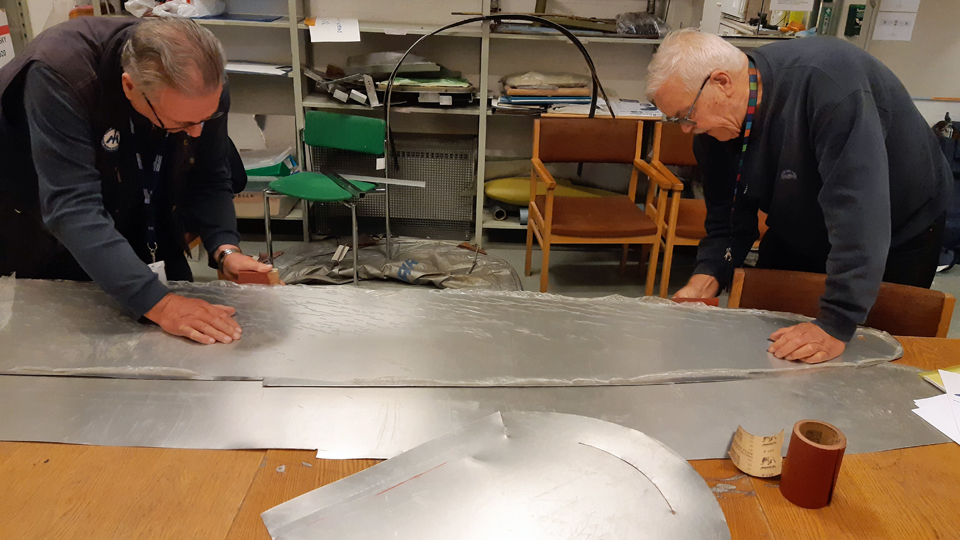

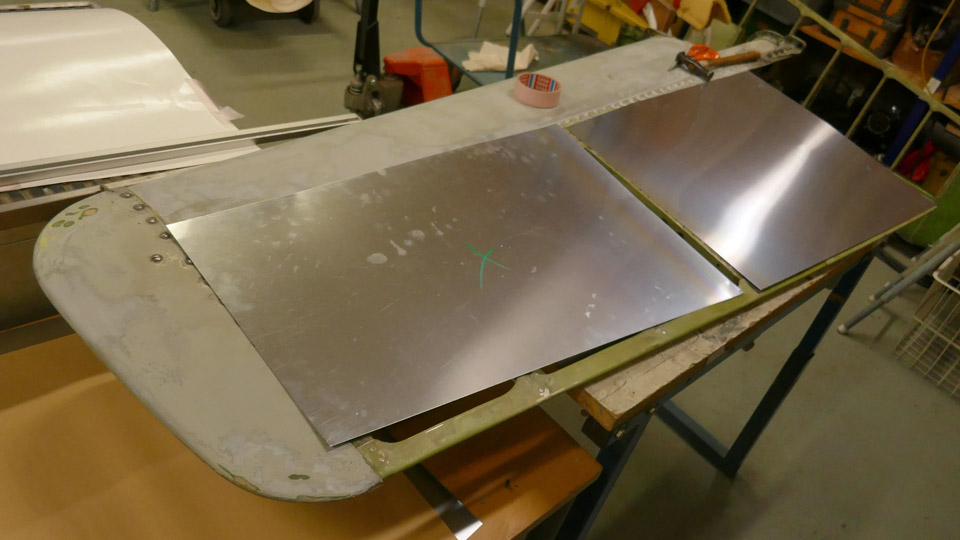

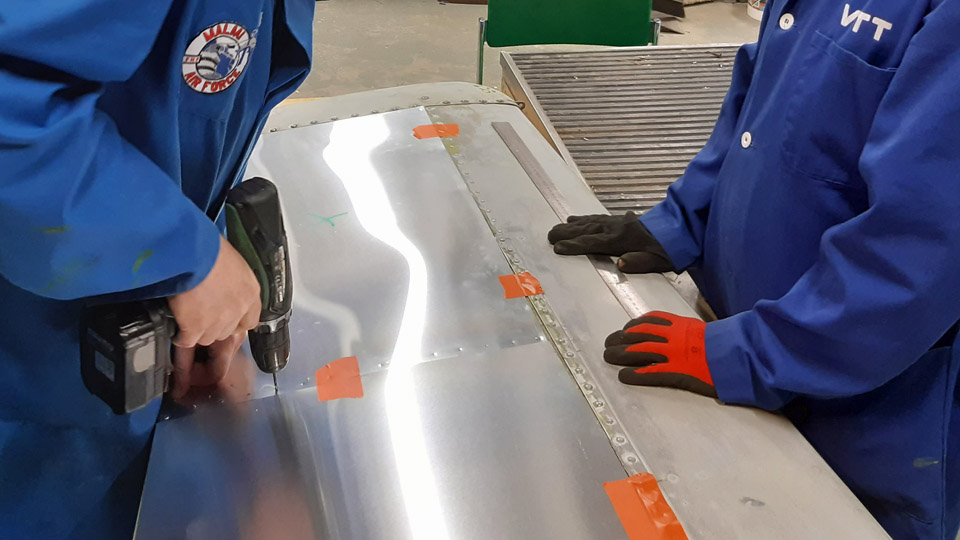

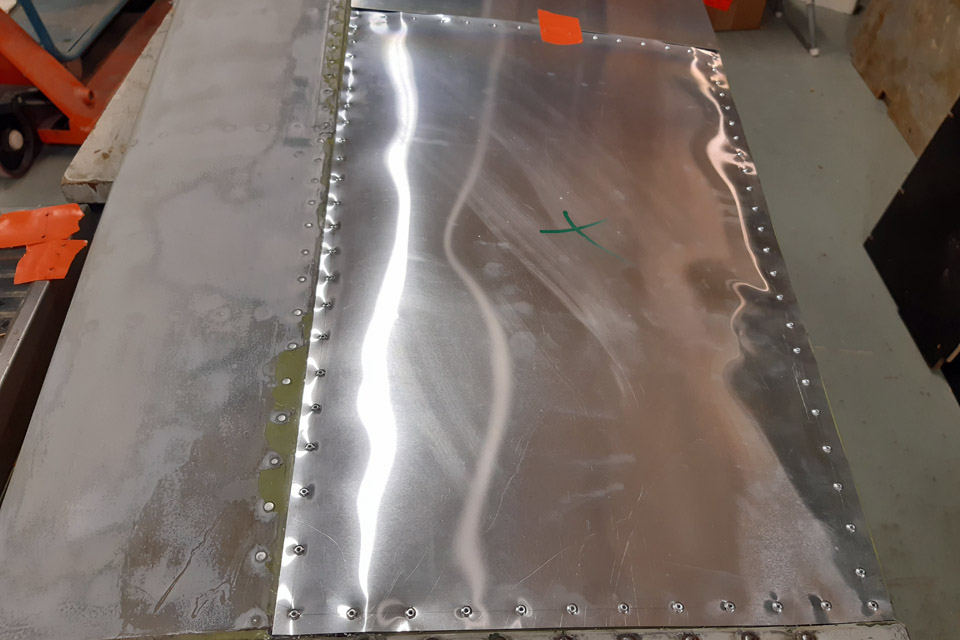

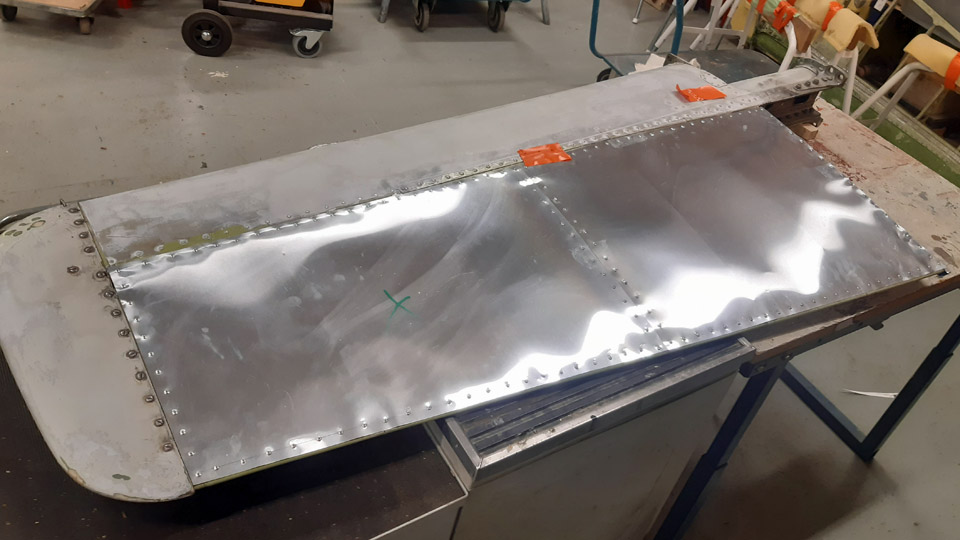

Repairing the Caravelle right-hand wingtipSunnuntai 14.1.2024 - Tuesday Club member Acquired from Sweden by Aviation Museum Society Finland, the Caravelle (OH-LEA) restored at Turku airport as Finnair’s “Bluebird” had had its right-hand wingtip leading edge badly damaged during its stay in Sweden. It was damaged for a distance of ca. 40 cm, and at the process the wingtip navigation light was also destroyed. Luckily the left-hand wingtip is intact, so that it can be used as a model when rebuilding the right-hand smashed wingtip. So the destroyed wingtip must be remade.

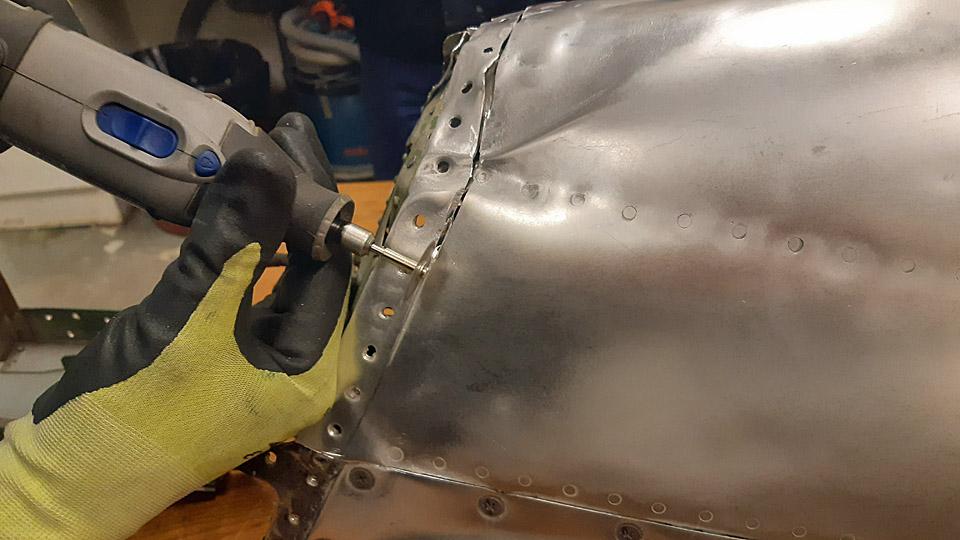

The remaking the right-hand wingtip was started by dismantling the damaged area. The rivets on the crumpled aluminium sheets were drilled away, so that the wingtip covering could be bent open, and the covering sheets detached from the wingtip support frame. We tried to straighten the detached aluminium sheets to their original shape, but they turned out to be so brittle, that they broke when straightened to their shape. So we concluded that the right-hand wingtip leading edge had to be covered with new sheets of aluminium.

We dismantled the detachable support frames of the damaged area. Part of the structure didn’t need to be detached, so it could be used as such in reconstructing the wingtip leading edge. The detached and usable frames were straightened to their original shape. They were fastened with pop rivets to their places, utilizing the intact left-hand wingtip when positioning the support frames.

After this the back wall and bottom plate of the right-hand wing navigation light bay was constructed with the left-hand wing navigation light bay as a model. The back wall and bottom plate were cut off from 1 mm thick aluminium plate. When the navigation light bay back wall and bottom plate were tentatively in place, the wingtip leading edge was nearing its original shape.

An opening was made in the bottom plate of the navigation light for the wiring of the navigation light. Also a cup-like socket was lathed for the later fixing of the light in mind. After that the whole navigation light bay was locked from its edges to the remaining original frames of the wingtip with strips cut from 1 mm thick aluminium plate. The fastening was done with pop rivets.

The next phase was to make a support frame between the edge of the intact area in the wingtip and the back wall of the navigation light, where the original frame had been destroyed. The edge of the intact area is formed by the wingtip’s original curve. However, the curve is somewhat damaged in its upper edge, but repairable and will be hidden by the wingtip new covering.

