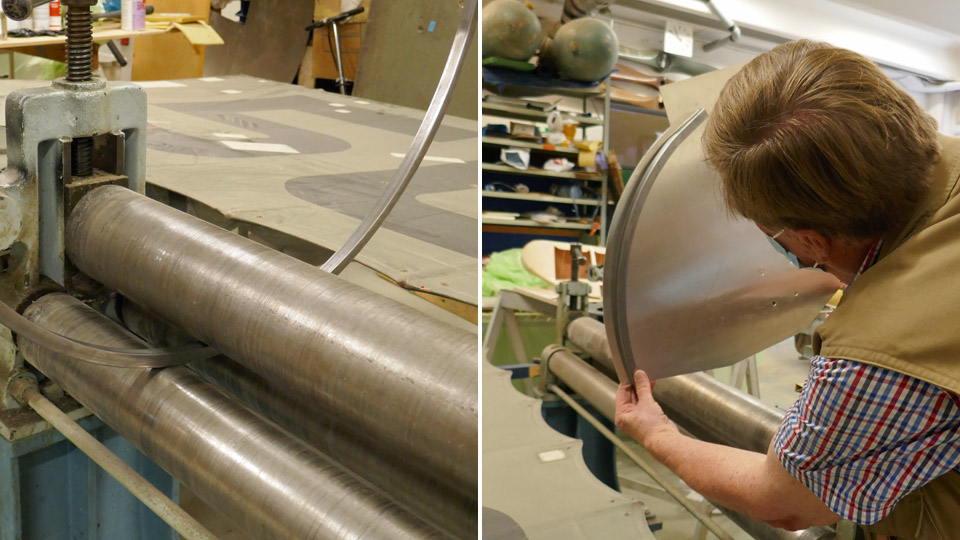

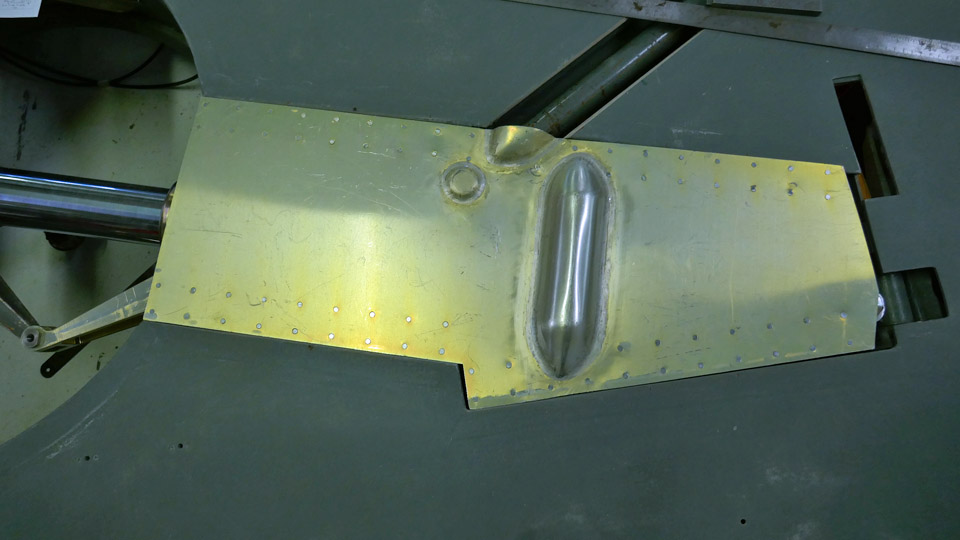

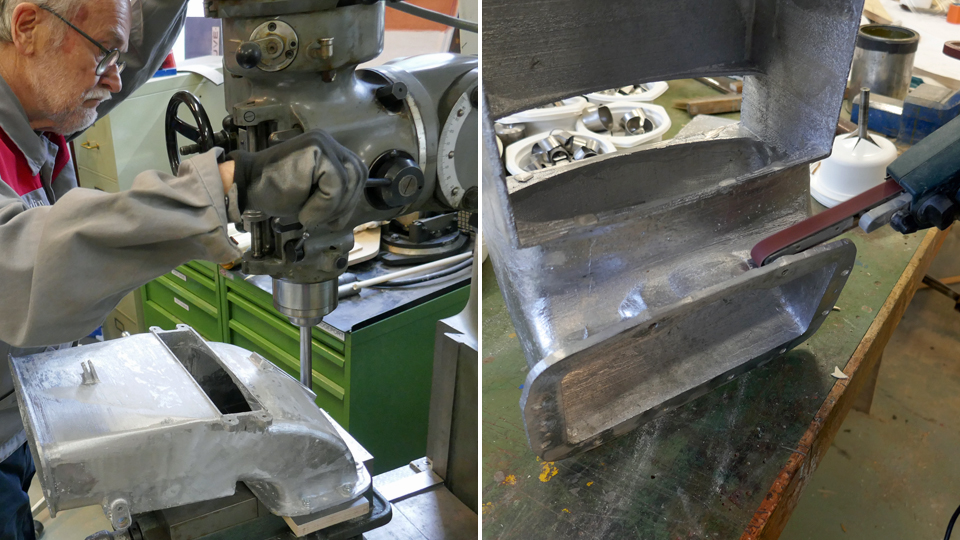

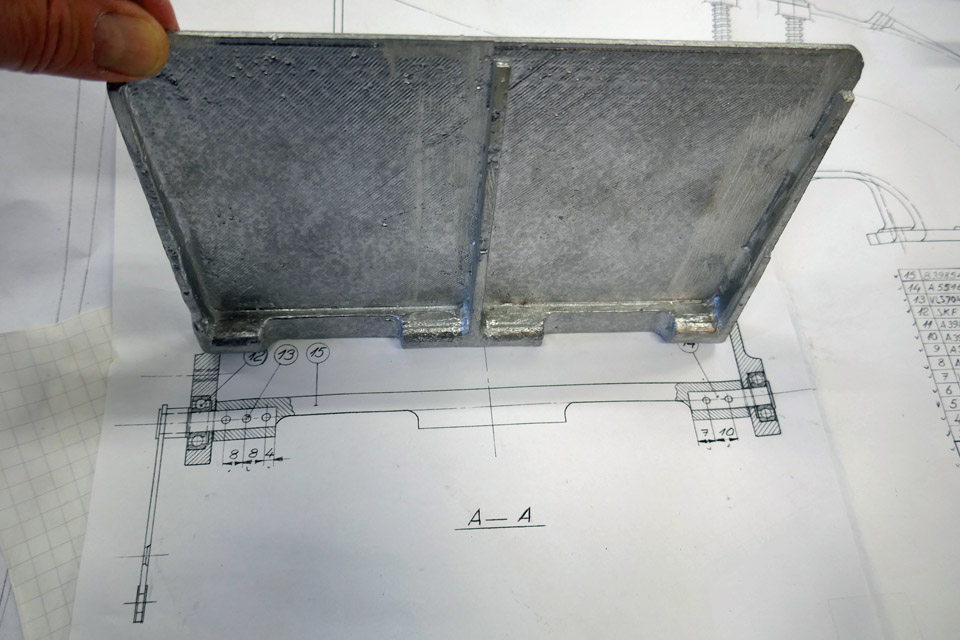

Work on Myrsky's landing gear wheel hub cover is continuedTorstai 26.8.2021 - Tuesday Club member The Tuesday club team has continued preparing the cover which is fastened on the wheel hub of the starboard wing landing gear on the VL Myrsky II (MY-14). At the moment the metal support is being made for the inner edge of the cover. The support circles the edge of the cover, and it is made of 15 mm thick square steel tube. It is fastened at a 10 mm distance from the edge of the cover.

The square tube is a supporting frame for the cover, cut from aluminium plate, and it also forms a fastening surface for the stiffeners which are fastened on the inner side of the cover. The stiffener plates, cut from aluminium plate, are riveted on the cover so that the square tube is between the cover and the stiffener plate. The stiffener plates are waiting to be assembled. The stiffeners on the test wing’s wheel hub have already been riveted. The wheel hub cover of the test wing has been used as a model when the actual covers for the landing gear are made.

The upper edge of the wheel hub cover is curved, and the square tube had to be modified in a mangling machine to make it match the cover shape. The shape was modified step by step. When the square tube began to curve, its shape was compared to the curved edge of the cover and mangled again. When the desired curved shape had been reached, the square tube was cut into pieces which will be fastened on the cover’s upper edge.

The lower edge of the wheel hub cover is not curved but angular. A piece of the square tube was cut for the cover’s lower edge. To modify the square tube into an angular piece, a cleft was sawed at the point where the cover edge has its steepest angle. Several clefts were made where the slighter angle is. The tube was bent, using the clefts, to meet the shape of the cover’s lower edge.

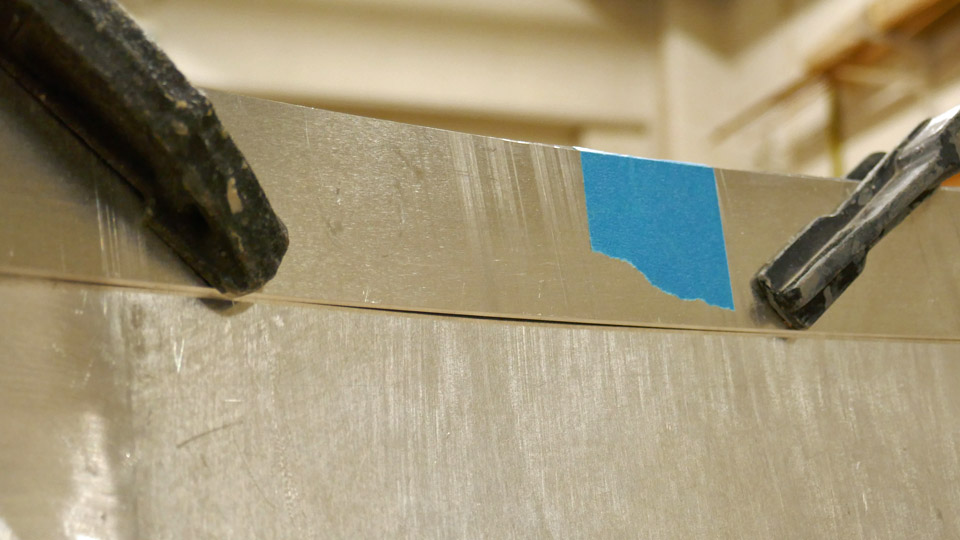

The following phase was to mark with tape the line of the corner joint, where the curved square tube on the upper edge of the cover meets the angular square tube of the lower edge. The tube ends were cut slanted according to the marked line. The slanted tube ends were placed against each other and fastened on the cover plate with clamps. At first the tube ends will be lightly welded together so that the whole tube frame can be moved from the aluminium cover plate for the actual welding work. When this has been done, the square tube forms a complete supporting frame along the edge of the wheel hub cover. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