The support frame was made of 2 cm wide strips cut off from 1mm thick aluminium plate. To be able to rivet the ends of the support frame strips to the edge of the curve, the original damaged aluminium covering which had been on the frame, was cut off with a Dremel blade. Five strips were fastened between the edge of the curve and the back wall of the navigation light. The fastening was made with pop rivets. To make the structure sturdy enough to bend and fasten the aluminium cover sheets on the frame, two additional crosswise support strips were riveted to the structure. Now we’ll be ready to start covering the right-hand wingtip leading edge with 1 mm thick aluminium sheets. Photos by Lassi Karivalo. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird, Tuesday Club |

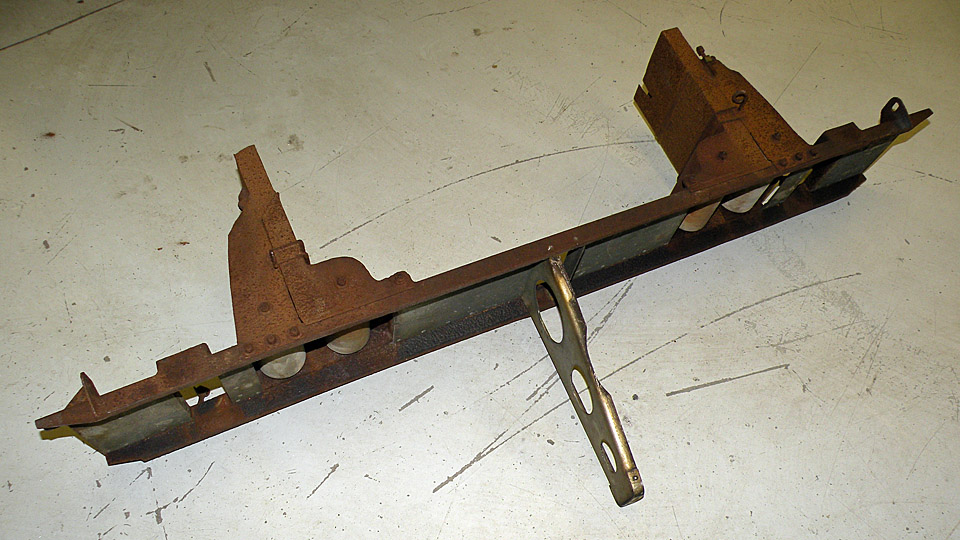

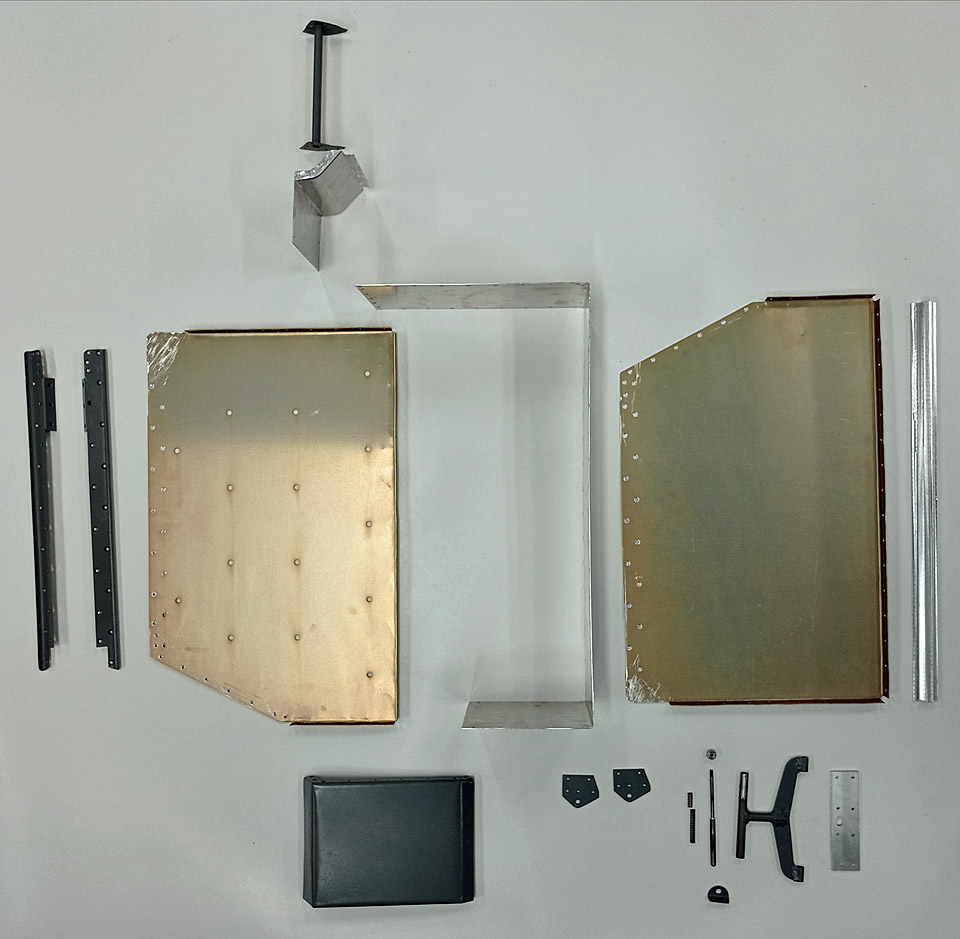

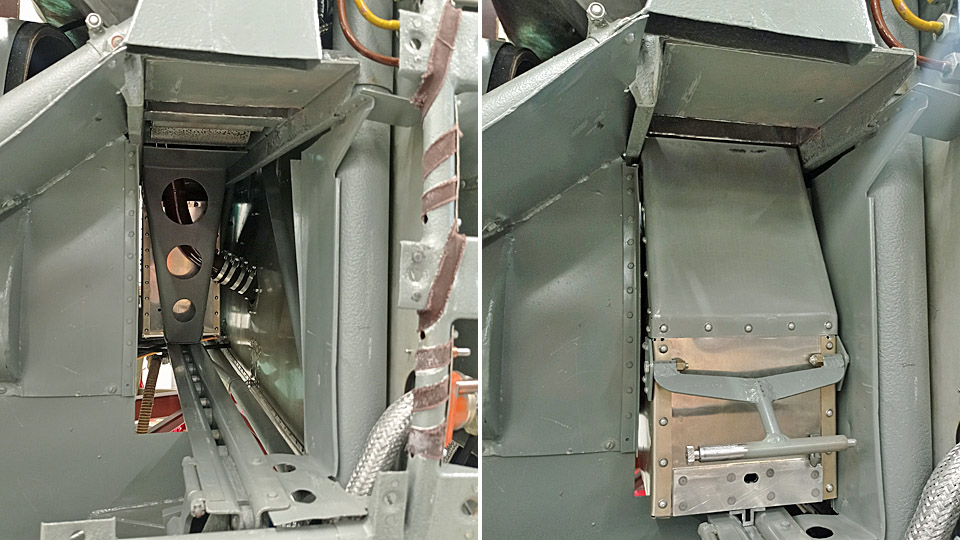

MY-14 lateral machine gun caissonsTorstai 14.12.2023 - Reino Myllymäki The armament of VL Myrsky II consists of four synchronized heavy 12,7mm VKT machine guns, located in the front fuselage. Each machine gun has its own caisson. The machine gun caissons in the middle hold 220 and the lateral gun caissons 260 rounds.

The VL Myrsky II restoration project has available three Myrsky fuselages (MY-5, MY-9 and MY-14). In all of them the original rails for the caissons were in place. In all these the rails were intact, but the steel parts were badly rusted. The original caissons couldn’t be found anywhere.

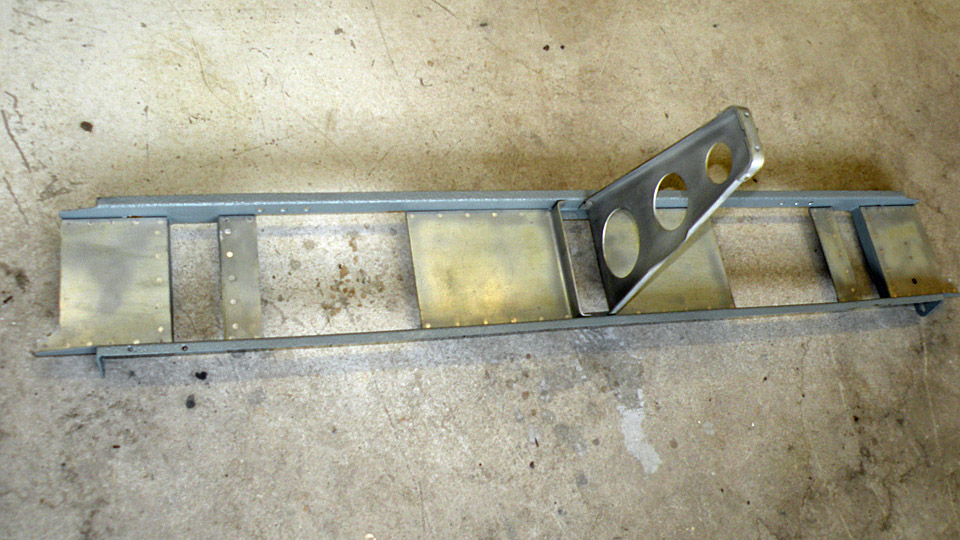

The MY-14 rails were picked out to be restored, dismantled from the fuselage and all the screws and rivets were taken apart. The rust from the steel parts was blown away with glass ball blasting, the surfaces were treated with Isotol-klarlack and painted grey. The aluminium parts were cleaned with glass ball blasting. The parts were riveted together again with aluminium rivets according to the blueprint, and the entity was painted grey all round. The refurbished rails were installed back to their original place.

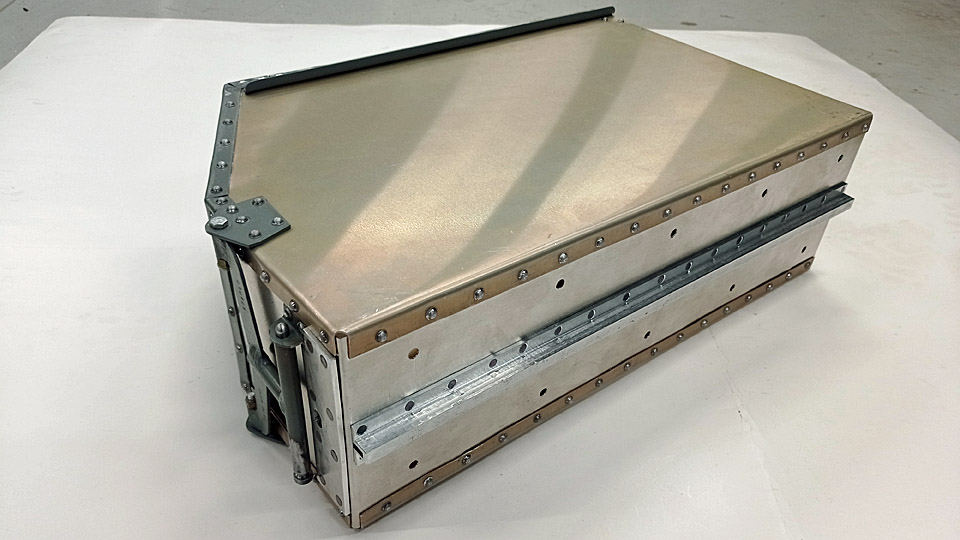

The entirely new caissons were made according to the blueprints. The blueprints lacked the detail picture of the rear handle, the necessary measurements were obtained from the assembly blueprint. The finished caissons turned out to be slightly too big and they didn’t fit properly into place. The matter could be corrected by adjusting the rails and hammering the caissons. The left-hand caisson remained a bit ill fitting. This was mostly because the left-hand adjustment screws of the rails couldn’t be properly reached. The locking of the caissons was observed to be working.

How the caisson is fitted into place and locked: The caisson slides to place on a roller rail. The locking lever in the lower rail is turned up, and with a screw in the lever the caisson is tightened into place. The handle of the caisson is turned down and a locking peg inside the handle locks the handle in the down-position. The square-shaped tip of the locking screw leans now against the handle of the caisson and prevents the locking screw from turning on its own account. The steel front plate of the caisson is meant to guide the spent cartridges, coming from the gun above, into the collection box.

The caissons will be painted grey all over later, at the same time as other larger parts are taken to be spray painted. |

|

Avainsanat: aviation history, restoration, MY-14, VL Myrsky |

The wings of a Link Trainer to the Tuesday Club to be coveredSunnuntai 3.12.2023 - Tuesday Club member The collection of the Karelian Aviation Museum includes a Link Trainer (LT-1). This Link Trainer has last been in use at Immola. The retired link Trainer was collected in a trailer to the Karelian Aviation Museum to Lappeenranta on June 6th, 2004.

Photos by Kimmo Marttinen. This Link Trainer has wooden wings with ailerons. The fabric covering of the wings is badly torn. On top of that the left aileron is missing. The wings are structurally more or less intact, so for that part there isn’t much to repair.

Photos by Ari Aho. The chairman of the Karelian Aviation Museum, Mr Kimmo Marttinen, turned to the Tuesday Club, whether the Tuesday Club could cover anew the LT-1 wings. The Club has several restoration projects active, but we answered in the affirmative because the wings are tiny, and their covering anew won’t take much room. The LT-1 wings were brought from Lappeenranta to the Finnish Aviation Museum at the beginning of November.

Photo by Ari Aho.

Photo by Kimmo Marttinen. At the Aviation Museum we examined more closely the Link Trainer’s fabric covered wings. There were damages on the covering of the upper surface of both the wings, but they could be patched. The covering of the underside of both the wings, instead, was badly damaged. However, we decided to cover both wings anew, because the end result wouldn’t be tidy, if it consisted of both old patched and new fabric covered surfaces.

Before we started to dismantle the covering, the right-hand wing’s aileron was taken off. Even though the covering was intact, it was dismantled. The reason for this being that we’ll have to build the lacking aileron for the left-hand wing, and for that we needed the structure of the right-hand aileron as a model. The structure of the aileron for building the lacking one can’t be seen without taking off the covering from the aileron.

When dismantling the covering fabric from Link Trainer’s wings, our attention was drawn to the thickness of the covering fabric. At the same time it was noticed that where there was damage in the fabric, silver and dark blue paint appeared from under the beige paint. The Link Trainer’s wings have originally, or before the last coat of paint, been blue on the upper surfaces and silver on the undersurfaces.

The covering fabric also told us that the wing had been covered with fabric consisting of several pieces sewn to each other. While covering the wing the stitches have been hidden with strips of fabric with zig-zag edges put into place with tightening lacquer to protect the seams.

When scrutinizing the wings stripped of the fabric, we noticed that the stem of the left-hand wing differed in form from that of the right- hand wing. Could it be that the entrance to the Link Trainer is on the left-hand side, therefore “a sidestep” has been made to the wing stem to facilitate entering the Trainer cockpit. We also noticed that the gluing seam in the wing structure had opened in places. These seams must be glued before commencing the covering. The airframe of the wing and aileron are very well and meticulously done, and also very typical wing structure with spars and ribs. Actually one wonders why the wing has been made so complete, because the Link Trainer’s wings weren’t meant to be airworthy. It would have been easier to construct the wings, if the wing had been made of plate, cut into wing form, as is the case in some Link Trainers. Before we get to covering the Link Trainer’s wings, we must find a suitable fabric. In this case an ordinary white cotton fabric will do, as long as it has good tightening qualities. So we bought two different kinds of cotton fabric from Eurokangas for testing the tightening qualities (Bed sheet fabric 150 and Satin), whose tightening qualities we now will test with nitro cellulose lacquer. Hopefully one of them will meet our requirements in covering the Link Trainer’s wings. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Link Trainer |

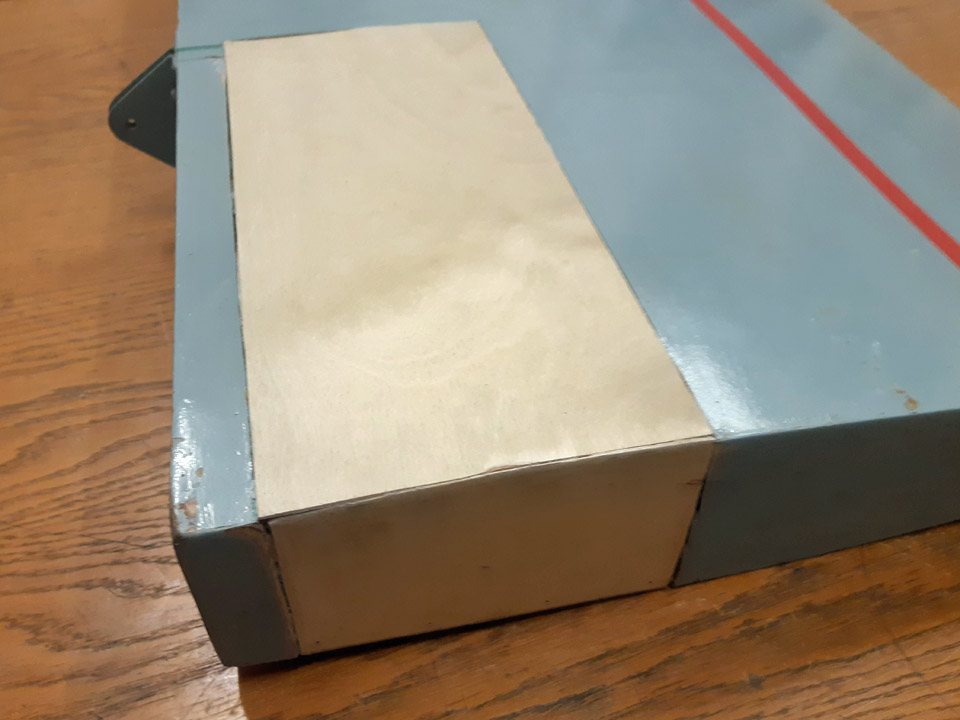

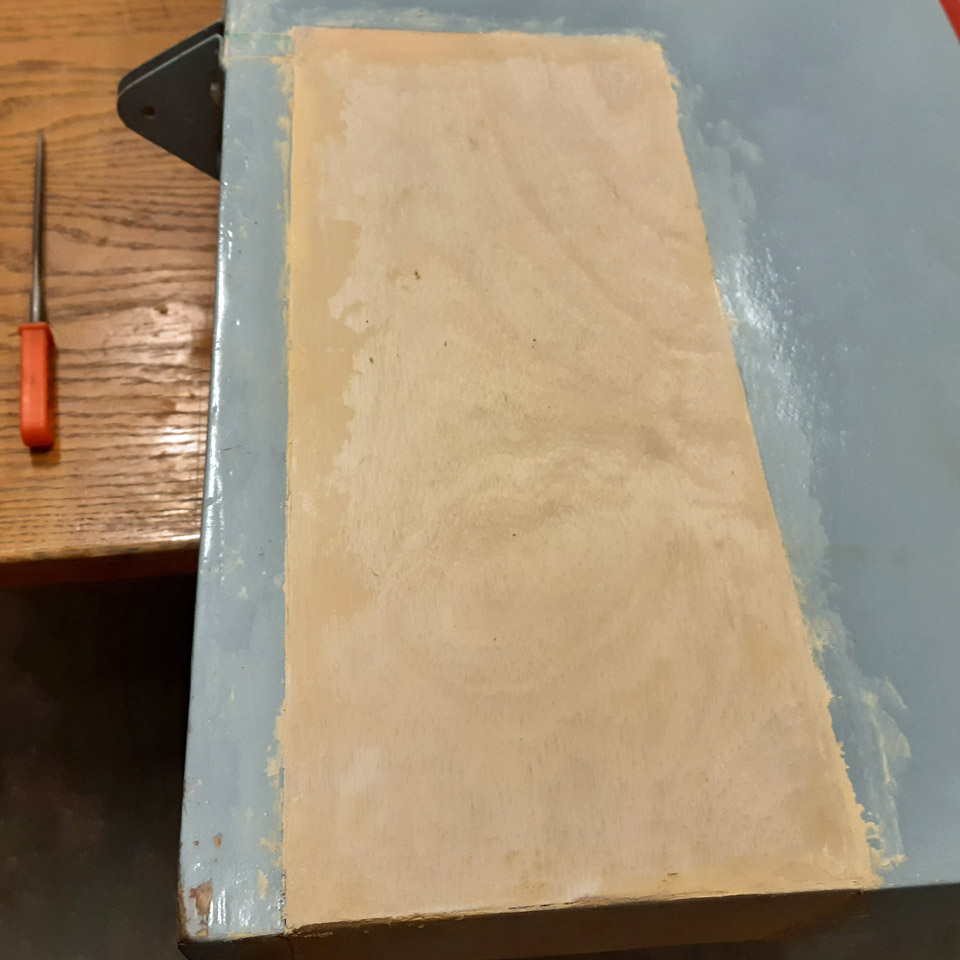

The plywood covering of OH-XEA Ressu is under repairPerjantai 1.12.2023 - Tuesday Club member Ressu’s restoration has progressed well in the Finnish Aviation Museum’s restoration workshop. The left wing, ailerons, vertical stabilizer, rudder, horizontal stabilizer, wing struts and tail wheel assembly are all now under work. Maybe we should actually be talking about repairs, because Ressu is mainly in good condition – except the fuselage and vertical stabilizer. Therefore we mainly concentrate on repairing the damages in the plywood covering.

The aim in repairing the damages in Ressu’s plywood covering is to save as much of the original plywood as possible. Where a blow has damaged the covering and the plywood is still a strip which is in one piece, we aim to repair the damage by gluing the strip back into place, using a supporting piece of new plywood. However, if the damage is an open hole, the plywood is shattered, or there is a piece of plywood missing, we will patch the damaged area with new plywood. The latter repairing method is introduced in this blog, using the repair of the damaged plywood covering on the elevator as an example. In all cases the glued seams of the patches are spackled and sanded, and the patched area is painted to the original hue of the painted surface so that the damaged area can hardly be noticed.

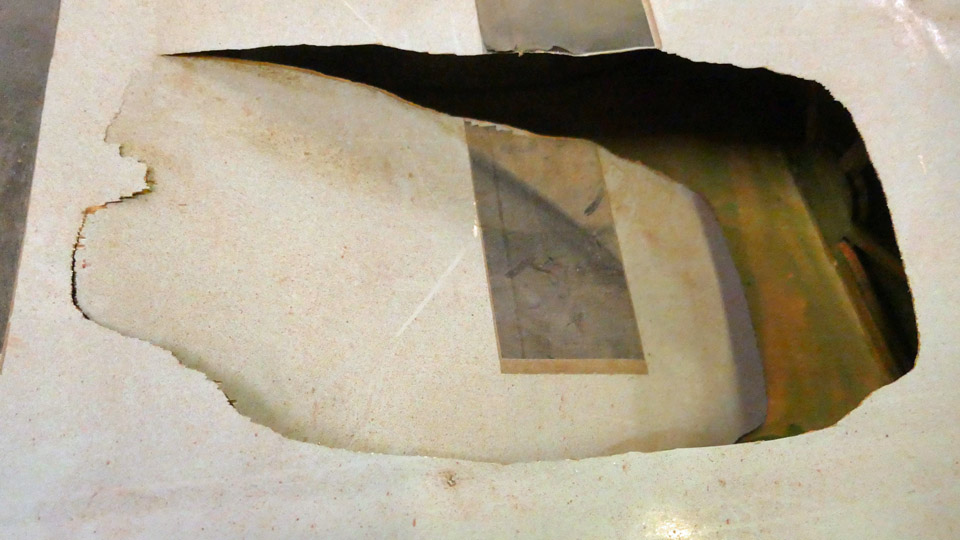

The plywood covering of Ressu’s elevator had one larger damaged area to be repaired. The damaged area is located on the elevator’s left-hand end, in the trailing edge side corner. Here the plywood covering has been broken on the elevator’s upper side and on its end. The plywood has broken in several places and parts of the covering are missing. We decided to patch the whole damaged area with new plywood.

First we removed the broken pieces of the covering plywood at the damaged point on the upper surface. Then we drew a rectangle around the damaged area and cut the plywood off along its edges, using a Dremel circular saw blade. This is how we created an opening for the patch on the upper surface. In a similar manner we cut a rectangular opening around the damaged area on the elevator’s end. Now the whole damaged area had been opened for patching.

The next step was to fasten supporting strips on the edges of the opening. The plywood patch will be supported by these strips when it is glued to cover the opening. Some of the supporting strips were glued with strengthening nails to the structure of the elevator. A strip was fastened also on the area where the patches on the elevators upper surface and on its end meet, i.e. at the upper edge of the elevator’s end.

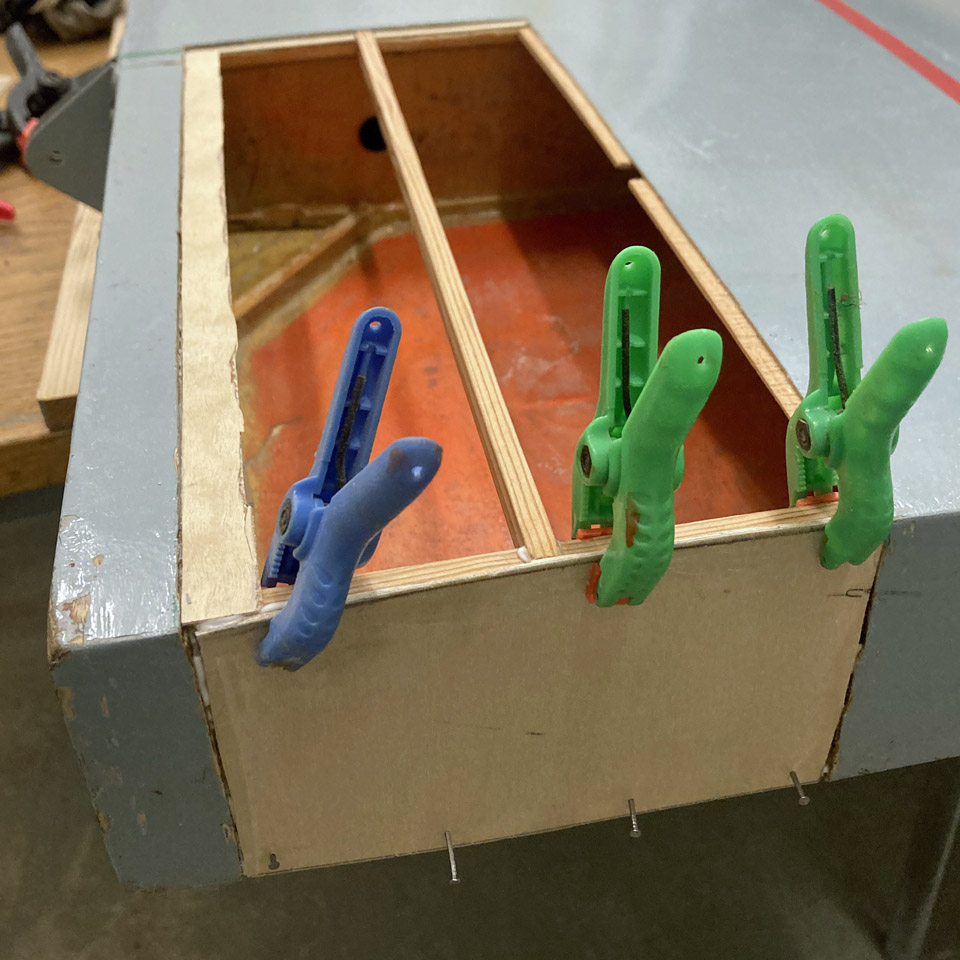

Photo by Antti Hietala. One of the supporting strips was glued on the underside of the plywood edge so that a little less than one centimetre of the strip was left outside the plywood covering’s edge. Before gluing, the old varnish was sanded away from the underside area of the plywood covering which was to be glued. The supporting strip was glued on the edge of the plywood covering and pressed tight on the plywood with small plastic clamps. The glue we used was Casco Outdoor wood glue. Furthermore, a longitudinal supporting strip was fastened across the opening on the upper side. This strip is needed to support the plywood patch on the opening and make it slightly curved so that it follows the gently curving profile of the elevator’s upper surface.