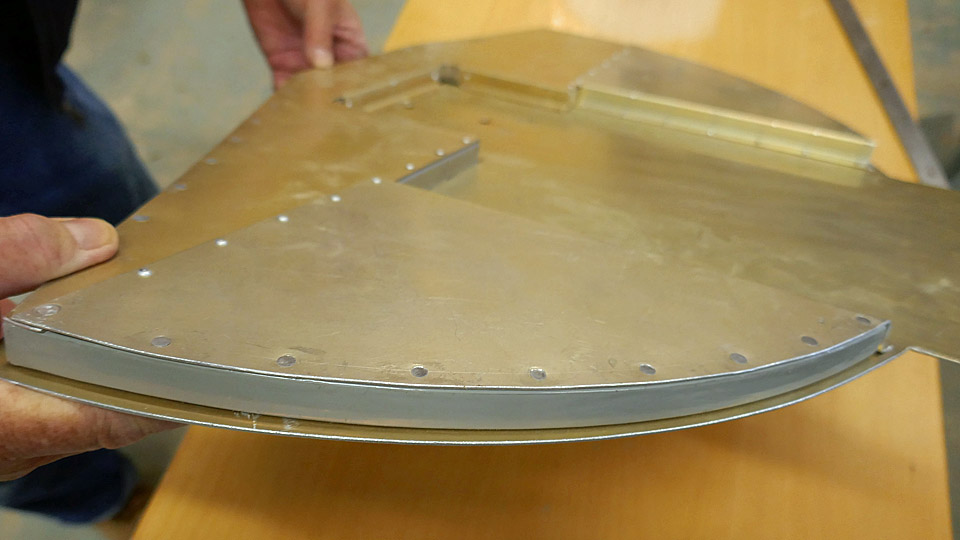

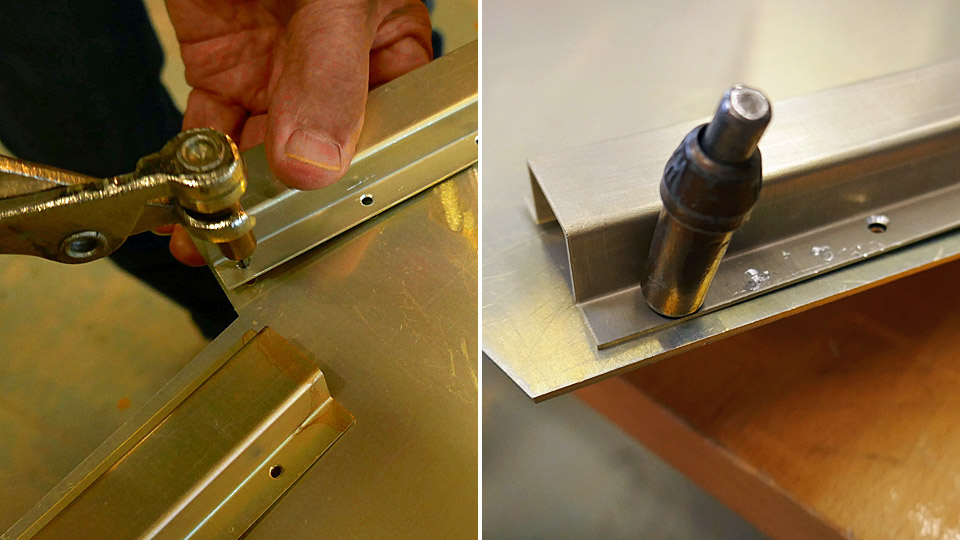

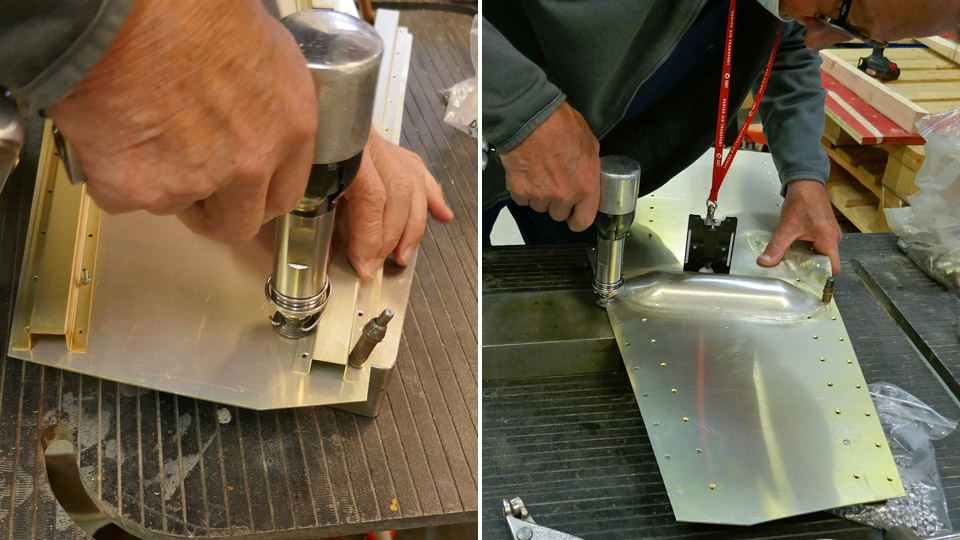

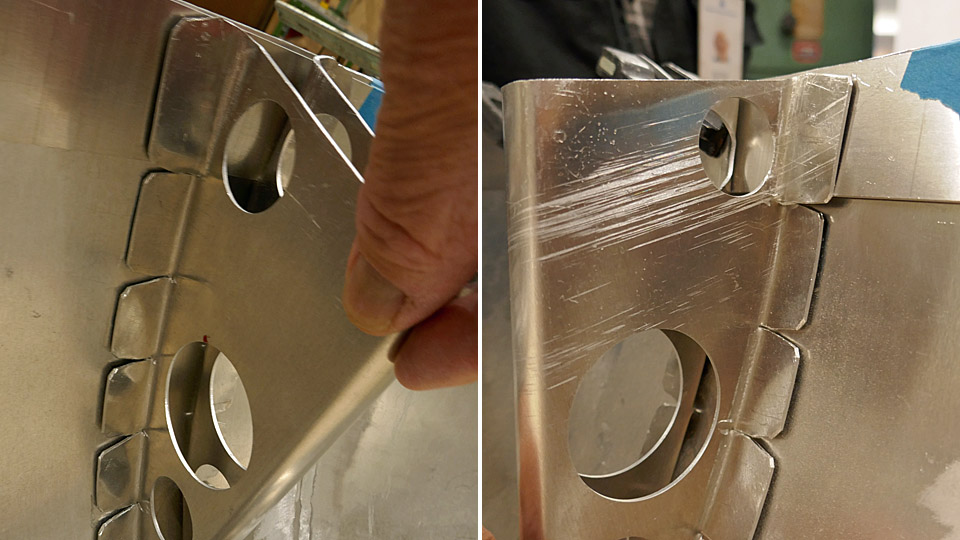

Stiffeners were riveted on cover of landing gear oleo strut on Myrsky's starboard wingMaanantai 23.8.2021 - Tuesday Club member The Tuesday Club team has continued its work on the covers for the Myrsky fighter’s landing gear on the starboard wing. U-profile stiffening battens were riveted on the cover of the oleo strut, which was otherwise ready. The stiffeners were cut from aluminium plate and pressed into shape. They are riveted on the inside edge of the cover. The cover and stiffeners have already been chromated.

The riveting was started by fastening the first of the four stiffening battens on the edge of the cover with cleco fasteners. Clecos, which are fastened in the rivet holes with nose pliers, are used for the temporary fastening of work pieces which will be riveted or welded together. In spite of the cleco-fastening, the rivet holes had to be slightly shaped with a round file to make the rivets slide nicely into their holes.

The rivets used were 3x6 mm flathead rivets. The stiffeners were riveted on the cover plate rivet by rivet. A compressed air riveting gun was used. All four stiffeners have now been riveted. The cover plate has been preliminarily assembled on the oleo strut of the starboard wing. It fits nicely into its place. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

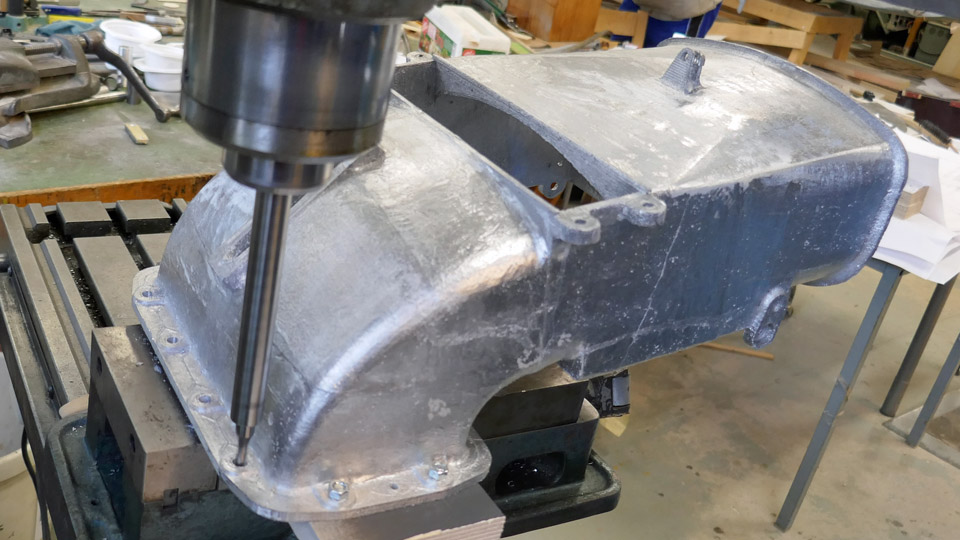

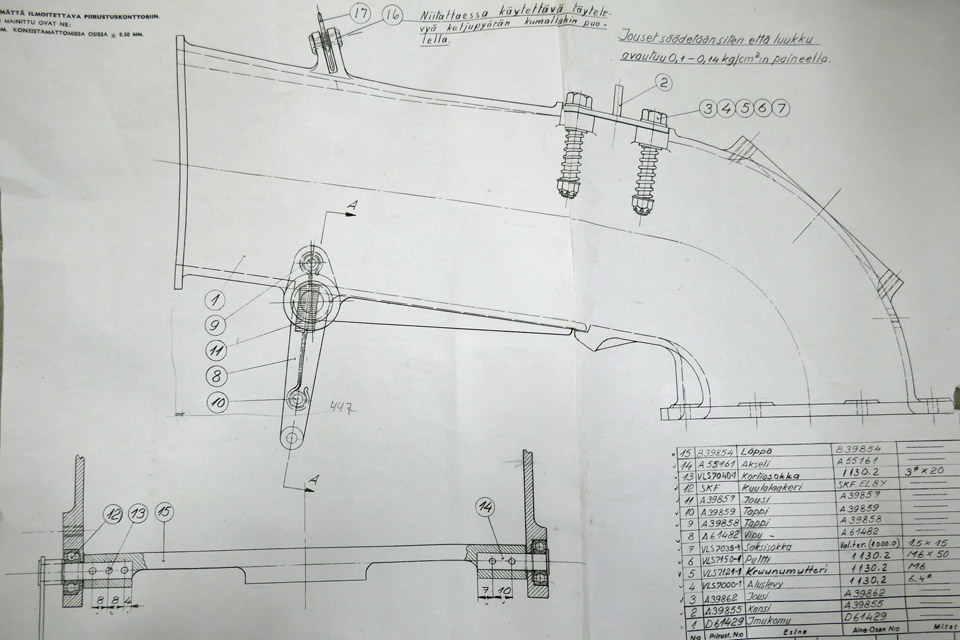

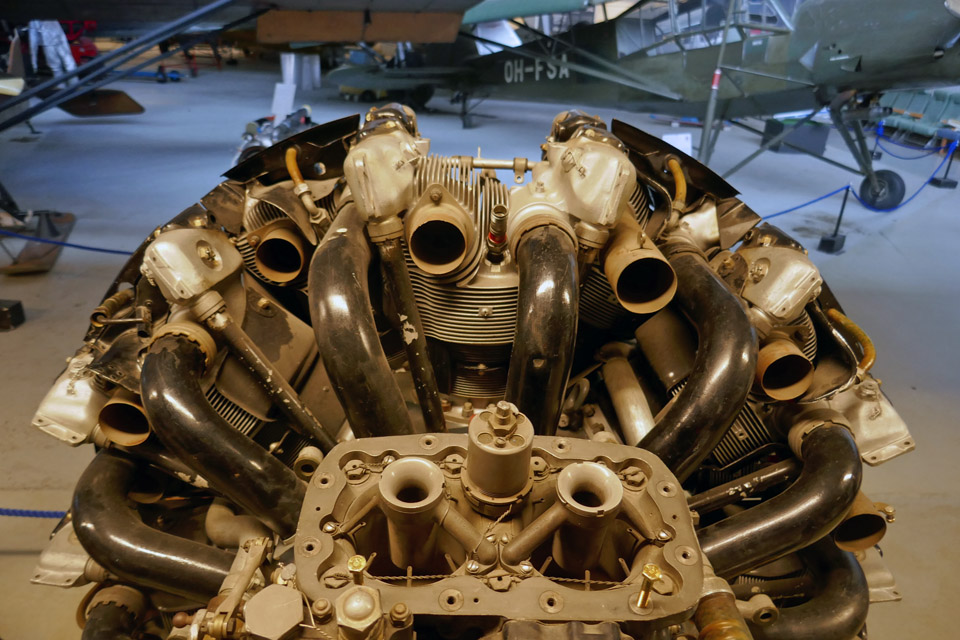

Works on Myrsky carburettor air intake and NACA-ringTiistai 22.6.2021 - Tuesday Club member The half-finished air horn and air intake ducts have been preliminarily assembled on the VL Myrsky II which is under restoration. The Myrsky had a Pratt &Whitney R-1830 radial engine and a similar engine is available at the Finnish Aviation Museum. Fortunately it has been possible to test the assembly at the museum and there is no need to travel to the Air Force Museum at Tikkakoski, where a similar engine has already been installed on the Myrsky’s (MY-14) fuselage.

Holes for the fastening bolts were drilled on the cast aluminium air horn and the air horn was fastened with a couple of bolts onto the carburettor of the engine, located in the museum hall. It fitted nicely into its place. Then the two air duct sections could be assembled into place between the air horn and the NACA-ring.

The Tuesday Club team noticed that the section of the air duct, made of steel plate because of its location above the hot engine, did not fit properly. The reducers made on its lower part were too shallow and the air intake duct couldn’t be pressed sufficiently deep between the cylinder head covers. The air intake duct was heated using a welding flame and shaped to fit better. Then the two air intake duct sections were assembled above the engine and fastened on the air horn. Even when half-finished it is a great sight!

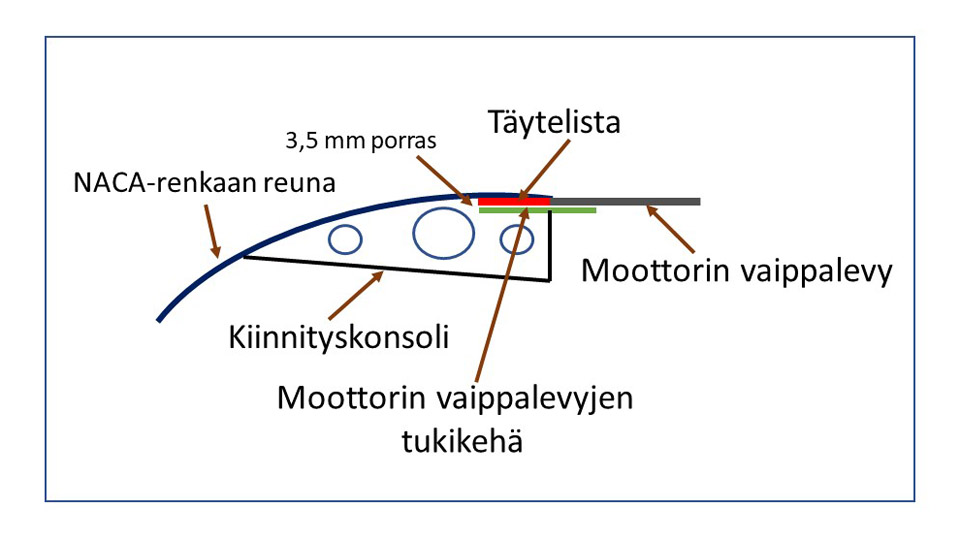

The consoles of the NACA-ring, which are needed to fasten the ring on the brackets on the cylinder heads, had to be modified before riveting on the edge of the NACA-ring. Especially the console hems have needed shaping. The console is riveted on the NACA-ring by its hem. The hem has to meet the curved shape of the NACA-ring and to take into account the filler batten, which is a 2,5 mm aluminium batten riveted on the edge of the NACA-ring, and the 1,0 mm aluminium supporting frame of the engine fairings. The supporting frame is 75 mm wide, and it is riveted on top of the filler batten so that it extends 32 mm outside the edge of the NACA-ring. It forms a shoulder on which the edge of the detachable engine fairing rests and meets the edge of the NACA-ring in a butt joint. There is a very general overview picture of this structure attached.

Translation: NACA-renkaan reuna = Edge of NACA-ring, 3,5 mm porrastus = 3.5 mm offset, Kiinnityskonsoli = Console, Moottorin vaippalevyjen tukikehä = Supporting frame of detachable engine fairing rests, Täytelista = Filler batten, Moottorin vaippalevy = Detachable engine fairing rests.

The hems of the NACA-ring consoles were shaped using pliers and a plastic-headed hammer and a piece of wood. A 3,5 mm offset was made on the upper end of the console for the filler batten and the supporting frame. All console hems have now been shaped and are ready to be riveted into place. Before that can be done, the filler batten and the supporting frame on top of it will have to be riveted onto the edge of the NACA-ring. The supporting frame is made of four sections and the sections are ready to be installed.