When the supporting strips had been fastened, patch pieces of 1 mm aircraft plywood were cut for the openings on the upper side and the elevator’s end. The patches were fitted into place, shaping their edges until the patch edges pressed tightly against the sides of the opening.

Photo by Matti Kainulainen. First the plywood patch was glued into place on the elevator’s end. The upper edge of the patch was pressed against the supporting strip with small clamps and the glued seam on the lower edge was secured with some small nails.

Photo by Matti Kainulainen. Then the larger patch on the upper surface was glued into place. On the elevator’s leading edge side, the glue seam of the plywood patch could be pressed tight with ordinary clamps. A piece of plywood was placed between the clamps and the glue seam to distribute the pressure evenly on the seam. On the other side of the opening a metal weight was placed on the glued seam to press the plywood patch against the supporting strip.

The gluing of both plywood patches went well. The patch seams were spackled using Plastic Padding’s two-component Chemical Wood. The spackled seams and the whole newly patched area will be sanded before painting. The plywood patches will be painted later, together with several other plywood patches on Ressu’s surfaces. Photos by Lassi Karivalo except if otherwise separately mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Hietanen HEA-23b, OH-XEA, "Ressu" |

Priming the HS-4 tail boom stabilizersTorstai 30.11.2023 - Tuesday Club member When both the fabric covered areas of the Mil Mi-8T (HS-4) helicopter tail boom stabilizers had been covered with thin 0,3 mm aluminium offset printing sheet, we could move on to priming these new aluminium surfaces. Obviously, the decayed fabric coverings were renewed with aluminium sheets instead of fabric.

Right hand side photo by Mårten Juslin. The first phase in priming is to remove grease and dirt from the surface to be painted. KUSTOM-anti grease agent was used to remove the grease. The agent was applied to clean cloth and both stabilizers’ new aluminium surfaces were meticulously wiped with it. The anti-grease operation for other surfaces of the stabilizers will be done in conjunction with the paintwork because their surfaces are already set up for the paintwork.

Photo by Mårten Juslin. The next step is the graining of the new aluminium surfaces to be adhesion-primed, especially as the HS-4 tail boom stabilizers’ new surfaces are smooth like a mirror.

Photo by Mårten Juslin. The graining of the new aluminium surfaces was done with a traditional scouring pad. After graining, the graining dust was wiped off the surfaces with a clean cloth. It was noticed that more dirt had accumulated to the cloth used for wiping off the grease and dirt than to the cloth used for wiping off the graining dust. This goes to show, how important part of the priming, the removal of grease and dirt is.

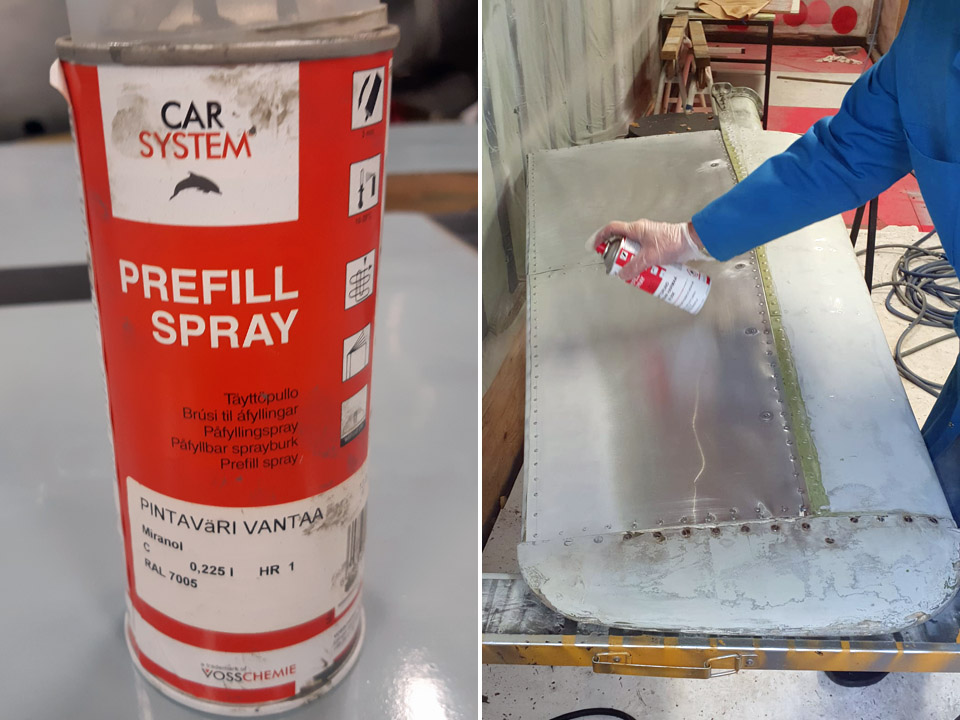

Right hand side photo by Ari Aho. As a primer or adhesive primer we chose the handy spray paint (Car System Prefill Spray Miranol) and its tone (RAL 7005). Light grey is in this case a good tone for the adhesive primer, because the stabilizers’ undersurfaces will be painted light grey (Light aircraft grey).

Photo by Mårten Juslin.

The stabilizers that were ready for priming, were taken to the painting tent at the yard of the Finnish Aviation Museum. There the primer was misted on the stabilizers’ surfaces as a thin, but engulfing veil. The stabilizers are now ready for the paintwork. Photos by Lassi Karivalo except if otherwise separately mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Mil Mi-8, HS-4, Tuesday Club |

The restoration of OH-XEA Ressu has been startedTiistai 21.11.2023 - Tuesday Club member As told in the previous blog, the parts of the OH-XEA, designed and built in the 1960s by the Hietanen brothers from Turku, will be restored by the Tuesday Club. The aircraft was nicknamed Ressu. Its wings, horizontal stabilizer, elevator, rudder, tail wheel assembly, wing struts and fuel tank have been brought to the Finnish Aviation Museum. We will concentrate on the restoration of its fuselage frame later. When the condition assessment and the restoration plan of the Ressu’s parts brought to the Museum had been completed, it was time to set to work.

The restoration of the wings was started by cleaning the plywood surfaces, painted blue. Both wings were brought to the restoration workshop of the Finnish Aviation Museum. We started the cleaning of the painted wing surfaces with a well-tried method: a magic sponge. Naturally the worst dust was first vacuumed off. The aileron was unfastened to be washed separately. The dust in the joint of the aileron and the wing was brushed off with a paint brush and vacuumed clean.

When using a magic sponge no cleaning agent is used. The tools you need are the magic sponge, a soft cloth, and half a bucket of water. The painted surface of the wing is cleaned by rubbing the surface of the wing, a small area at a time, with the magic sponge dipped in water and squeezed damp. With the soft cloth in the other hand the rubbed area is wiped at short intervals. The magic sponge removes the dirt from the wing surface, and it is wiped off with the cloth, which is rinsed in the bucket. There were also splashes of red paint on Ressu’s wings. Even they could be removed with the magic sponge. The rubbing with the magic sponge does not damage the painted surface unless excessive force is used.

The plywood covered horizontal stabilizer and elevator were treated in a similar manner. We managed to get their surfaces very clean too. We were satisfied to see that after the wash the greyish blue surfaces of the wings, horizontal stabilizer and elevator were as if newly painted. We wonder whether they have been painted in the 1960s using durable Miranol enamel paint as the painted surface has been so well preserved.

For the rudder surfaces no washing was needed, but the covering fabric was removed from the metal frame of the rudder. The covering fabric needs to be completely replaced. A carpet knife was used when removing the fabric. We could see that a strip of fabric had been spun around the outer edges of the frame. This strip protects the fabric which covers the metal rudder frame. On the other hand the covering fabric can be sewn on the fabric strip, but we could not tell whether this had been the case here. The fabric strip covering the edges of the metal frame was removed with a carpet knife. The rudder’s metal frame, stripped of the covering fabric, is now ready for rust removal and the surface treatment after it.

Photos by Reino Aatsalo.

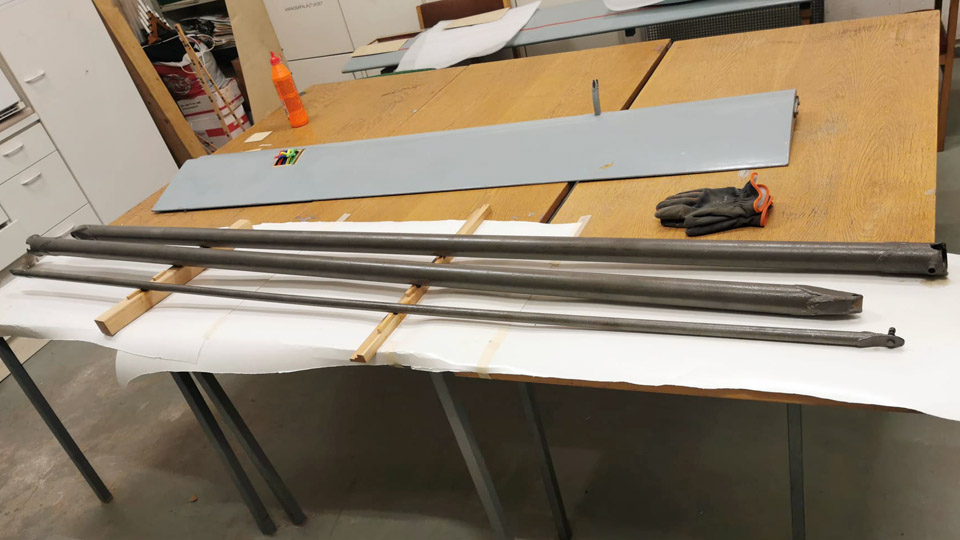

Photo by Antti Hietala. Three of the Ressu’s four wing struts have been preserved. The struts are surprisingly heavy, so they are probably made of ordinary steel tube. The surfaces of the struts have been painted yellow but are now covered in rust. The surfaces were sandblasted clean. Then the struts were treated with Isotrol varnish which prevents rust. Now the wing struts are waiting for their final surface treatment, and they will be painted yellow as in the original paint scheme.

Photo by Lassi Karivalo.

Photos by Osmo Väisänen. The restoration of Ressu’s sprung tail wheel assembly was started by disassembling it. Even the tail wheel had to be disassembled so that we will have access to the wheel bearings, which are totally jammed. When the four bolts on the wheel rim had been unfastened, the rusty wheel halves could be wrenched apart by force. When the bearings were visible, we sprayed a lot of rust removing chemical in them and on the rusted surfaces of the wheel rim and left them “to mature” for a week. When a week had passed, we were able to clean the wheel rim halves quite well from rust and the bearings were preliminarily working. The following task will be to repair the sprung tail assembly. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Hietanen HEA-23b, OH-XEA, "Ressu" |