Up to now the filler batten has been fastened on the upper edge of the NACA-ring with clamps. Now it is debated how the riveting of the filler batten and the supporting frame on the NACA-ring edge will be done so that the filler batten settles exactly to the same level as the NACA-ring’s edge. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |

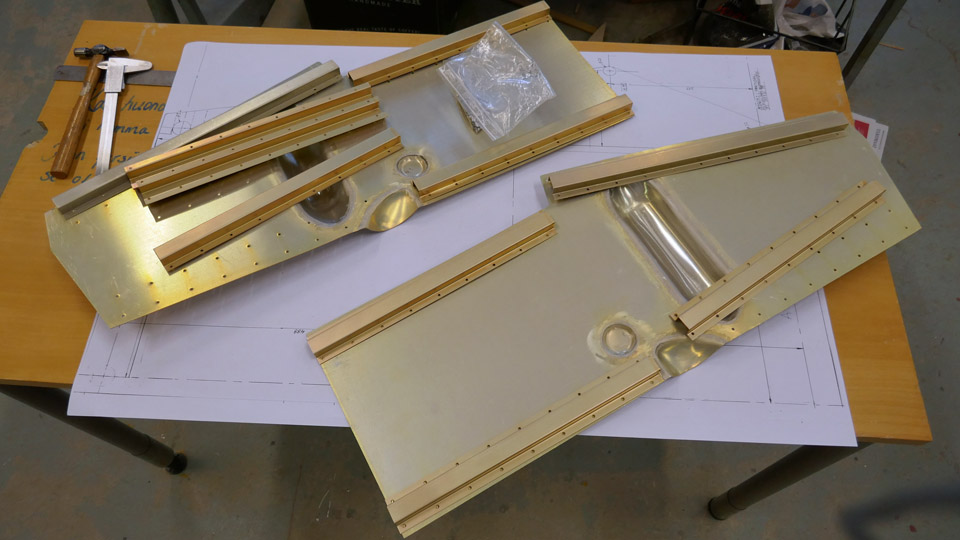

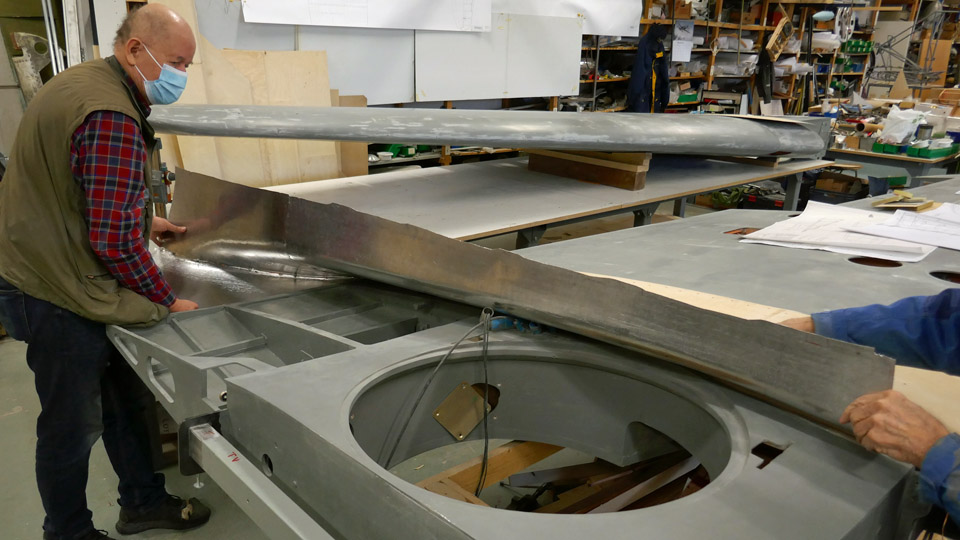

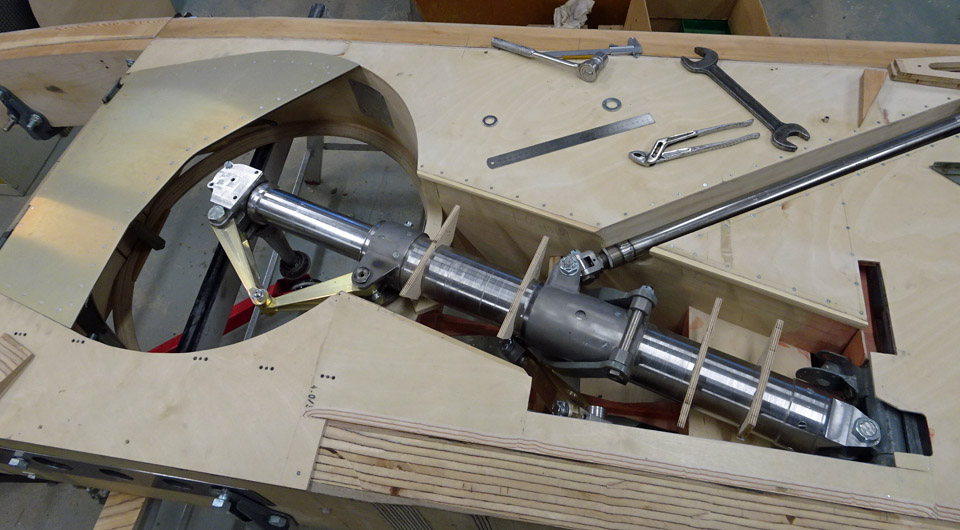

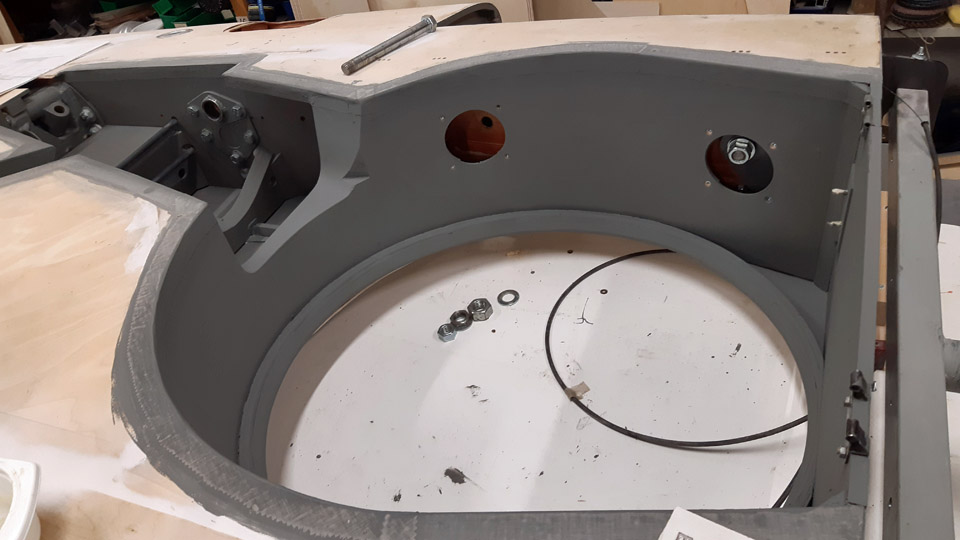

Myrsky's starboard wing half was turned for installing landing gearSunnuntai 13.6.2021 - Tuesday Club member The assembly of the landing gear has been started on the wing halves of the VL Myrsky II (MY-14), which is under restoration at the Tuesday Club. Thorough test assembly has already been done on the test wing which was prepared in the Myrsky-project. The test wing is a 2,5 metres long root piece of the wing, meant mainly for testing the landing gear installation. The landing gear will first be assembled on the starboard wing half.

The wing halves were painted with undercoat paint and after this work they remained on the worktable the upper side up. First the starboard wing had to be turned so that the landing gear well is facing upward, and the landing gear can be installed. The wing halves have already been turned around several times during the different work phases. For this purpose steel supports have been made for the wing tip and the wing root and they are used to support the wing when it is lifted and turned.

Two lower photos: move the cursor over photo and you will see more photos! The turning supports were fastened on the wing tip and the wing root. Then a lifting device was moved to both ends of the wing and the lifting devices were connected to the steel supports with cargo straps. Then the lifting devices were pumped, and the wing was lifted in the air, supporting it manually all the time. When the wing had been lifted high enough, the wing was tilted in order to turn it around. The wing was carefully manoeuvred onto one side by supporting it from the other side. When the wing had been turned, it was lowered back on the worktable and it was placed horizontally by supporting it at the ribs.

Photos: Jorma Laakkonen. Photo: Jorma Laakkonen. Now the landing gear well was facing upwards, and the landing gear assembly could be started, following the procedure developed when testing the gear on the test wing. The first preliminary test was to place the landing gear oleo strut in the well with its wheel hub and axle. At the same tame the wheel well doors were fitted into place. These include the diagonal support door, the oleo strut door, the wheel hub door and the opening door, which is fastened on the fuselage side edge of the wheel well. All parts seemed to settle nicely into their places.

Photo: Jorma Laakkonen. Now there is ahead the demanding work of fitting all the hinges and fastenings of the starboard landing gear into place so that the landing gear extends and retracts smoothly. The aluminium covers will also have to be assembled into place on the diagonal support, on the oleo strut and on the wheel hub. Another challenge is to fit into place the aluminium cover on the fuselage side of the wheel well and to make its opening and closing mechanism work as planned. This door is opened automatically by a spring lever when the landing gear is taken out. When the landing gear is retracted the wheel presses against a pin in the mechanism and closes the door. Photos: Lassi Karivalo except if otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |

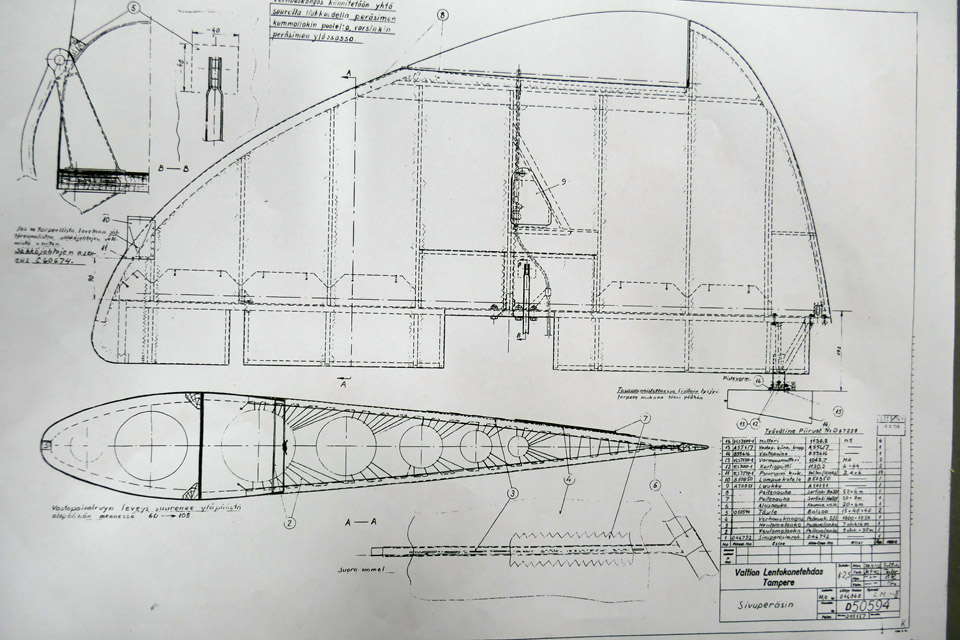

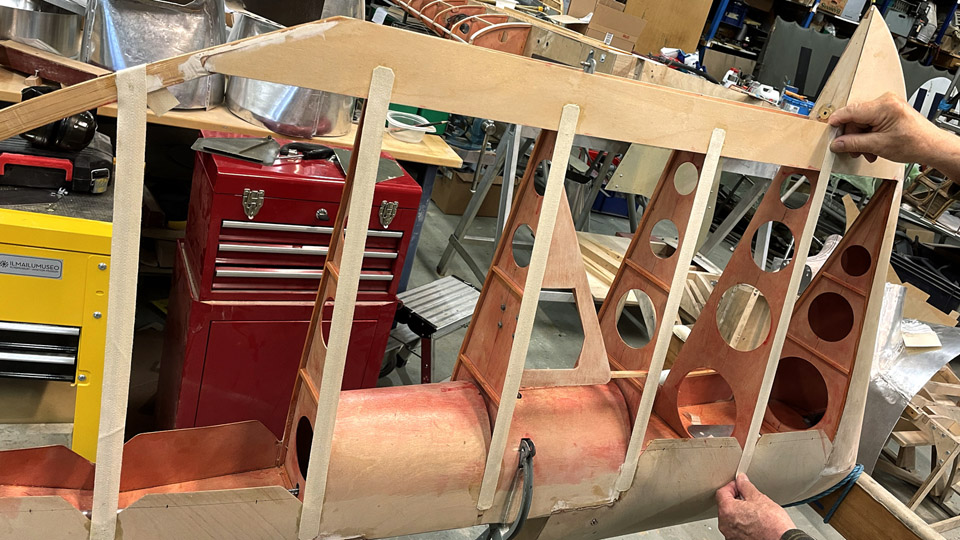

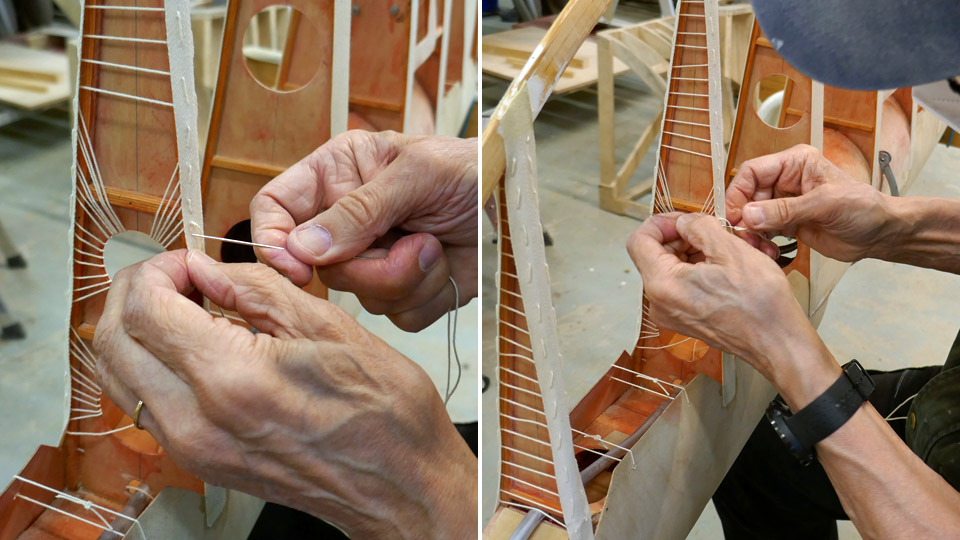

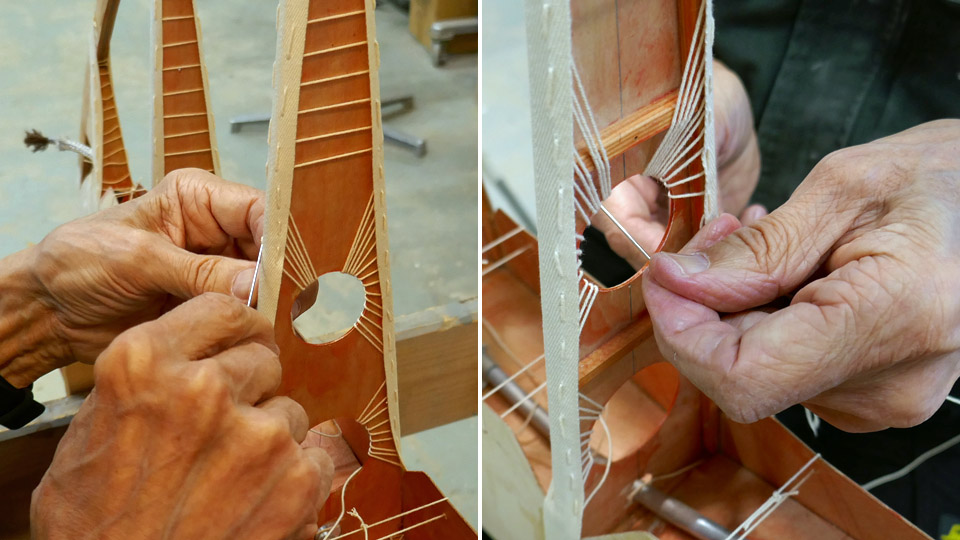

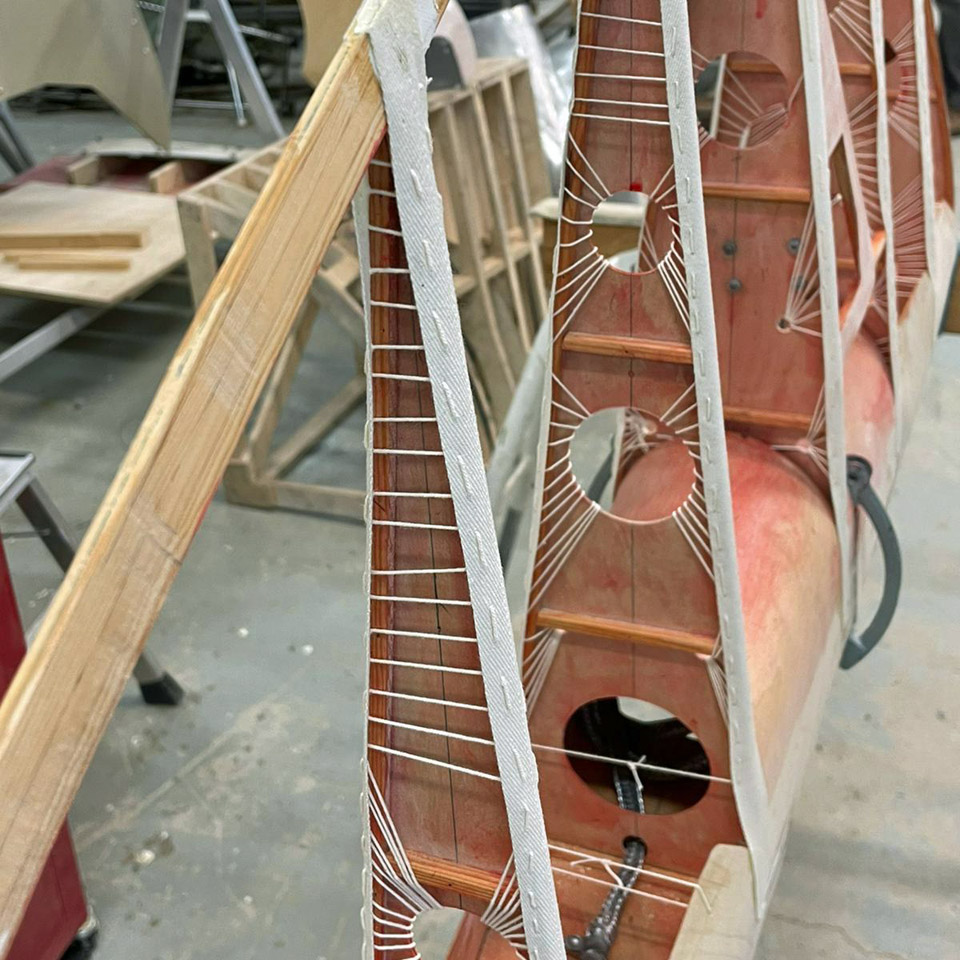

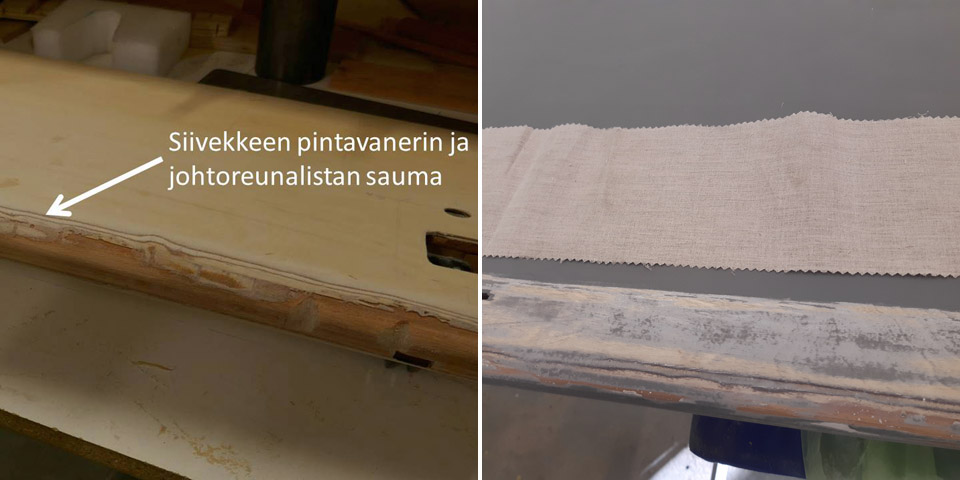

MY-14's vertical stabilizer gets its fabric covering webbing ribbonsSunnuntai 6.6.2021 - Tuesday Club member When the webbing ribbons for the fabric covering had been sewn on the horizontal stabilizer ribs of the VL Myrsky II (MY-14), the sewing work continued on the vertical stabilizer. The vertical stabilizer has a wooden structure, according to the original drawings.

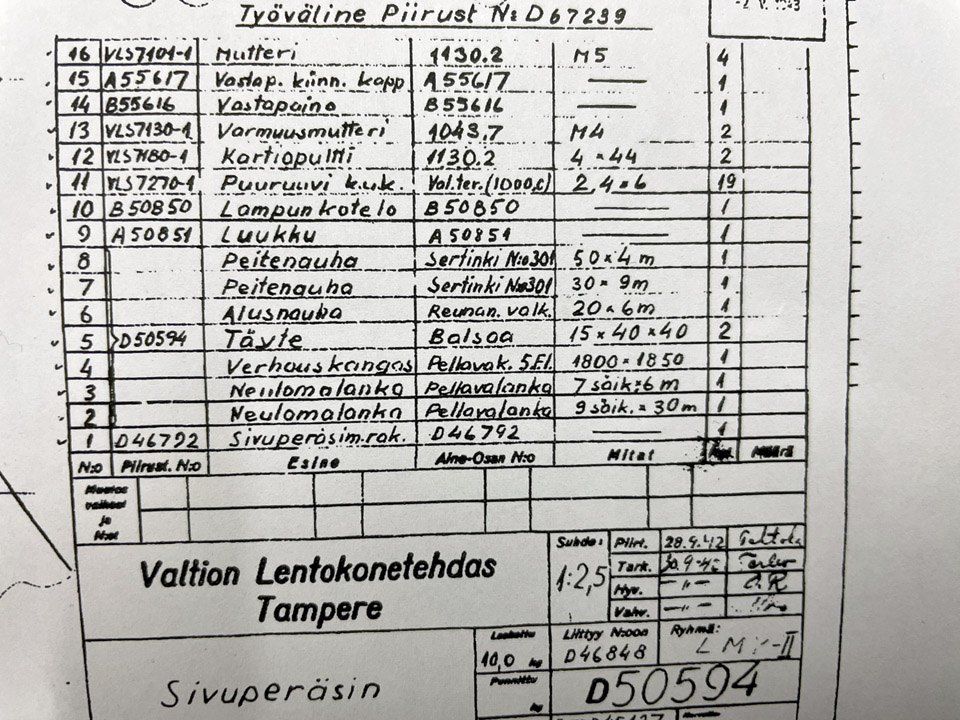

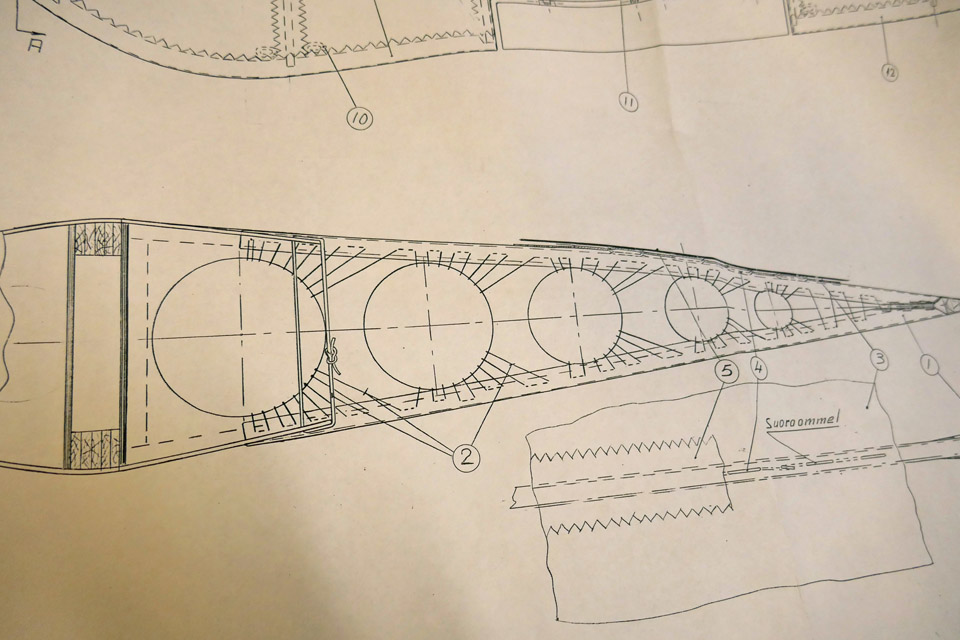

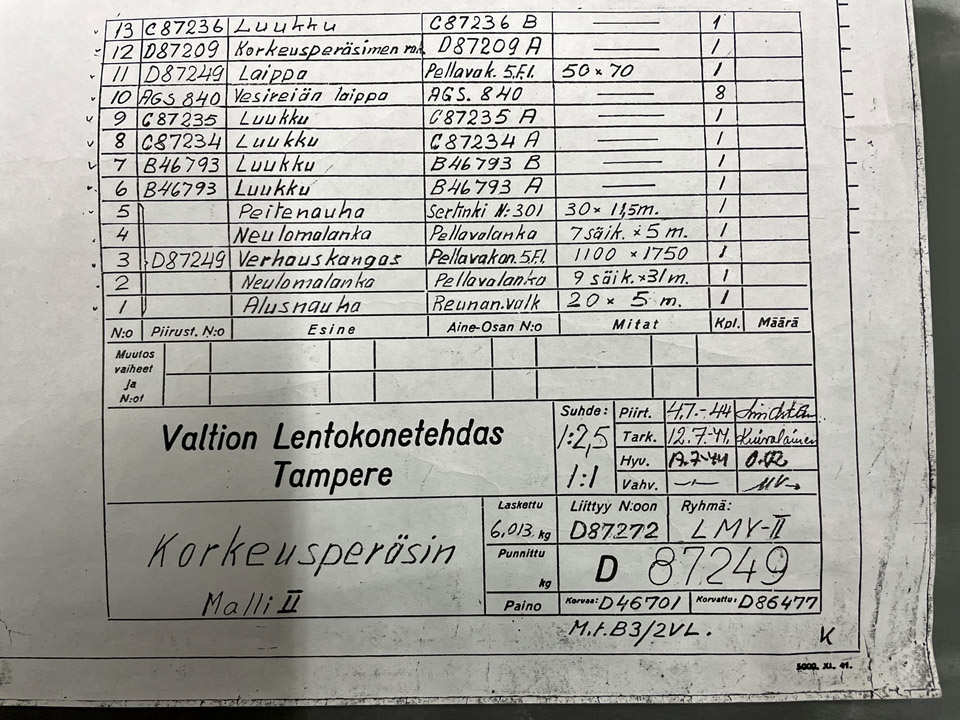

Photo: Heikki Kaakinen. The Tuesday Club team used the original drawing of the vertical stabilizer, prepared by the State Aircraft Factory and dated 30.9.1942, as instructions for the work. The drawing shows very well how the ribbons must be sewn. The bill of materials on the drawing shows a detailed list of the accessories needed in the work. The list includes the covering fabric, the webbing ribbons, cover ribbons and sewing threads. A 20 mm wide diagonally woven linen ribbon was used as the webbing ribbon.

Photo: Heikki Kaakinen.

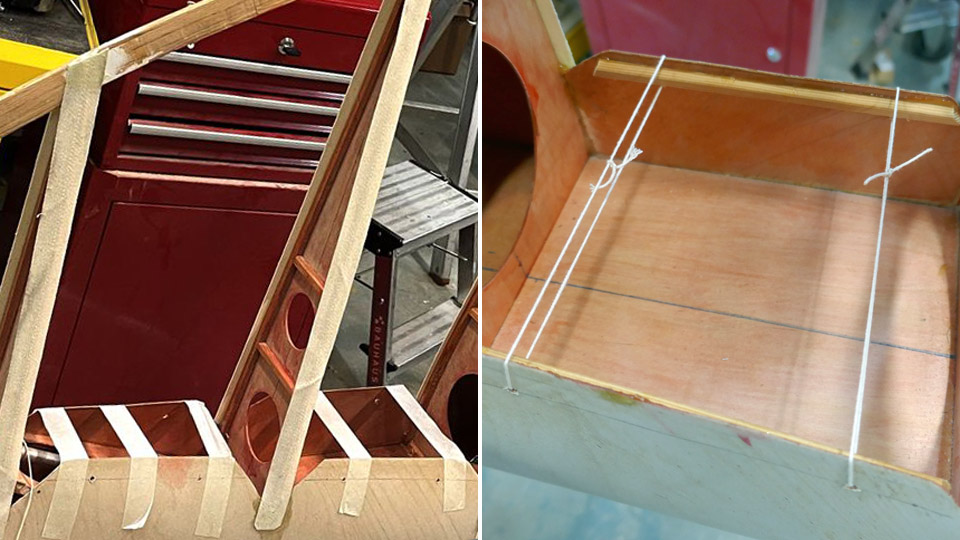

Photo: Heikki Kaakinen. In order to keep the webbing ribbons in place on the rib of the vertical stabilizer when doing the sewing, the ribbon was stretched on the rib and its one end was glued on the plywood of the leading edge and the other end on the plywood of the trailing edge. Contact glue was used in this work.

Left photo: Heikki Kaakinen. One more work phase had to be completed before the actual sewing could be started. The edges of the plywood sheet covering the leading edge had to be bent inwards so that the edges won’t chafe the fabric covering and gradually damage it.

Photo: Heikki Kaakinen.

Photo: Heikki Kaakinen. To bend the plywood edges, 3 mm holes were drilled where the drawing indicated. Then the edges were bent against each other and tied temporarily into this position using painter’s tape. Linen thread was pulled through the drilled holes and then the threads were tied together into a tightening loop, connecting the edges of the plywood. Then the supporting painter’s tapes could be removed, and the sewing of the webbing ribbons could be started.

Photo: Heikki Kaakinen. The webbing ribbons for the fabric covering of the vertical stabilizer were sewn in a similar manner as on the horizontal stabilizers. At the tapered part of the rib the edges of the ribbon were stitched together. At the broader part of the rib, where the round lightening holes are, the thread was slipped through the lightening hole and fastened on the ribbon’s edge on the other side and repeating back again. A radial pattern of the threads was formed in the lightening hole. Now the vertical stabilizer had its webbing ribbons in place. Photos: Lassi Karivalo except if otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |

Webbing ribbons for fastening fabric covering of Myrsky's horizontal stabilizer are sewnTiistai 1.6.2021 - Tuesday Club member The VL Myrsky II fighters had originally wooden horizontal stabilizers. The aeroelastic flutter caused the damaging and even breaking of the stabilizers. Therefore the Myrsky’s horizontal stabilizers were replaced with metal stabilizers, which endured the flutter. The documents concerning the MY-14 which is under restoration don’t mention whether the aircraft got metal horizontal stabilizers before it was written off. However, the board of the Myrsky restoration project decided that the restored MY-14 would have metal horizontal stabilizers. One of the reasons for this was that there were original metal stabilizers available, but somewhat damaged and without covering.