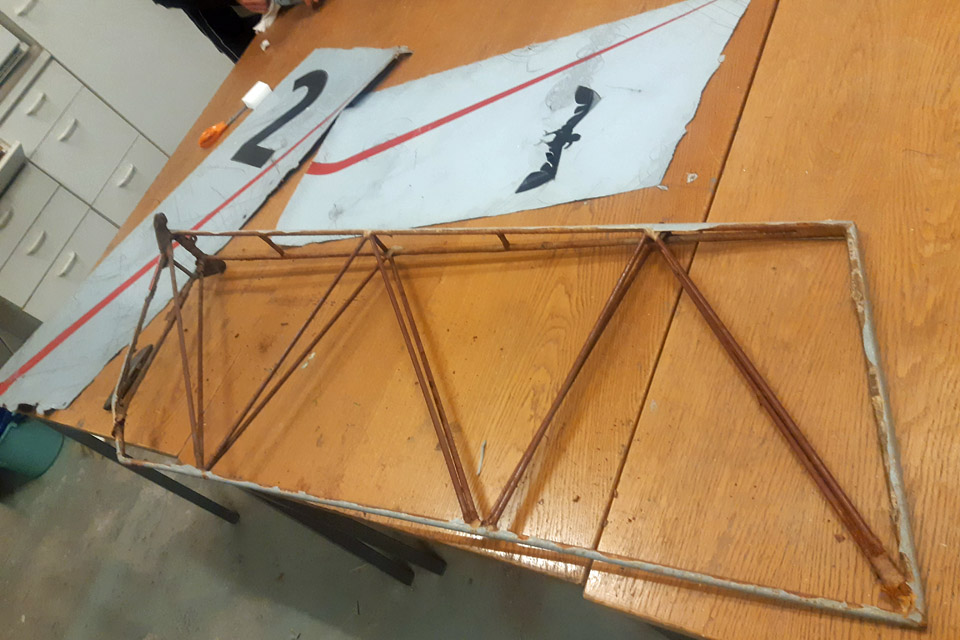

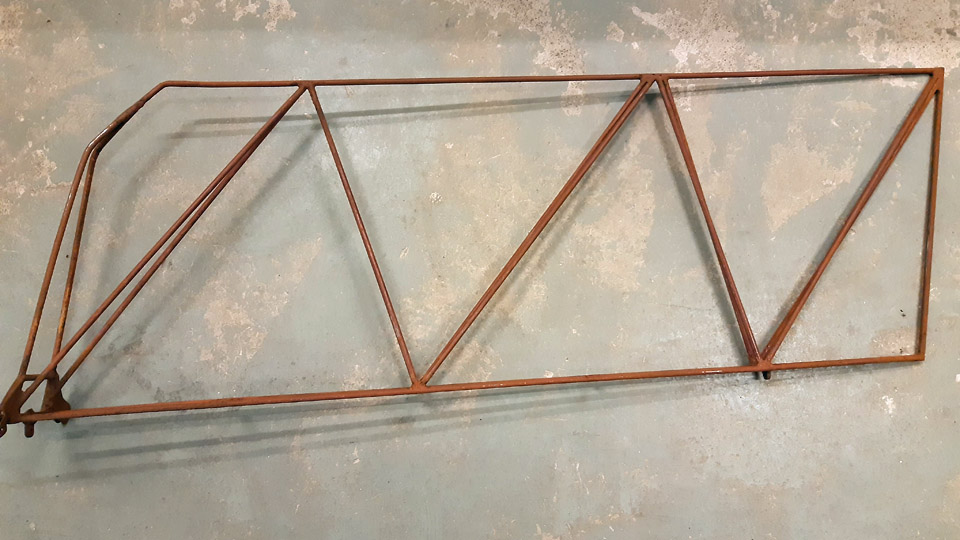

The condition and damage assessment of Hietanen OH-XEA Ressu and its restoration planSunnuntai 19.11.2023 - Tuesday Club member The Tuesday Club is starting the restoration of the Hietanen OH-XEA Ressu aircraft which has been stored at Lemu in the Turku area. The aircraft was built in the 1960s by Ari and Esko Hietanen from Turku. The first phase of the restoration will include the wings, horizontal stabilizer, elevator, rudder, tail wheel assembly, wing struts and fuel tank, which have been brought to the Finnish Aviation Museum from Lemu. The fuselage has no covering, but it remained at Lemu, and its turn will come later. The first step in the renovation work is to assess the condition of the aircraft and its possible damage. Therefore we took the Ressu’s parts into the restoration workshop at the Finnish Aviation Museum and went carefully through the condition and damages of each part and made preliminary restoration plans for them.

We could see that the plywood covered surfaces of the wings, horizontal stabilizer and elevator are very dirty and have stains of red paint. The damages on the plywood covering are mainly small crushes or holes. However, on the underside of the left wing there is a large area around the registration mark where the plywood covering is badly broken. Or should we say has been intentionally broken – it certainly looks that way. The first phase in the restoration will be to clean the surfaces of the wings, horizontal stabilizer, and elevator and then to repair the damages on the plywood covering.

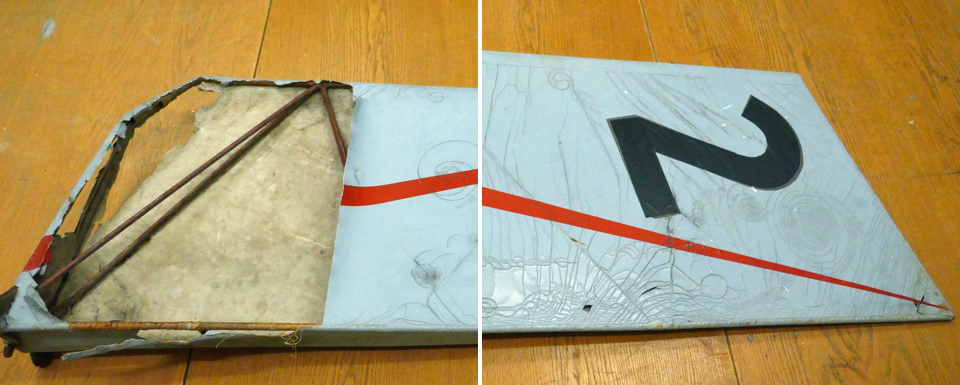

Ressu's rudder has metal structure and fabric covering, in similar manner as the tubular structure fuselage. The covering fabric is torn on one side of the rudder and a piece is missing.

The rusty metal frame of the rudder can be seen under the torn fabric. The metal frame will be cleaned and painted as it originally was. It seems that the frame has been painted with red Ferrex, the anti-rust paint which was commonly used in the 1960s. The red colour is visible under the rust. We will paint the frame using modern red Isotrol paint.

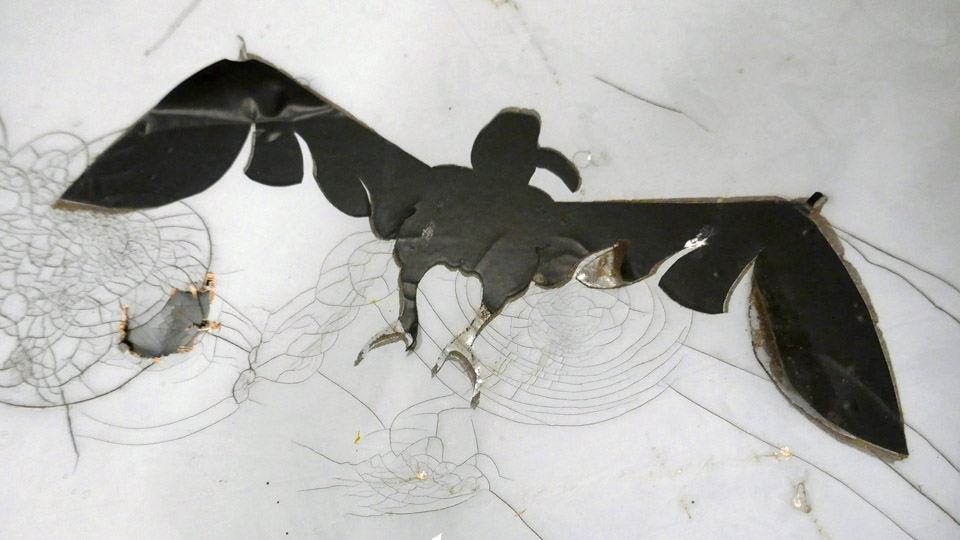

Finally the rudder will be covered with new fabric and painted pale blue, following the original paint scheme. Red stripes will be painted on both sides of the rudder, following the original look. Number 2 will be painted on the left side and a black bird figure on the right.

Ressu's tail assembly has metal structure and an air-filled tyre. The wheel bearings are completely stuck. We will try to repair the wheel into operating condition. The tail frame will be cleaned of rust and painted yellow, following the original paint scheme.

Ressu’s wings are supported with two wing struts, made of metal tube. Two of them are sturdier, fastened on the brackets on the wing’s front spar, and the two thinner ones are fastened on the brackets on the rear spar. We have both front struts but only one rear strut. The wing struts had been stored inside Ressu’s fuselage frame. The struts have been painted yellow but are now badly covered in rust. They will be sandblasted clean by a contractor and painted yellow as the original ones. We will make a new rear strut to replace the missing one.

The fuel tank is located at the root of the left wing, it has been lowered into place from the upper side of the wing. The fuel tank has dents, and they will be straightened. The fuel tank has had some kind of cap with a rubber seal, there are marks of it left on the wing as well as on the tank. The cap has disappeared. If we can find out what the cap has been like, we will make one. And if we can’t find what it has been like, a good alternative is to make a cap from e.g. 1,2 mm thick aircraft plywood. The Hietanen brothers have obviously been planning to double the size of the 21-litre fuel tank. We can judge this from the fact that the wing rib next to the tank had already been removed and the wing’s plywood covering had been opened between the wing spars up to the following rib. We will, however, restore the wing structure to its original condition where there is only space between the wing root rib and the first rib for the original fuel tank. This means that the missing rib will have to be made and the opened plywood covering repaired. Photos by Lassi Karivalo. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Hietanen HEA-23b, OH-XEA, "Ressu" |

Covering the DO-5 tail openingsSunnuntai 12.11.2023 - Tuesday Club member The rain covers for Aviation Museum Society owned Douglas C-47 (DO-5) tail openings were finished in October. The tail has been without vertical and horizontal stabilizers and the tail cone for donkey’s years. Due to that rainwater and snow have penetrated into the fuselage. The building of the covers out of aluminium plate has been reported already earlier in a Tuesday Club blog.

A strike force of Tuesday Club members set off from the Finnish Aviation Museum to Turku Airport to fasten the covers to the DO-5 tail at the end of October. The covers and other equipment came along in a trailer. The DO-5 fuselage is on display beside the Caravelle III, restored as Finnair’s “Bluebird” (OH-LEA) in the vicinity of Turku Airport Passenger Terminal. After arriving at the Airport we got the covers made of aluminium plate and other necessary tools and a ladder out of the trailer got on with the job.

We divided into suitable work groups. One of them fastened the ILS look-alike antenna and the thermometer probe we had brought with us for the DO-5. These were fastened in their original places on the undersurface of the nose cone.

Another working duo started to fasten the covers for the openings of the right- and the left-hand side horizontal stabilizers. The third pair concentrated on fitting the covering shields for the tail cone. The fourth pair was tasked to fit in place the covering case we had built to cover the vertical stabilizer fastening point and to fasten in place the shaped hood, made of thin aluminium sheet, to protect the front end of the case and the fixed fuselage fin at their seam.

The fitting advanced rapidly, because the covers made at the Museum’s restoration workshop according to blueprints, settled in place as we had planned. The horizontal stabilizers’ covers were fastened to the edge of the opening at their top edge with stainless steel screws. Holes were drilled through the covers into the fuselage for the screws. After this the cover was fastened to the fuselage also from its lower edge. We used stainless steel screws deliberately, so that they won’t start leaking rusty streaks along the fuselage surface as time goes by. An extra bit had to be cut off from the rear end hem of the left-hand horizontal stabilizer’s cover, to get the cover to press tightly along the edges of the horizontal stabilizer’s opening.

When thinking about the way to fasten the covers, it occurred to us that we could have utilized the existing holes in the fuselage. However, it would have been extremely difficult to match exactly the fastening holes in the cover with the holes of the horizontal stabilizer fastening screws. That’s why we ended up with the above-mentioned method, which produced a few extra holes in the fuselage. If the DO-5 were to be made airworthy, the method would have certainly been different.

The tail without the tail cone was protected with two separate aluminium covers. We had to shape the edges of the upper cover a bit before it clicked into place and was fastened with a few screws. We also had to shape with a hand drill the curved opening in the lower cover, so that we could get the protuberant strip in the fuselage to “pop out” through the opening and press the cover tightly against the end of the fuselage. This cover, too, was fastened with a few stainless-steel screws. The edges of the lower cover shielding the rear fuselage were bent at 10 cm width to an angle of 90 degrees. This way the sides of the cover could be pushed under the covering sheet of the horizontal stabilizer’s rear end and linked to it with a couple of screws.

The vertical stabilizer’s fastening point wasn’t covered with just an aluminium cover, like the other openings, but a nearly three metres long covering case was made for it. The seams of the aluminium sheets were covered with duct tape, after which the case was lifted to place on the low support braces of the fastening point. It was noticed that the case settled in its place as planned. The rear end of the case’s aluminium sheet was bent from its lower edge to form a canopy against rain on the rear end of the fuselage. Despite the case being fairly heavy, it was fastened by its hem with a few screws to the fuselage. Thus not even a strong gust of wind gets to throw it from its place.

Photo by Mikko Jaakkola

Photo by Esko Ruohtula When the protecting case of the vertical stabilizer’s fastening point was in place, we started work on the final shaping of the hood, covering the joint of the case and the fixed fin. The hood had been bent to its preliminary shape from 0,3 mm thick aluminium sheet at the Museum. We had to shorten it quite a bit before it was the right size to protect the joint. The hood was fastened from its lower edge to the fuselage with a few screws and the sharp head of the hood was shaped round.