Photo: Heikki Kaakinen. The original horizontal stabilizers with aluminium structure have already been repaired and painted by the Tuesday Club and they have been waiting for the fabric covering for a while. The metal stabilizers are covered with fabric in the same way as the corresponding wooden stabilizers. First fabric webbing ribbons are sewn on the ribs of the stabilizer. The fabric covering is fastened on these ribbons by sewing. The fabric is tightened using several layers of nitrocellulose varnish and finally painted according to the aircraft’s paint scheme.

Photos: Heikki Kaakinen. The Tuesday Club team has now started the sewing of the webbing ribbons on the MY-14’s horizontal stabilizers. To make the work easier, one of the stabilizers was fastened into an upright position against two trestles. The first step was to stretch a 20 mm wide linen upholstery webbing ribbon on the stabilizer’s ribs. This was done by gluing the ends of the ribbon on the rib at the leading edge. This way the ribbon will stay in place when sewing it onto the ribs.

After the gluing the sewing could be started. The instruction drawing for sewing the ribbons on the wooden horizontal stabilizers was applied, because the instructions for the metal stabilizer have not been preserved. According to the instructions multithreaded 0,5 mm linen thread was used in the sewing work.

The sewing work was started at the trailing edge end of the rib. The edges of the ribbon stretched on the upper and lower edge of the rib were stitched together. This was the method used at the tapered end of the rib where there are no lightening holes.

When the work reached the broader part of the rib where the round lightening holes are, the sewing method was changed. Now the thread fastened to the edge of the ribbon was slipped through the lightening hole and to the other side to the ribbon’s edge, and back again. The webbing ribbon was sewn onto the rib following the original instructions, weaving the thread through the lightening hole.

Photo: Heikki Kaakinen. When the ribbons had been sewn on all the ribs of one stabilizer, the procedure was repeated on the other stabilizer. Now the horizontal stabilizers are ready for fastening the fabric covering. In the original drawing’s instructions the fabric quality has been defined as linen fabric 5.F.I. Photos: Lassi Karivalo except if otherwise mentioned. Tranlation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |

Myrsky engine's air horn and air intake are madePerjantai 28.5.2021 - Tuesday Club member The air flow entering an aircraft’s carburettor is controlled in the air horn, which is attached to the carburettor. When necessary, there is an air intake duct connected to the air horn. This is the case in the VL Myrsky II fighter, among others. In the Myrsky the two-sectioned air intake duct is connected to the air intake, located at the top of the NACA-ring, and is led between the upper cylinders to the air horn of the two-throat carburettor behind the radial engine. The suction air flow is controlled with the damper located in the air horn as well as the warm air flow, which comes through the engine space and protects the carburettor from freezing.

The Myrsky’s air horn is made of cast aluminium. The front piece of the two-section air intake duct, which is fastened on the NACA-ring, is made of aluminium plate. The tail section of the air intake duct is made of steel plate because it is located at a hot place between the cylinders. The tail section of the duct also connects the front section of the air intake duct to the air horn and is fastened to them with fastening clamps.

No original Myrsky engine’s air horn or parts of the air intake duct have been preserved and they had to be made in the restoration project of the MY-14. The sections of the air intake duct have already been made. The front section of the duct was made according to the drawing from 1,0 mm thick aluminium plate, using a mould. The tail section was made from 1,0 mm thick steel plate. The sections of the air intake duct have been fitted into place and the front section of the duct is being fastened to the opening in the NACA-ring.

The SASKY Municipal Education and Training Consortium at Sastamala helped to manufacture the air horn from cast aluminium. They were interested in the ongoing Myrsky restoration project and asked if there was some restoration work which could be made as 3d-printing by the SASKY students. The Tuesday Club team suggested that they could make the rather difficult air horn - and they accepted the challenge.

Photo: SASKY

The project was started at SASKY by 3d-printing a plastic 1:1 scale model of the Myrsky’s air horn according to the drawings. Then the actual cast mould for the aluminium cast was made based on the 3d-print. The 3d-printed model was dipped several times in a ceramic solution and a ceramic layer was formed, layer by layer, on the plastic model. Flow channels and air extract were also made on the cast mould. Then the plastic 3d-model was melted from inside the ceramic shell, and the cast mould for the air horn was ready. The liquid AlSi 12 aluminium was poured into the mould. When the aluminium had cooled the mould was broken and the flow channels were removed, and the surface was ground smooth.

The cast aluminium air horn is now at the Tuesday Club and is ready for further work. Some extra material has been ground off. Holes for fastening bolts will be drilled. The Tuesday Club wishes to thank the SASKY Municipal Education and Training Consortium for preparing the aluminium cast of the air for the restoration the restoration project of the VL Myrsky II (MY-14). Photos: Lassi Karivalo except if otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky II, MY-14 |

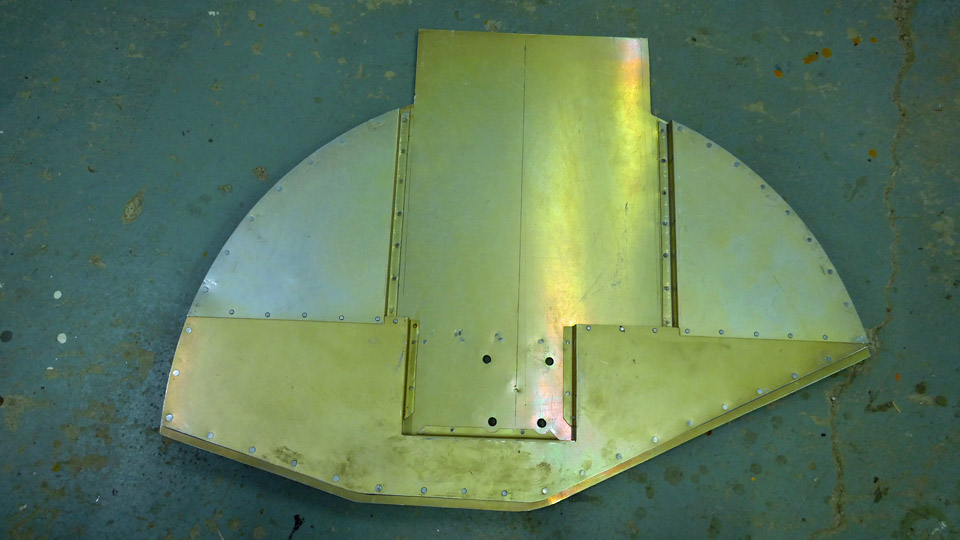

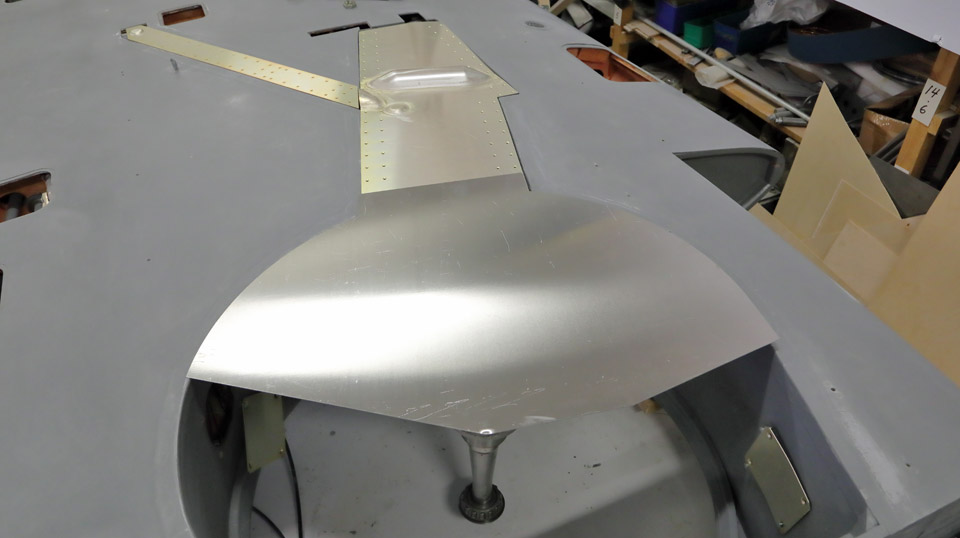

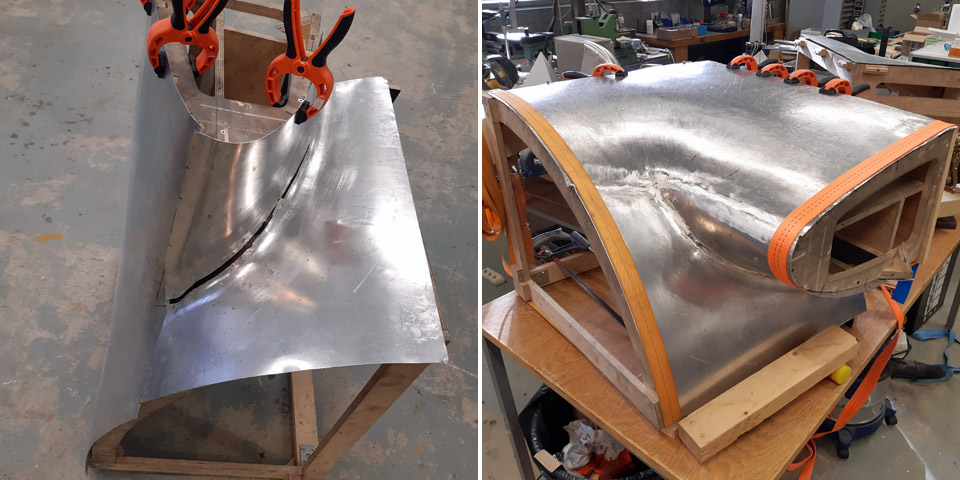

Wing root fairing of Myrsky?s port wing at Tuesday ClubSunnuntai 11.4.2021 - Tuesday Club member The joint of Myrsky-fighter’s (VL Myrsky II) fuselage and wing is covered with a wing root fairing, made of 1 mm thick aluminium sheet. The wing root fairing consists of a short front section, which covers the leading edge of the wing and reaches under the fuselage. The longer rear section of the wing root fairing covers the seam of the fuselage and the wing, all the way to the trailing edge and around it.

The rear section of the port wing root fairing was sent to the Tuesday Club for further modifications. It came from Flanco Oy where Antero Flander had forced it into shape against a mould. The Finnish Air Force Museum, working on Myrsky’s restoration at Tikkakoski, had made the sturdy plywood mould. The wing root fairing was made from three aluminium sheets, forced into shape against the mould and then welded together.

The parts of the port and starboard wing root fairings, which cover the front section of the fuselage and wing joint, had already been sent from Flanco Oy to the Tuesday Club in Vantaa where the parts were welded together. The moulds for the front sections had been made by the Tuesday Club. Flanco Oy has helped in making several other metal parts that are needed in the restoration of the Myrsky MY-14.

The Tuesday Club team had now both sections of the port wing root fairing and they could be preliminarily fitted into place at the root of the port wing.

The front and rear sections of the wing root fairings will be finalized at the Tuesday Club, joined together and test assembled. The front and rear sections will be joined together with a joint where the aluminium plate riveted on the lower side of the rear section’s front edge is pushed under the front section’s edge. The holes have not yet been made for the flange nuts, which are used for fastening the wing root fairing sections to the side of the fuselage and to the wing surface.

The wing root fairings will be test assembled when the wing halves, made and undercoat painted at the Tuesday Club, will be assembled on the fuselage frame of VL Myrsky MY-5 at the Finnish Aviation Museum. However, it will take some time before the wing root fairings are ready for the test assembly. Photos: Lassi Karivalo Translation: Erjan Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

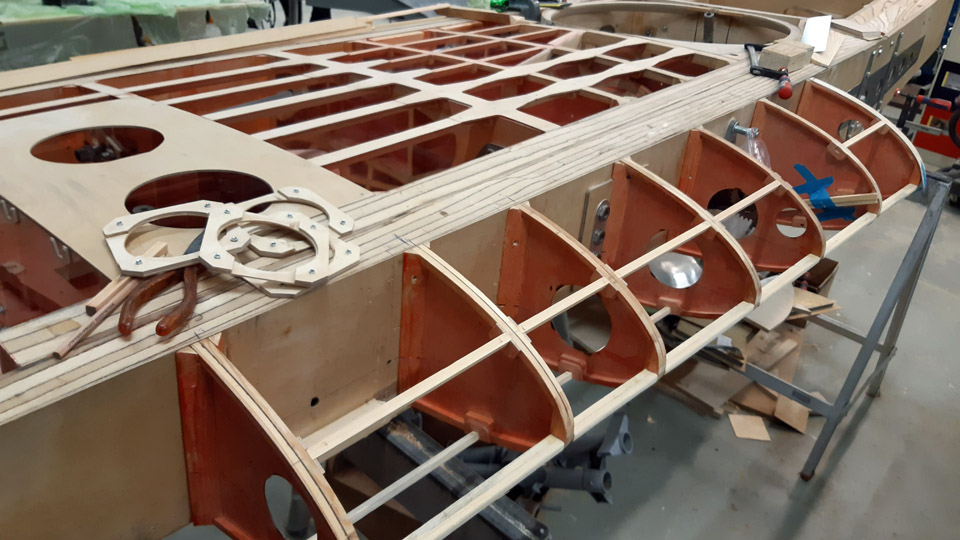

Wheel well and aileron inspection hatches on Myrsky?s test wingSunnuntai 21.3.2021 - Tuesday Club member When the undercoat painting of VL Myrsky II’s (MY-14) wings and tail part surfaces had been completed, the activity of the six Tuesday Club members working on the Myrsky project could be targeted to other things. The new work item is the test wing and the construction of its wheel well and the installation of the ailerons’ inspection hatch covers.

The wheel well of the test wing is in the square space bordered by the front and rear spars and the wing ribs. The wall of the wheel well is made of 2 mm thick plywood. The wall billet had been cut earlier, now it was fitted into place by bending the plywood into a circle, in the space bordered by the spars and ribs. At the fitting stage the plywood wall was too tall for its space. When the wall had settled into place as desired, the excessive height was cut away and the plywood wall was fastened. The next phase was to make from plywood the corner pieces to cover the empty spaces in the corners of the wheel well.

A supporting curb will be built on the upper edge of the plywood wall of the wheel well. The pressure lathed aluminium cover will be fastened on the curb to shield the wheel well. The covers have already been lathed for both wheel wells of the test wing. The supporting curb and the cover on the starboard wing half are already in place. The wheel wells and their covers will be hidden under the aluminium wing root fairings, which cover the seam of the Myrsky’s fuselage and wing.

The supporting curb for the wheel well’s upper edge on the port side wing half was made from plywood strips which were glued together and forced into a mould. When the glue had dried, the supporting curb was unfastened from the mould and modified into measure and is now waiting to be installed.