Photo by Mikko Jaakkola The openings for the DO-5 horizontal stabilizers, vertical stabilizer and the fuselage rear end had now been protected against the weather, and we could start the home journey to the Finnish Aviation Museum, satisfied with our work. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Matti Liuskallio |

|

Avainsanat: aviation history, restoration, Tuesday Club, DC-3, C-47, DO-5 |

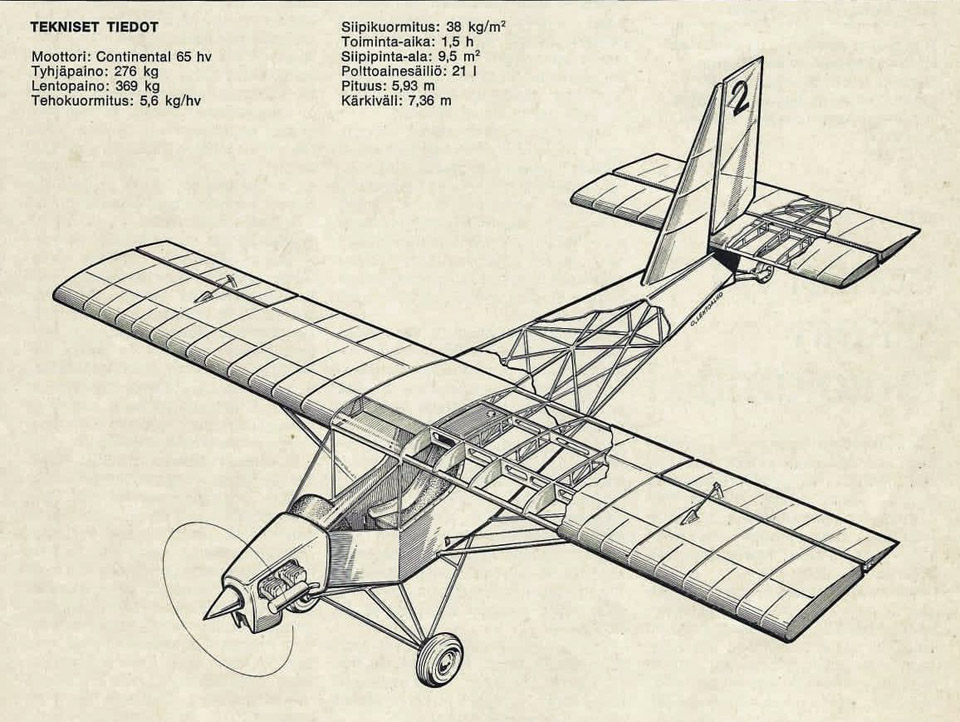

Hietanen OH-XEA "Ressu" to be restored by the Tuesday ClubPerjantai 10.11.2023 - Tuesday Club member Last year Aviation Museum Society Finland was donated a single-seat experimental aircraft, designed and built in the 1960s by Esko and Ari Hietanen, two brothers from Turku. The aircraft was inspected and registered in the civil aircraft register on August 13th, 1969, with the registration OH-XEA. The aircraft, nicknamed Ressu (meaning Snoopy), is a high-winged, mixed structure single-seat aircraft. The tubular framed fuselage is fabric-covered. The wings, ailerons, vertical stabilizer and rudder have wooden structure and plywood covering. The rudder is tube-structured and fabric-covered.

Photo via Aviation Museum Society, Finland. Ressu is a small aircraft. Its wingspan is 7,4 m and the fuselage is 5,5 m long. The widest part in the fuselage is the landing gear, with 1,4 m from one end of the axle to the other. In its time, Ressu had several registration marks. First it was registered as H-EA (Hietanen Esko and Ari), then OH-HEA and eventually OH-XEA when it was approved in the civil aircraft register. Ressu’s engine was Continental A 65. The aircraft was removed from the civil aircraft register on January 1st, 1973. We don’t know how many hours Ressu has flown.

Photo via Aviation Museum Society, Finland. After the flying activity ended, Ressu was stored in several places and its fuselage was badly damaged. Today the fuselage has no traces of the fabric covering and the tubular frame is covered in heavy rust. In the cockpit there is just the pilot’s seat, control stick, pedals, and an empty instrument board. The engine, the instruments from the cockpit panel and the landing gear wheels have all disappeared during the years. Out of four wing struts only three remain. The wings were painted pale blue, the horizontal stabilizer and the elevator have been preserved quite well, there are only some damages on the plywood covering. The fabric covering of the rudder is broken and the paint on the fabric is badly crackled. The fabric covering on the fuselage has probably been painted pale blue as the wings.

The aim is to restore Ressu at the Tuesday Club to resemble its appearance in 1969 when it was registered. This means that the plywood covered surfaces of the wings and parts of the tail will have to be cleaned and the damages repaired. After that we can consider restoring the fuselage. There the first step would be to treat the rusty fuselage before covering it with fabric. We will try to find instruments for the cockpit if we are able to find the kind of instruments Ressu had. The engine could well be a discarded and inoperative Continental A 65, if we could find one.

Photo by Elias Viitanen.

In autumn 2022 Aviation Museum Society Finland volunteers assembled Ressu in the former shipyard hall in Pansio where the Caravelle III, owned by the Society, was under restoration. Ressu was also on display at the Society’s stand in the Turku Airshow in June.

After that Ressu has been stored at Lemu, in the Turku area. From there we fetched Ressu’s wings, horizontal stabilizer, elevator, rudder, tail wheel assembly, fuel tank and wing struts, and brought them on a trailer to the Finnish Aviation Museum in Vantaa. In the Museum’s restoration workshop the Tuesday Club members have already started the restoration of Ressu’s parts. The fuselage remained at Lemu, but it will probably be taken under restoration next year. The Tuesday Club has now started Ressu’s restoration project which is estimated to take a couple of years. Photos by Lassi Karivalo except if otherwise mentioned. Translation by Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, Tuesday Club, Hietanen HEA-23b, OH-XEA, "Ressu" |

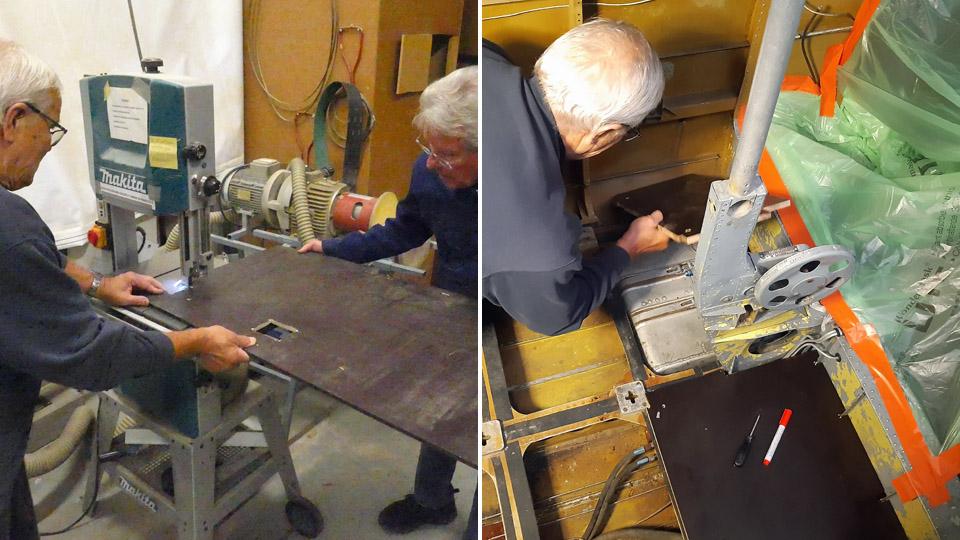

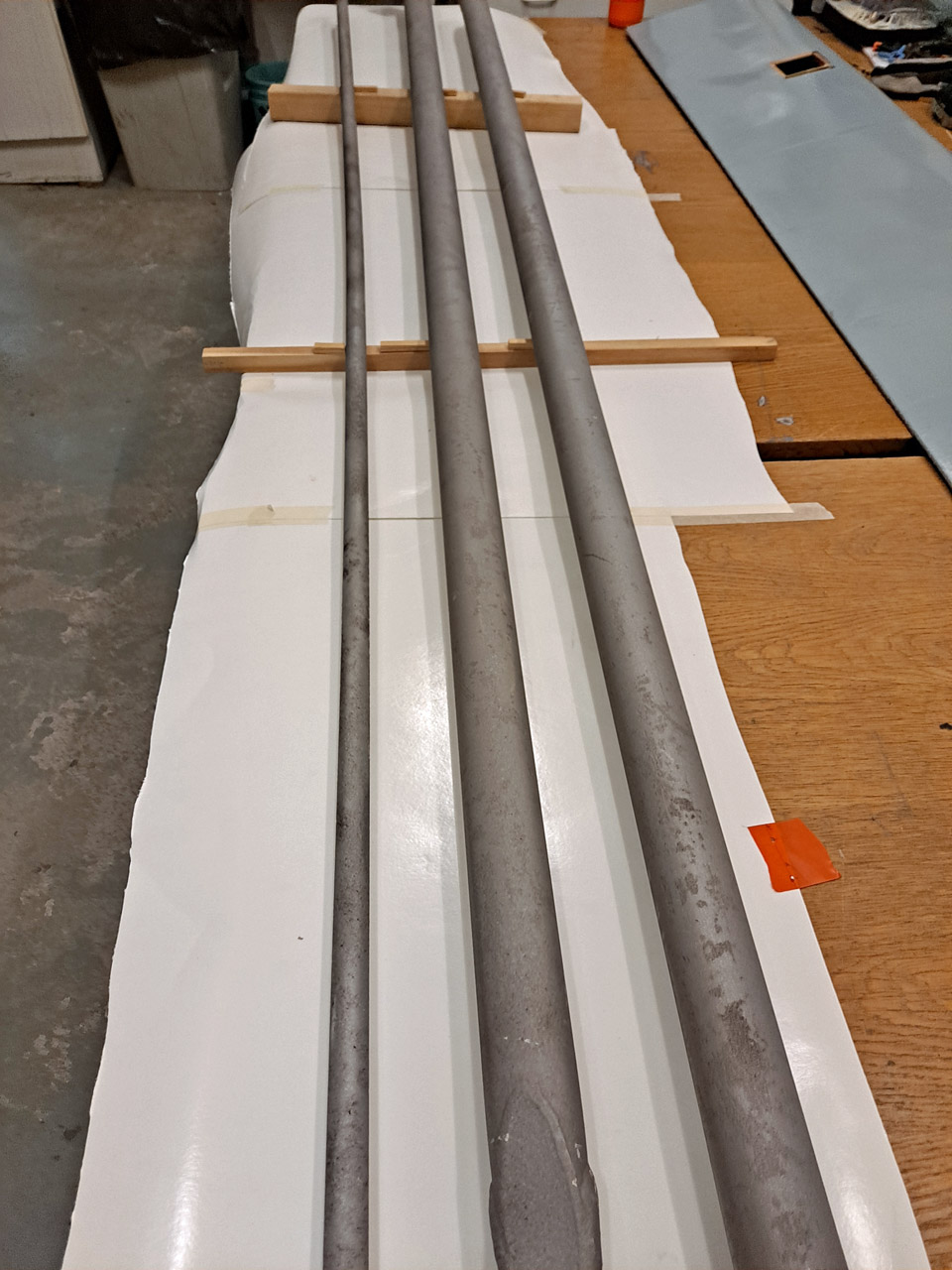

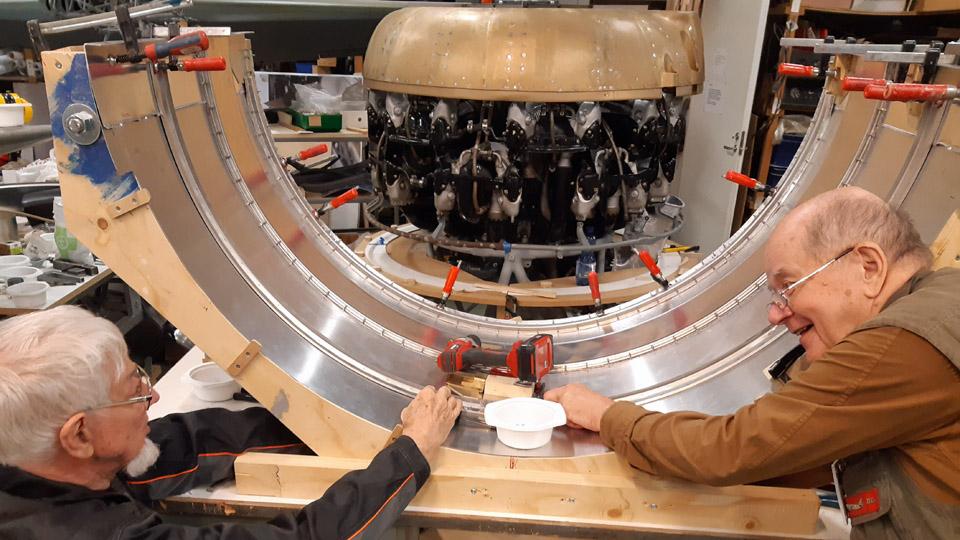

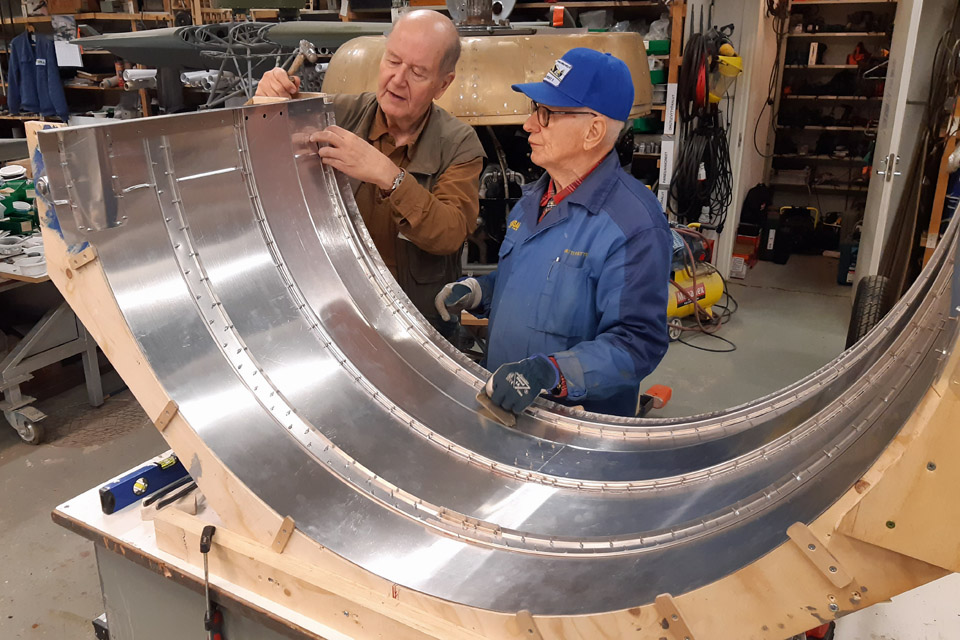

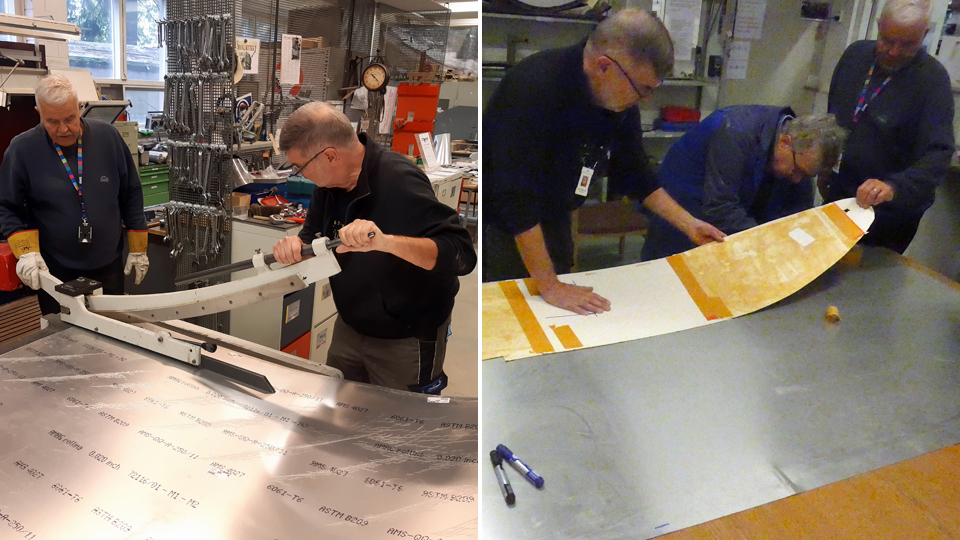

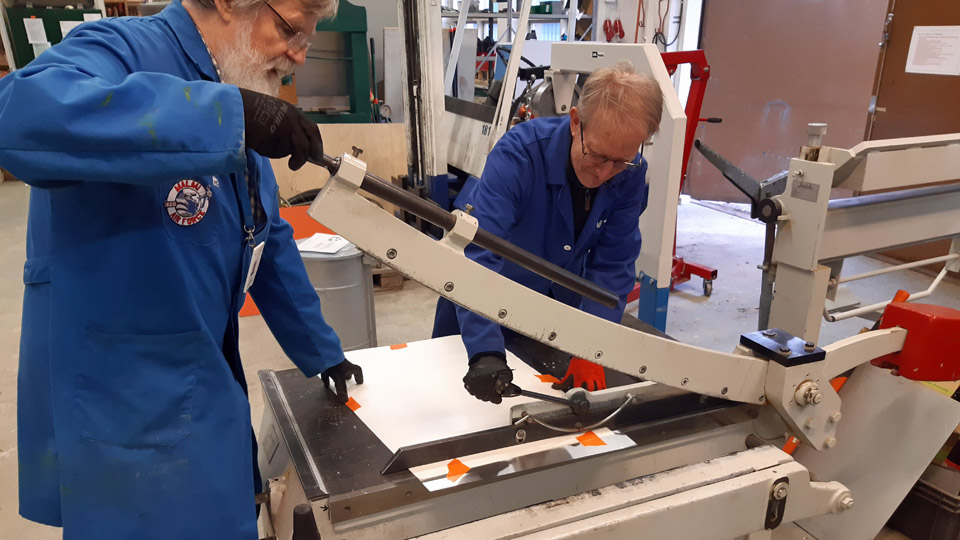

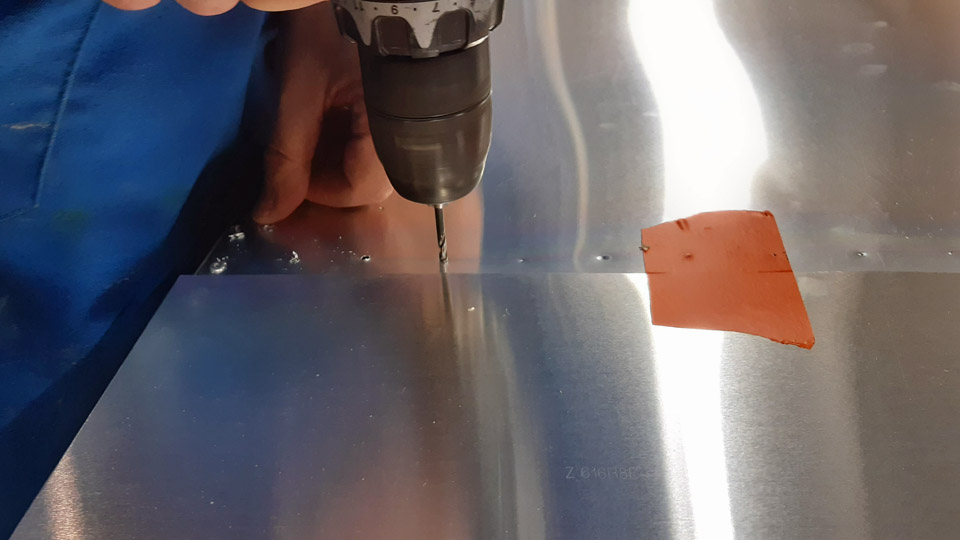

Making the lower sheet metal cowling for the Myrsky engineMaanantai 6.11.2023 - Tuesday Club member The VL Myrsky II (MY-14) engine has a lower and upper cowling, made of sheet metal. The lower cowling was built at the Tuesday Club. The cowling was made of 1 mm thick aluminium sheet. The stiffening formers that were fastened on the inside surface of the cowling were made of the same material. The upper engine cowling will be built at the Finnish Air Force Museum, where the main undertaking will be the restoration of the MY-14 fuselage.

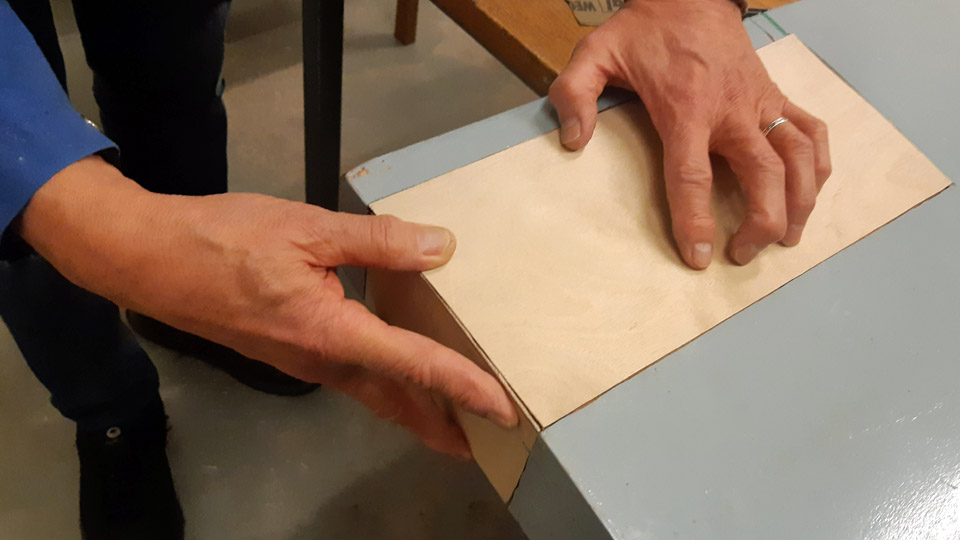

Before the 1 mm sheet, cut out of aluminium plate, was started to be formed into the U-form of the lower engine cowling, a female forming last was cut out of sturdy plywood. This forming last works as a model, showing that the lower engine cowling needs a curved shape. The shaping of the sheet was done by mangling the sheet in a mangler with three rollers and comparing the sheet to the forming last at intervals. After the mangled sheet had been made to press itself tightly against the forming last, it had reached its correct form. Next the formed sheet could be tried on the Pratt & Whitney engine used in the Myrsky. The engine was moved into the restoration shop in the Finnish Aviation Museum. We managed to fit it snugly on the side of the engine.

Photo by Heikki Kaakinen. The lower engine cowling needs several stiffening profile strips to keep it in form. The stiffening strips were cut and bent according to the programming information given at Prolaser Oy. After this we started to fasten the stiffening profiles on the inner surface of the engine cowling. The stiffening strips are fastened by riveting onto the metal casing.

The Myrsky blueprints gave us the exact position of each profile strip on the inner surface of the engine cowling. So we started fastening the profile strips, but not straight with rivets but at first they were fastened in place with 12x3 mm small bolts. The holes for the bolts were drilled on the rivet spots according to the blueprints, and a small bolt was put in the hole to fasten the stiffening strip to place. When all the profile strips had been fastened, the inside of the engine cowling looked a bit like a porcupine, because the nuts of the small bolts were sticking out of the edges of the profile lists.

Now the engine cowling with stiffening profiles was fitted on the engine. The casing still settled laudably in place, so we could start fitting the fastening latches in the top part of the engine cowling. The lower and upper engine cowlings are fastened to each other with openable latches because the cowlings have to come off when maintaining the engine or armament.

Before we started changing the fastening bolts of the stiffening profiles to countersunk aluminium rivets, the outside holes of the bolts were countersunk to suit the flush rivets. The profile strips were riveted, one hole after the other, onto the engine cowling’s inner surface with 8x3 mm aluminium rivets. The riveting was done with a riveting pin and a counter part pressed on the rivet head on the opposite side.

Finally it was checked that the flush heads of the rivets had been riveted flush with the engine cowling surface. Some rivet heads had to be tapped with a hammer flush with the engine cowling surface, so that the outside surface of the cowling was left absolutely smooth after the riveting. The finished lower engine cowling will still be chromated, the same way as all the Myrsky aluminium parts. Photos by Lassi Karivalo expect if otherwise mentioned. Translation by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, MY-14, VL Myrsky, Tuesday Club |