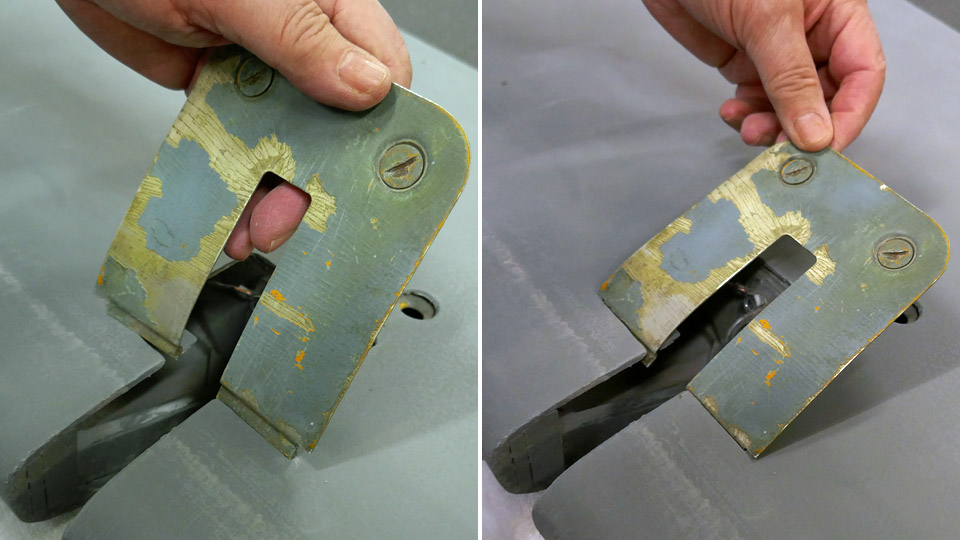

Simultaneously with the building of the wheel well, the fitting of the half-finished aileron inspection hatch covers was started. This task has been waiting while the ailerons were being painted with undercoat paint.

The aileron is fastened on the wing with three hinges. The hinge knuckles inside the aileron’s leading edge are fastened on the journaled hinge arms on the wing with bolts. On the lower side of the aileron’s leading edge there is an inspection hatch for each hinge. The opening of the inspection hatch has a cover made of 1 mm thick aluminium plate. The Tuesday Club team has one original hinge hatch cover as a model. The cover is for the hinge hatch in the middle of the aileron. However, the team made new covers for all aileron inspection hatches. On the front side of each inspection hatch opening there is a slot on the aileron’s surface for fastening the cover.

These slots for fastening the inspection hatch covers had been covered during the undercoat painting of the aileron, when a strip of linen fabric was fastened to reinforce the leading edge. The covered slots were cut open with a sharp knife, then the inspection hatch covers were fitted into place, one by one. When the hatch is closed, the front edge of the cover is slipped into the slot in the aileron, then the cover is pressed against the aileron surface to cover the opening. The cover is locked into place with one or two screws, located on the rear edge of the cover. The screws are pressed and locked into the locking holes with springs. The new aluminium hatches don’t have the locking screws yet. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

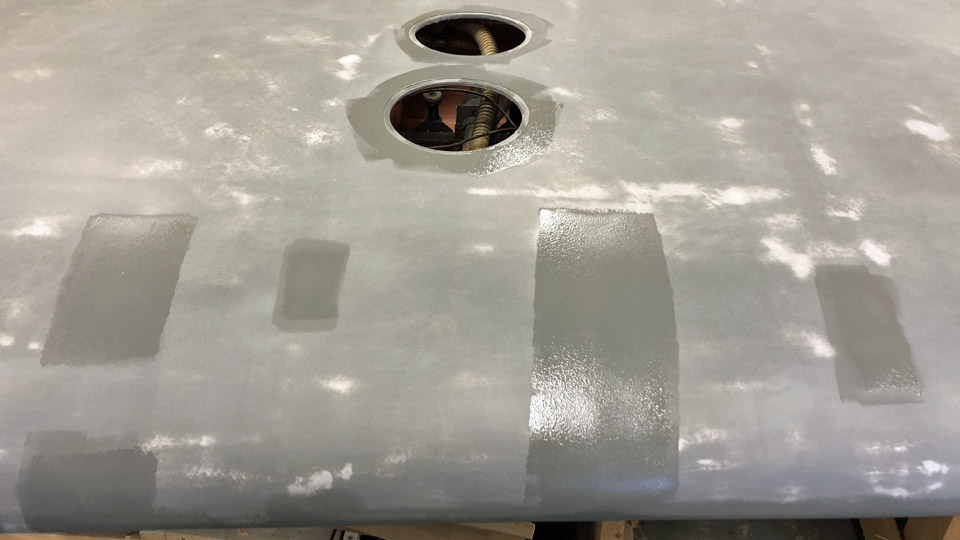

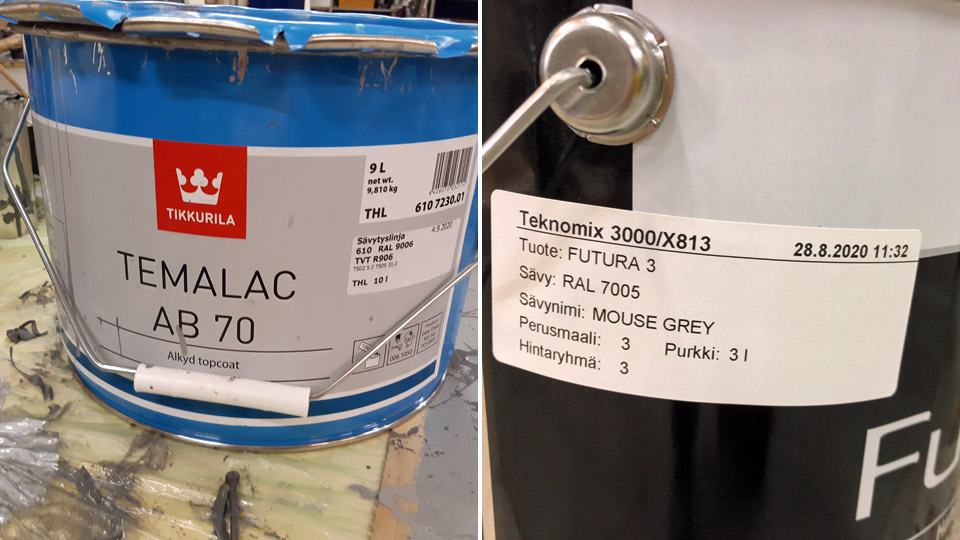

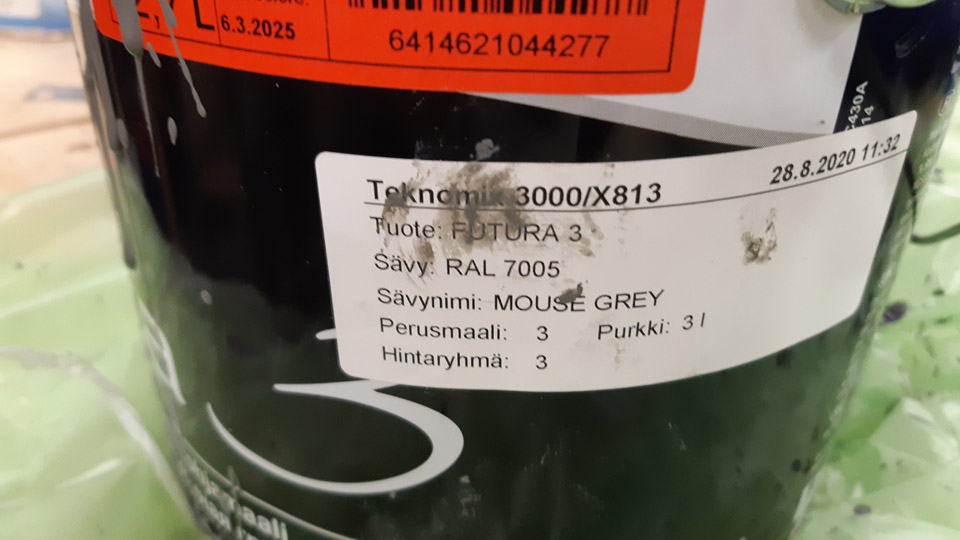

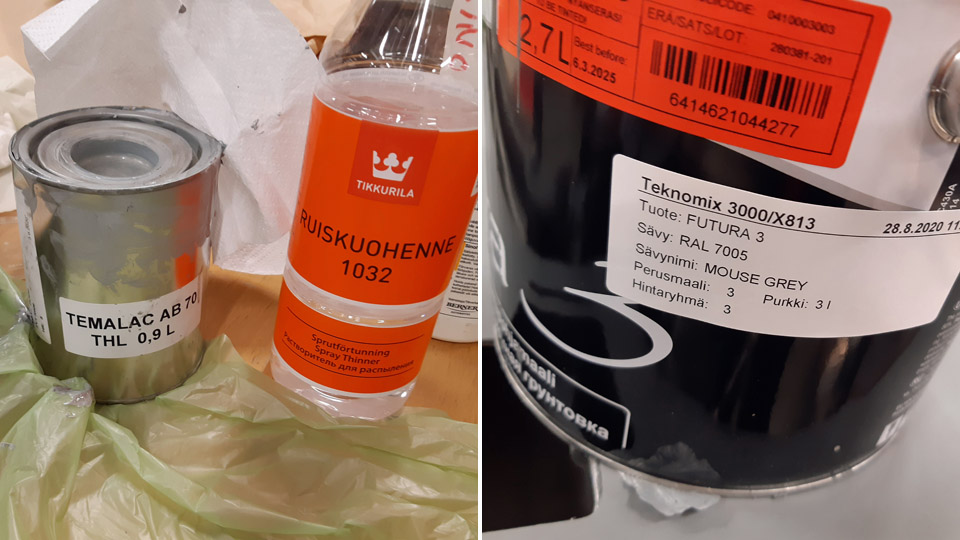

Undercoat painting of Myrsky?s wings was finishedLauantai 27.2.2021 - Tuesday Club member The undercoat painting of the upper sides of Myrsky’s (VL Myrsky II, MY-14) wing halves took about two months. Now the work is ready. The undercoat painting procedure of the upper sides followed the undercoat painting of the lower sides of the wings. First the plywood surfaces are painted with pale grey TEMALAC AB 70 alkyd paint which contains aluminium flakes, and it is covered with a couple of layers of dark grey Teknos Oy adhesion primer Futura 3.

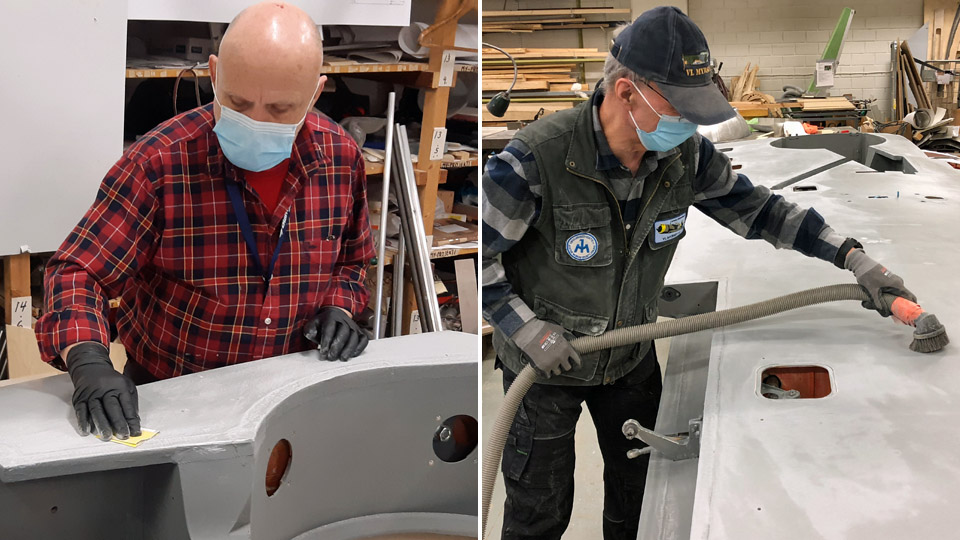

Photo: Jouni Ripatti. The painting of the upper surfaces of the wing halves with aluminium flake undercoat paint was described in the previous blog. Before the dark grey adhesion primer could be applied on the aluminium flake undercoat paint, the painted surface was ground smooth and some uneven spots on the plywood surface had to be spackled.

Photo: Jukka Köresaar.

The Teknos Oy's Futura 3 RAL 7005 adhesion primer was spread with a mohair roller. When the paint had dried, it was noticed that the painted surface wasn’t as smooth as it should have been. Some uneven “orange peel surface” was detected. The painted surface was therefore ground smooth manually and with a disk grinder, using 180 sandpaper grit.

Photos: Jouni Ripatti. The paint dust was removed and a new layer of Futura 3 paint was applied. This time the paint was thinned with white spirit to a solution of 80%. The soft mohair roller was changed into a harder foam rubber roller. This time the result was satisfactory, but in some places some uneven paint surface could still be seen. However, after grinding the Futura 3 undercoat paint surface was very smooth.

Photo: Jouni Ripatti. When the small uneven areas were ground, the paler grey aluminium flake paint was revealed from under the darker adhesion primer and the surface looked patchy. It is important, that the two undercoat paints have different shades. Because of this it can be seen when the lighter grey layer of alkyd paint becomes visible when the top layer of the adhesion primer surface is ground.

When using the disk grinder to grind the Futura 3 surface, the bare plywood surface appeared in some places. This was not the purpose. These places were patched with a layer of adhesion primer. When the patched spots had dried they were ground manually, using first a rougher (150) INDASA Fine sanding pad and then a finer (240) INDASA Super Fine sanding pads.

Now the upper and lower sides of the MY-14 wing halves have been painted with undercoat paint and they are waiting for the paint finishing. The upper surface will be dark green with black camouflage and the lower side will be DN-blue. The paint finishing will not be done at the Tuesday Club, it will be bought from outside. The main reason for this is that the restoration space of the Finnish Aviation Museum is not sufficiently dustless or suitable for the large-scale spray painting of the wing surfaces.

The Tuesday Club team can now continue with the other remaining work in the construction of the Myrsky’s wing. The installation of the step plates on the upper surface of the wing root has been started. The step plates have been cut from 2 mm thick plywood and they haven’t been painted yet. The aluminium wing root fairings, which protect the seam of the fuselage and the wing, are fastened on the inner edge of the step plates. Photos: Lassi Karivalo except if otherwise separately mentioned. Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Plywood surfaces of upper sides of Myrskys wings are ground and painted with undercoat paintLauantai 6.2.2021 - Tuesday Club member When the lower sides of VL Myrsky II’s (MY-14) wings had been painted at the Tuesday Club with undercoat paint, the wings were turned around and the undercoat painting of the upper sides was started. The procedure follows the undercoat painting of the lower sides of the wings. First the plywood surfaces are painted with Tikkurila Oy pale grey TEMALAC AB 70 alkyd paint which contains aluminium flakes, using fine rollers. The flake paint is used to make the plywood surface very smooth. The aluminium flake alkyd paint is covered with a layer of TEKNOS Oy adhesion primer Futura 3. The wing surfaces are painted with several layers of both paint types and after each layer the surface is ground smooth with sandpaper. The adhesion primer has a darker shade of grey than the alkyd paint, so that it can be seen when the lighter grey layer of alkyd paint becomes visible when the adhesion primer surface is honed.