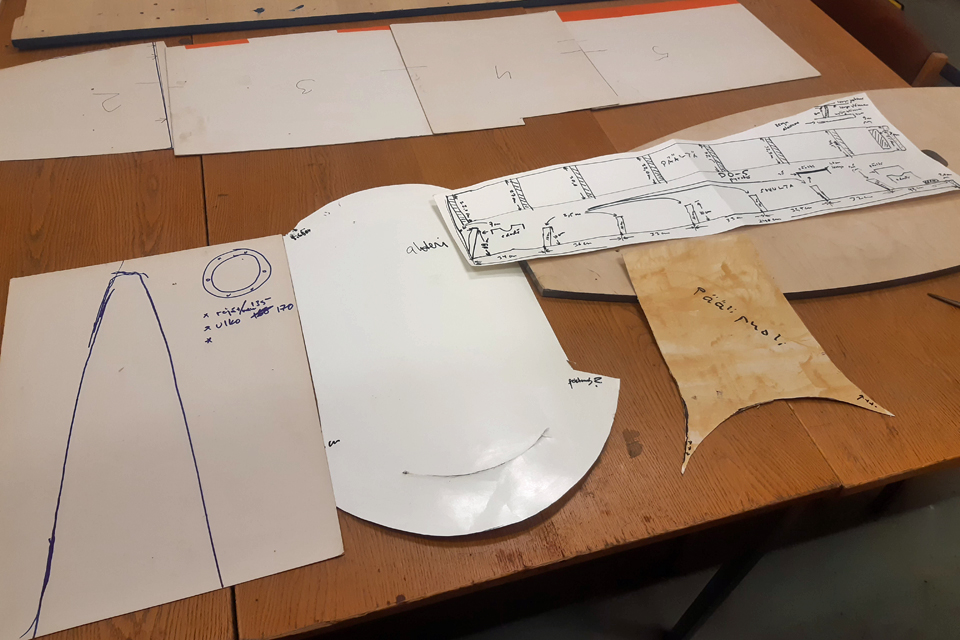

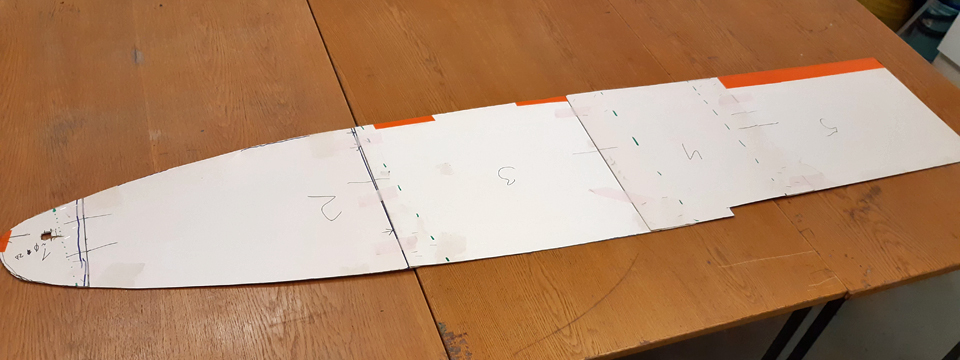

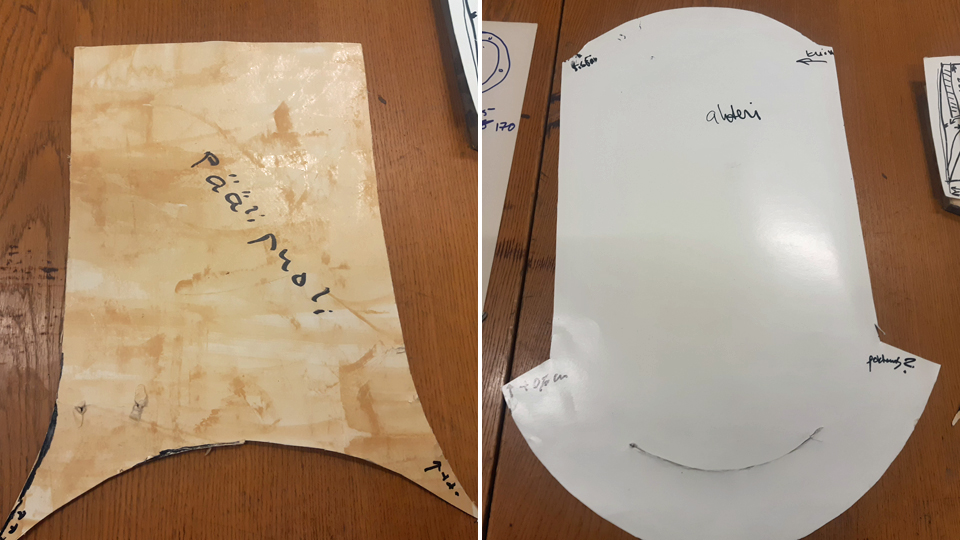

Constructing the weather shields for the stabilizer openings for the DO-5 (Douglas C-47)Lauantai 4.11.2023 - Tuesday Club member The fuselage of the Douglas C-47 (DO-5) owned by Aviation Museum Society is situated in vicinity of the Turku Airport passenger terminal, close to the Caravelle III, magnificently restored as Finnair “Bluebird”. The DO-5 tail has no elevators or rear cone. That’s why rainwater and snow blizzards have penetrated into the fuselage for years, to play havoc inside. Now we can get rid of this problem when the Tuesday Club has made shields to cover the openings. To build them we visited Turku to measure the sizes of the openings and cardboard templates were made. (see the blog from Sep.21st 23)

Photo by Ismo Matinlauri

When we were starting to build the covering shields, we contemplated, whether we’d build the shields from plywood, or thin aluminium sheet. We ended up with a compromise, where we would build a plywood case covered with aluminium to shield the vertical stabilizer’s fastening point. The openings of the horizontal stabilizers and the rear openings we would shield with aluminium sheets. Building the vertical stabilizer covering caseThe fastening point of the vertical stabilizer is built in such a way that it can’t be covered with a shield alone. That’s why we’ll be building a covering case from plywood, which can just be pressed into place, supported by the fastening point’s 10 cm high supporting brackets. The top of the case will be built from sturdy plywood plate. The sides will be from thin plywood. Because the plywood we use isn’t weatherproof, we’ll cover the plywood case with thin aluminium offset-press sheet, which goes well with the aluminium fuselage of the DO-5.

The construction of the covering case of vertical stabilizer fastening point was started from the top, which duplicates as the frame of the case. To make that we used sturdy 12 mm thick plywood plate. We had to build the top from two joined pieces, because the length of the plywood plate at our disposal wasn’t enough to cover the 240 cm length of the vertical stabilizer’s fastening point.

We cut two pieces of plywood, which were a bit broader than the fastening point of the vertical stabilizer. The pieces were joined with a 30 cm long plywood joint piece. The form of the fastening point was drawn according to the blueprint on the more than 240 cm long case top. After that the extra bits according to the drawing line were sawn off, so that we had the finished piece of plywood for the top of the case.

The sides of the case were made from 3 mm thick aviation plywood. 15 cm broad ”strips“ were cut, using a cutter, from the plywood plate to form the sides of the covering case. A 15 cm broad plywood side shields well the vertical stabilizer’s fastening point. The plywood strips were fastened from their upper side to the side of the roof plywood with 20 mm nails. They were joined to one another with a lap joint, so that the ends of the plywood overlapped 10 cm.

When the vertical stabilizer’s covering case was structurally ready, it was covered with 0,3 mm thick offset printing sheets. From 100x70 cm aluminium sheets at our disposal, we cut off strips that were 1 cm broader than the sides of the case. That way the covering strip reaches a bit past the plywood side forming a “dripping edge”, preventing rainwater from rising into the plywood under the aluminium sheets. The aluminium strips were nailed with 20 cm nails to the edge of the 12 mm thick top plywood edge. The strips were joined with lap joints overlapping about 5 cm. The lap joint will be covered with aluminium tape when the covering case is fitted into place.

After the sides of the case had been covered, the case roof was covered. Three one-metre-long pieces were cut from the offset sheets. The sheets were cut about 5 cm broader than the case roof. This is because the edges of the aluminium sheets will be bent over the roof edge to cover the roof/side plywood joint. As the roof covering sheet had been fastened in place, its edges were bent with gentle beating with a hammer onto the top edge of the side sheets. The overlapping edge of the offset sheet was fastened to the roof edge with a few sheet metal screws. The case covering the vertical stabilizer joint was finished. To shield the front end of the covering case, there will be a tapered “hood”, which will be formed from aluminium sheet. This hood will cover the joint of the vertical stabilizer’s front part (fin) and the covering case. The hood was made from 0,3 mm thick offset sheet and it was bent into form with a bending machine. The so far oversized hood will be formed to its final shape when fitting the vertical stabilizer covering case to the DO-5. Making the horizontal stabilizer opening covers

The covers for the DO-5 horizontal stabilizer openings were made from 0,7 mm aluminium sheet. A piece was cut, big enough for both the openings of the horizontal stabilizers. The cardboard template of the openings was fastened on the aluminium sheet with adhesive tape. The outline of the template was drawn on the sheet with a felt pen, along which a billet to cover the opening was cut with a cutter and tin snips. Because the cutter and tin snips left the edges of the aluminium piece jagged and sharp, the edges were smoothed with a file. In a similar way the other cover was also cut using the cardboard template. We presume that the covering pieces we cut, are mirror images and will fit either of the two openings.

At the leading-edge head of the stabilizer opening there’s a fixed pipe for the stabilizer’s anti-ice rubbers’ pressure hosepipe. A hole was cut in the covering shield for the hosepipe. Now we were ready to remove the protective plastic sheets on the covering piece. Any traces of the plastic were washed off with white spirit.

The horizontal stabilizers’ opening covers, cut from 0,7 mm aluminium sheet, are very flexible, so it was decided to stiffen them with strips of plywood. From 3 mm plywood panel about 10 cm wide plywood strips were cut with a cutter. They were glued on the inside of the horizontal stabilizers’ covers using the Sikaflex 221.This way the covers gained suitable stiffness, which facilitates their fitting in place to shield the openings of the horizontal stabilizers of the DO-5. The tail end covering plates

The DO-5 tail is without the tail cone, so the rear end of the fuselage is prone to rain. The rear end will be covered with two aluminium plates, of which the upper is small compared with the lower one. A template from cardboard we had made was placed on the 0,7 mm aluminium plate and the outlines of the templates were drawn on the plate with a felt pen. Covers for both of the rear fuselage openings were cut from the plate. The edges were smoothed with a file. A curved slit a few mm wide had to be made to the lower shield, through which a solid protuberance on the fuselage “peeps” out. That slit was made by drilling a hole to the end of the slit and then drilling the slit open with a keyhole saw.

The covers for the vertical and horizontal stabilizer openings, as well as the rear fuselage, were ready to be fitted to the fuselage of the DO-5. The fittings will be completed yet before the winter sets in. Photos by Lassi Karivalo except if otherwise mentioned. Translated by Matti Liuskallio. |

|

Avainsanat: aviation history, restoration, Tuesday Club, C-47, DC-3, DO-5 |

How to Fence a CaravelleKeskiviikko 1.11.2023 - Ismo Matinlauri Since the beginning of June, the restored Caravelle has been protected at Turku airport by temporary rented fencing – providing only rather moral security. On Tuesday October 24th the permanent fence around the aircraft was completed. Fortunately during these months before the real fence was built there were no damages or accidents caused by the lack of proper fencing.

Photo by Ismo Matinlauri When the Caravelle’s location was planned in the Turku airport area, it was already obvious that a fence must be built around the aircraft. The main worry were vandals, graffiti sprayers and odd curious visitors. Secondly the fencing helps to control visitors and in other times protects the curious passers-by from accidents in the vicinity of the aircraft. Naturally the fence will not stop the most persistent trespassers, but it will, however, provide sufficient security. The purchase of the fence material started already before the Caravelle arrived in Turku. In spring 2022 Aviation Museum Society Finland bought the material for the fence and the gates. First the construction of the fence was scheduled to take place before the aircraft is moved to the site in spring 2023. Soon it was discovered that the fence will hamper the crane operations on site during the assembly and also make the actual assembly work more difficult. Therefore it was decided that the Caravelle is assembled first, and the fence is erected after that. The construction of the fence was left to a professional – that means that a contractor was hired to erect the fence. For cost saving reasons some of the work was done by the Aviation Museum Society Finland volunteers. In this case this meant assisting in setting the fence poles into concrete and in spreading the net wiring between the poles. This reduced the total cost nicely. Building the fence was an efficient procedure, completed in five workdays: • Day 1: marking and levelling the fence line, digging the holes for the concrete foundations,

Photo by Janne Salonen

Photo by Janne Salonen

Photo by Ismo Matinlauri

Photo by Jouko Tarponen

Photo by Jouko Tarponen Building the fence in late October was eventually a good thing. The weather is getting cold and there is quite a limited amount of work which can be done inside and outside the Caravelle due to the cold and wet weather, so we had plenty of time to assist in erecting the fence. |

|

Avainsanat: aviation history, restoration, Caravelle, OH-LEA, Sinilintu, Bluebird |

Mil Mi-8T (HS-4) helicopter tail boom stabilizers' covering with thin aluminium sheetSunnuntai 29.10.2023 - Tuesday Club member The tail boom stabilizers’ covering of the Mil Mi-8T helicopter, situated in the Karelian Aviation Museum, has started briskly. As was told in an earlier blog about the HS-4, the stabilizers will be covered with a thin aluminium sheet, instead of covering fabric. This is because the aluminium sheet stands much better to weather. And we must remember that HS-4 stands outdoor at the Museum yard most of the time and it’s not airworthy anymore. The covering of the stabilizers got really started after they had been stripped off tattered and rotten fabric and the faded aluminium surfaces were ground and waiting for painting after covering.

We decided to start the covering from the underside of the right-hand stabilizer. The covering will be done with 0,3 mm thick aluminium offset-printing sheets that were donated to us. Because one printing sheet isn’t enough to cover the whole area, both sides of the elevator will be covered with two aluminium sheets, joined to each other with edge joints.

We drew the area to be covered from the stabilizer stem and tip onto cardboard and cut the cardboard with a cutter to serve as models for the stem and tip aluminium covering sheets. Then we put the cardboard models on the aluminium sheets and attached them to the sheet with tape. This way the cardboard models stuck to the sheet when the aluminium sheets were cut to form with a cutter.

The edge joint of the stem and tip sheets is made on the centre rib of the stabilizer. Therefore a 5 cm wide aluminium support strip was riveted on the rib. The edge joint of the aluminium sheets will be placed in the middle of the support strip and the sheets will be riveted into the strip at the edges. Now the covering sheets could be placed on the stabilizer to their final form. The edges were formed, however, in such a way that the sheets are equally wide at the joint and their top edge joins tightly with the edge of the steel reinforcement on the surface of the stabilizer.

When the underside sheets had been shaped into place, the riveting was commenced from the tip sheet. The sheets will be riveted to the stabilizer at their outer edges with 3,2 x 6,0 mm blind rivets or pop rivets. First the places of the rivets were marked with a pen at three cm intervals at the edges of the sheets. Then the marks for drilling the rivet holes were snapped with a spike. The drilling took place with a 3,2 mm bit.

After the holes on one side were done, the pop rivets were riveted in place one after the other. The rivet was tightened with rivet pliers through the covering sheet into the structure of the stabilizer. After the stabilizer tip sheet had been riveted at its edges to the stabilizer underside, the stabilizer stem covering sheet was riveted to its place.

Because the aluminium sheets were only riveted at their outer sides, the contact surface of the rib and aluminium sheet was seamed with silicone. That way the aluminium sheet glues itself to the rib and won’t resonate in strong winds.