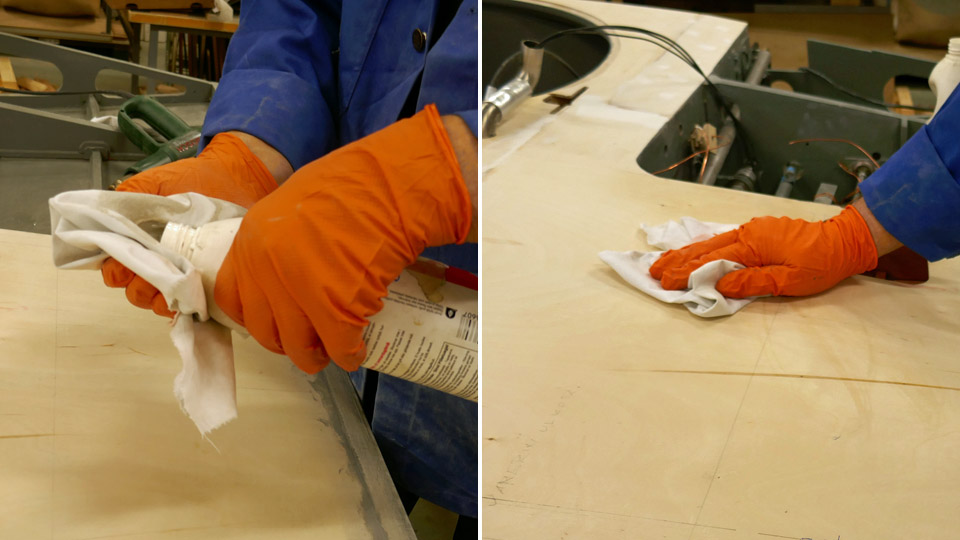

Before starting with the aluminium flake alkyd paint, a couple of plywood seams were spackled on the upper side of the wing. Then the plywood surfaces were ground as smooth as possible. A disk grinder was used, with 180 grinding paper grit. The disk grinder also removed the grinding dust. After this the plywood surfaces were vacuumed and wiped with an alcohol solution which removes grease. The solution contained 50% Sinol and 50% water. Then the damp surfaces were dried with a heat blower. Then the grinding was repeated, now manually and using 240 sandpaper grit. Then the surfaces were cleaned again.

Photo: Jouni Ripatti.

Photo: Jouni Ripatti.

Photo: Jouni Ripatti.

Photo: Jouni Ripatti. The aluminium flake alkyd paint was applied on the upper sides of the Myrsky’s wings with mohair rollers. In spite of this the paint surface quality wasn’t acceptable – it had some uneven “orange peel surface” parts. Therefore the first layer of paint was carefully manually ground smooth. The surfaces were painted again, this time with aluminium flake paint, thinned to 80%. This is how the desired quality of the painted surface was reached. The upper sides of the wings will be painted with another layer of TEMALAC aluminium flake undercoat paint before the Teknos Futura 3 adhesive primer is applied. Photos: Lassi Karivalo except when separately otherwise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Myrsky restoration continues after Christmas breakPerjantai 29.1.2021 - Tuesday Club member Since mid-January the Tuesday Club team has been working again in the restoration space of the Finnish Aviation Museum, continuing the restoration of Myrsky after the Christmas break. Other Tuesday Club activity is still on a break due to the Covid-19 pandemic. Myrsky restoration is continued by only half a dozen club members, taking all Covid-19 restrictions and recommendations into account.

Lower photo: Jouni Ripatti. The lower sides of Myrsky’s wings were painted with another layer of the grey adhesion primer and then it was time to begin with the undercoat painting of the upper side of the wing. Before the wings were turned, excessive paint was scraped from the edges of the inspection hatches on the lower side of the wing. This allows the aluminium hatch doors to sink properly into their openings and to the level of the plywood surface. Some rather awkward working positions were needed in this phase.

When the undercoat painting of the lower sides had been finished, the Tuesday Club started the preparations for turning the wings so that the upper sides can be painted. Steel tube lifting frames had been made to be fastened on the wing tip and wing root when the wing is turned. The frames have a shaft extension for fastening the lifting slings.

Tip: move your mouse on the photo!

The lifting slings were fastened on the frames and one wing at the time was lifted from the worktable with a stacker and a lifter and turned around. Now the unpainted wing surface was facing upward. The wing was place back on the worktable and the lifting frames at the ends of the wing were unfastened. Now all preparations have been made and the undercoat painting of the upper side of the wings can be started. Photos: Lassi Karivalo except when separately otherwise mentioned Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Myrsky project goes on Christmas breakKeskiviikko 23.12.2020 - Tuesday Club member

Merry Christmas 2020 and New Year 2021! The Tuesday Club Member. The hammering and tinkling of the Myrsky project have stopped in the restoration space of the Finnish Aviation Museum. It is time to have a break and rest over Christmas. We will be back at work on January 5th. Because of the coronavirus pandemic this year has been very exceptional for the Tuesday Club. Naturally it has also been exceptional for Finland and for the whole world. In March we had to terminate all our activities. Since June it has been possible to continue the restoration of VL Myrsky II (MY-14), but with only a handful of club members working at a time. The restoration of the Caudron C.50 aircraft and the reparation of the PZL SM-1SZ helicopter blades have been on a break all the time. In spite of the small task force, a lot has been accomplished in the Myrsky restoration work. The Myrsky’s wing structures have been completed and now the lower sides of the wings have been painted with undercoat paint. After the Christmas break the undercoat painting will continue on the upper sides of the wings. The Tuesday Club team has worked in close co-operation with the Finnish Aviation Museum and the Finnish Air Force Museum. I hope sincerely that the coronavirus pandemic will be blocked next year and the whole Tuesday Club team can return to work at the Finnish Aviation Museum. Hopefully in the autumn 2021, at the latest, it will be possible to continue the restoration work on the historically valuable aircraft with the full task force. We wish you a peaceful Christmas time and a better New Year 2021! Photo: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

Myrsky?s test wing is built to be wing for MY-5Tiistai 22.12.2020 - Tuesday Club member During the corona virus pandemic, the work in the Tuesday Club has concentrated on the restoration of VL Myrsky II (MY-14) and the number of workers has been limited to only a few at a time. The finalisation of the Myrsky-project’s test wing has been on a break. Now both wing halves of the MY-14 are in the undercoat painting phase and carpenters are available for other work. The team decided to continue building the test wing and to get it ready.

The test wing is the root section, 2.5 meters long, of the Myrsky’s starboard wing, which was built to test and model the construction of the actual wing for the Myrsky. The main emphasis was on testing how the landing gear area is built, and the landing gear installed. Testing was useful because the original drawings were inadequate and inconsistent and several times it was necessary to discuss how to proceed. Sometimes the built section had to be dismantled. Due to the test wing the mistakes were not repeated when the actual Myrsky wing was built.

The test wing will be useful also in the future. Originally the aim was to place the test wing on display at the museum as an example of a wooden wing structure in a WWII fighter, designed by the State Aircraft Factory. This is why the upper surface of the wing will be partly covered with transparent plexiglass so that the interesting inner structures and equipment can be seen.

The saying goes that the appetite grows while you are eating, and this is what happened with the test wing. A fuselage frame of Myrsky MY-5, in poor condition, is available for the test assembly of the MY-14 wing. The Tuesday Club team decided to restore this fuselage frame so that it could be placed on display with the test wing assembled on it. Then the museum visitors could see the mixed-structure Myrsky, having a fuselage frame made of steel tube and the wooden root part of the starboard wing. The MY-5 fuselage frame has already been restored, but it has been cut behind the cockpit and is now waiting for the test assembly of the MY-14 wing

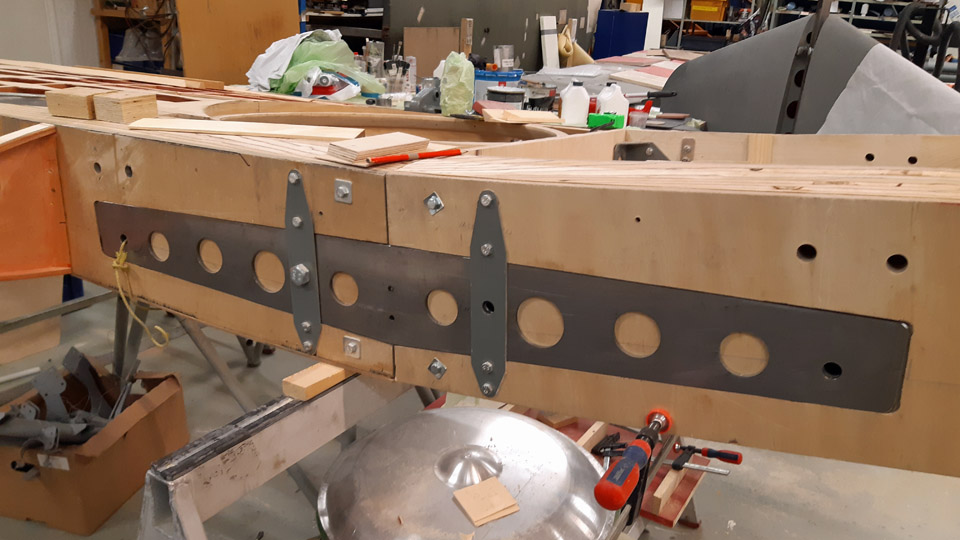

But the appetite kept on growing. The team decided to build a 1.0-meter section of the Myrsky’s port wing to go with the 2.5-meter section of the starboard wing. The port wing section includes the wheel well of the landing gear. Neither of the wing sections is ready but they have been joined with a steel plate and the preliminary wing assembly for the MY-5 can already be seen. We can start talking about the Myrsky MY-5 wing instead of the test wing, because it has already done its task as the test item in the MY-14 restoration.

And this is not all yet! The Tuesday Club team is dreaming – when the Myrsky MY-14 restoration has been completed – of continuing with the MY-5 fuselage frame and assembling original parts and equipment, which are available, and building the missing vertical and horizontal stabilizers and elevators. The MY-5 would be a great example for the museum visitor of how the mixed-structure Myrsky has been built. How far the MY-5 fighter will eventually be built and assembled remains to be seen in the future.

The Tuesday Club team will continue with the construction of the Myrsky’s wing sections, 2.5 m on the starboard side and 1.0 m on the port side. The starboard side section structures are almost ready, and the landing gear has once already been assembled on it. Work continues with the leading edge. The leading edge ribs have now been glued on the front spar. The edge strip connecting the ribs to each other has been glued on the tips of the ribs as well as the battens between the ribs.

The construction of the wheel well on the port wing section is ongoing. The plywood ring on the upper edge of the wheel well was built from narrow plywood strips which were glued into a pack on a mould. The wheel well cover is fastened on this ring. The wheel well cover will be made from aluminium sheet by metal spinning. For the 2,5 m starboard wing the cover has already been made.

The wheel well walls are also being covered with plywood. The billets for the walls were cut from 1,2 mm plywood sheet. The billets will be fitted into place and finalised. The short wing section on the port side will not have the landing gear as the longer starboard wing section does, the wheel well will remain empty. Photos: Lassi Karivalo. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14, MY-5 |

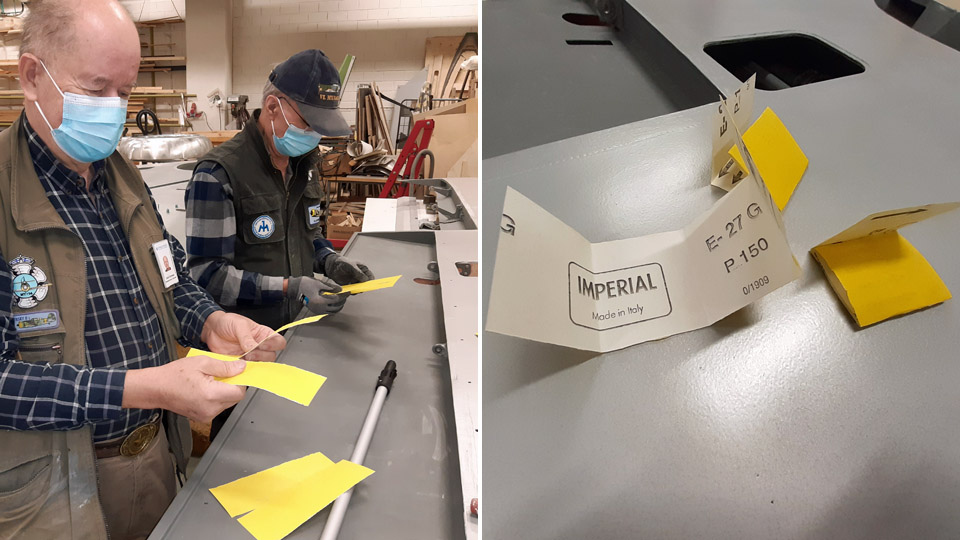

Undercoat painting of Myrsky?s wing is well under wayMaanantai 14.12.2020 - Tuesday Club member Due to the corona virus pandemic only a handful of Tuesday Club members can continue the restoration of VL Myrsky II fighter (MY-14), but some results have been achieved, nevertheless. The undercoat painting of the wing halves is under way at the moment. Before that the edges of the compartments of the wing were covered with protective linen fabric strips. This phase has been described in the previous blog.

The undercoat painting of the Myrsky’s wings will be done in two phases and with two different kinds of undercoat paint. First the cleaned and ground plywood surface is painted with alkyd paint which contains aluminium flakes. The undercoat paint used in this phase is TEMALAC AB 70 alkyd paint which contains aluminium flakes, and the shade of the paint is RAL 90006, white aluminium. This paint is used to fill the grain structure on the plywood surfaces and to make the plywood surface very smooth. The flake paint is applied on the plywood surfaces twice and after both rounds the surface is honed with sandpaper. The aluminium flake alkyd paint is covered with a layer of slightly darker grey paint, Teknos Oy’s adhesion primer Futura 3, with the shade RAL 7005 Mouse Grey. After this the surfaces of the wing are ready for the final camouflage painting.

Left photo: Heikki Kaakinen.

The undercoat painting of the wings was started by painting the compartments for the landing gear, the flap and the aileron. They were painted with the Teknos Oy paint Futura 3. The work was mainly done with a small roller, but the tight spots were painted with a brush. When the compartments had been painted, the lower surfaces of both wings were painted with the Tikkurila Oy TEMALAC AB 70 aluminium flake alkyd paint. The alkyd paint was spread with a dense foam rubber roller. The areas where precision was required were painted with a brush. The possible drippings were wiped with a cloth.

When the flake paint had dried, the surfaces were honed with Imperial P 150 sandpaper, pressing only with fingertips. This means that a piece of cork or wood was not used with the sandpaper. Fingertips are flexible and a good tool when honing painted surfaces. Before the honing work the sandpaper was torn into four strips and each strip was folded into a pack of four layers. Now the sandpaper was a square with four layers. The honing was done by moving the sandpaper with fingertips in circles on the painted plywood surface. When one of the layers of the sandpaper pack got blocked with honing dust, the next layer was taken into use. When the honing work was ready, the dust was removed from the plywood surface with a vacuum cleaner and by wiping the surface with a damp cloth.

Right photo: Jouni Ripatti.

Photo: Heikki Kaakinen. When the lower sides of the wings had been painted twice with the aluminium flake alkyd paint, the painting work on the upper sides of the wings was started. The flake paint was spread with a roller. When both sides of the wing have been painted with the flake paint, they will be ready to be painted with the TEKNOS Oy Futura adhesion primer. On top of this the Myrsky’s green-black camouflage painting will eventually be added. Photos: Lassi Karivalo, except othervise mentioned. Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

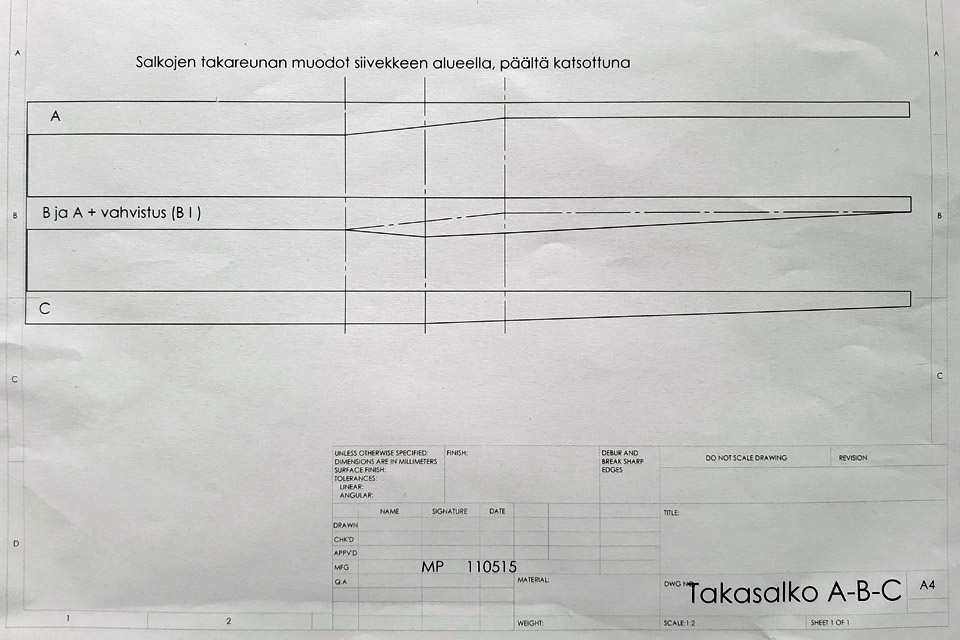

Reinforcing fabrics for plywood seams on Myrsky's wingSunnuntai 22.11.2020 - Tuesday Club member The C-type wing of the Myrsky-fighter (VL Myrsky II) has plenty of plywood seams which are reinforced with linen fabric strips. The purpose of the fabric is to protect the plywood seams from problems caused by moisture. There are fabric strips e.g. on the edges of the aileron and flap compartments, on the leading edge of the aileron, on the edges of the landing gear wells and on the wing tips. The tips of the horizontal stabilizers have also been reinforced with fabric. Originally the Myrsky’s wings didn’t have these fabric strips to prevent moisture problems. The aircraft factory started planning these for the wing in late 1944 when the whole Myrsky series had already been built. The reason for this were the problems in the plywood seams, caused by moisture, and due to which some glued plywood seams on the wings had opened. In the same modification the structure of the rear wing spar was changed, and the Myrsky C-wing was created. The first series production aircraft the A-type wing. It was replaced by the B-wing, then the B1-wing and eventually in 1945 by the C-wing. The construction of the VL Myrsky II meant continuous improvements and modifications.

The structure of the Myrsky’s A-, B- and C-wings differed mainly in the rear spar. In the A-wing the rear spar became thinner at the seam of the aileron and the flap, thinning steeply towards the wing tip. This point proved to be weak and led to the breaking of the wing. This is why the rear spars of the A-wings were reinforced by adding a strengthening piece on the side of the spar – and this is how the B-wing was created. This was not a good solution either. That is why a new rear spar was designed, it thins linearly towards the wing tip. The wing with the new kind of rear spar was called the C-wing and the aim was to replace the Myrsky’s B-wings with the new type. Only about a dozen C-wings were built during 1945 and they were only installed on a couple of Myrskys before the aircraft type was written off. Obviously the MY-5, the MY-41 and the MY-50 were the only ones which had the C-wing. The MY-14, which is under restoration, had a B-wing. In December 1945 the aircraft got a new wing at the Lentorykmentti 1 (Flight Regiment 1) Depot in Pori. It is not known what kind of wing was installed. Around the same time a C-wing was installed on the MY-5. So it can be speculated whether the MY-14 got a C-wing, too. The MY-14 will get a C-wing when it is being restored. The steering committee of the Myrsky restoration project decided that building a C-wing for the MY-14 is both justifiable and appropriate. This solution was chosen mainly because the drawings that are available for the restoration work represent the C-wing and, excluding the rear spar, the wing resembles the B-wing. It can be speculated, as shown above, whether the MY-14 had a C-wing in 1945 or not.

During the autumn the Tuesday Club team has fastened linen fabric strips on the plywood seams of the wing, i.a. the edges of the flap compartment on the port wing. The work was started by cutting the saw-toothed fabric strips for all the edges of the flap compartment from 105 g/m2 linen fabric using ”zig-zag” scissors.

The fabric strips will be glued on the edges of the compartment with grey Futura 3 undercoat paint, hue RAL 7005, which is the same undercoat paint with which the whole MY-14 wing will be painted. The fabric strips are glued on the clean plywood surface before the plywood covering is painted. This was not the procedure with the fabrics on the leading edge of the aileron. The team was too eager to get the work done and the first layer of undercoat paint had already been applied on the ailerons before the fabric strips were remembered!

Before gluing, areas matching the width of the fabric strip were drawn on the edges of the flap compartment. Above the plywood edge the paint was applied with a roller and below the edge with a small brush. The layer of paint was the adhesive surface for the fabric. Now the saw-toothed fabric strip could be pressed against the wet paint surface. When the fabric had been smoothed tightly against the painted surface with fingers, a layer of paint was applied on it with a roller and a brush so that the whole fabric strip was covered with paint.

At the moment the fabric strips have been installed on the edges of the flap and aileron compartments, the edges of the landing gear well and the seams of the wing tip on the port and starboard wings. The strips protect the seams from moisture. The surfaces of the strips will be honed smooth before the wing gets its undercoat paint.

The both wing halves of the Myrsky MY-14 are practically ready for the undercoat painting of the wings’ plywood surfaces. The plywood surfaces have already been honed smooth. Before applying the first layer of undercoat paint, the plywood surfaces will be washed to remove any grease and oil. A solution containing 50% Sinol and 50% water will be used. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

About wing root fairings on VL Myrsky IIMaanantai 9.11.2020 - Tuesday Club member The wing root fairing, which covers the joint of the Myrsky’s wing and fuselage, consists of two sections. The longer rear section of the fairing covers the joint of the fuselage and wing from the trailing edge of the wing up to the level of the front spar. From there the front section of the fairing continues all the way around the leading edge of the wing. The front and rear sections of the wing root fairing are joined together with a butt joint. An aluminium plate has been riveted on the lower surface of the rear section of the fairing and this plate is pushed under the edge of the front section of the fairing. The wing root fairing is fastened on the wing and the fuselage mainly with flange nuts. The front fuselage of the Myrsky is covered with thin aluminium plate.

The front section of the wing root fairing bends around the leading edge of the wing to the lower surface of the wing, up to the edge of the wheel wells. The fairing also covers the bottom of the front fuselage between the engine stand and the wheel wells. The wing root fairings on the port and starboard side are joined together in the middle of the fuselage. Both fairings can be unfastened separately. The outer edge of the port side fairing borders with the oil cooler air intake. The cooler exhaust opening is located on the starboard wing root fairing on the lower surface of the leading edge.

Not a single original Myrsky wing root fairing has been preserved for the restoration work. This means they had to be built. The Tuesday Club team decided to make first the front sections of the wing root fairings based on the original drawings. Manufacturing them was a complicated and multi-staged process. The front section of the wing root fairing curves in many directions and it had to be made from three different aluminium plates, which were modified separately and welded together.

The material for the fairings was 1 mm thick aluminium thin plate, from which the billets for the front sections of the fairings were cut. To shape the fairing sections into the desired shape, a mould of the front fuselage and wing connection was made from battens and plywood. Separate moulds were needed for the port and starboard wing root fairings. The billets of the fairings from aluminium thin plate and the two shaping moulds were delivered to Flanco Oy, where the shaping was done. From there the shaped fairing sections, still attached to the shaping mould, were delivered to GA Telesis Engine Services Oy for welding. From there the welded front sections of the wing root fairings came back to the Tuesday Club. The shaped front sections of the wing root fairings are now waiting for the Myrsky MY-14 wing halves, built by the Tuesday Club, to be joined with a steel plate into a uniform wing. Then the wing will be tested on the fuselage frame of the MY-5. The fuselage frame of the MY-5 has already been sandblasted and painted. At the same time, the front sections of the port and starboard wing root fairings can be tested, whether they need additional shaping before their details can be finished. Photos: Lassi Karivalo Translation: Erja Reinikainen. |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Leading edge of Myrsky's aileron is strengthened with a fabric insetTiistai 3.11.2020 - Tuesday Club member The plywood covered aileron of Myrsky-fighter (VL Myrsky II) has a reinforcing linen inset on the leading edge. The purpose of this inset is to protect the seam of the leading edge batten and the plywood sheets which are fastened on it. The strip of linen fabric is fastened on the leading edge with paint during the undercoat painting. The leading edge is not uniform, there are two notches in it for the hinges of the aileron. A reinforcing strip of linen fabric will be installed also on the edges of the wheel wells on the wings.

The MY-14 fighter, under restoration at the Tuesday Club of the Aviation Museum Society, has now the reinforcing strips on the leading edge of its ailerons. However, a small mishap occurred. Both ailerons had already been painted with the first undercoat paint, which is used for smoothing the surface, when the team remembered the reinforcing linen strip. Therefore, the undercoat paint, already honed smooth, had to be removed on the leading edge, over the width of the reinforcing fabric strip. The plywood surface was roughened so that the adhesive surface would be better for fastening the linen fabric on the leading edge with undercoat paint.

For the ailerons’ leading edge, a strip 15 cm wide was cut from 105 g/m2 linen fabric. A sawtooth pattern was cut on the fabric edges zig-zag scissors to make the adhesive surface of the fabric better than that of a straight edge. On airplane covering fabrics frayed edges were used for this purpose in the 1920s. When the fabric edge was frayed, the warp was unwoven over some centimetres’ distance. The sawtooth practice became common in the 1930s.

Before assembling the fabric on the leading edge, the aileron was supported to an upright position. Then a good layer of paint was spread on the leading edge, using a small foam rubber roller, over the width of the linen fabric strip. The fabric strip was placed carefully on the leading edge and pressed as tightly as possible against the wet paint.

When the fabric had fastened on the paint, adhesive undercoat paint was brushed on it. The Tuesday Club team made sure there was a sufficient layer of paint all over the fabric strip and that the sawtooth edge of the fabric had fastened tightly on the leading edge surface.

Both of Myrsky’s ailerons were treated in the similar manner. When the paint has dried, the painted surface on the fabric will be carefully honed smooth, making sure that the honing will not break the surface of the reinforcing fabric. If needed, an additional layer of paint will be added on the fabric and honed. Finally, the aileron will get the paint finishing with the green-black paint scheme. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Undercoat painting of Myrsky's ailerons and horizontal stabilizerTorstai 22.10.2020 - Tuesday Club member The VL Myrsky II (MY-14) is under restoration in the Tuesday Club and the surface finishing work on its horizontal stabilizer and ailerons has continued. The finishing work will be done in three phases. First the cleaned and ground plywood surface is painted with alkyd paint which contains aluminium flakes, this is repeated with grinding and honing in between. This paint is used to fill the grain structure on the plywood surfaces of the horizontal stabilizer and ailerons, and to make the plywood surface sealed and smooth. The undercoat paint used by the Tuesday Club team was TEMALAC AB 70 alkyd paint which contains aluminium flakes, and the shade of the paint is RAL 90006, white aluminium. The undercoat painting work has been described in an earlier blog.

The aluminium flake alkyd paint will be covered with another undercoat layer of alkyd paint, which will form the adhesive surface for the actual finishing paint on Myrsky’s horizontal stabilizer and ailerons. The Tuesday Club team used TEKNOS adhesion primer Futura 3, with the shade RAL 7005 Mouse Grey. The Futura 3 adhesion primer is slightly darker than the TEMALAC, so it was easy to see where the new layer of paint had not yet been applied. Two layers of paint were applied on the horizontal stabilizer and ailerons, with grinding and honing between the layers. The painting work was done using a polyester roller. The horizontal stabilizer and ailerons now have their undercoat paint.

The ailerons are not ready for the finishing paint yet. A strengthening strip of linen fabric needs to be fastened on the ailerons’ leading edge. The strengthening fabric reaches around the leading edge so that it protects the seam of the plywood surfacing and the solid wood leading edge. The strip of linen fabric will be glued on the leading edge using the adhesive primer. Before fastening the fabric on the leading edge, the paint surface on the leading edge has been ground away over the width of the fabric strip. Photos: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |

Tuesday Club activities are suspended until end of the yearMaanantai 19.10.2020 - Tuesday Club member Tuesday Club activities have been suspended due to the Covid 19 coronavirus pandemic since March. However, the restoration work on VL Myrsky II (MY-14) has been continued by a small task force, so that the continuation of the project is ensured. The coronavirus pandemic seemed to subside during the summer, and we thought it would be possible to relaunch Tuesday Club activities in the autumn. Then we would know whether the positive development of the epidemic is permanent and there would not be a second wave. But this is not what happened. The epidemic started to spread again in August and by September it was obvious that the second wave had arrived. Therefore the Finnish Aviation Museum and the Aviation Museum Society came to the conclusion that the risk for the Tuesday Club members, many of whom were in the risk group, to catch the virus in the museum’s restoration space would be too high if the activity continued. Therefore, it was decided that the Tuesday Club activities are suspended until the end of the year. This was very disappointing decision for the Club members, but it was the right and understandable thing to do.

The Finnish Aviation Museum and the Aviation Museum Society decided, nevertheless, that the restoration activities of VL Myrsky II (MY-14) can be continued by the Tuesday Club at the museum, but with restrictions. The aim of these measures is to ensure that the Myrsky restoration project can be completed next year. The restrictions mean that only about half a dozen Club members can be working simultaneously on Myrsky in the restoration space – naturally wearing masks and other protective items also, if needed. The Finnish Aviation Museum decided to suspend also other activities run by volunteers (such as guided tours) until the end of the year. The justification is to protect the risk group members in the common spaces of the museum. The recommendations, given on 21.9.2020 by the Ministry of Education and Culture and the Finnish institute of health and welfare, say that the risk group members should avoid close contacts during the epidemic, and therefore it is not advisable to take part in public events or gatherings, or activities arranged in public spaces. Photo: Lassi Karivalo Translation: Erja Reinikainen |

|

Avainsanat: aviation history, restoration, VL Myrsky, MY-14 |